Patents

Literature

54results about How to "Meet environmental standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Urban household garbage sorting and charring comprehensive treatment resource recovery method

InactiveCN107497831AHigh degree of automationImprove sorting efficiencyTransportation and packagingSolid waste disposalSolid carbonResource recovery

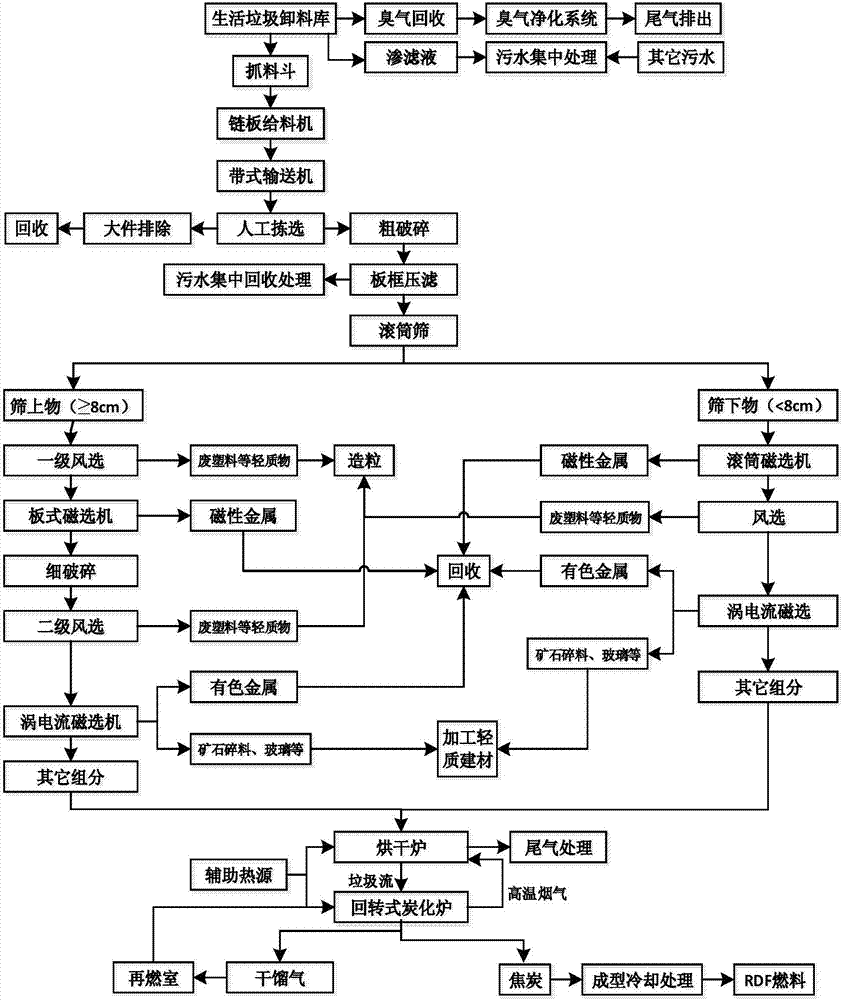

A urban household garbage sorting and charring comprehensive treatment resource recovery method comprises the first step of garbage sorting treatment, wherein original household garbage is subjected to uniform feeding, manual large garbage sorting, coarse crushing, plate-frame pressure filtering, rolling cylinder screening, full-closed mechanical selecting by winnowing, plate-type magnetic separator treating, eddy current magnetic separator treating and fine crushing process treatment; the second step of garbage drying treatment; the third step of garbage charring treatment, wherein a rotary charring furnace is adopted, and garbage charring is carried out in a normal-pressure low-temperature and low-oxygen atmosphere so that solid carbon can be prepared; the fourth step of coke forming and cooling treatment; the fifth step of bad smell purifying treatment, wherein bad smell generated in a household garbage discharging warehouse and bad smell generated in all treatment process links are collected to a bad smell purifying system through a negative pressure induced draught system; and the sixth step of waste water purifying treatment. The urban household garbage sorting and charring comprehensive treatment resource recovery method is relatively high in automation degree, sorting efficiency and recovery utilization rate and has more sorting functions.

Owner:李新方

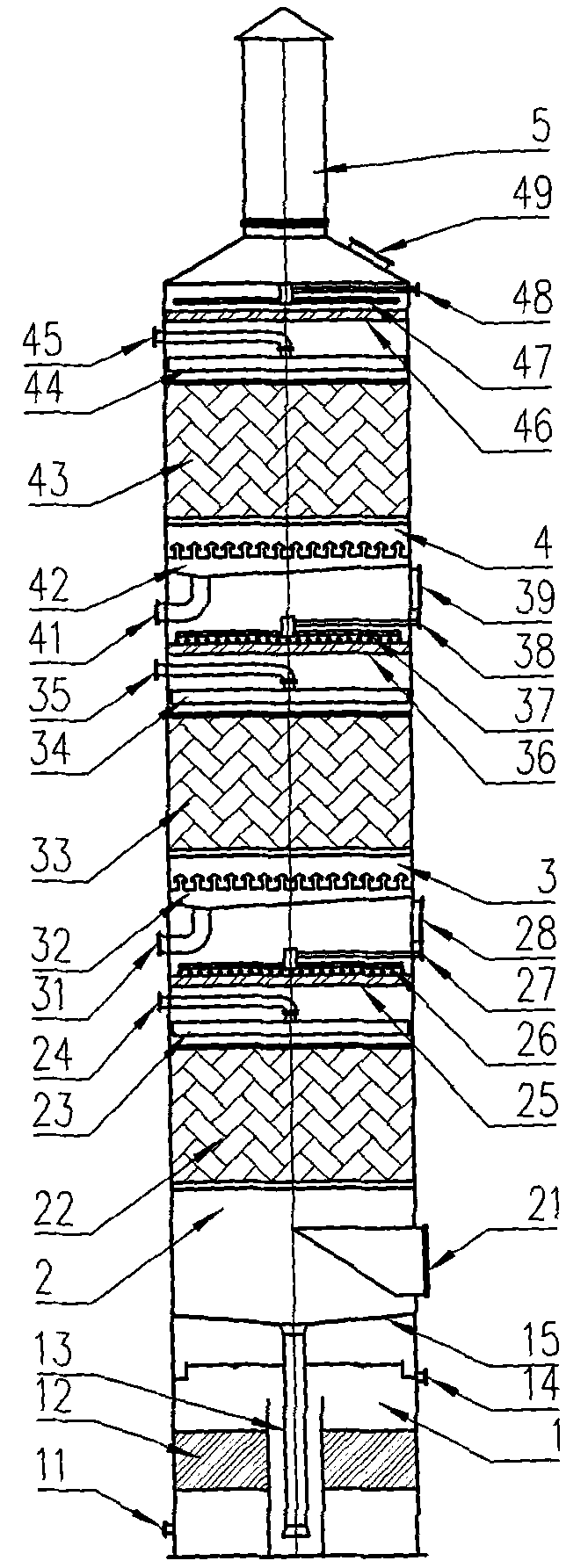

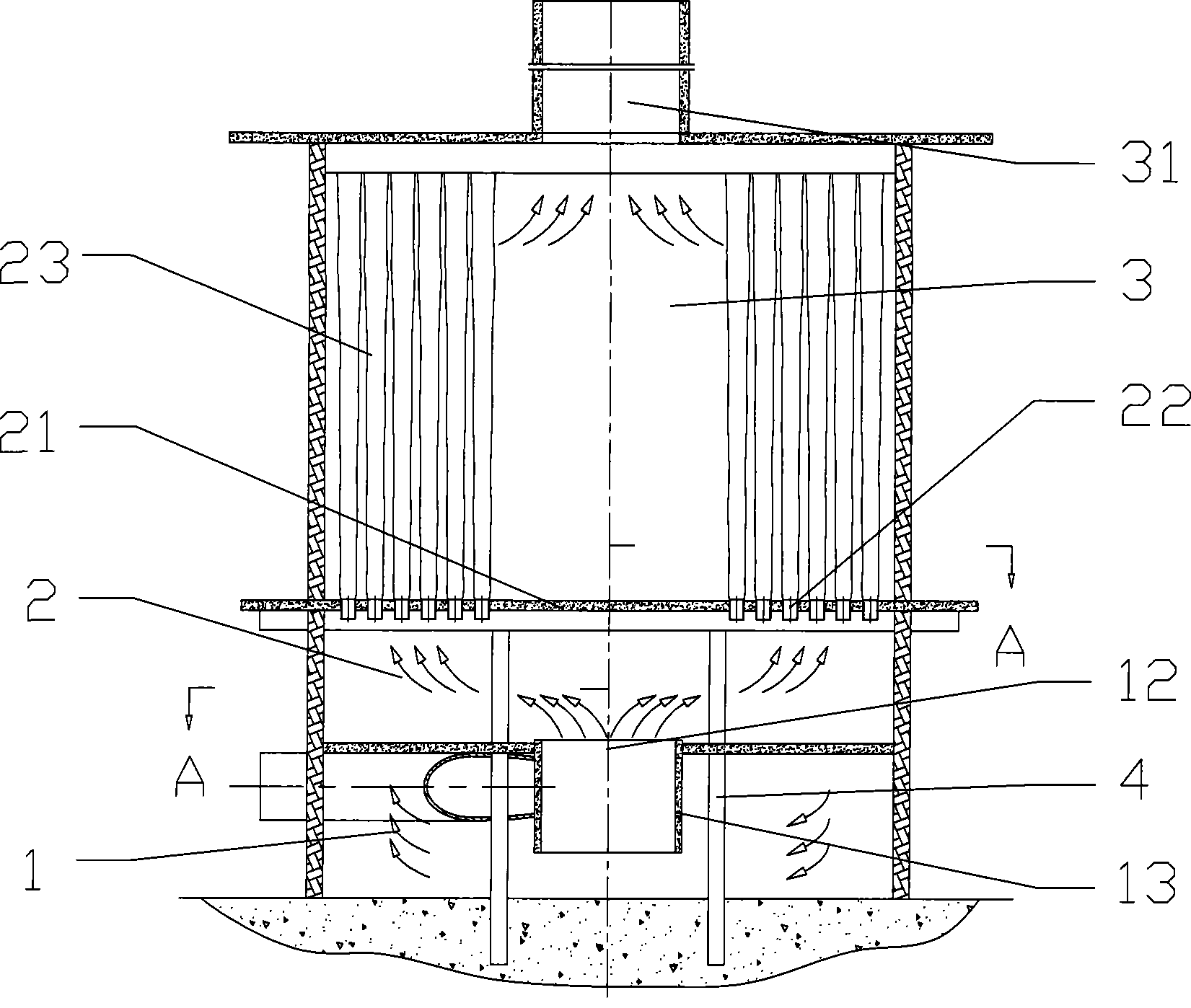

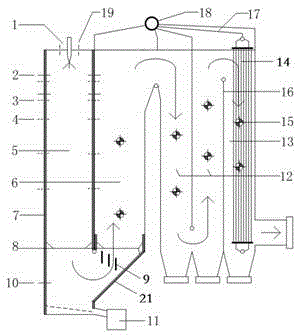

Burning process and burning boiler for processing high-density saliferous organic wastewater

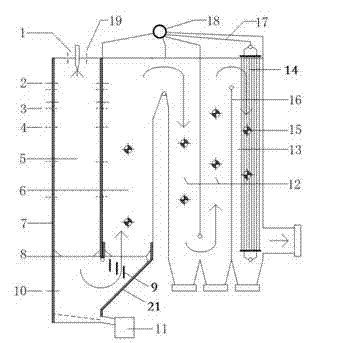

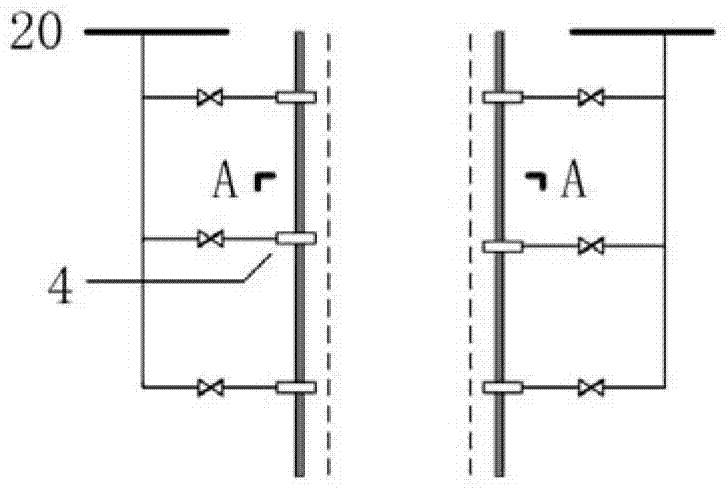

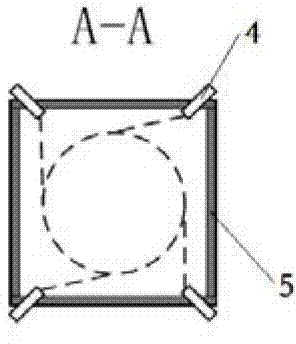

ActiveCN103047659AGuaranteed combustion temperatureReduce flue gas velocityCombustion technology mitigationIncinerator apparatusChemical industryGas burner

The invention discloses a burning process and a burning boiler for processing high-density saliferous organic wastewater. The burning boiler comprises a down heat insulation boiler cavity, a multilevel radiation cooling chamber, a convection heat exchange chamber, an ash blowing device, a steam outlet pipe and a steam pocket. The down heat insulation boiler cavity comprises a waste liquid atomizing spraying gun, a two-layer auxiliary gas burner, a secondary air nozzle, an air flow shielding device, a water cooling wall, a fireproof material, a compensation fuel gas burner, a liquid slag removing device and a root portion air nozzle. A radiation heat exchange chamber I comprises a water cooling wall, a fireproof material and a flow guide device. The convection heat exchange chamber comprises a water cooling wall and a convection screen. The burning process effectively controls and optimizes the problems of stable complete burning of heat value high-moisture waste liquid, heating surface slag bonding and ash accumulation, tail heating surface low temperature corrosion, NOX discharge and the like, has good processing effect on the high-density saliferous organic wastewater, achieves effective recycle of resources and is suitable for organic wastewater burning processing of chemical industries.

