Downward subsection filling method

A filling body and high-stage technology, which is applied in the direction of filling, earth square drilling, underground mining, etc., can solve the problems of limiting mining efficiency and mine production capacity, limited stage height, and small filling volume at one time, so as to reduce the filling process link, guarantee the safety of mining, and improve the effect of filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

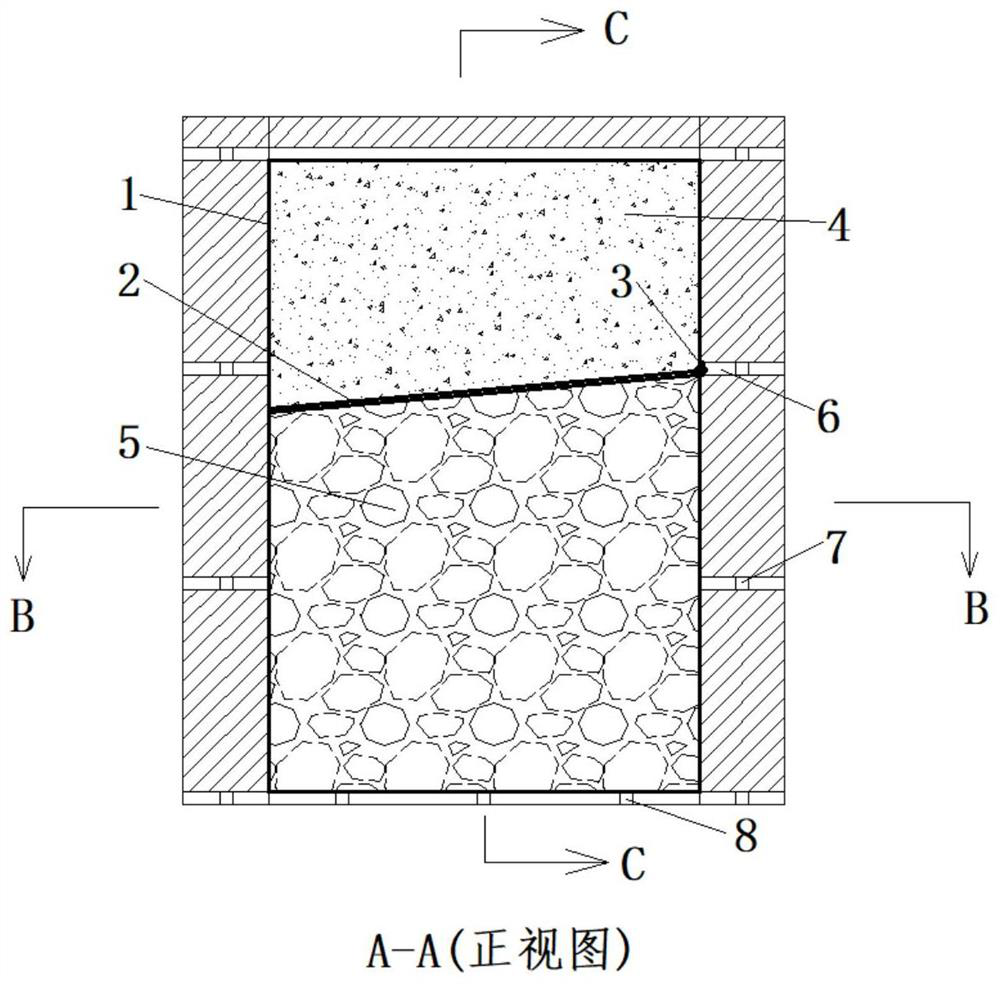

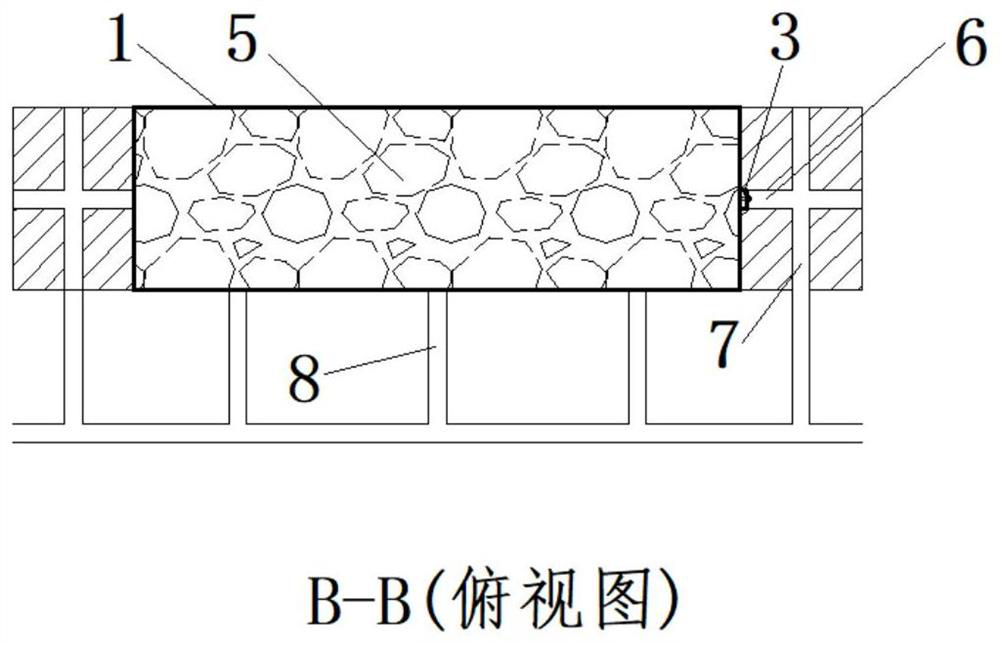

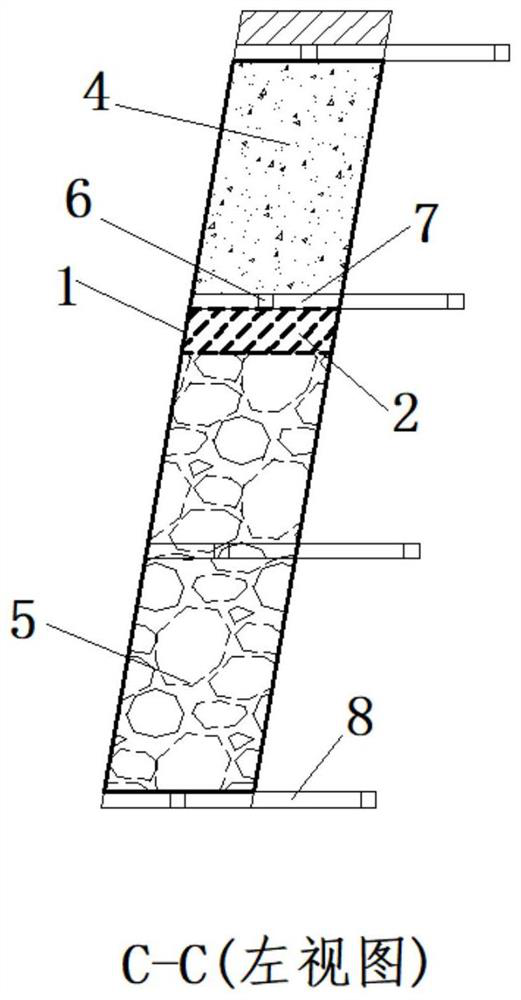

[0028] like Figure 1-4 As shown in the figure, a downward segmented filling method proposed by the present invention is aimed at the high-stage large-scale mining of the underground medium stable ore body in metal mines, and it includes but is not limited to the following steps and conditions:

[0029] A. The stage stope (1) is divided into several sections in the vertical direction, and the height of the sections is appropriately adjusted according to the stability of the surrounding rock, and the height of each section should be greater than 15m;

[0030] B. Fill the filling body (4) in the stope open area (9) to limit the displacement of the roof and side walls;

[0031] C. The caving ore is blasted in the stope (1) as the storage hole ore (5), and the ore is discharged under the protection of the upper filling body (4);

[0032] D. The upper filling body (4) is isolated from the lower loose ore by the flexible isolation layer (2) located on the upper surface of the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com