Hidden cutting LED chip and manufacturing method thereof

A LED chip and invisible cutting technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to split, poor splitting, and low output rate, so as to facilitate mass production and improve Fragment yield rate, the effect of solving the leakage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

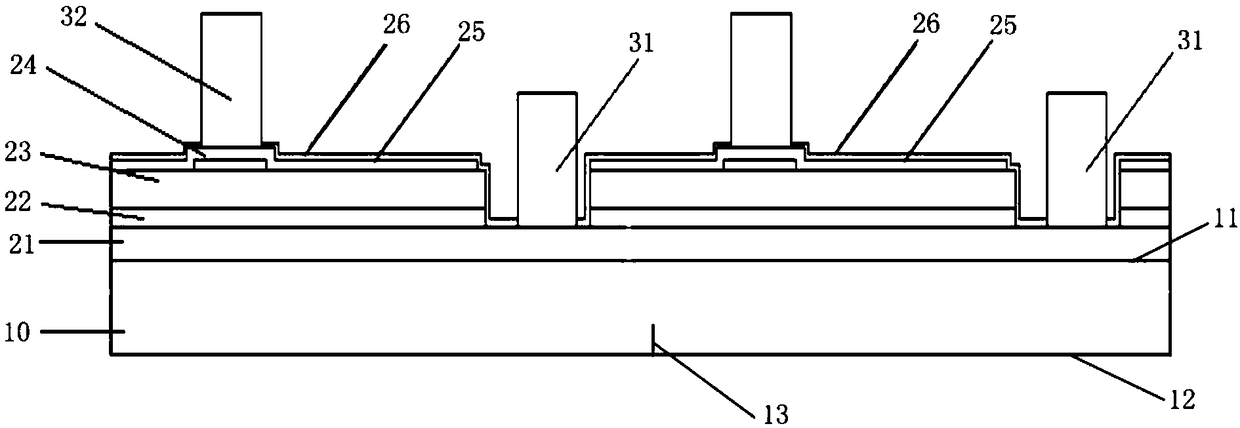

[0038] see figure 1 , a stealth-cut LED chip provided by the present invention includes a substrate 10, which includes a first surface 11 and a second surface 12, a light-emitting structure arranged on the first surface 11 of the substrate 10, and a light-emitting structure arranged on the second surface of the substrate 10. Scratches 13 on the surface 12 , the depth of the scratches 13 is greater than one-fifth of the thickness of the substrate 10 and less than one-third of the thickness of the substrate 10 .

[0039] The material of the substrate 10 may be sapphire, silicon carbide or silicon, or other semiconductor materials. The substrate in this embodiment is preferably a sapphire substrate. The first surface 11 and the second surface 12 of the substrate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com