Owner:BEIJING NATION POWER GRORP +1

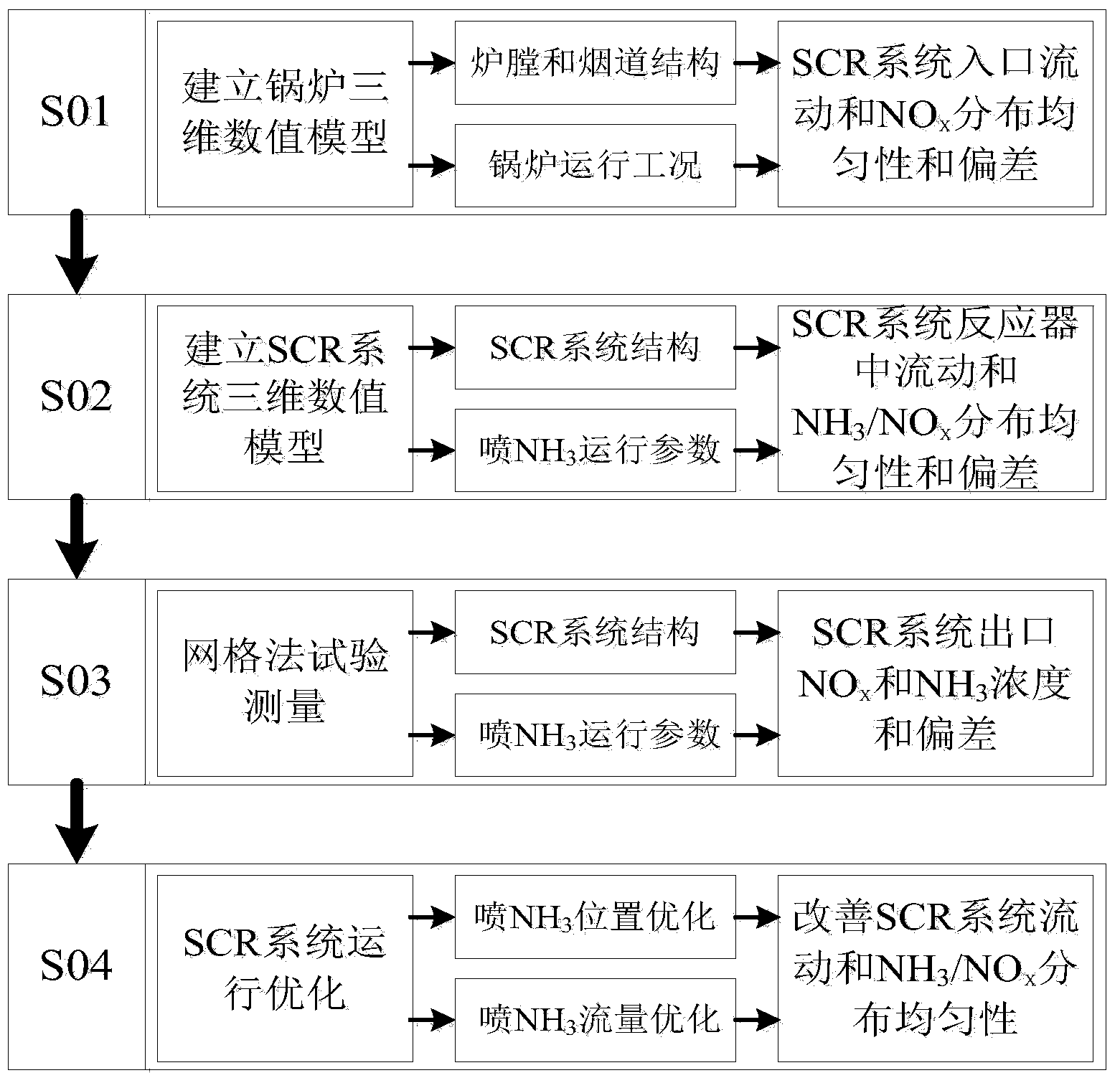

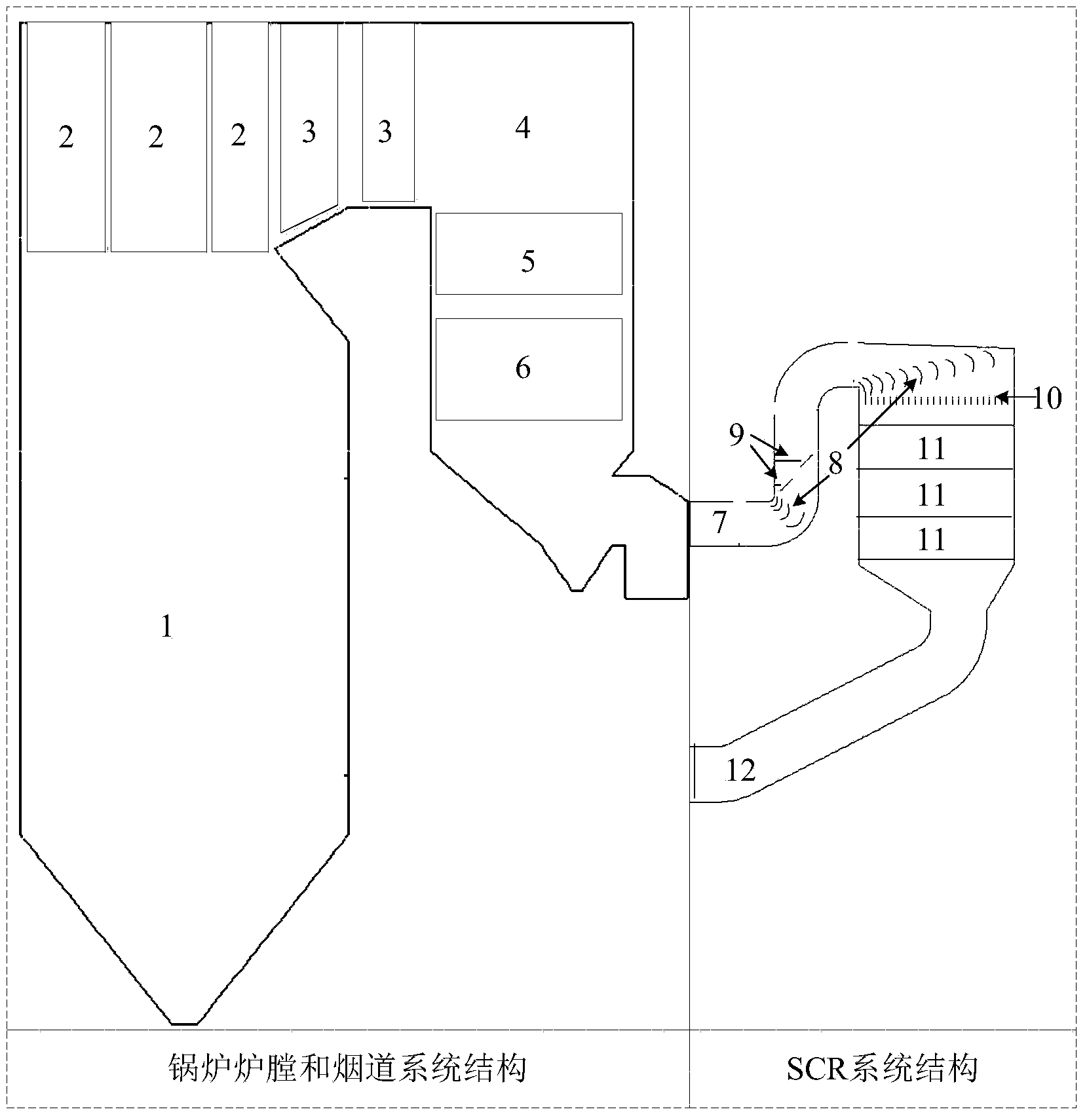

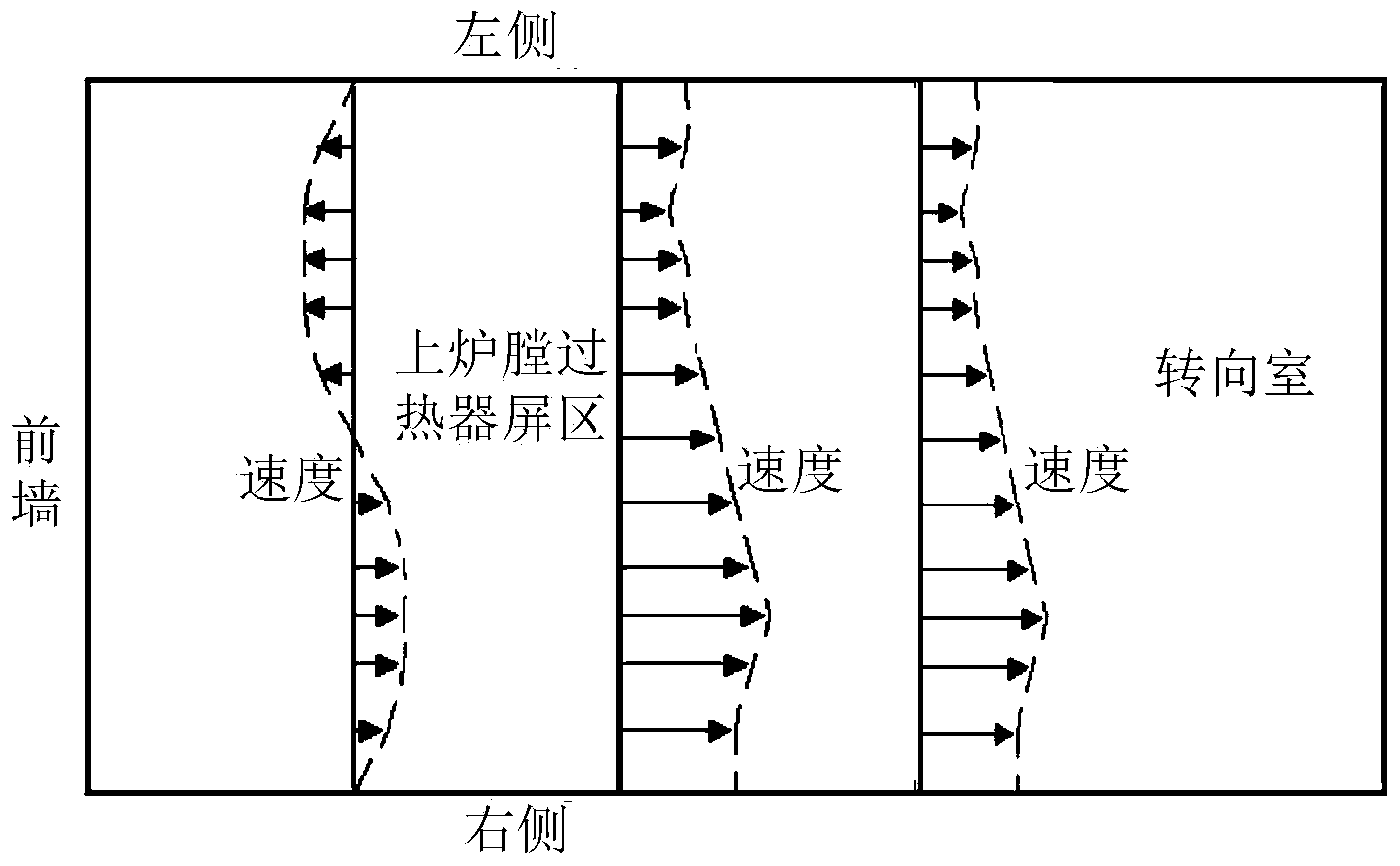

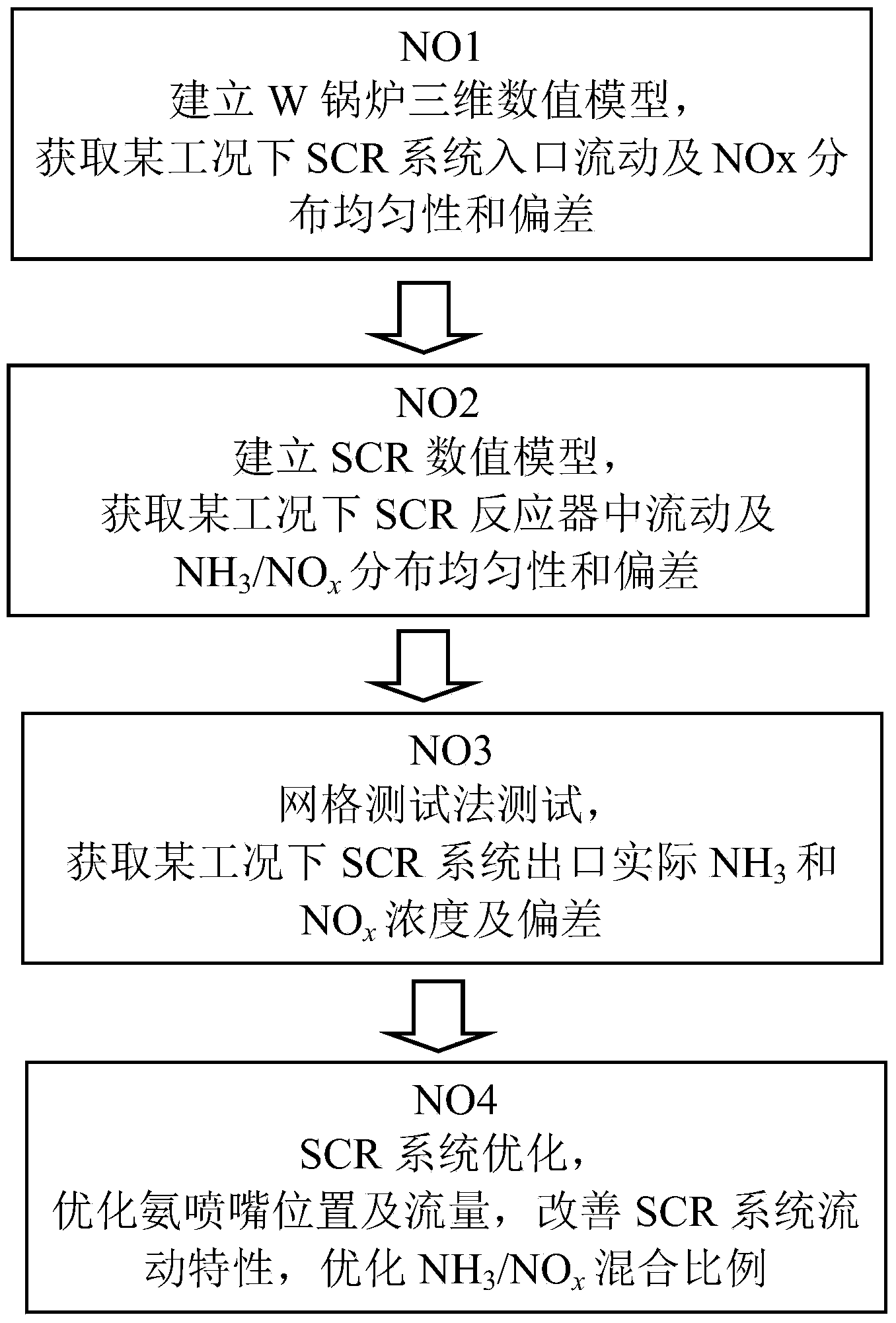

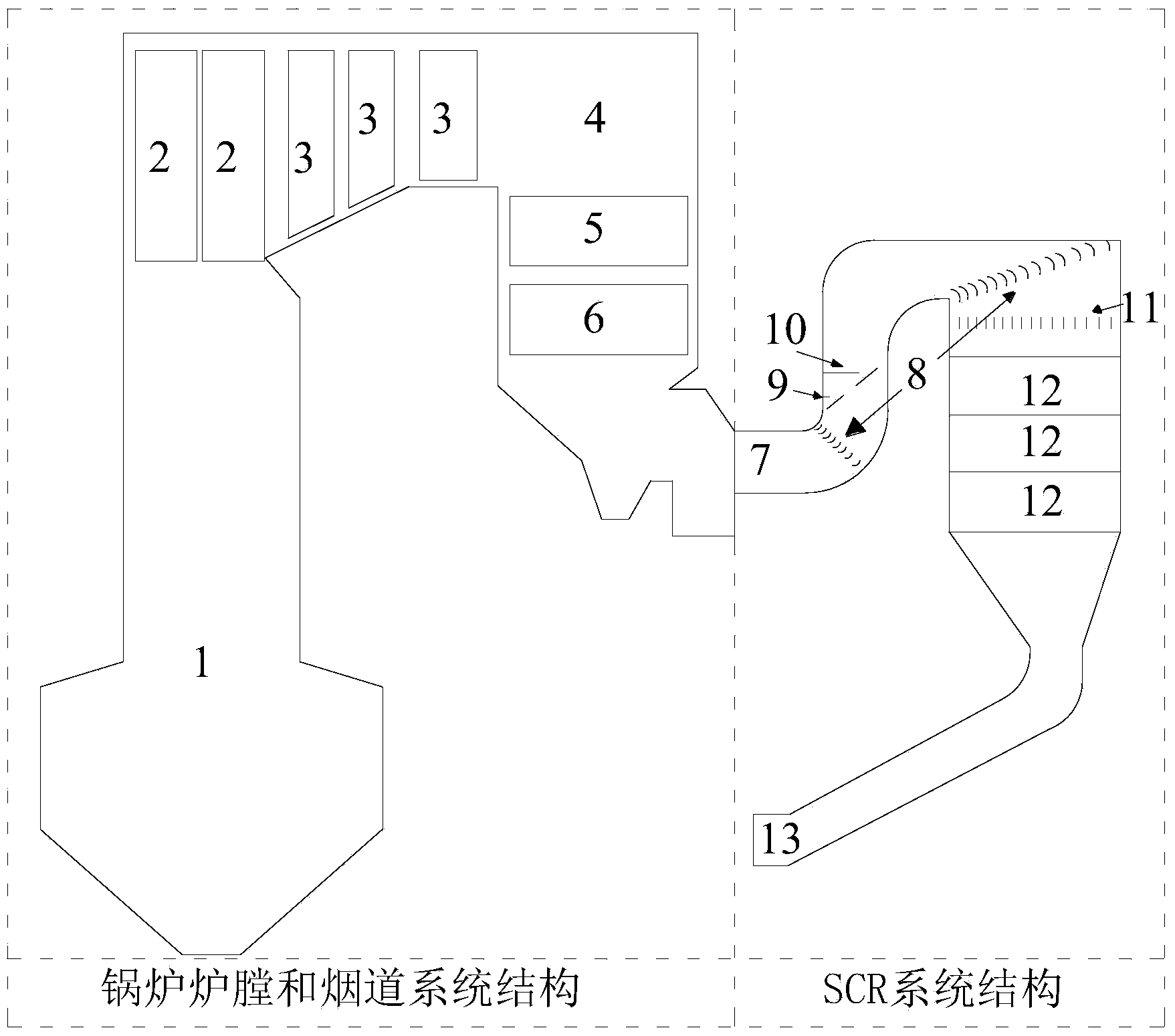

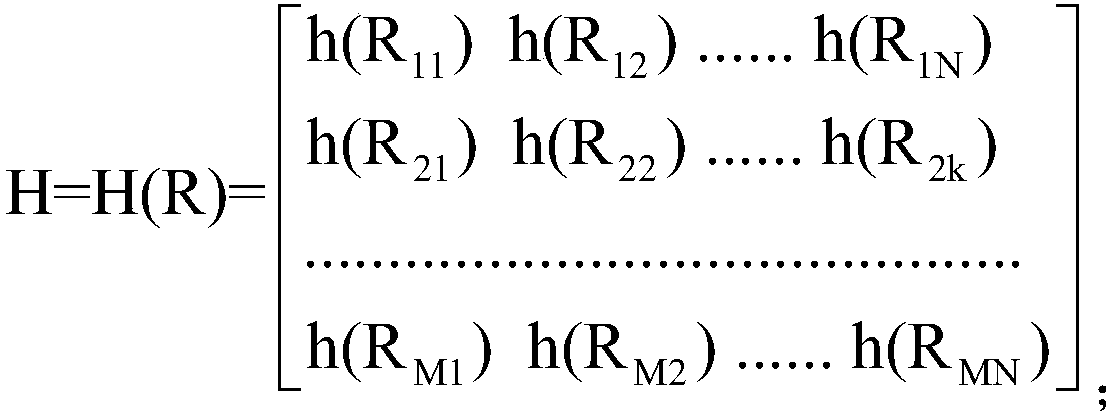

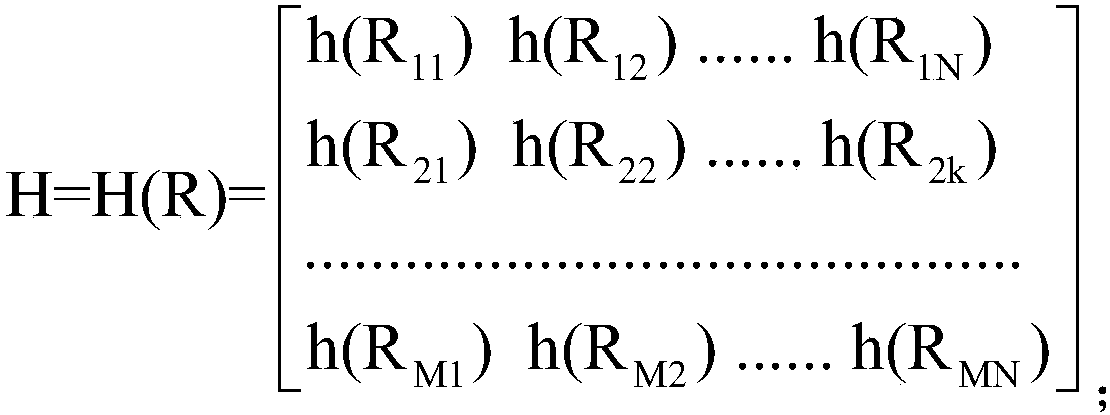

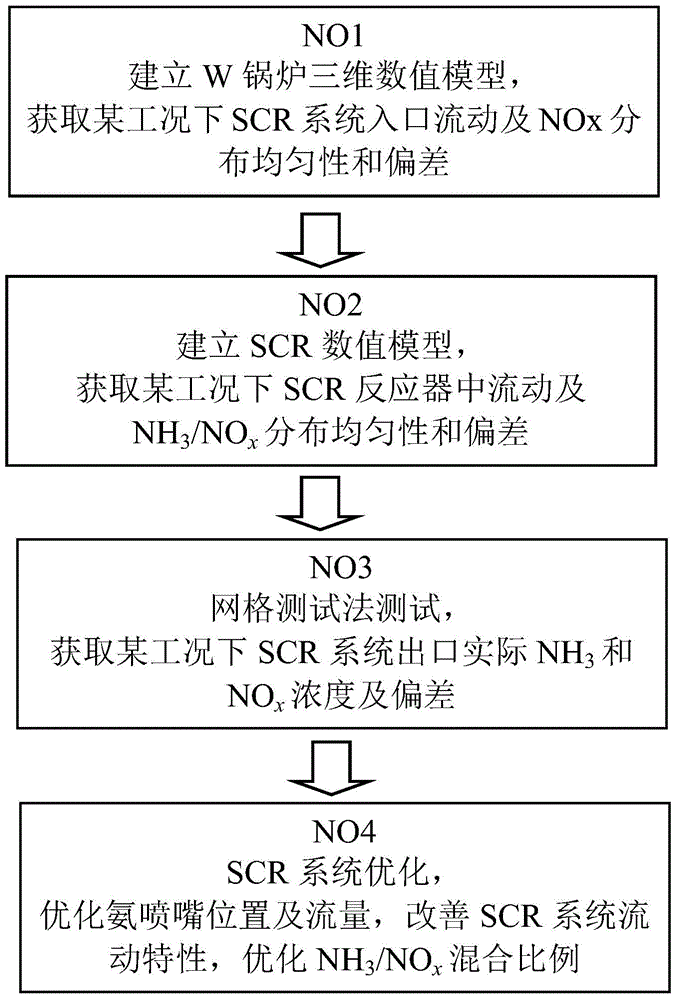

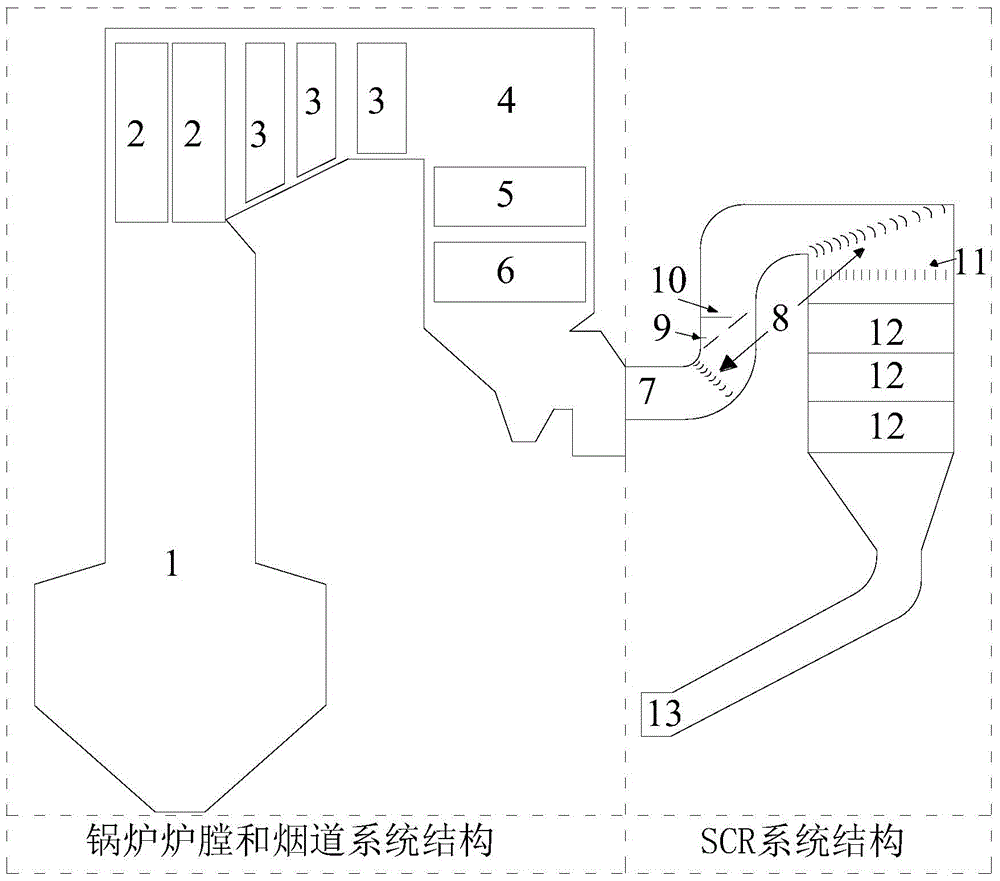

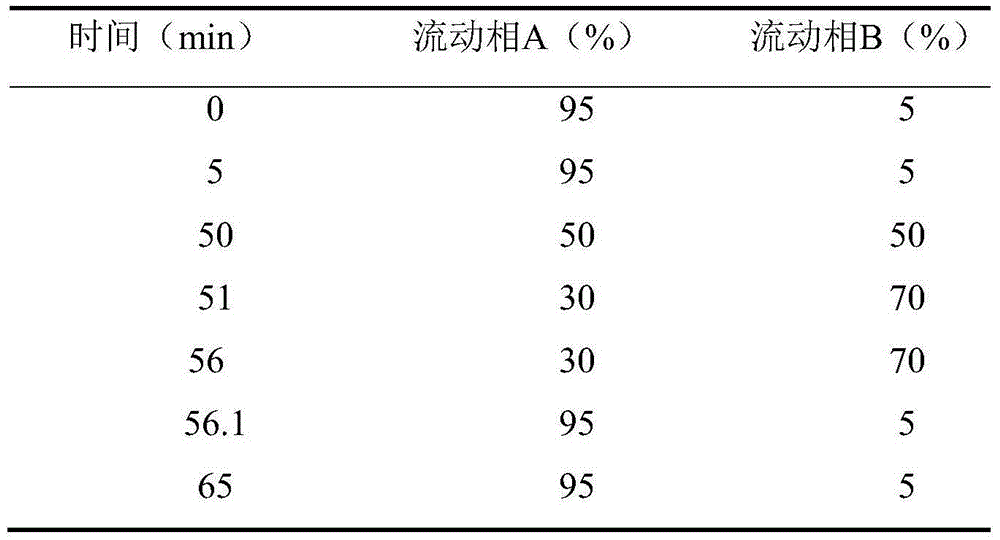

Denitration operation optimization method for SCR (Selective Catalytic Reduction) system of tangential firing pulverized coal boiler

InactiveCN103752170AOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEngineeringStreamflow

The invention discloses a denitration operation optimization method for an SCR (Selective Catalytic Reduction) system of a tangential firing pulverized coal boiler. The denitration operation optimization method comprises the special steps of using a numerical simulation method; obtaining a velocity of flue gas, an NOx concentration distribution uniformity and a deviation of an outlet of the boiler by means of considering the structure and the operation condition of the boiler as a boundary condition of an inlet of the SCR system; obtaining the velocity of the flue gas, an NH3 / NOx distribution uniformity and a deviation inside the SCR reactor; optimizing and adjusting an ammonia spraying flow of an ammonia spraying nozzle on a flue of the SCR system according to the velocity of the flue gas and the NH3 / NOx; increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger velocity of the flue gas, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller velocity of the flue gas; and increasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the smaller NH3 / NOx, and decreasing the ammonia spraying flow of the ammonia spraying nozzle corresponding to an area with the larger NH3 / NOx. The denitration operation optimization method provided by the invention can be used for optimizing and adjusting by comprehensively considering the structures and the operation conditions of the boiler and the SCR system, so that the denitration efficiency of the SCR system is improved; the spraying amount and the release rate of ammonia can be reduced; the security, the economical efficiency and the environmental friendliness of the operation of the boiler unit can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

