Waste liquid incineration boiler of recycling smoke adherence protection

A technology of recirculation and flue gas, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of boiler wall corrosion, difficulty in smooth discharge, furnace wall corrosion, etc., to reduce the generation of NOX, excellent treatment effect, improve The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

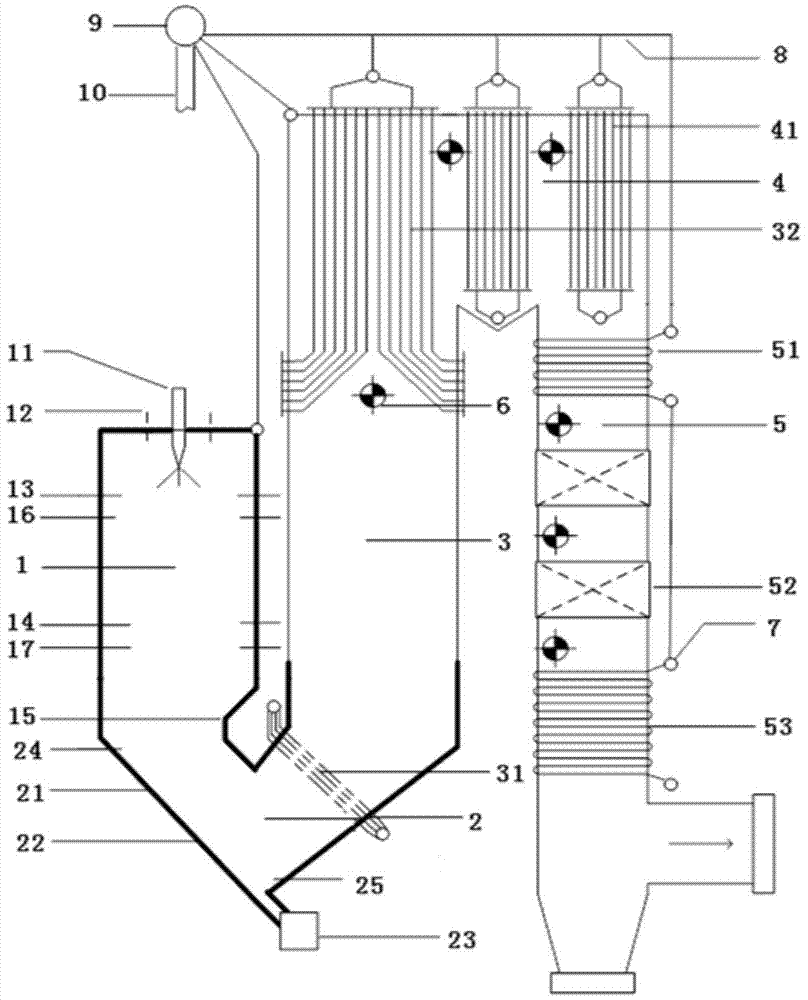

[0038] The present invention provides a high-concentration salt-containing organic waste liquid incineration boiler for wall-protected recirculation flue gas. The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the incineration boiler mainly includes a downward adiabatic furnace 1, a radiation cooling chamber 3, a horizontal flue 4, and a tail flue 5 connected in sequence, and is arranged on the radiation cooling chamber 3, the horizontal flue 4, and the tail flue 5. The soot blowing device 6;

[0039] The top surface of the downward adiabatic furnace 1 is provided with a waste liquid atomizing spray gun 11 and a root air nozzle 12, an auxiliary gas burner I13 is provided at the upper part, an auxiliary gas burner II14 is provided at the middle part, and a flame angle 15 is provided at the lower part of the rear wall;

[0040] A slag catcher 31 is set at the entrance of the radiation cooling chamber 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com