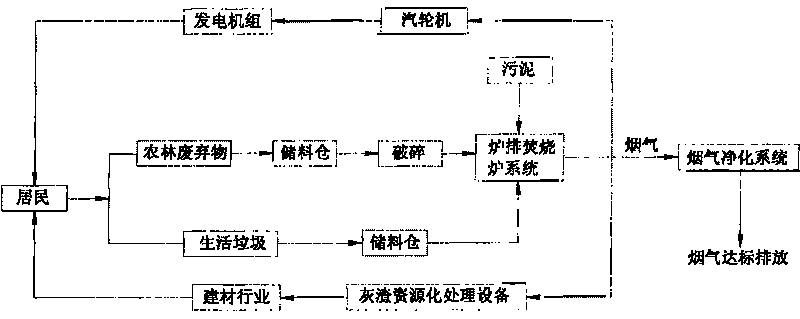

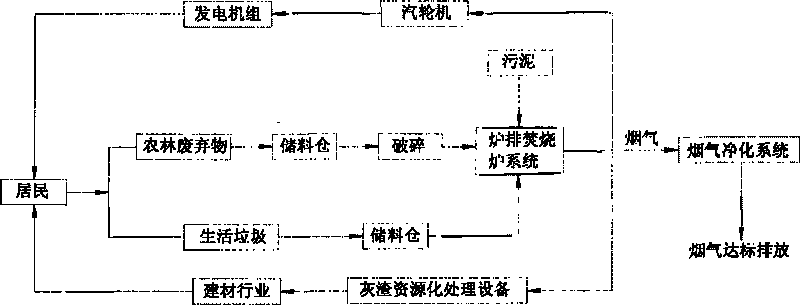

Method for mixed burning of agriculture and forestry waste, sludge and household garbage by using grate furnace

A technology for agricultural and forestry waste and domestic waste, applied in the field of urban domestic waste, to achieve the effects of improving stability, saving investment, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] When the boiler is started, spread the straw evenly on the grate of the incinerator. The ignition bed material generally chooses the bulk material with a length less than 100mm, and the ignition bed material is required to be 30-40cm thick. The straw on the grate is ignited by means of burning. Turn on the primary air, and when the furnace temperature rises to 400°C, continuously add agricultural and forestry waste to the furnace through the screw feeder, adjust the primary and secondary air volumes, and when the furnace temperature rises to 850°C, add to the furnace according to a certain ratio Municipal solid waste and sludge can be co-fired. Organize the air distribution reasonably, and gradually adjust the bed temperature to 850°C to 1000°C.

Embodiment 2

[0048] Municipal solid waste has high moisture content and low calorific value. The moisture content and composition of sludge are complex, and the calorific value varies greatly. In the actual process of waste incineration, the specific blending ratio of agricultural and forestry waste should be flexibly adjusted according to the quality of waste and sludge. When the waste coal ash content is high in winter in the north, or the moisture content of the waste in the rainy season in the south is high, and the combustible components are low. The proportion of mixed combustion of agricultural and forestry waste can reach 30%-40%, so that the calorific value of the mixed fuel can be increased to more than 1200kcal / kg; when the quality of garbage and sludge is good, the calorific value is about 1000-1200kcal / kg. The proportion of mixed combustion of waste is within 10%; the combustion temperature in the incinerator is maintained in the range of 850 ° C to 950 ° C, and the residence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com