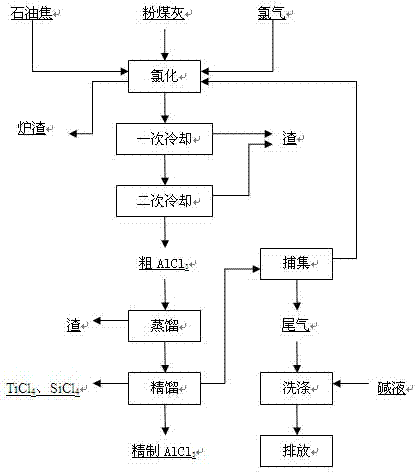

Refining process method for producing anhydrous aluminum chloride through high aluminum fly ash

InactiveCN104773747ARaw materials are cheap and easy to getHigh purityAluminium chloridesDistillationChloride

The present invention discloses a refining process method for producing anhydrous aluminum chloride through high aluminum fly ash, wherein high aluminum fly ash (the alumina content is more than or equal to 25%) is adopted as a raw material, a carbon value reducing agent is matched, chlorine gas is introduced to carry out a chlorination reaction, and the mixed gas discharged from a chlorination furnace is subjected to treatments such as cooling, distillation and rectification to prepare the anhydrous aluminum chloride product meeting the national standard. The method of the present invention has characteristics of cheap and easily available raw material, high product purity, easy large-scale industrial production, and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

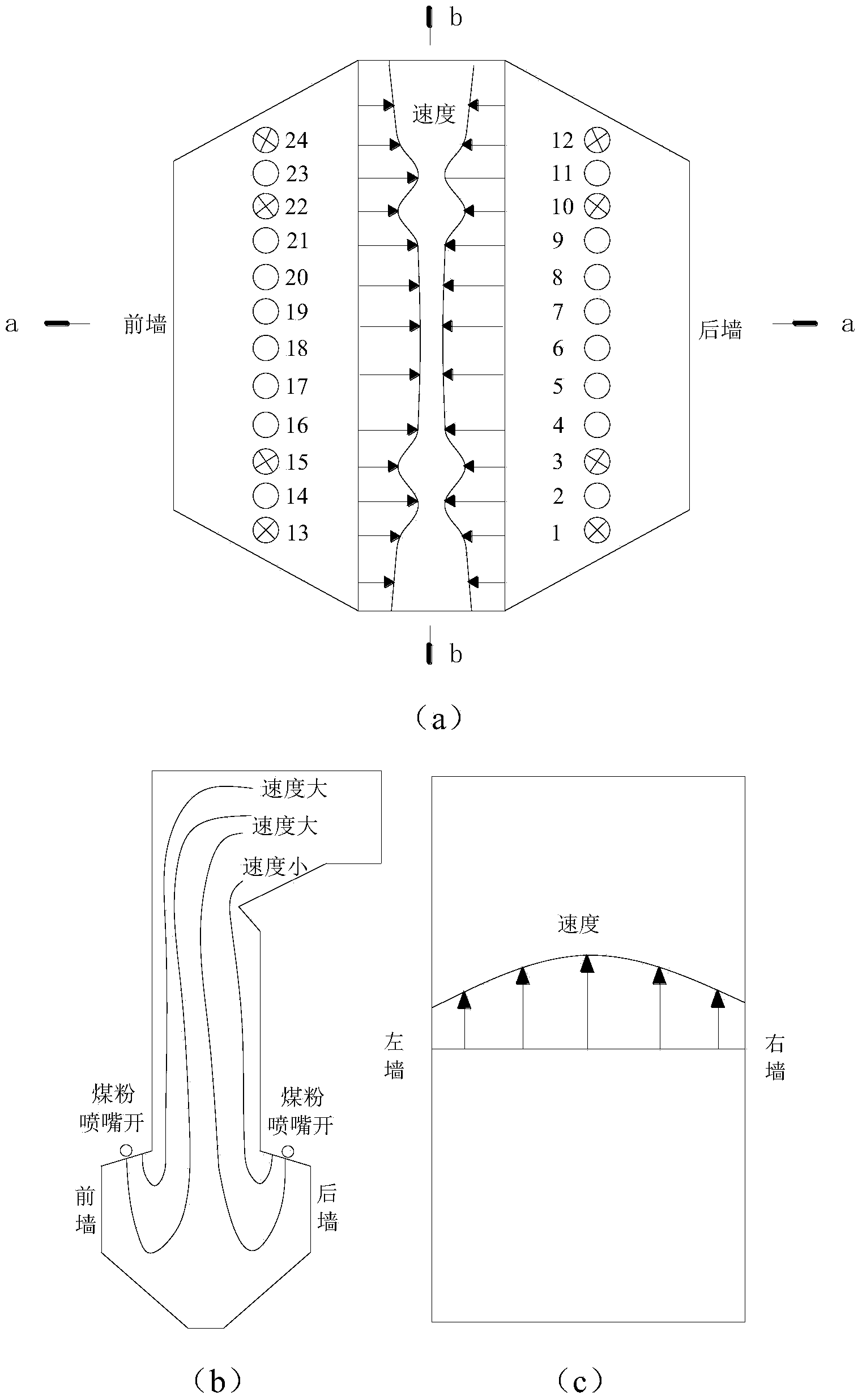

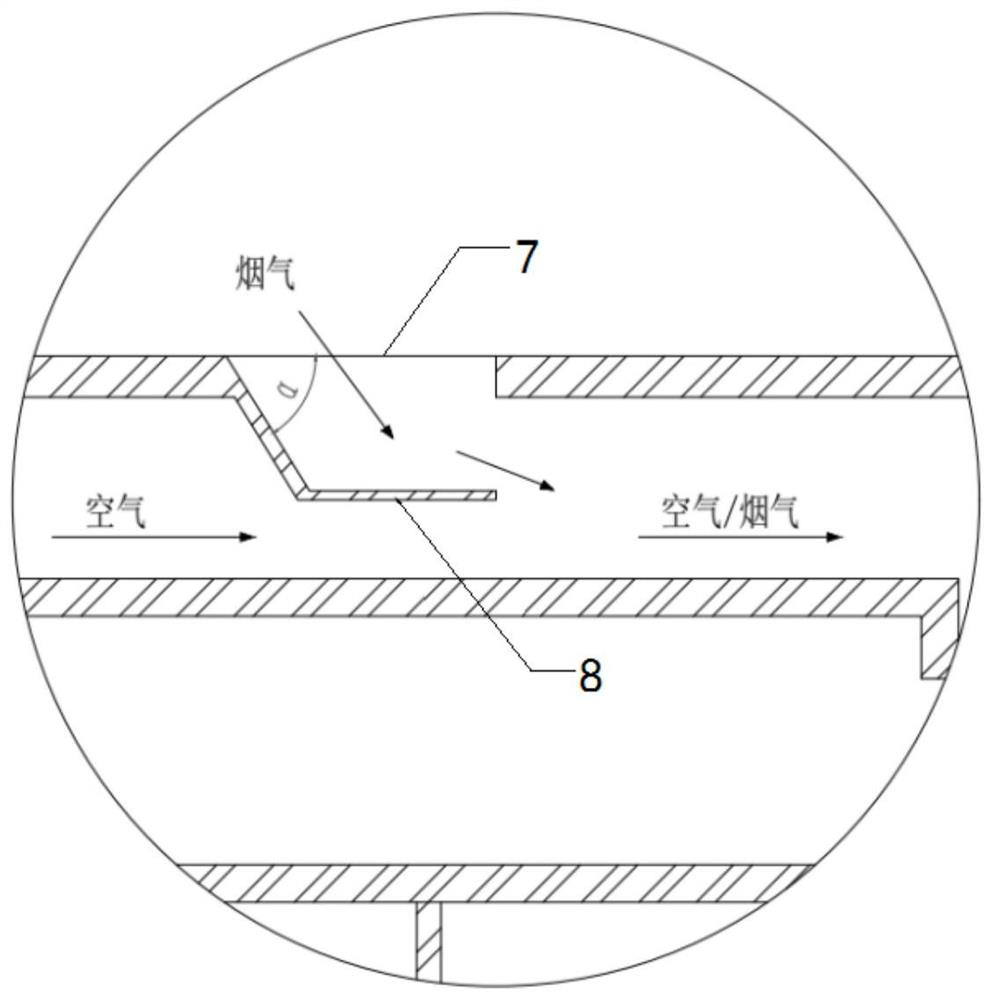

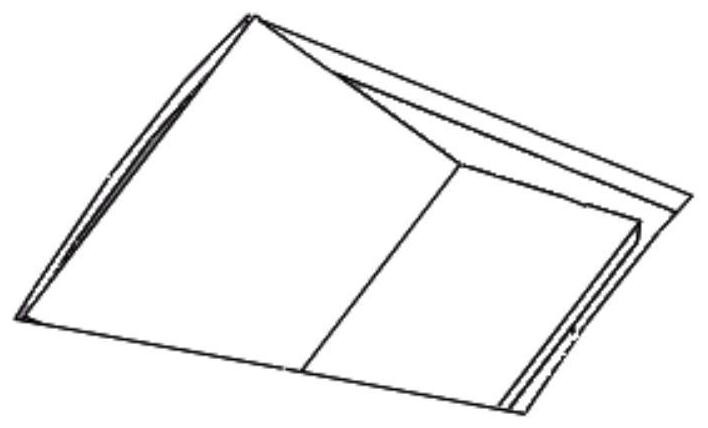

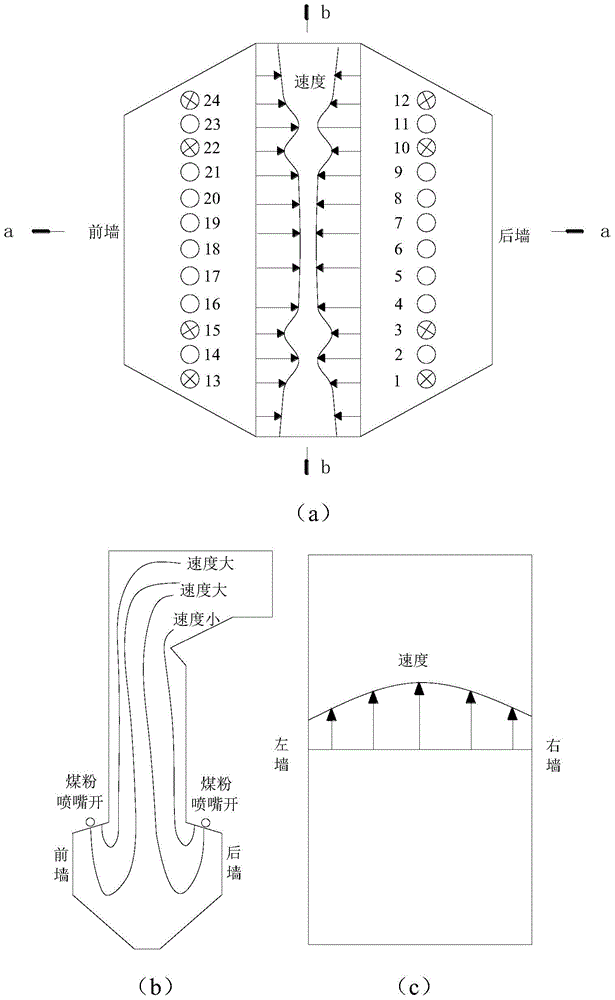

Denitrification operation optimization method of SCR (selective catalytic reduction) system of W flame boiler

InactiveCN103831016AOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEscape rateSpray nozzle

The invention discloses a denitrification operation optimization method of a SCR (selective catalytic reduction) system of a W flame boiler. The denitrification operation optimization method particularly comprises the following steps: acquiring the smoke flow speed and the NOx concentration distribution uniformity and deviation at an outlet of a boiler by considering the structure and the running working condition of a W flame boiler so as to act as inlet boundary conditions of a rear-stage SCR system; adjusting the ammonia spraying flow rate corresponding to the region at which the flue flow speed is slightly high and the NH3 / NOx is slightly low to be low, increasing the number of ammonia spraying nozzles, and adjusting the ammonia spraying flow rate corresponding to a region at which the flue flow speed is slightly slow and the NH3 / NOx is slightly high to be low when the standard criterion that the ammonia spraying flow rate at the upper layer is higher than that at the lower layer, and the ammonia spraying flow rate at the middle is higher than that at two sides is met. According to the invention, the structures and the running situation of the boiler and the SCR system are optimized and adjusted, the denitrification efficiency of the SCR system is improved; the spraying-in quantity and the escape rate of ammonia are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

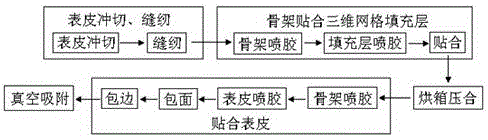

Automobile dashboard coating process

The invention discloses an automobile dashboard coating process. The automobile dashboard comprises a skeleton, a 3D grid filling layer attached to the skeleton and a surface skin coating the 3D grid filling layer. The coating process comprises the following steps: (100) punching and sewing the surface skin; (200) attachingthe 3D grid filling layer onto the skeleton; (300) pressing in an oven; (400) mounting the surface skin and (500) carrying out vacuum suction. Through the manner, the attractiveness and comfort requirements of the surface can be met and the environment standard of automobile interior can be met; meanwhile, the stability and yield of the product are greatly improved and the interior level is elevated.

Owner:常熟安通林汽车饰件有限公司

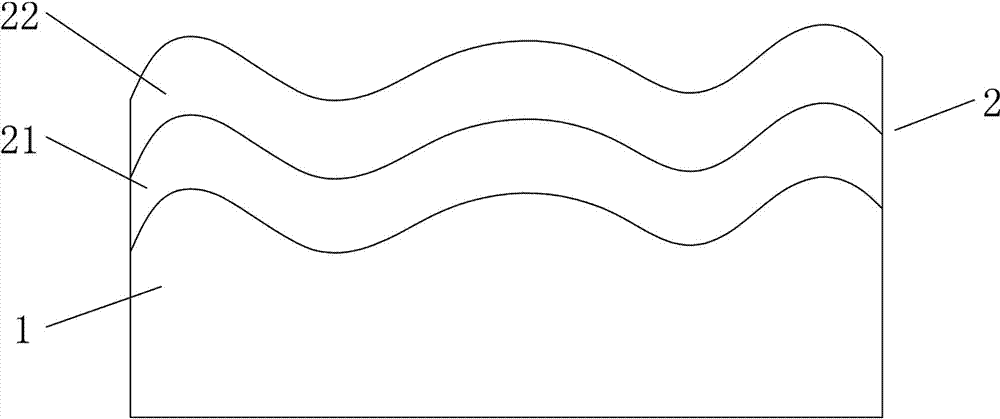

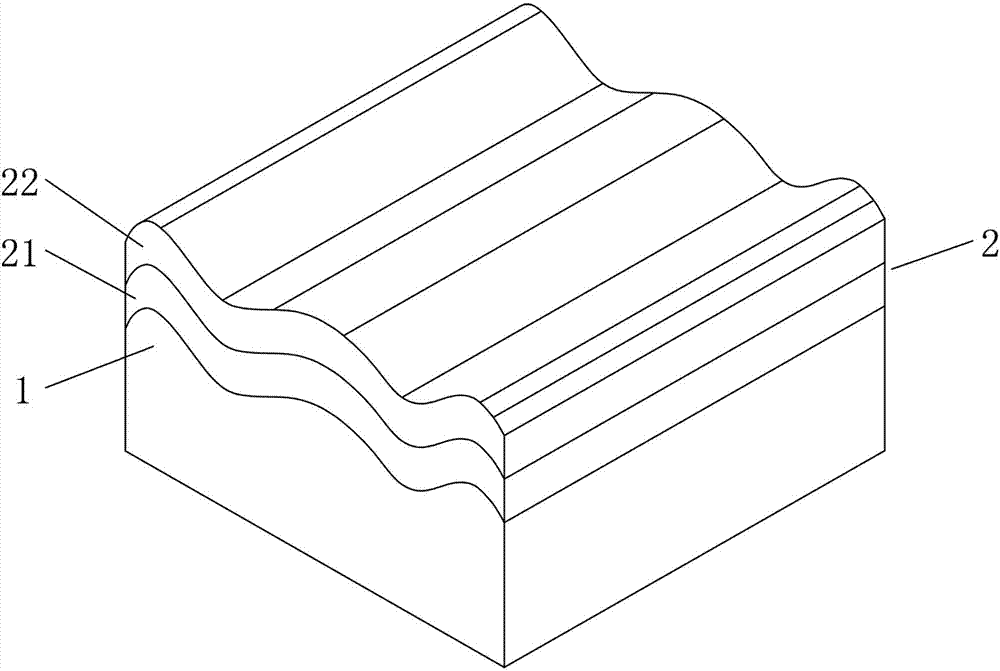

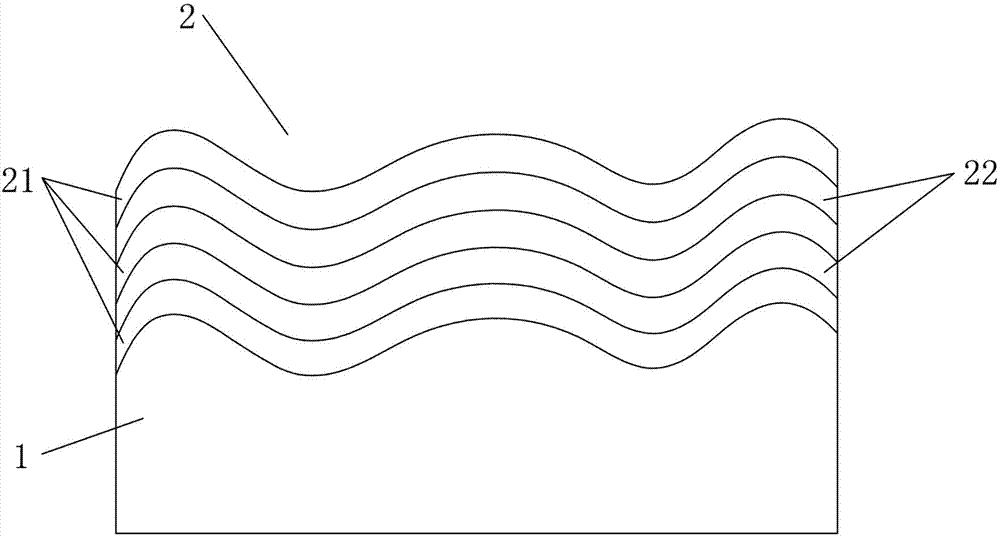

Composite heat dissipation layer of power component, technology of composite heat dissipation layer of power component and power component with composite heat dissipation layer

ActiveCN103594434AUniform weightReduce temperature riseSemiconductor/solid-state device detailsSolid-state devicesPower componentMaterials science

The invention relates to a composite heat dissipation layer of a power component, a technology of the composite heat dissipation layer of the power component and the power component with the composite heat dissipation layer. The composite heat dissipation layer is formed by compositing at least one thin insulating layer and at least one thin solid metal heat dissipation layer. The bottom layer of the thin composite heat dissipation layer is the thin insulating layer, and the insulating layer located at the bottom layer is used for being closely attached to the outer surface of the power component. After the composite heat dissipation layer is combined with the power component, the thin composite heat dissipation layer formed by compositing at least one thin insulating layer and at least one thin solid metal heat dissipation layer can be formed quickly on the surface of the power component; the thin composite heat dissipation layer can form a cambered heat dissipation layer on the surface of the power component, wherein the heat dissipation layer is of an arbitrary shape and is attached to the component. In this way, the weight of a product is uniform; traditional single sided heat conduction is transformed to multiple sided composite heat conduction by utilizing high heat conductivity of metal ( traditionally, single sided heat conduction is mainly adopted, and the heat conduction is not uniform in different directions); therefore, the heat produced by the power component can be conducted quickly and effectively, the temperature rise of the protected power component is reduced, and the service life of the power component is prolonged.

