Burner with chip test function and burning method thereof

A technology of chip testing and burning machine, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc. It can solve problems such as chip insertion error, burning, pin burning, etc., and achieve the effect of preventing code readback and verification errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below according to accompanying drawing and specific embodiment:

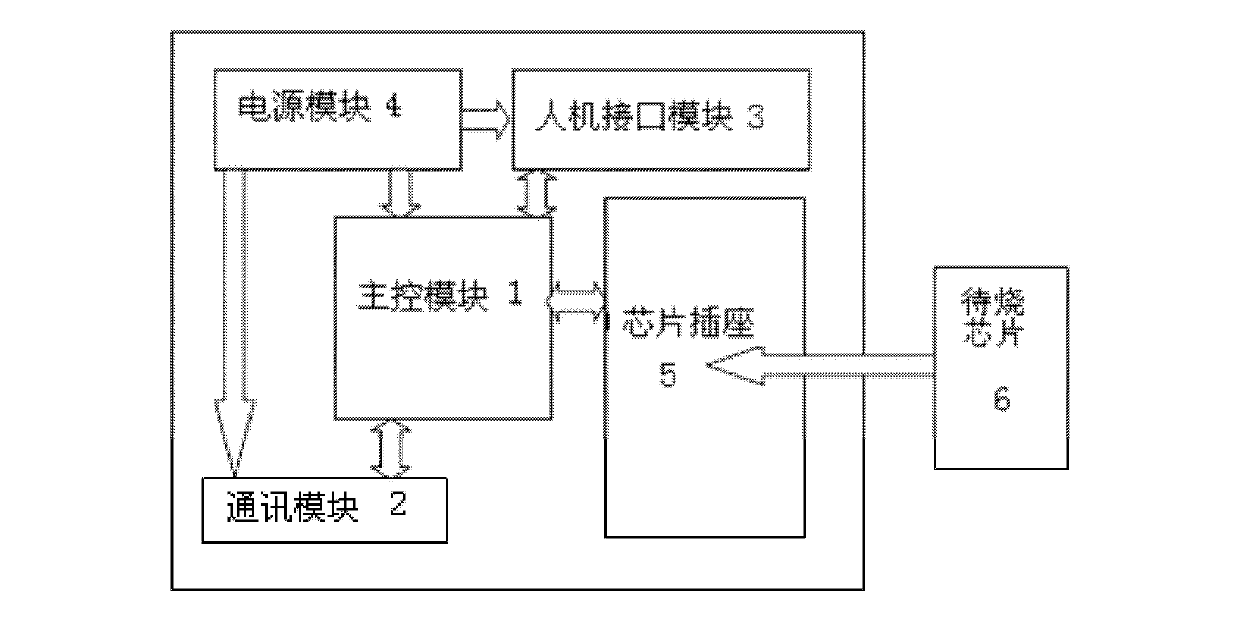

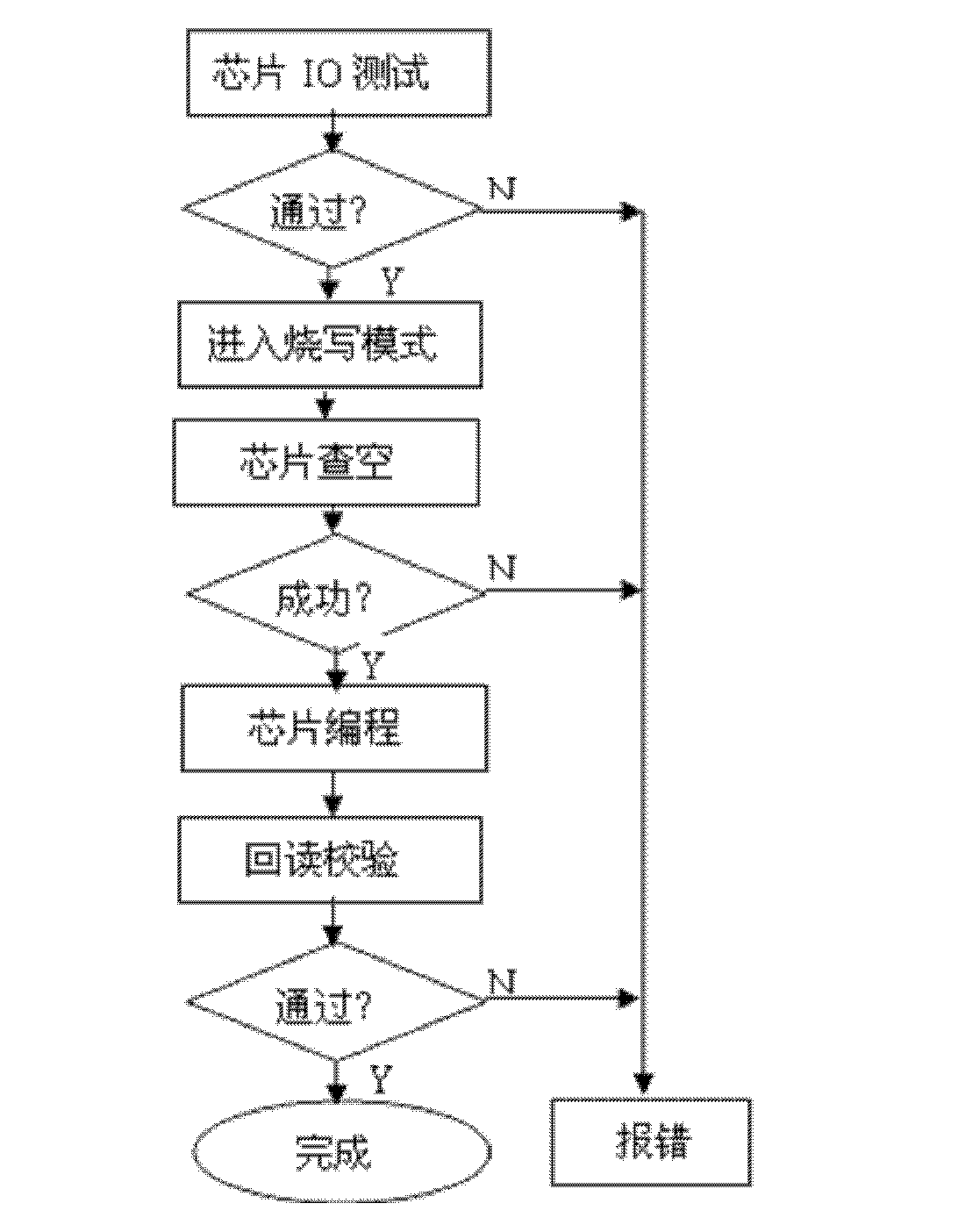

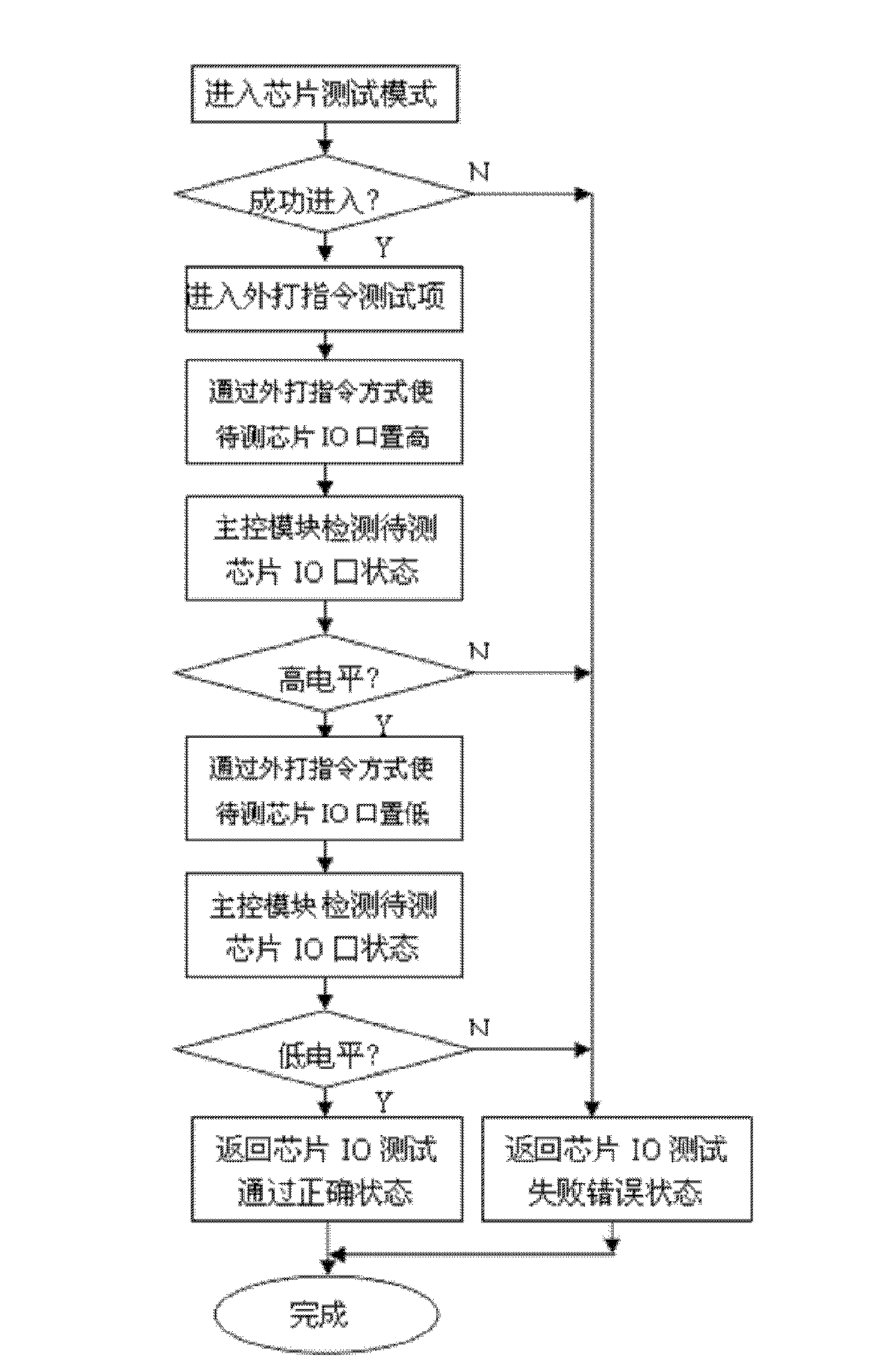

[0034] Such as figure 1 As shown, the burner with chip testing function of the present invention includes a main control module 1, a communication module 2, a human-machine interface module 3 and a power supply module 4 that provides power to the above modules, and the main control module 1 is responsible for the communication module. 2. Control sending and receiving, save communication data, and be responsible for the interaction of the human-computer interaction module 3, and be responsible for programming and testing the sequence of the chip outside the chip. The burner also includes a chip socket 5, which passes the pin It is directly connected to the main control module 1, and the chip to be burned is inserted into the chip socket 5 and controlled by the main control module 1. There are pins used for testing at the end of the chip socket 5, and the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com