Spark duration time monitoring circuit for engine ignition system

A duration and ignition system technology, applied in the direction of engine ignition, engine components, machines/engines, etc., can solve the problems of reducing the service life of spark plugs, accelerating the ablation of spark plug electrodes, and not significantly improving the combustion effect of spark duration, etc., to achieve Accelerated ablation, complete combustion, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The spark duration monitoring circuit of the engine ignition system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

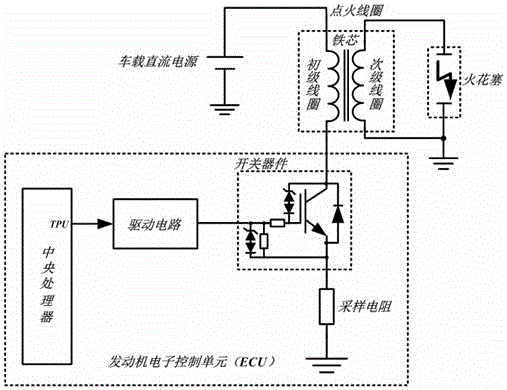

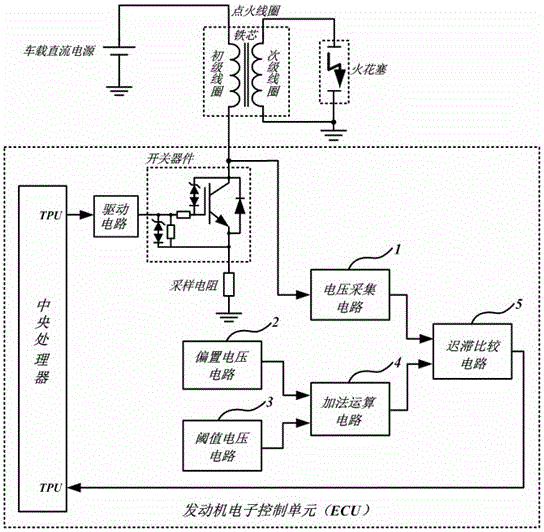

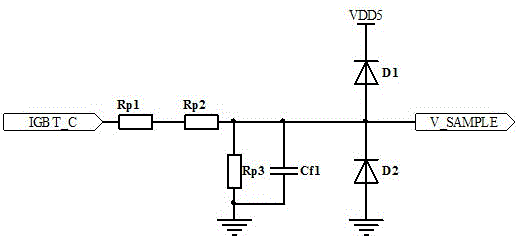

[0027] Such as figure 2As shown, the spark duration monitoring circuit of the engine ignition system, the spark time is the time when the secondary coil terminal current of the ignition coil flows through the spark plug. Since the voltage at the secondary end of the ignition coil is extremely high (12000-20000V) and it is difficult to monitor, the feedback function of the spark duration is realized by monitoring the voltage at the primary end of the ignition coil. The spark duration monitoring circuit is composed of a voltage acquisition circuit 1 , a bias voltage circuit 2 , a threshold voltage circuit 3 , an addition circuit 4 and a hysteresis comparison circuit 5 . IGBT is the switching device of the ignition system. The spark duration monitoring circuit of the ignition system is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com