Owner:GUANGDONG MENLO ELECTRIC POWER

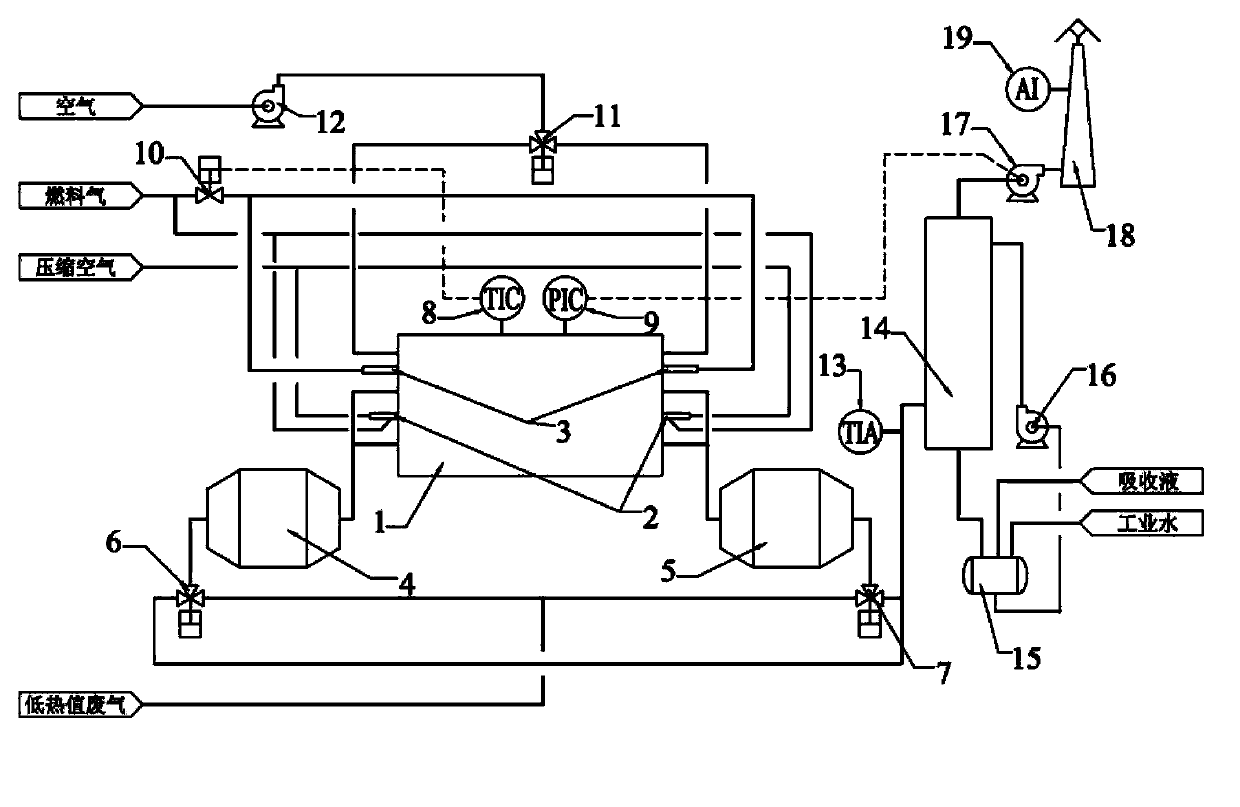

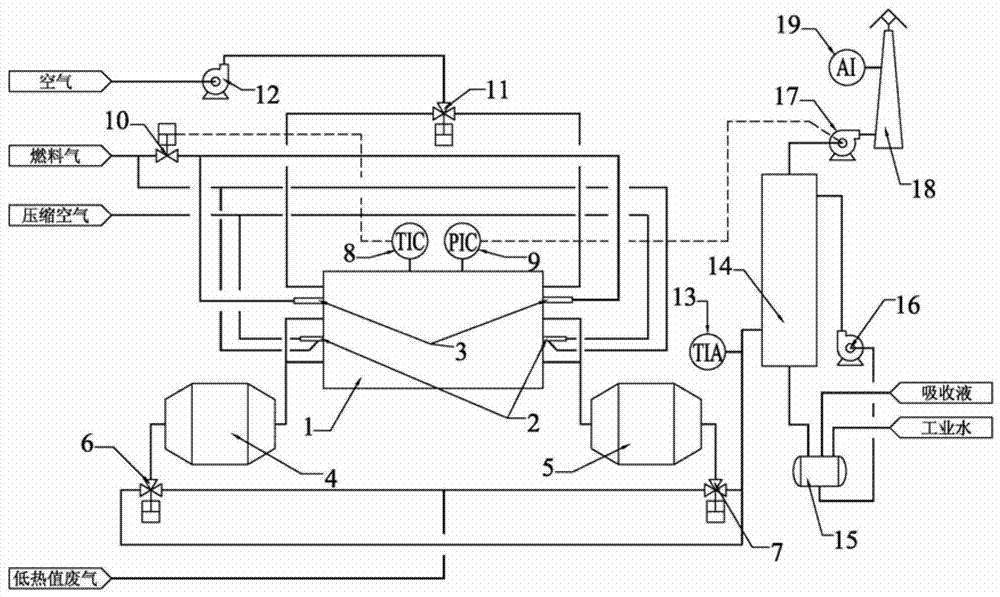

Large-flow and low-heat-value harmful waste gas incineration disposal process

The invention belongs to the technical field of harmful gas treatment, particularly relates to a large-flow and low-heat-value harmful waste gas incineration disposal process, and aims to develop a novel process for treating high-air-volume and low-heat-value harmful waste gas in a regenerative combustion manner. According to the adopted technical scheme, a ceramic heat accumulating body is taken as a carrier for recovering heat of high-temperature flue gas and pre-heating waste gas, the temperature of the high-temperature flue gas falls rapidly in a heat accumulating chamber, and the heat energy is stored in the heat accumulating body and is released for heating waste gas needing to be treated in a next cylinder. The process has the beneficial effects that the system can treat waste gas containing acid components, and the temperature of flue gas is higher than the dew point temperature of acid in the heat accumulating chamber, thus corrosion to the heat accumulating body is prevented, and the emitted flue gas is up to the natural environmental protection standard; the waste gas preheating temperature can be up to 80 DEG C or higher, thereby saving over 80 percent of fuel; by adopting a rigid-flame incandescent light, stable combustion state of the system is ensured, and effective residence time of the flue gas in a hearth is ensured.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

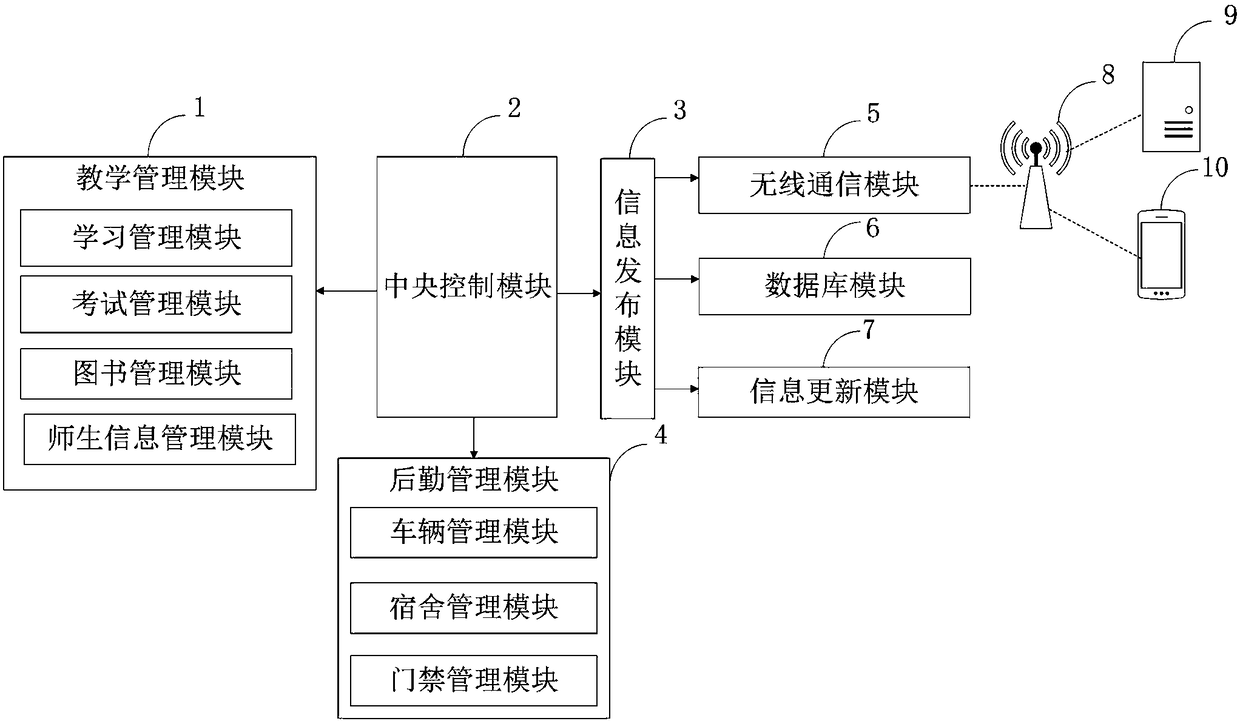

Mobile smart campus system based on Internet of Things

InactiveCN108259173AImprove management efficiencyImprove work efficiencyKey distribution for secure communicationLogistics managementThe Internet

The invention belongs to the technical field of smart campuses and discloses a mobile smart campus system based on the Internet of Things. The system comprises a teaching management module, a centralcontrol module, an information publishing module, a logistics management module, a wireless communication module, a database module, an information updating module, a wireless base station, a campus server and an intelligent mobile terminal. In the system, learning management of students and teachers, examination management, book management and teacher and student information management are subjected to network-based management through the teaching management module, management is very convenient, management efficiency of schools is improved, and manpower and resources are saved. In the systemprovided by the invention, through the wireless communication module, and by taking technologies, such as a smart mobile terminal and the campus server, as carriers, the students and the teachers canperform information query and management through accessing to a campus network by the smart mobile terminal and also can complete online services, thus, work efficiency of the schools is improved, and convenient digital services are provided for the students and the teachers.

Owner:WUHAN CITY VOCATIONAL COLLEGE

Ammonia recovery device

InactiveCN102641656AHigh puritySolve pollutionUsing liquid separation agentAmmonium halidesSmall footprintAmmonia

The invention discloses an ammonia recovery device, relates to the technical field of waste gas purification, and solves the recovery problem of ammonia in tail gas containing polyacrylamide dust and oil. The device of the invention comprises a washing liquid circulating separation tank, a washing region, a primary absorption region, a secondary absorption region, and a chimney; water is used as the washing agent for removing polyacrylamide dust and oil in tail gas so as to ensure pure ammonium salts are obtained at the absorption region; a dilute acid is used as the absorption liquid for ammonia recovery so as to prepare ammonium salts. The device is compact in structure, less in land occupation, high in recovery efficiency, simple and reliable in operation management; the purity of the recovered ammonium salts is high; and the environmental protection standard for tail gas discharge is completely satisfied.

Owner:王树岩

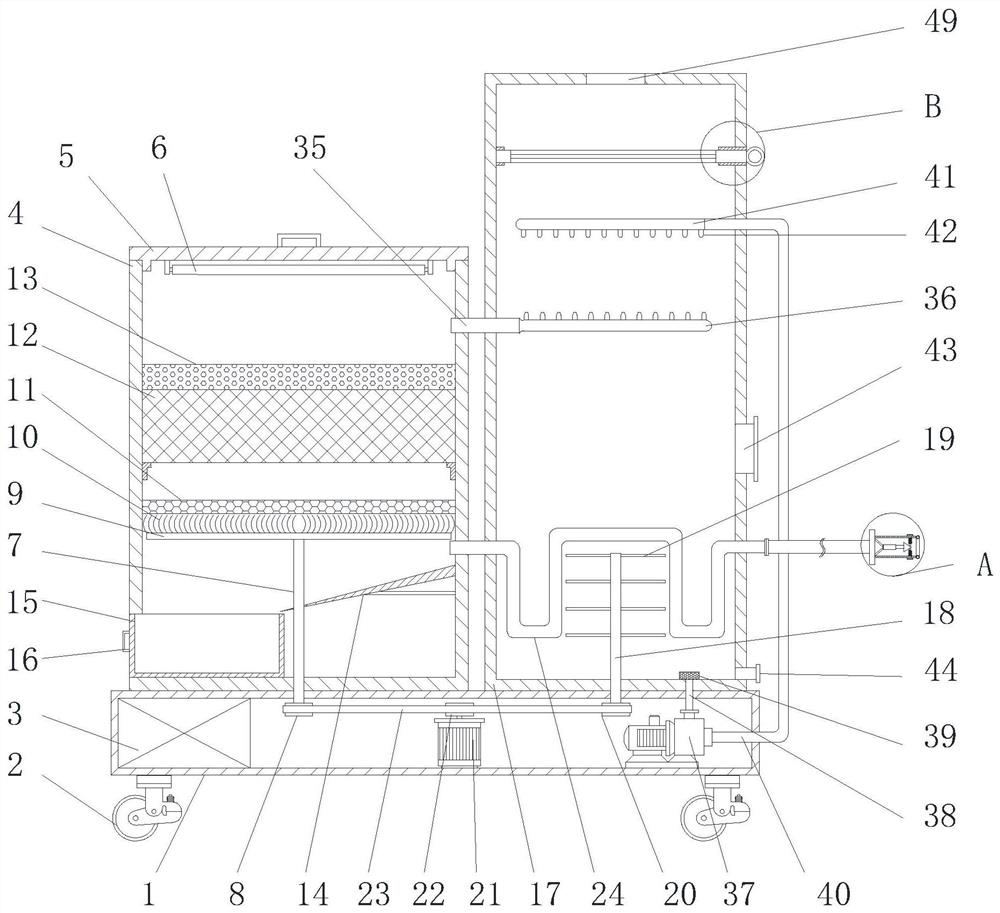

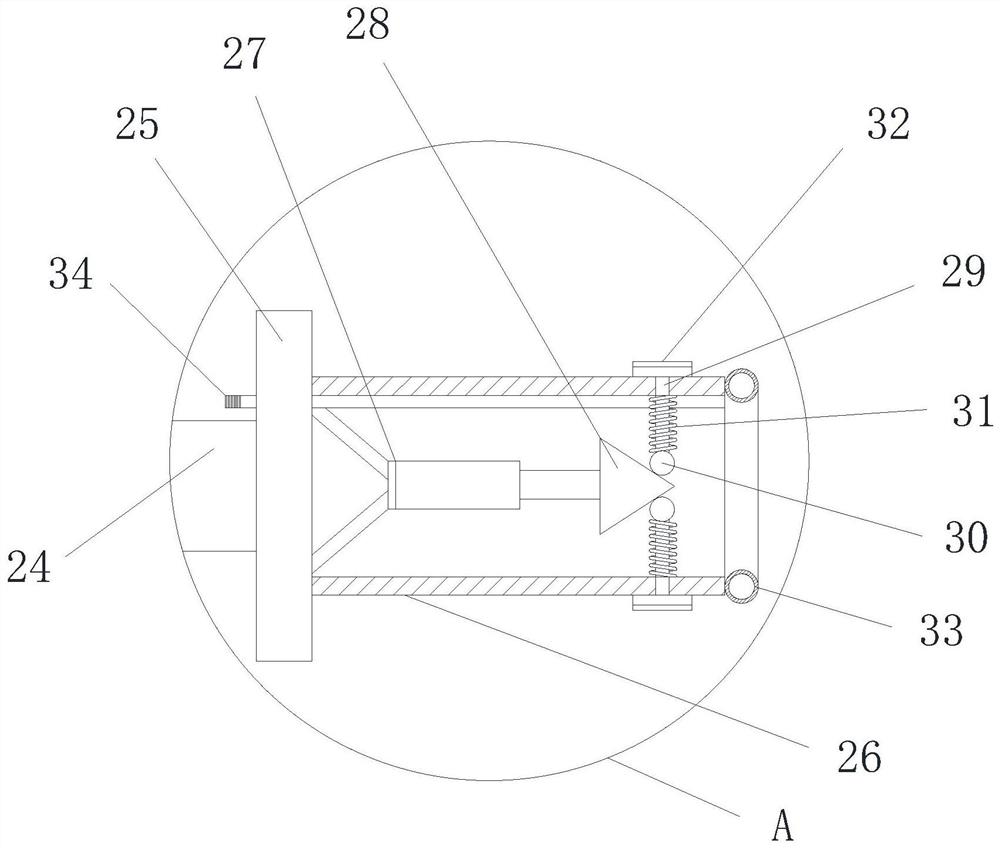

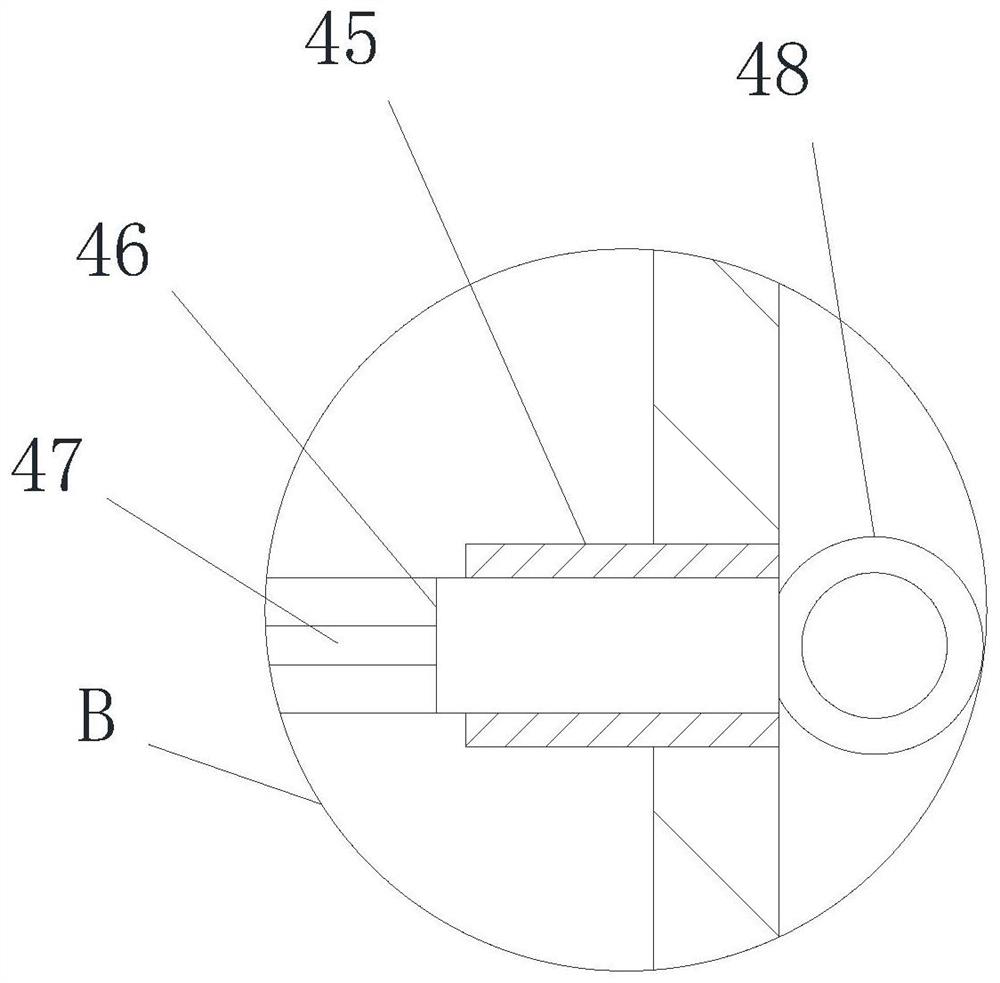

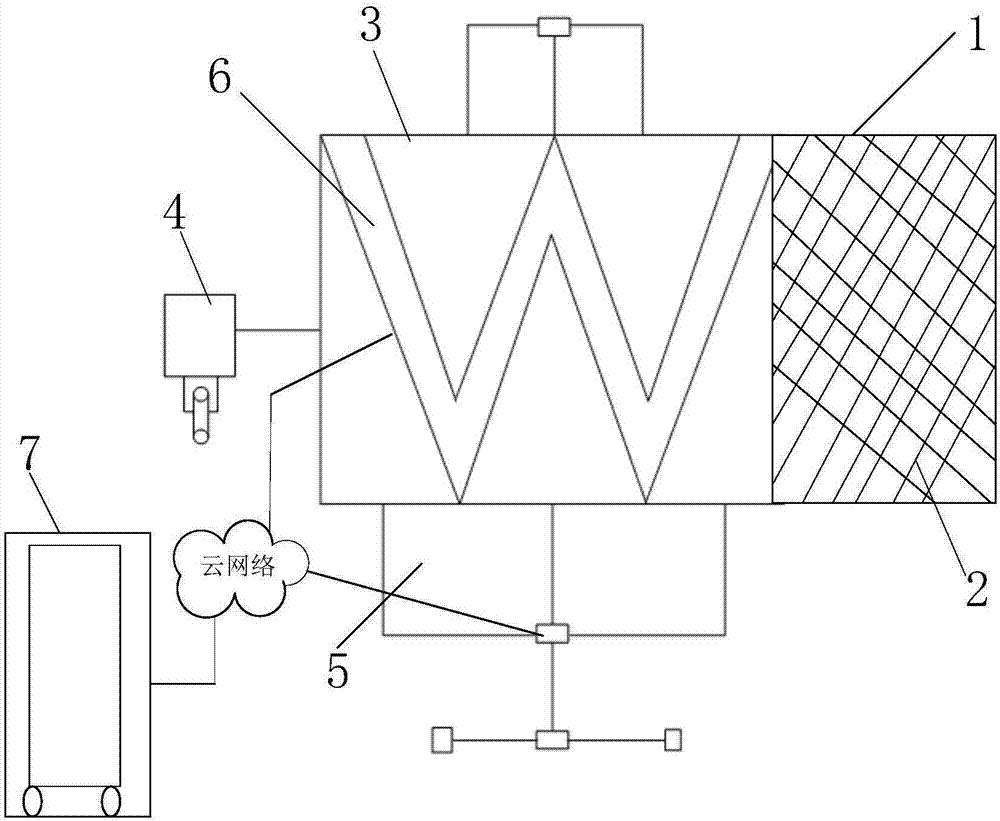

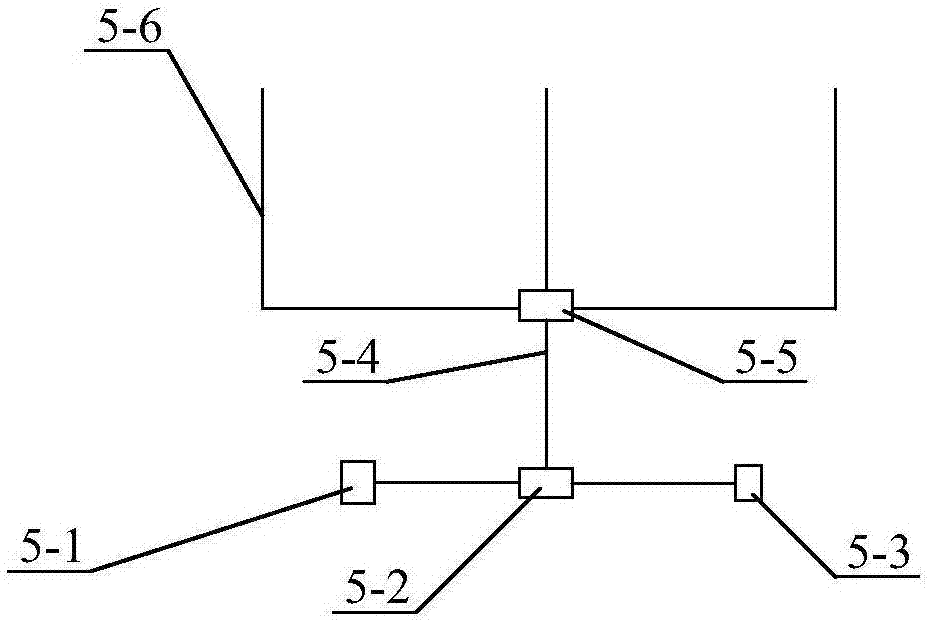

Wet dust collection device with anti-explosion function and polishing system

InactiveCN105999972AStable structureImprove securityCombination devicesGrinding/polishing safety devicesDust explosionDust collection system

The invention relates to a wet dust collection device with an anti-explosion function. The wet dust collection device comprises an air guiding spraying system and a wet dust collection system communicated with the tail end of the air guiding spraying system, wherein the air guiding spraying system comprises an air suction pipe and a first exhaust fan; the air suction pipe is used for collecting and guiding dust; the first exhaust fan is located on the air suction pipe; an air guide port, through which the dust can one-way enter, is arranged on the air suction pipe; the wet dust collection system comprises a purifying chamber communicated with the end part of the air suction pipe; a wet purifying component and a filtering component are respectively arranged above and under the purifying chamber; the top of the purifying chamber is communicated with the outside through a pipeline; an explosion vent is arranged on a side wall of the purifying chamber. The wet dust collection device provided by the invention is reliable in structure and high in safety; the possibility of dust explosion can be effectively reduced; the access is timely turned off after explosion, so that the harm to worker caused by the secondary explosion on the polishing position is avoided; the dust-containing air is purified for three times before the air is discharged; the dust purifying effect is promoted; the dust can reach the direct emitting environmental protection standard.

