NO2-absorption-characteristic-based drill rod feeding depth measuring system of coal gas drilling machine

A technology of coal mine gas and absorption characteristics, which is used in measurement, gas discharge, mining equipment and other directions to achieve the effect of ensuring safety and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained by specific examples below.

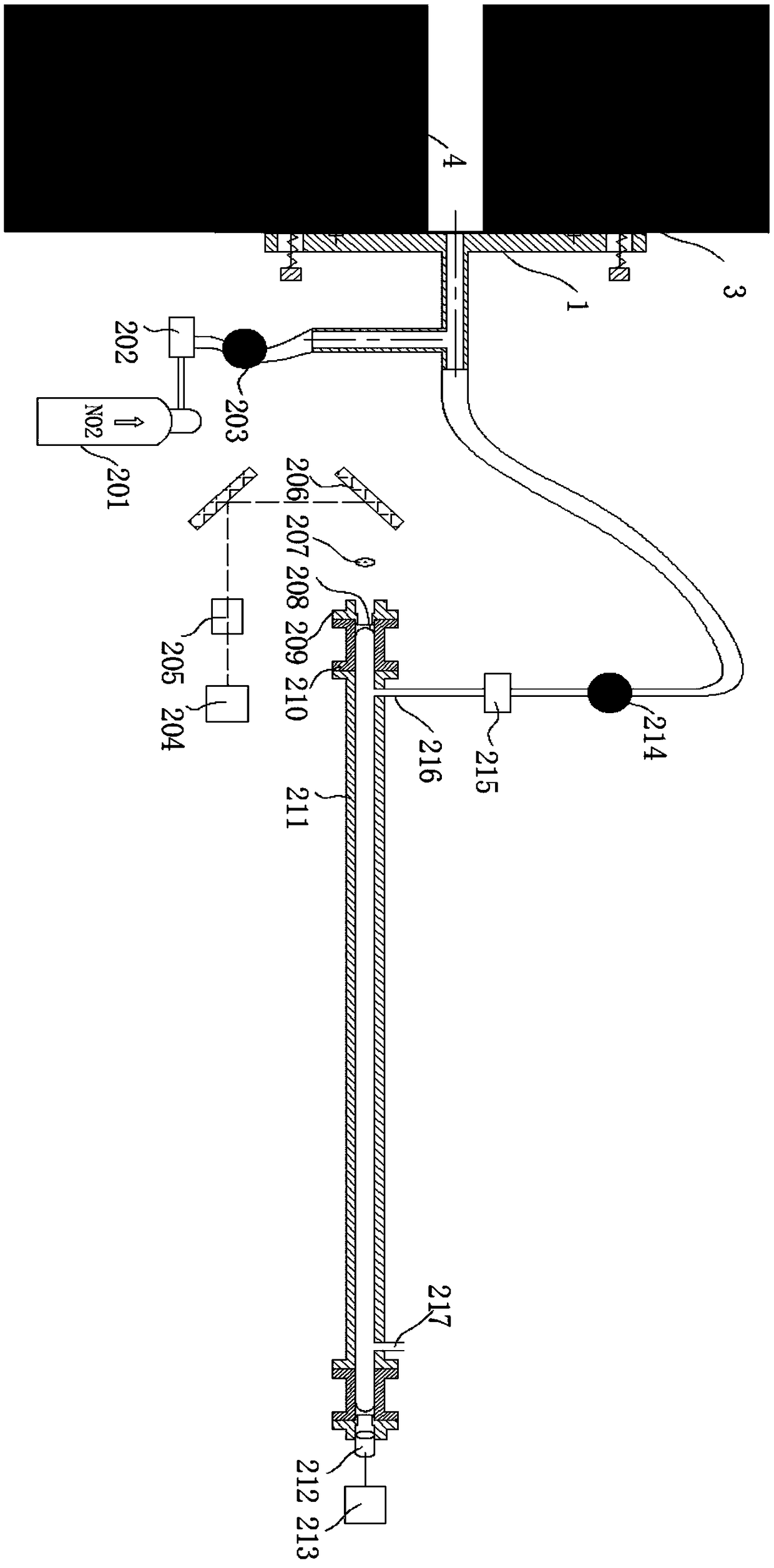

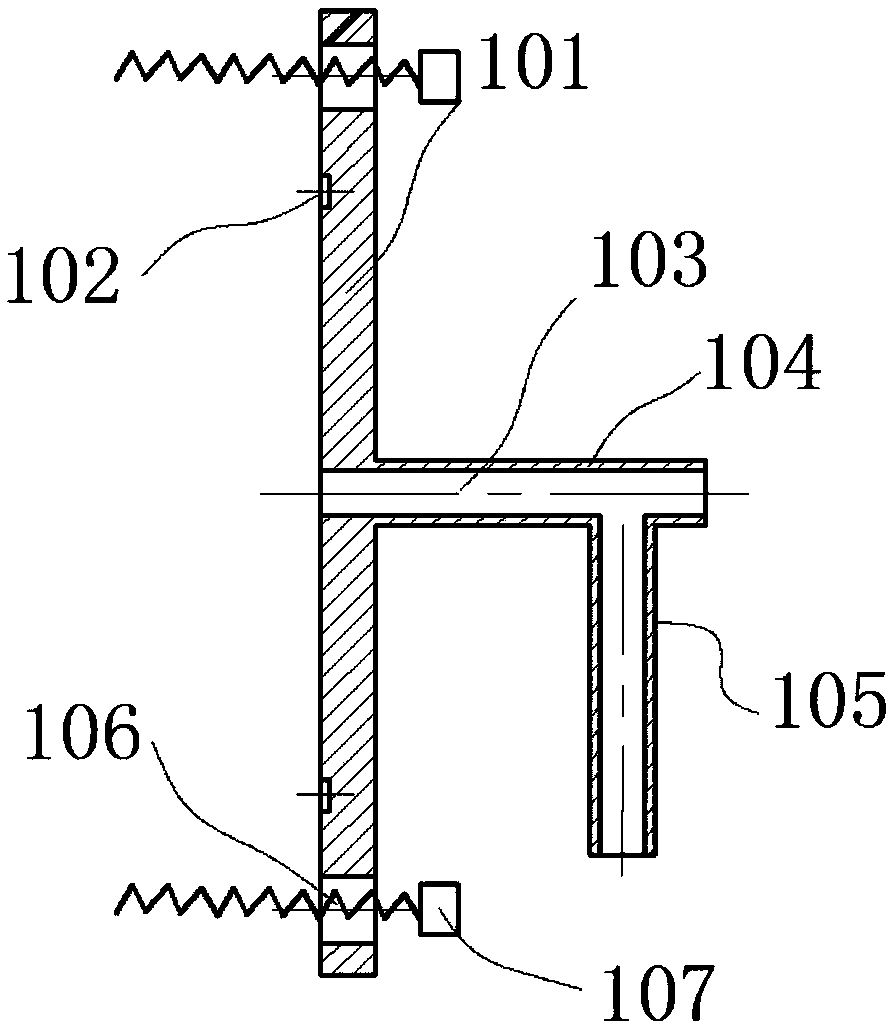

[0021] see figure 1 A coal mine gas drilling rig drill pipe feed depth measurement system based on NO2 absorption characteristics, comprising a hole sealing module 1 and a chamber ring-down NO2 concentration measurement module; the hole sealing module 1 includes a sealing plate 101, an annular sealing O-ring 102, Ventilation holes 103, the connection end 104 of the ring-down cavity leather tube, the connection end 105 of the sample gas tube, and the coal rock fixing piece 106 are used to seal the gas in the bore hole 4 and control the entry and exit of NO2 gas; the cavity ring-down measurement NO2 concentration module includes high concentration NO2 sample gas 201, flow control valve 202, sample gas solenoid valve 203, laser 204, isolator 205, reflector 206, aperture 207, mirror frame fixing part 208, high mirror 209, mirror frame 210, cavity main body 211, photoelectric detection element 212...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com