Owner:徐明凯

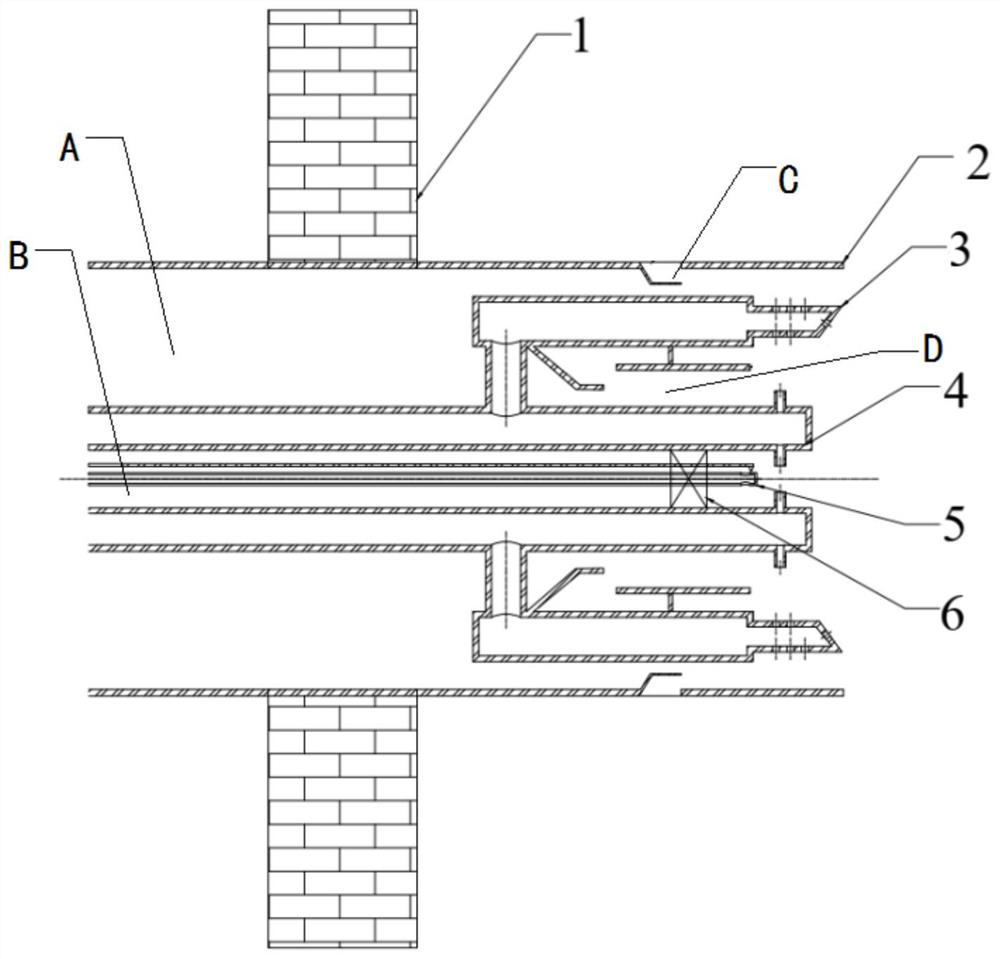

Method for producing manganese sulfate by recycling low-concentration sulfur dioxide flue gas from aluminum electrolytic cells

ActiveCN102258937ARealize resource utilizationMeet environmental standardsDispersed particle separationManganese sulfatesResource utilizationMaterials science

The invention provides a method for producing manganese sulfate by cyclically utilizing low-concentration sulfur dioxide smoke in an aluminum electrolysis cell. The invention relates to low-energy-consumption resource utilization for low-concentration SO2 smoke treatment and waste treatment in the aluminum electrolysis industry, belonging to the fields of energy saving, emission reduction and environmental protection. The method provided by the invention comprises the steps as follows: a chimney subjected to anti-corrosion treatment for exhausting aluminum electrolysis cell smoke is used as atwo-stage absorption tower; an aqueous solution containing MnO is used as an absorption solution; the exhausted SO2 smoke is directly absorbed by adopting an atomization spray and cyclic absorption mode; the nearly saturated solution containing 10-50wt% of manganese sulfate, generated in the reaction, is prepared into a manganese sulfate product through filtration, multiple-effect evaporation andflash vaporization crystallization; and after the residual sulfuric acid mist in the smoke is subjected to demisting treatment, the smoke is exhausted in accordance with the standards. The method provided by the invention can provide technical support for solving the high-standard exhaust problem of the low-concentration SO2 smoke in the aluminum electrolysis cell, enables harmful constituents inindustrial waste gas to be effectively utilized, realizes the sustainable development of resources and environments, has the advantages of low engineering investment, high SO2 absorption efficiency and low operation energy consumption, and can meet higher requirements for environmental protection and exhaust in accordance with the standards.

Owner:KUNMING METALLURGY INST

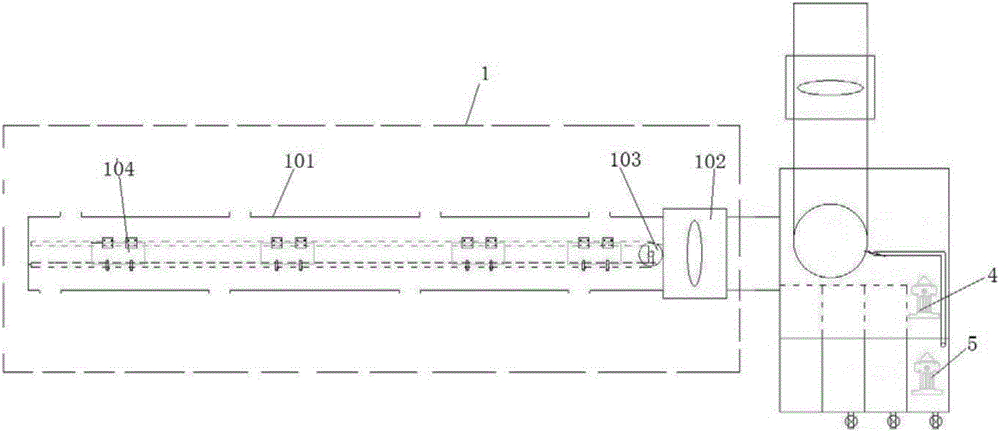

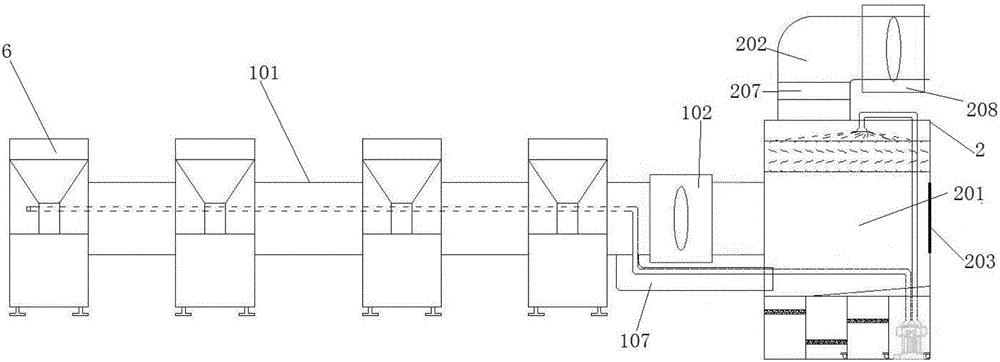

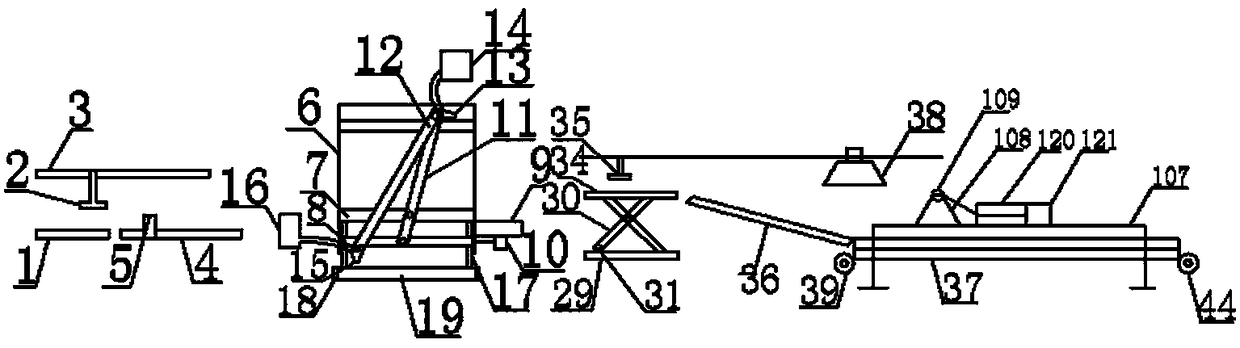

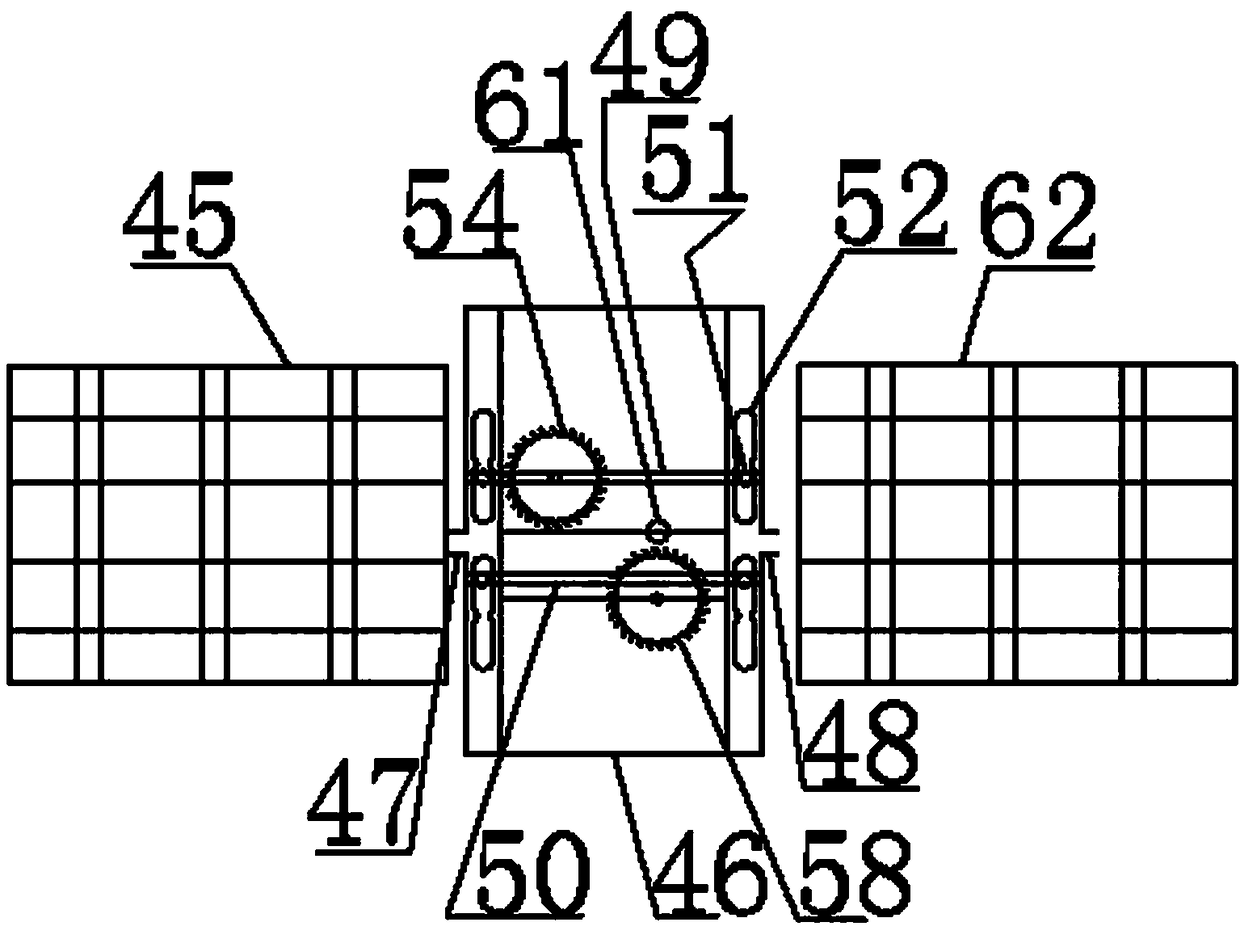

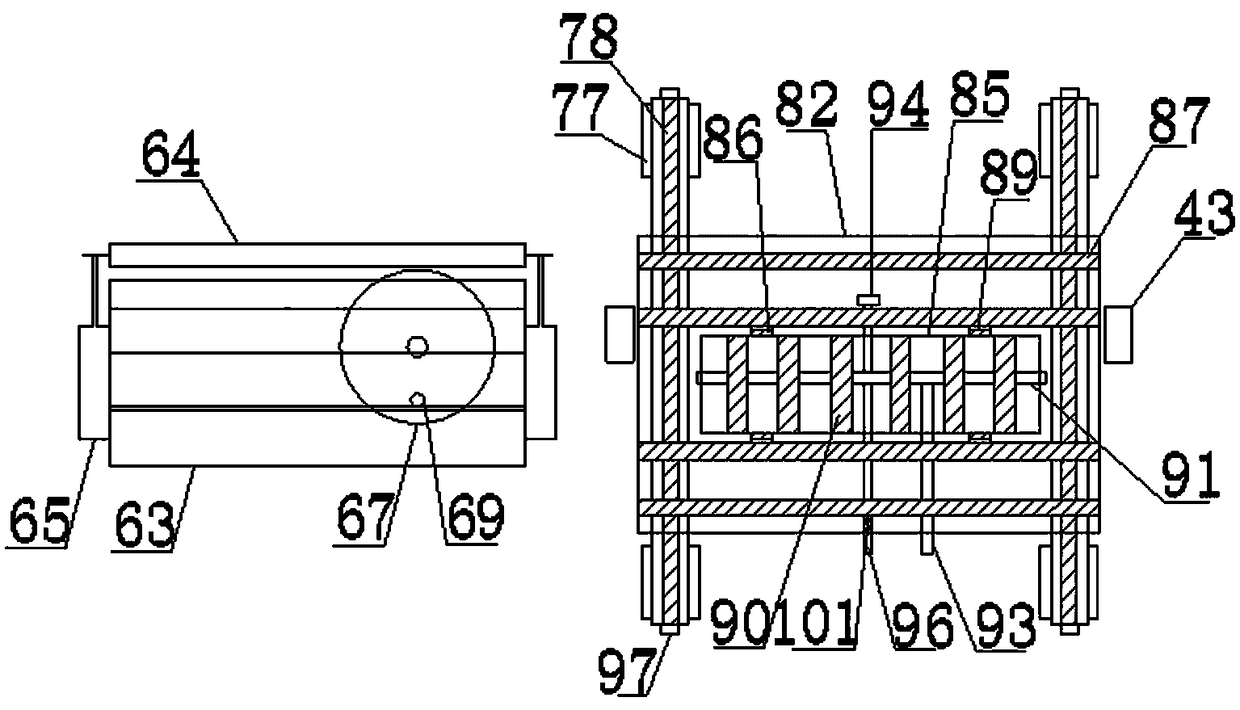

Production line of glass wool rock wool composite PU hard foam thermal insulation plate

PendingCN109203634ALose the effect of heat preservation and energy savingWith waterproof functionLamination ancillary operationsLaminationProduction lineThermal insulation

The invention provides a production line of a glass wool rock wool composite PU hard foam thermal insulation plate. The production line comprises a lower cement plate feeding device arranged on the front end of a first transmission device; the first transmission device is provided with a glue spraying and curing device, a composite plate adhering and rolling device, and an upper surface plate feeding device in sequence from front to rear; a dual crawler pressing machine is arranged between the tail end of the first transmission device and a second transmission device; the second transmission device is sequentially provided with a primary trimming and cutting chamber and a tracking-cutoff and cutting device from front to rear; and the tail end of the tracking-cutoff and cutting device is connected to a material receiving device through a secondary trimming and cutting device. The production line has the advantages of convenient construction, good thermal insulation effect, and low production cost, and the produced thermal insulation plates meet the national environmental protection standards.

Owner:河南省澳科保温节能材料技术开发有限公司

Industrial waste gas treatment and purification device

ActiveCN112808733AFirmly connectedImprove cooling effectCombination devicesGas treatmentFiltrationExhaust fumes

An industrial waste gas treatment and purification device comprises a base, a filter box and a purification barrel, wherein the base is of a hollow structure, the filter box is arranged on the left side of the upper end of the base, the upper end of the filter box is in threaded connection with an access cover, an ultraviolet lamp is arranged in the middle of the lower end of the access cover, a cleaning shaft is rotationally connected to the bottom end in the filter box, the lower end of the cleaning shaft penetrates through the filter box and the base and is connected with a first driven wheel, a cleaning cross rod is arranged at the upper end of the cleaning shaft, a brush is arranged at the upper end of the cleaning cross rod, and a filter screen plate is arranged on the lower side in the filter box. The device is rapid and convenient to mount and connect, stable and firm, excellent in sealing performance and good in cooling effect, the waste gas treatment efficiency and effect are improved through three filtration and adsorption layers in total, blockage can be avoided, sterilization and peculiar smell removal can be rapidly realized, dust, solid pollutants and the like in waste gas are further removed by means of cold water spraying, and the device is small in size, convenient to move and low in construction cost.

Owner:苏州瑞优程芯科技有限公司

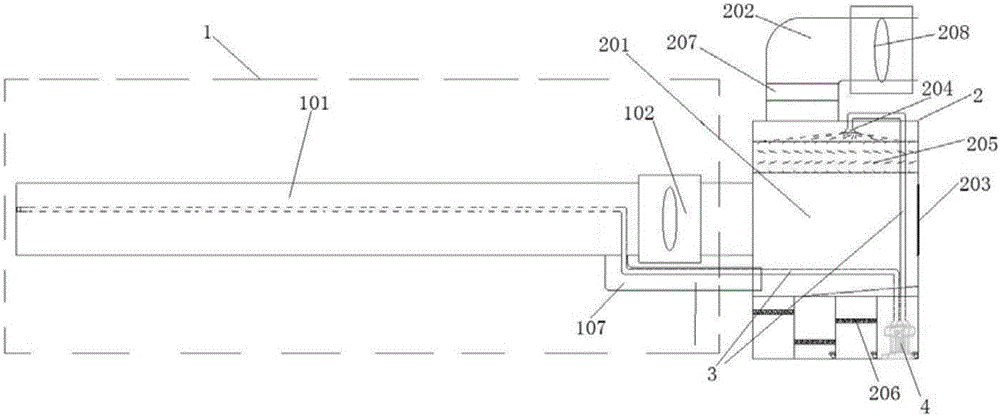

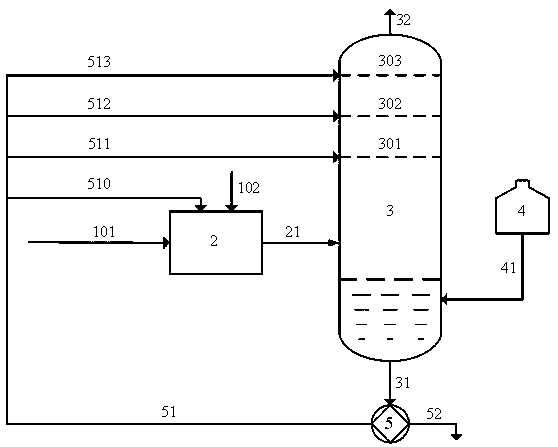

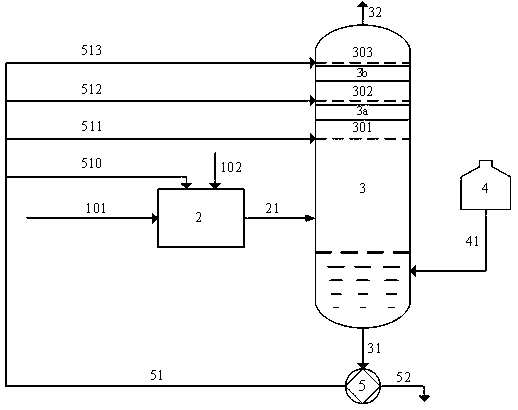

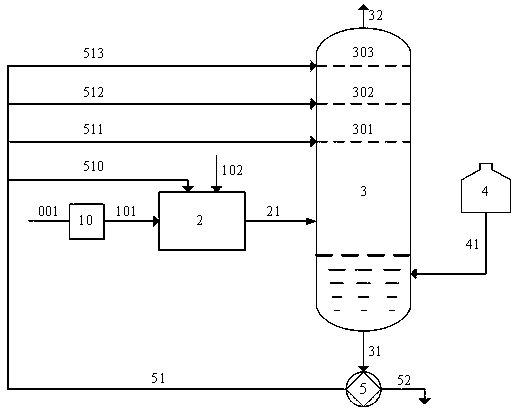

Desulfurization and denitrification device and method

InactiveCN110075677ARealize multi-stage desulfurization and denitrification treatmentGood desulfurization and denitrification effectGas treatmentUsing liquid separation agentEngineeringSolid particle

The invention provides a desulfurization and denitrification device and method. The desulfurization and denitrification device comprises a to-be-treated gas inlet (101), a fresh absorbent inlet (102),an absorption reactor (2), an absorption and regeneration mixed reactor (3), an alkali liquor tank (4) and a solid-liquid separator (5). By means of the desulfurization and denitrification device andmethod, continuous desulfurization and denitrification of to-be-treated gas can be realized, solid particles in the to-be-treated gas can be removed, the treatment efficiency is high, content of NOxand SOx in discharged gas is low, no dioxin is produced, and the national environmental protection standard can be met.

Owner:苏州华加星光新能源科技有限公司

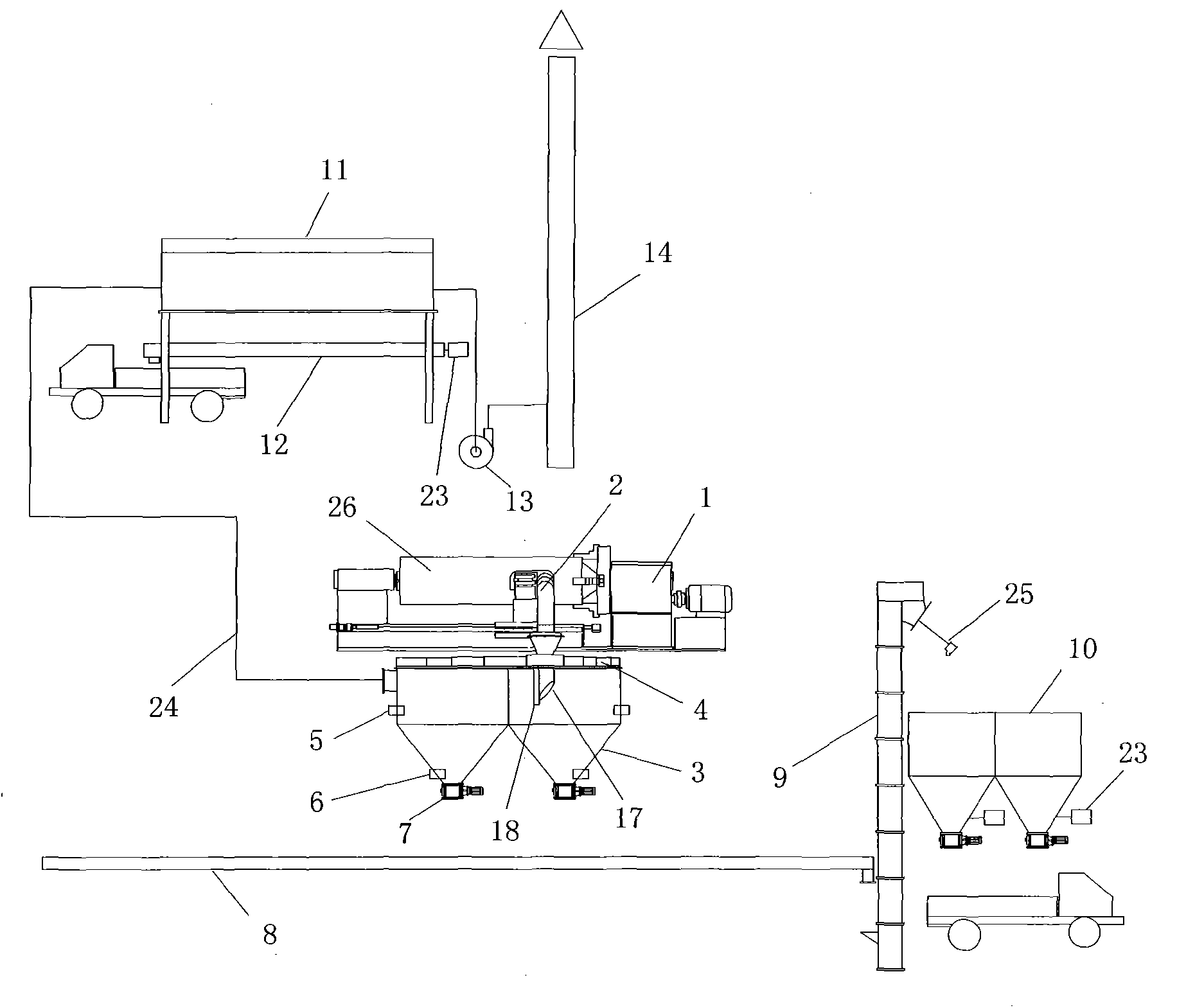

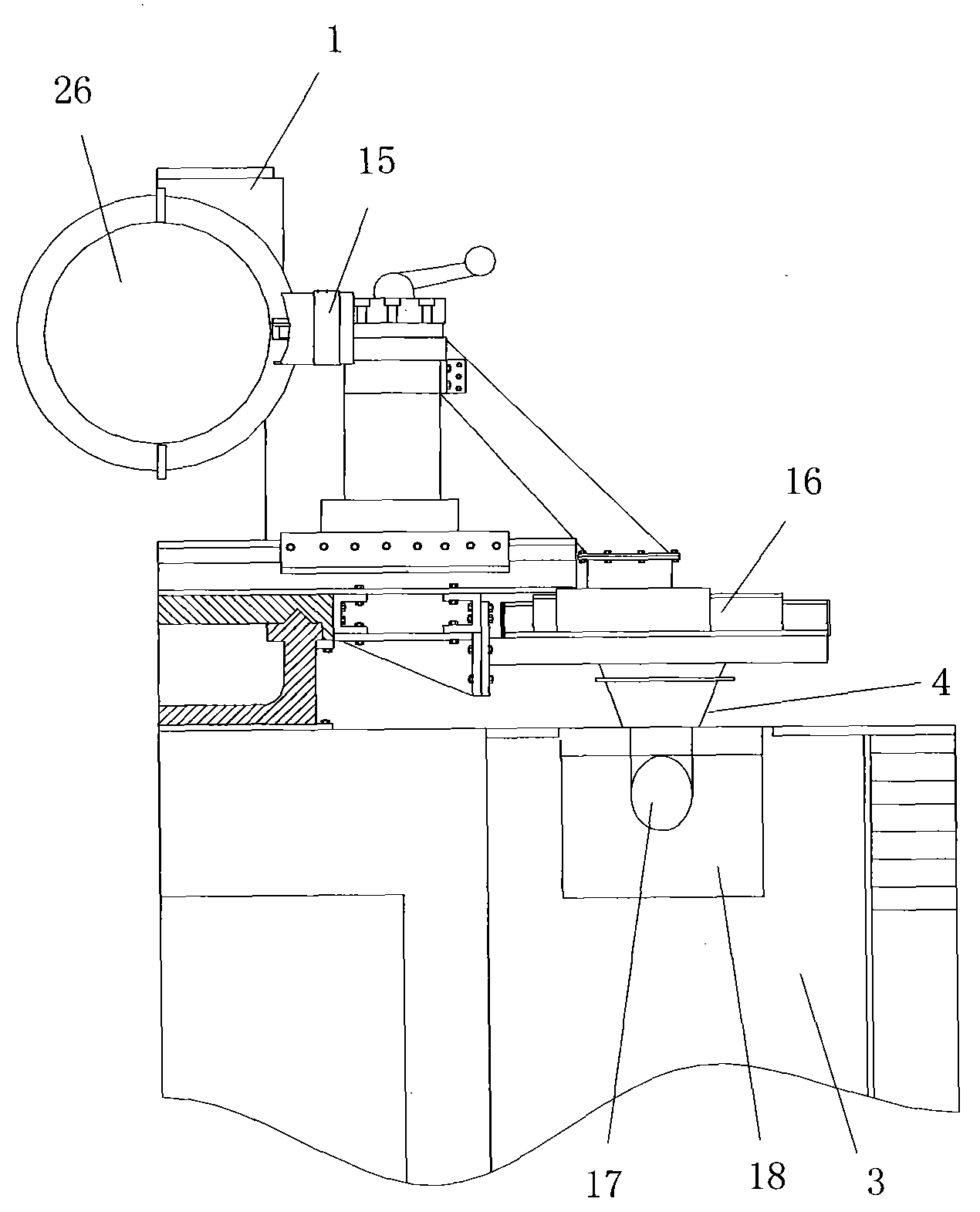

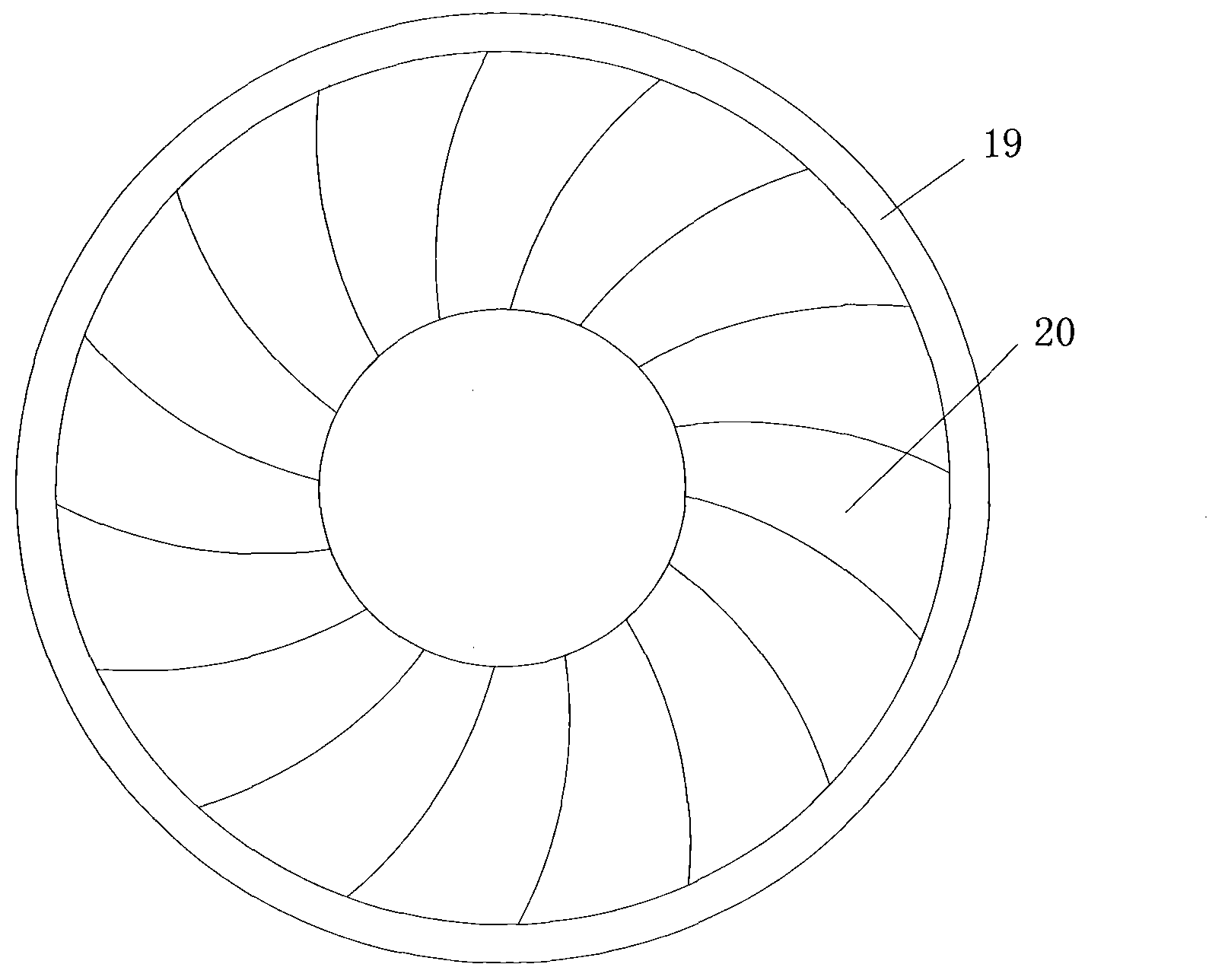

Cutting chipping gas-solid separation and dust collection treatment system

InactiveCN104338404AEasy to separateReduce the impact of settlementCombination devicesBaghouseMachine tool

The invention discloses a cutting chipping gas-solid separation and dust collection treatment system. The cutting chipping gas-solid separation and dust collection treatment system structurally comprises an induced air dust collection cover device arranged on a machine tool in a sliding manner; two settling bins are arranged in parallel under the induced air dust collection cover device; electric unloaders are arranged at the bottoms of the two settling chambers; an air outlet pipeline is arranged at one sides of the settling chambers; a scraper conveyor is arranged under the electric unloaders; an elevator is arranged at the discharge end of the scraper conveyor and connected with a storage bin; the air outlet pipeline is connected with a pulsing bag-type dust remover; a screw discharger is arranged under the pulsing bag-type dust remover; an air outlet of the pulsing bag-type dust remover is connected with an induced draft fan which is connected with a chimney. The cutting chipping gas-solid separation and dust collection treatment system is capable of overcoming the shortcomings in the prior art; as a result, the air pressure and air speed requirements of the system are reduced, the abrasion of particle recovering to the pipeline is reduced and the dust removal effect is good; besides, the labor intensity is reduced and the production efficiency is improved.

Owner:河北顺天电极有限公司

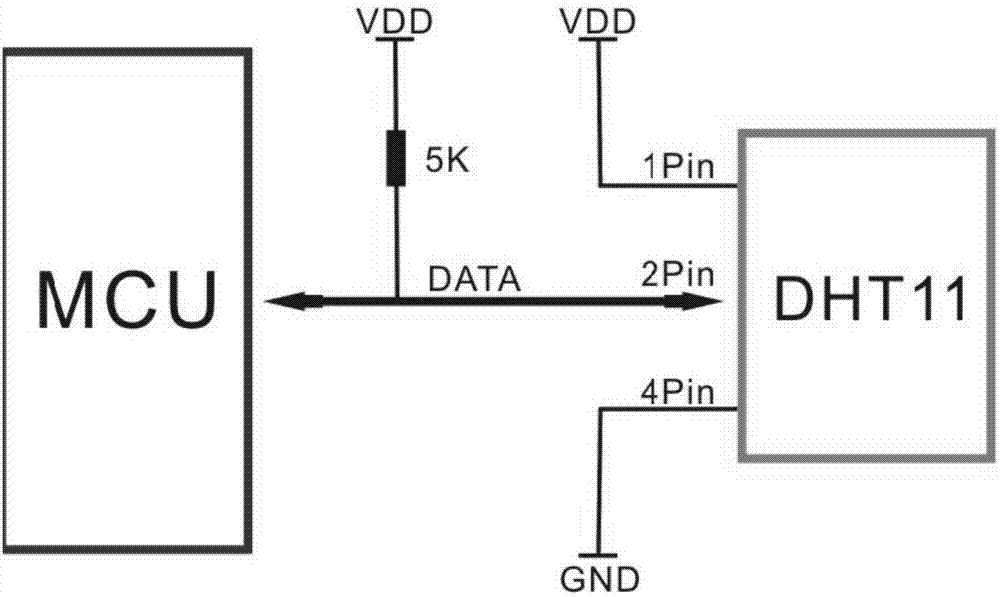

Household gauze, anti-mosquito and anti-insect gauze, multifunctional window and application

InactiveCN107988634AImprove sound insulationGood explosion-proofSpinning solution de-aeratingSynthetic resin layered productsInductorRemote control

The invention belongs to the technical field of smart homes and discloses household gauze, anti-mosquito and anti-insect gauze, a multifunctional window and application. The household gauze is woven from FDY, the anti-mosquito and anti-insect gauze is woven from FDY to which an anti-mosquito and anti-insect agent is added, and the outer layer of the multifunctional window is shielded by a gauze sash in a sliding mode. The anti-mosquito and anti-insect gauze is embedded into the gauze sash. A temperature and humidity inductor is embedded into a frame body and connected with a rainwater shielding device through a wire. An electronic control photochromic glass unit is embedded into the frame body, and the electronic control photochromic glass unit and the rainwater shielding device are both wirelessly connected with a remote control end. The abrasion resistance, oxidation resistance and strength of the FDY are greatly improved; in the aspect of the monofilament elongation-at-break Cv value, it is guaranteed that adhesive force is good after the anti-mosquito and anti-insect agent is added; the colors of the electronic control photochromic glass unit change according to different illumination environments, and the optimal practical effect is achieved.

Owner:高新航

Production process of interior wall putty powder capable of purifying formaldehyde

InactiveCN110885585AImprove adsorption capacityReduce releaseFilling pastesRegistered trademarkMaterials science

The invention discloses a production process of interior wall putty powder capable of purifying formaldehyde and relates to the technical field of decoration building materials. The invention aims tosolve the problem of formaldehyde release of interior wall putty powder. According to the production process of the interior wall putty powder capable of purifying formaldehyde, it is found that aftera German Ryan biological formaldehyde purification factor with the registered trademark of Ryansun is added, the formaldehyde release amount of the putty powder can be greatly reduced, meanwhile, formaldehyde in other materials can be adsorbed, and an obvious formaldehyde purification effect is achieved.

Owner:莱恩环境科技(青岛)有限公司

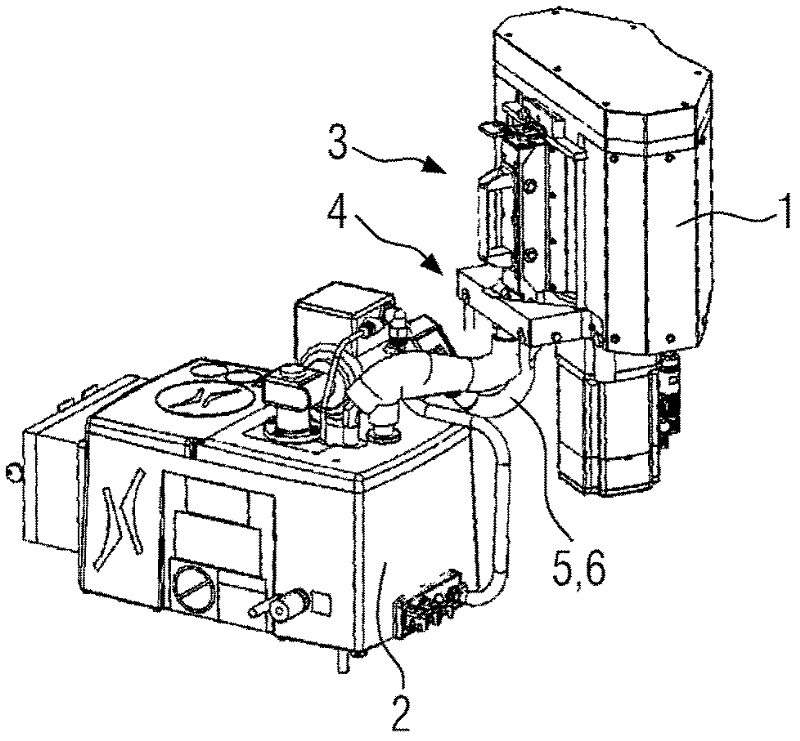

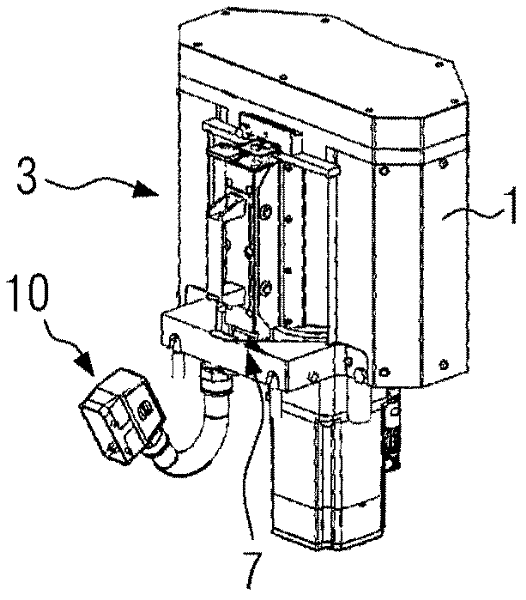

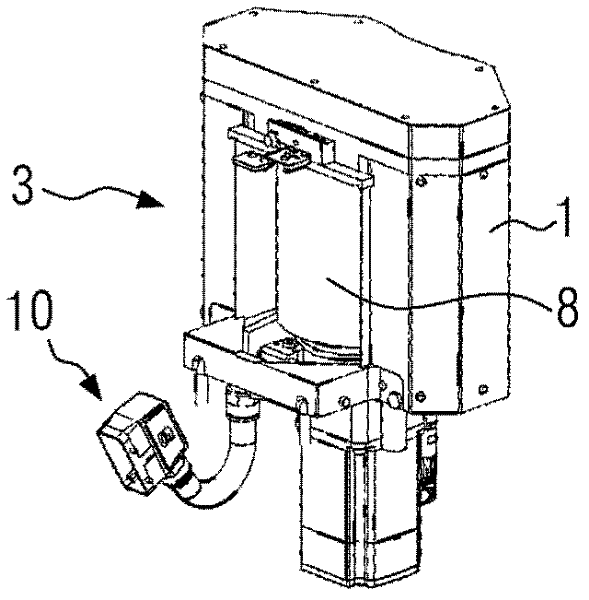

Glue applicator having removable glue storer and connectable cleaning unit

ActiveCN102582900AHigh outputMeet environmental standardsLiquid surface applicatorsSpraying apparatusEngineering

The present invention relates to a glue applicator having a removable glue storer and a connectable cleaning unit, i.e., a glue applicator used for a labeling machine, wherein, glue can be filled in the glue storer and can be coated on a glue spreader of the glue applicator, wherein the glue applicator has a connection part, a glue scraping knife matched with the connection part can be arranged on the connection part in the way of being removed again. The present invention also relates to a labeling machine having the glue applicator.

Owner:KRONES AG

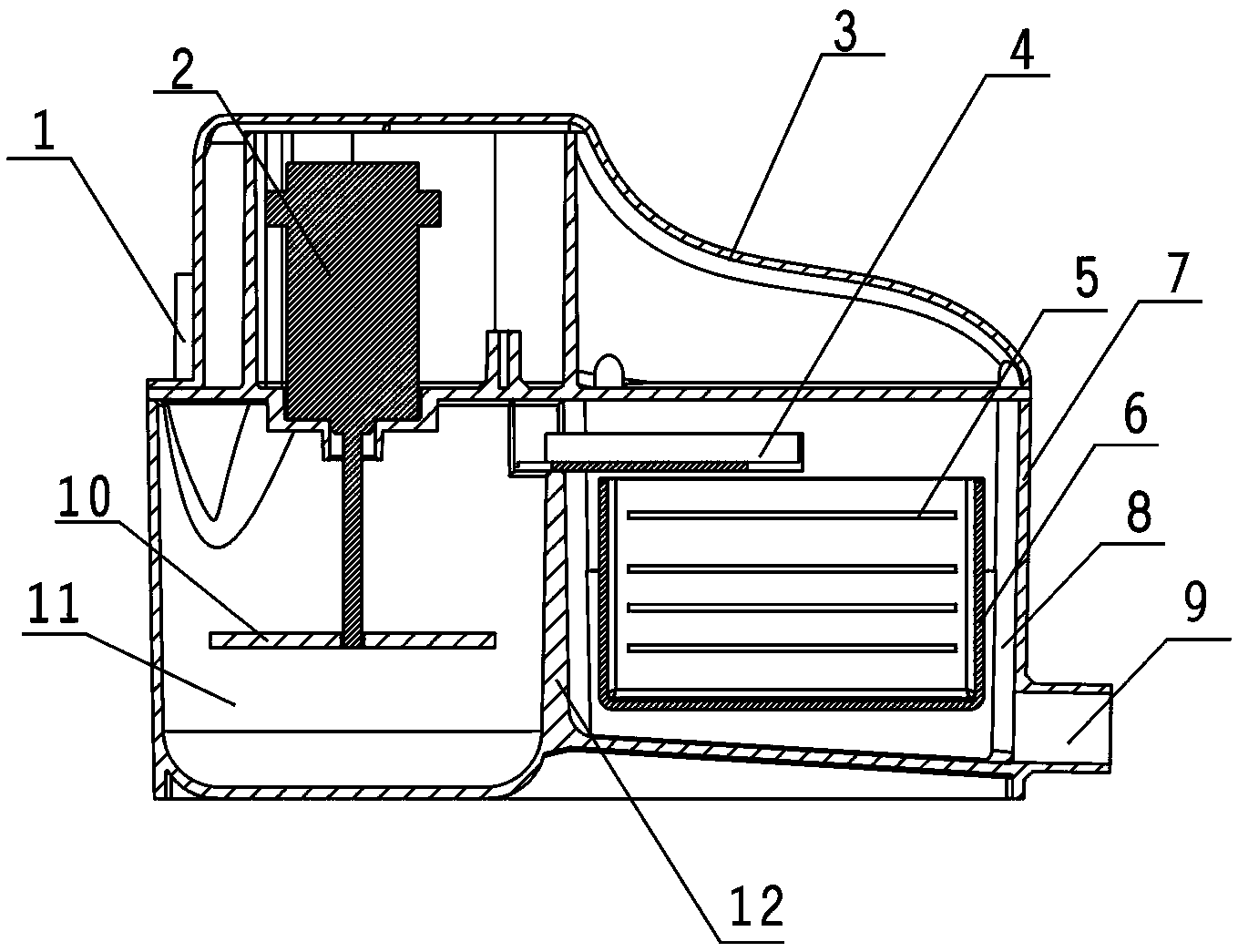

Food waste secondary treatment machine

The invention relates to a food waste secondary treatment machine. An upper cover body of the treatment machine is located on a lower shell; the lower shell is divided into a crushing cavity and a filtration cavity through a partition board, the crushing cavity is provided with an injection port, a cutter is disposed in the crushing cavity and is in connection with a motor disposed in the upper cover body; the crushing cavity and the filtration cavity are communicated through a guide plate, the filtration cavity is internally provided with a filter box, the groove guide plate is in joint with the filter box, and the side wall of the filter box is in a fence or net shape; and the filtration cavity is equipped with a slurry outlet. The food waste secondary treatment machine provided in the invention can be used for re-treatment of the food waste treated by a food waste first treatment machine to make the food waste into a slurry for discharge, and a very small part of food waste failing to meet the standards can be filtered out, thus making sure that the environmental protection standards can be reached.

Owner:ZHEJIANG GLES ELECTRIC

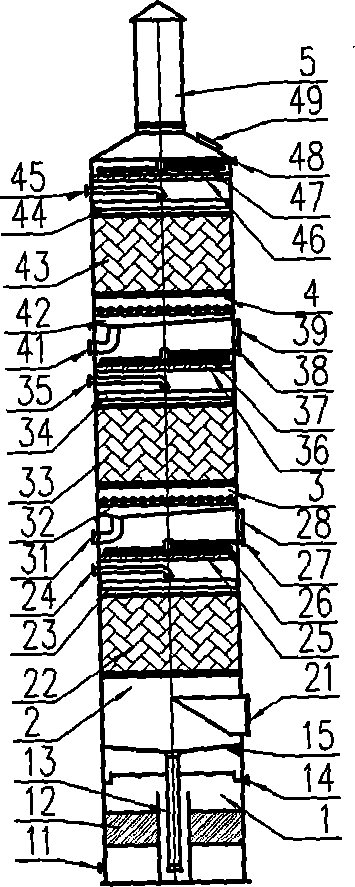

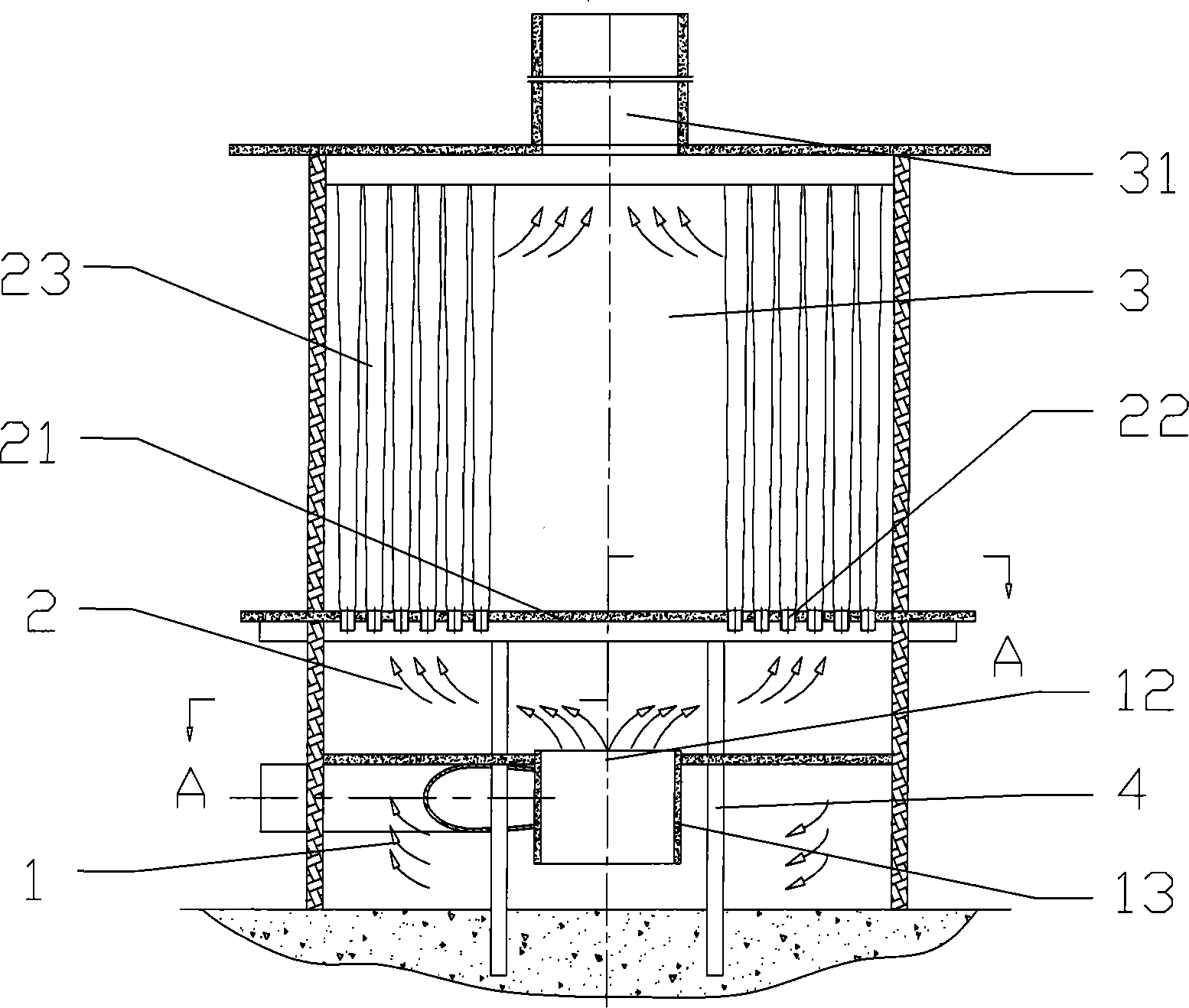

Dust removing equipment

The invention discloses a dust removing equipment, which comprises the following parts from down and up: a cyclone chamber used for cyclone type dusting, a diffuser chamber used for static dusting and a bag room used for bag type dusting. A three-grade dusting can be realized by connecting the three dusting devices in series. According to a dust removal system implemented in the invention, the dusting efficiency is as high as 99.5 percent; the flue gas exhausted from an outlet of cleaning air contains no more solid dust particles which can be directly discharged into atmosphere and reaches the state environment protection standards. Meanwhile, the dust removal system has advantages of simple inner structure, comparatively low construction cost, which can be widely applied to dust removingwork of various delivery capacities.

Owner:倪如宝

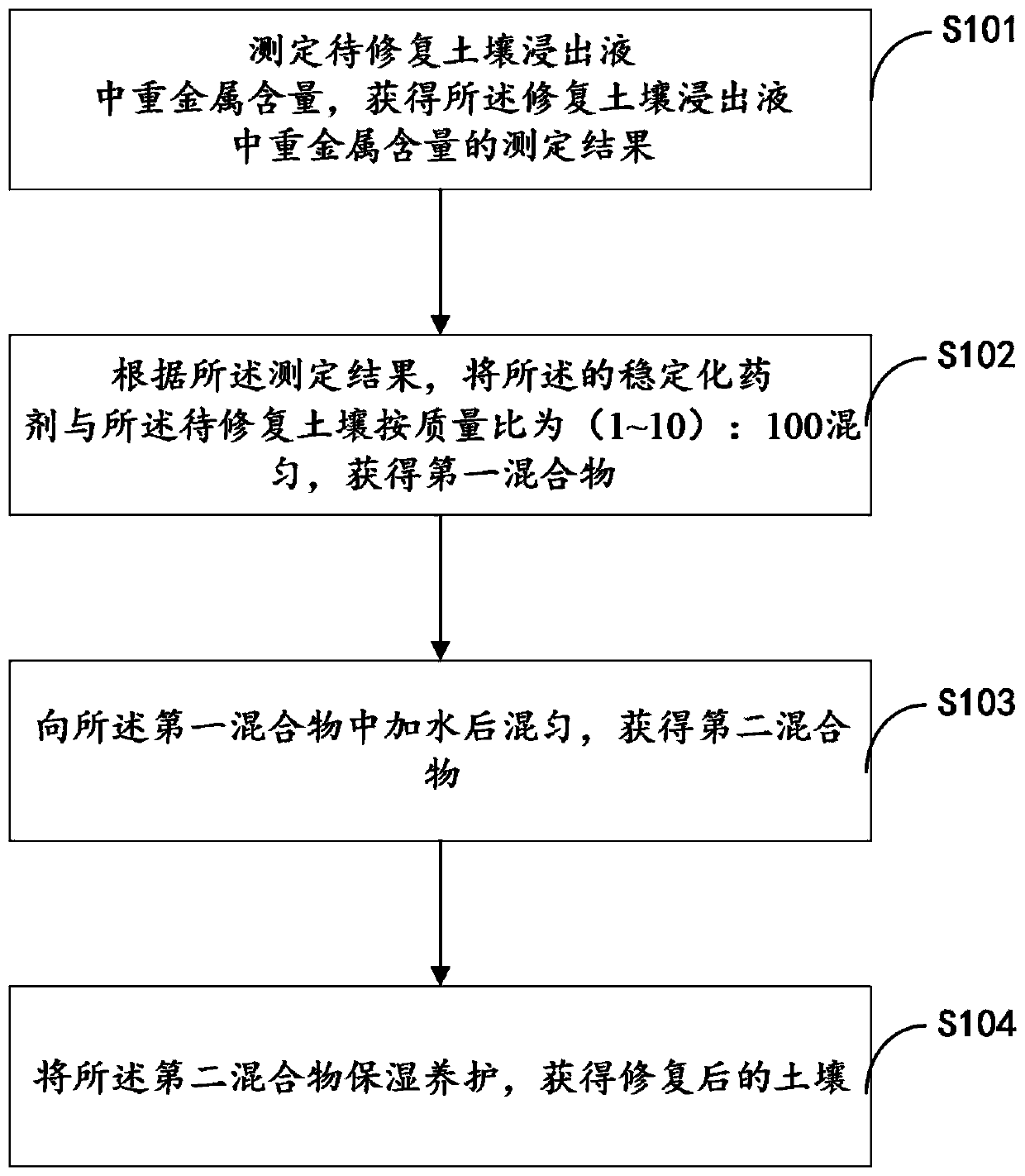

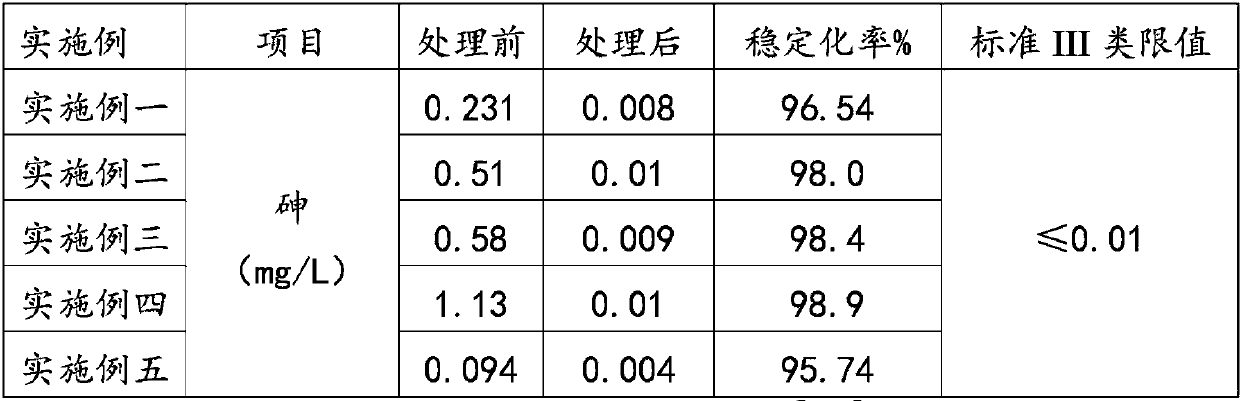

Stabilizing agent and method for repairing arsenic-polluted soil by utilizing urban solid wastes

ActiveCN110665958ASmall apertureSmall pore size and small specific surface areaAgriculture tools and machinesContaminated soil reclamationIndustrial wasteUrban solid waste

The invention relates to a stabilizing agent for repairing arsenic-polluted soil by using urban solid wastes. The stabilizing agent comprises, by weight, 100 parts of quicklime, 10-50 parts of fly ashand 30-80 parts of red brick powder. After adsorption, complexation and precipitation are carried out, the heavy metal pollution of the soil can be obviously reduced, and related environmental protection standards are met. The preparation raw materials of the repairing agent adopt construction wastes and industrial wastes, so the source is wide, the cost is low, a preparation method of the repairing agent is simple, and is convenient to operate, and certain environmentally-friendly effect of waste treatment is achieved.

Owner:SHOUGANG ENVIRONMENTAL IND

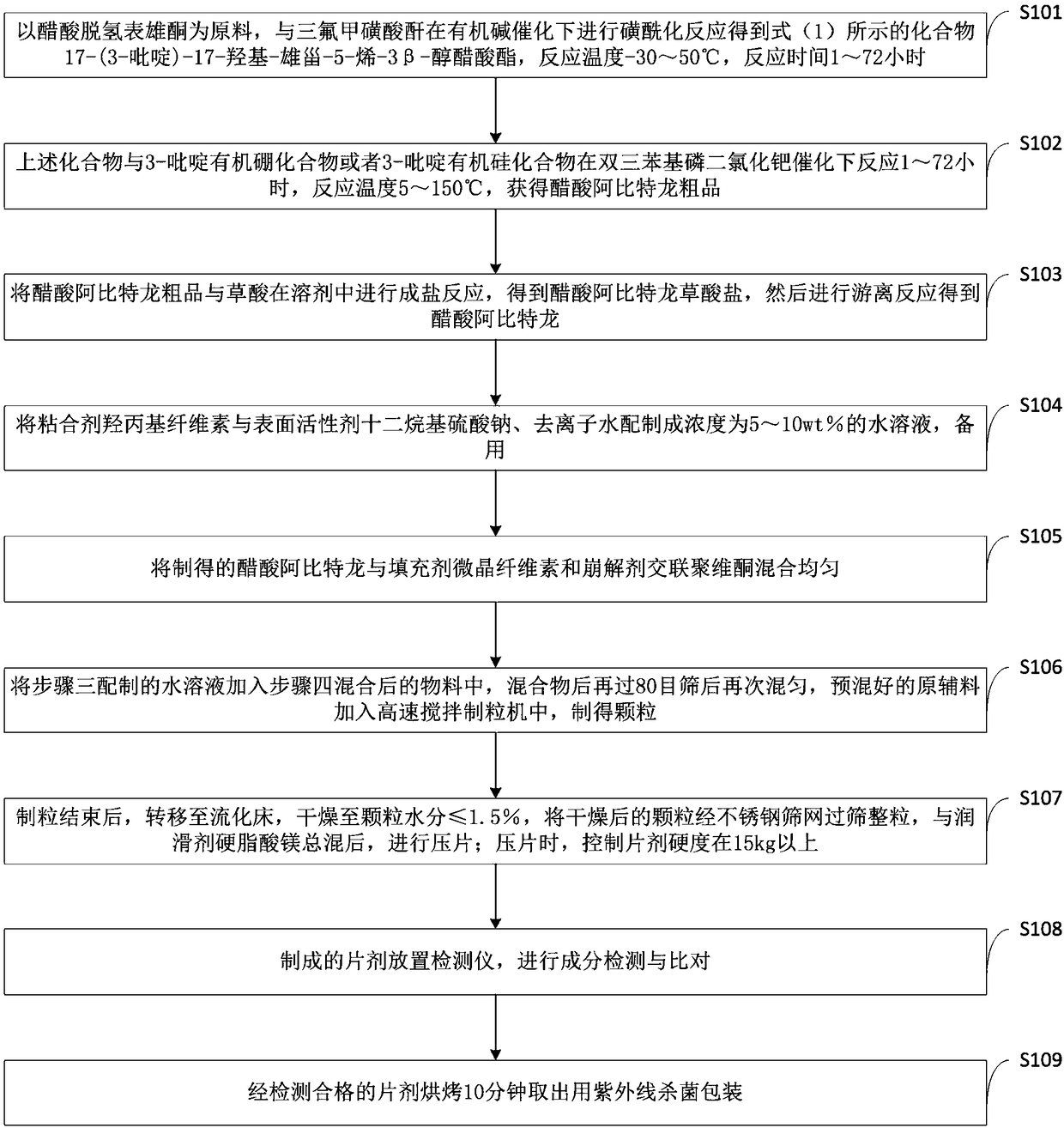

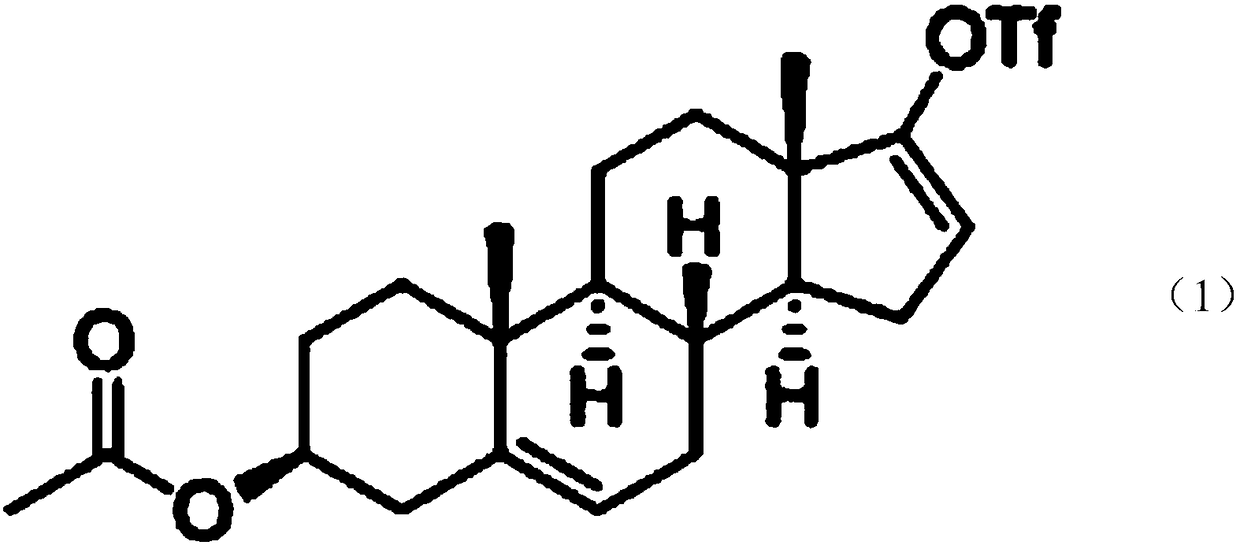

Abiraterone acetate tablets and preparation method thereof

InactiveCN108096253ALess impuritiesReduce allergic reactionsOrganic active ingredientsPharmaceutical non-active ingredientsCross-linkDocetaxel

The invention belongs to the technical field of biological pharmacy and discloses abiraterone acetate tablets and a preparation method thereof. The abiraterone acetate tablets are combined with prednisone to treat metastatic castration resistant prostate cancer patients who receive docetaxel-combined chemotherapy in the past. The abiraterone acetate tablets are prepared from dehydroepiandrosteroneacetate as a raw material and auxiliary materials including 3-pyridyllithium, 3-pyridineboronic acid, hydroxypropylcellulose, sodium lauryl sulfate, starch, microcrystalline cellulose, cross-linked povidone, magnesium stearate and silica. The prepared abiraterone acetate tablets contain fewer impurities and are purer, allergic reactions caused by impurity doping in the preparation process are reduced, and receivers are increased.

Owner:XUZHOU COLLEGE OF INDAL TECH

Novel nontoxic floor adhesive

InactiveCN101358119AReduce formaldehyde contentImprove environmental performanceAldehyde/ketone condensation polymer adhesivesAlkalinityAdhesive

The present invention relates to the formula and preparation technique of a woodworking glue, in particular to a novel non-toxic flooring glue. The non-toxic flooring glue is composed of ingredients with the following weight percent: 35 percent to 45 percent of urea, 45 percent to 55 percent of formaldehyde, 0.5 percent to 1.2 percent of industrial alkali, 0.3 percent to 1 percent of formic acid and 3 percent to 3.5 percent of melamine. The non-toxic flooring glue is prepared with the materials according to the following process flow: (1) feeding the materials; (2) keeping temperature; (3) adjusting acidity; (4) adjusting alkalinity; (5) adding melamine; (6) discharging material. The non-toxic flooring glue prepared by the formula and technique of the present invention has obvious environment-protecting effect, the content of formaldehyde is less than 1g / kg, and the actual test result is 0.5g / kg. The non-toxic flooring glue reaches the environment-protecting standard of European flooring glue.

Owner:卢厚明

Burning process and burning boiler for processing high-density saliferous organic wastewater

ActiveCN103047659BEasy to handleEmission reductionCombustion technology mitigationIncinerator apparatusChemical industryCooling chamber

Owner:BEIJING NATION POWER GRORP +1

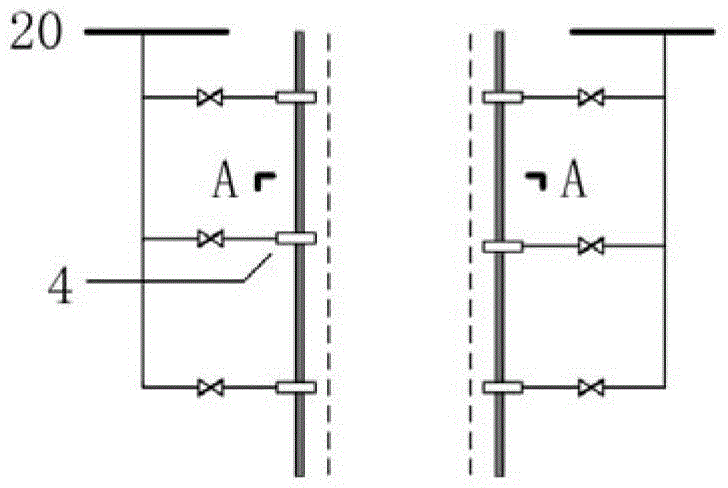

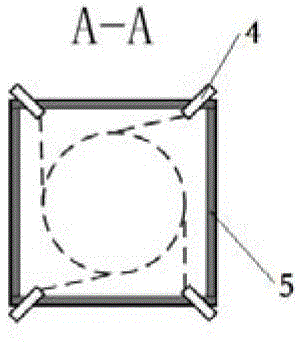

Large-flow low calorific value harmful waste gas incineration treatment process

ActiveCN103868080BProduce corrosionMeet environmental standardsIncinerator apparatusThermal energyCombustion

The invention belongs to the technical field of harmful gas treatment, particularly relates to a large-flow and low-heat-value harmful waste gas incineration disposal process, and aims to develop a novel process for treating high-air-volume and low-heat-value harmful waste gas in a regenerative combustion manner. According to the adopted technical scheme, a ceramic heat accumulating body is taken as a carrier for recovering heat of high-temperature flue gas and pre-heating waste gas, the temperature of the high-temperature flue gas falls rapidly in a heat accumulating chamber, and the heat energy is stored in the heat accumulating body and is released for heating waste gas needing to be treated in a next cylinder. The process has the beneficial effects that the system can treat waste gas containing acid components, and the temperature of flue gas is higher than the dew point temperature of acid in the heat accumulating chamber, thus corrosion to the heat accumulating body is prevented, and the emitted flue gas is up to the natural environmental protection standard; the waste gas preheating temperature can be up to 80 DEG C or higher, thereby saving over 80 percent of fuel; by adopting a rigid-flame incandescent light, stable combustion state of the system is ensured, and effective residence time of the flue gas in a hearth is ensured.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

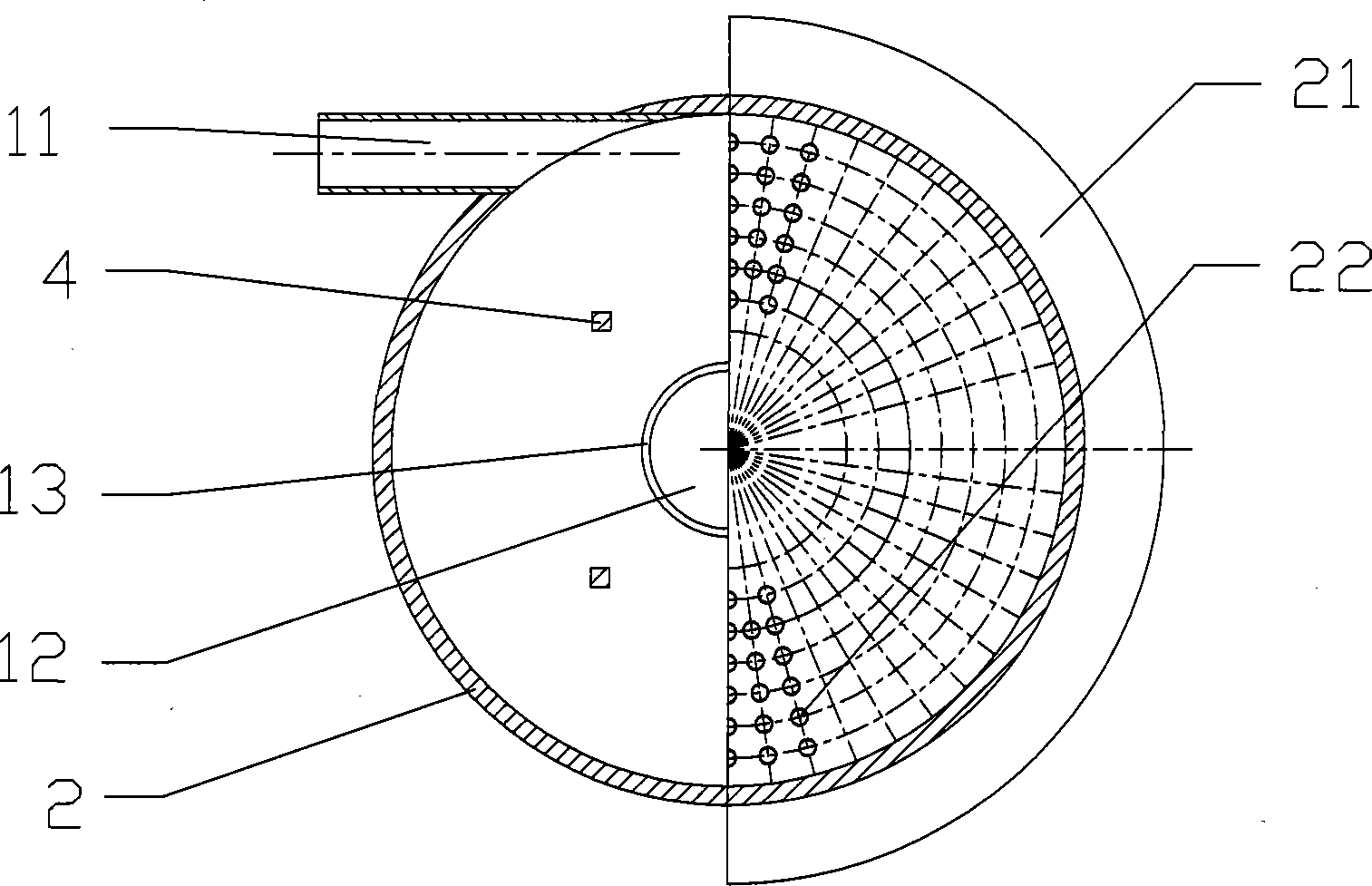

Rotational flow flue gas recirculation gas burner

PendingCN113405095AEmission reductionStable combustionGaseous fuel burnerCombustion apparatusNitrogen oxidesFlue gas

The invention discloses a rotational flow flue gas recirculation gas burner which comprises a nozzle, a gas gun center pipe, a gas spray gun, an outer flue gas injection unit, an inner flue gas injection unit, an ignition gun assembly and rotational flow blades. The outer flue gas injection unit comprises an outer flue gas inlet and a baffling wall, and an outer flue gas circulating chamber is formed among the outer flue gas inlet, the baffling wall, the outer wall of the fuel gas spray gun and the inner wall of the nozzle. The inner flue gas injection unit comprises an annular baffling wall and an annular plate, and an inner flue gas circulation cavity is formed among the annular baffling wall, the annular plate, the inner wall of the gas spray gun and the outer wall of the gas gun center pipe. On the premise of ensuring stable combustion, the emission of nitrogen oxides is less than 30mg / Nm<3>, so that the increasingly stringent environmental protection standard is met.

Owner:清华大学山西清洁能源研究院

Denitrification operation optimization method of SCR (selective catalytic reduction) system of W flame boiler

InactiveCN103831016BOptimal adjustment of ammonia injection flow rateIncrease the flow rate of ammonia injectionDispersed particle separationEscape rateSpray nozzle

The invention discloses a denitrification operation optimization method of a SCR (selective catalytic reduction) system of a W flame boiler. The denitrification operation optimization method particularly comprises the following steps: acquiring the smoke flow speed and the NOx concentration distribution uniformity and deviation at an outlet of a boiler by considering the structure and the running working condition of a W flame boiler so as to act as inlet boundary conditions of a rear-stage SCR system; adjusting the ammonia spraying flow rate corresponding to the region at which the flue flow speed is slightly high and the NH3 / NOx is slightly low to be low, increasing the number of ammonia spraying nozzles, and adjusting the ammonia spraying flow rate corresponding to a region at which the flue flow speed is slightly slow and the NH3 / NOx is slightly high to be low when the standard criterion that the ammonia spraying flow rate at the upper layer is higher than that at the lower layer, and the ammonia spraying flow rate at the middle is higher than that at two sides is met. According to the invention, the structures and the running situation of the boiler and the SCR system are optimized and adjusted, the denitrification efficiency of the SCR system is improved; the spraying-in quantity and the escape rate of ammonia are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

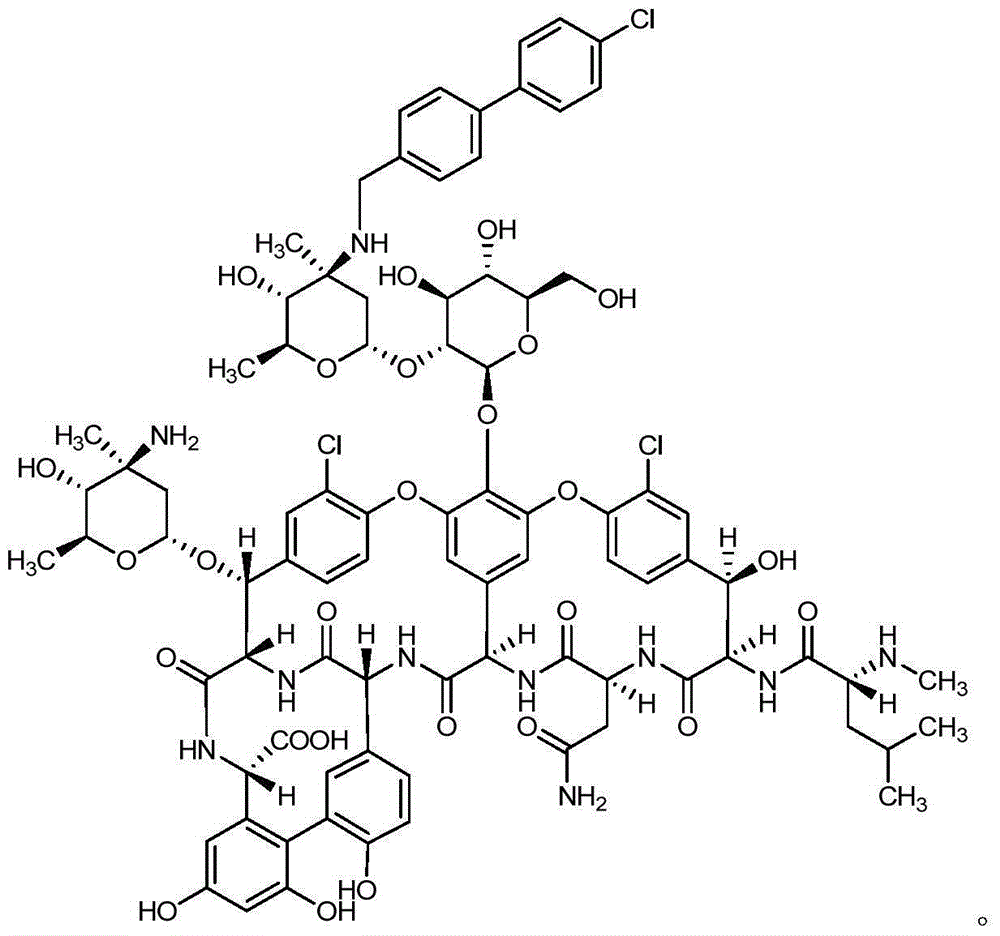

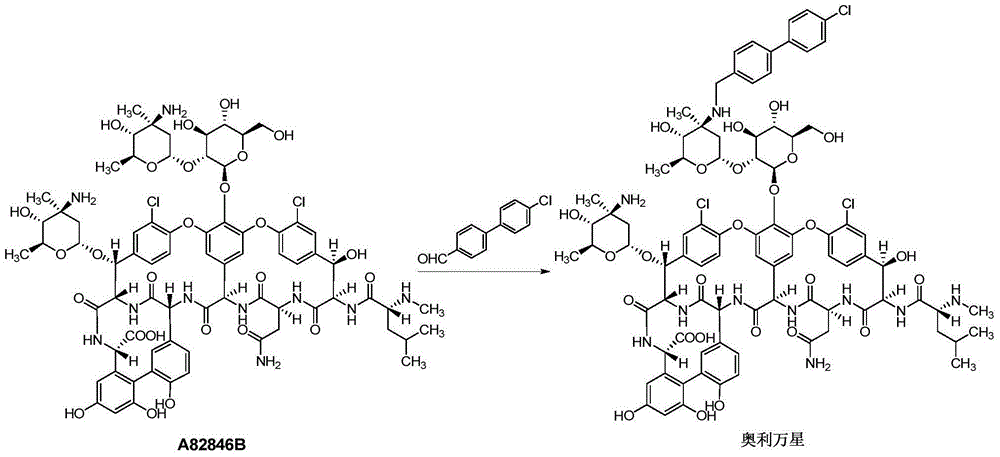

Reductive alkylation method for glycopeptide antibiotics

ActiveCN106467570AHigh yieldControl generationPeptide preparation methodsTert-ButylamineChemical compound

The invention relates to a reductive alkylation method for glycopeptide antibiotics and particularly relates to the reductive alkylation method for the glycopeptide antibiotics, of which N<4> bits have amino sugar. The method comprises the step of carrying out a reaction in a solution containing the glycopeptide antibiotics and a soluble copper compound in the presence of aldehyde and tert-butyl amine borane, wherein the reductive alkylation reaction is carried out firstly at the N<4> bits of the glycopeptide antibiotics. According to the method disclosed by the invention, the reaction yield is high, the production of byproducts is effectively controlled, the amount of N<4>,N<6>-disubstituted impurities is small, and the consumption of sodium cyanoborohydride is avoided, so that the method reaches environmental protection standards and is particularly applicable to industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

Aldehyde purifying product as well as production method and application thereof

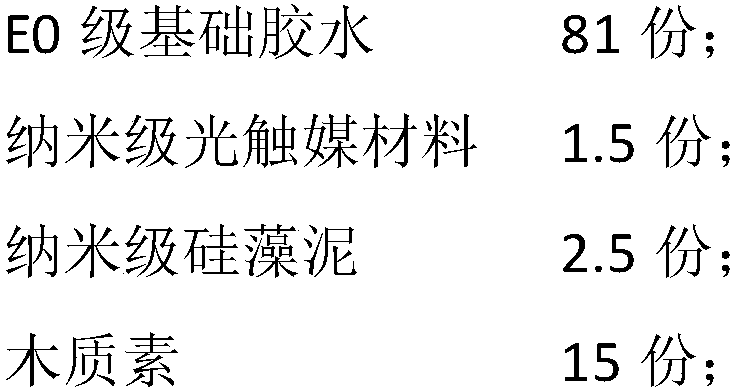

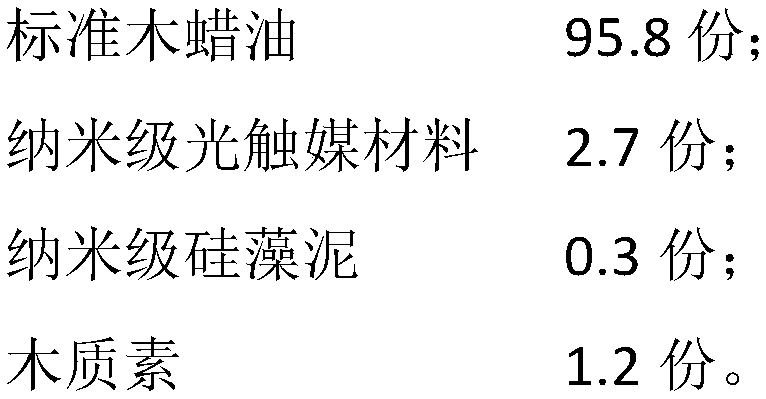

InactiveCN107815293AExtended service lifeReduce pollutionWax coatingsNon-macromolecular adhesive additivesWaxEnvironmental resistance

The invention belongs to the technical field of synthesis of artificial boards and relates to an aldehyde purifying agent in the artificial boards, in particular to an aldehyde purifying product as well as a production method and application thereof. A nanoscale photocatalyst material, nanoscale diatom ooze, lignin and E0 grade basic glue or standard wax oil are sequentially subjected to mechanical stirring and ultrasonic oscillation, a corresponding aldehyde purifying product is processed, and then the aldehyde purifying product is laminated with the artificial board. According to the invention, when the aldehyde purifying product prepared from the nanoscale diatom ooze, a photocatalyst, lignin and related materials is applied to the artificial board, service life of the artificial boardcan be greatly prolonged, pollution of the artificial board to the environment and people is reduced, (free formaldehyde in the air can be adsorbed and purified), namely environmental protection standard in national requirements can be well met.

Owner:LINYI YOUYOU WOOD IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com