Large-flow and low-heat-value harmful waste gas incineration disposal process

A treatment process, low calorific value technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of harmful gas leakage, frequent ignition, large consumption, etc., to achieve stable and adjustable temperature, guaranteed residence time, and stable combustion state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

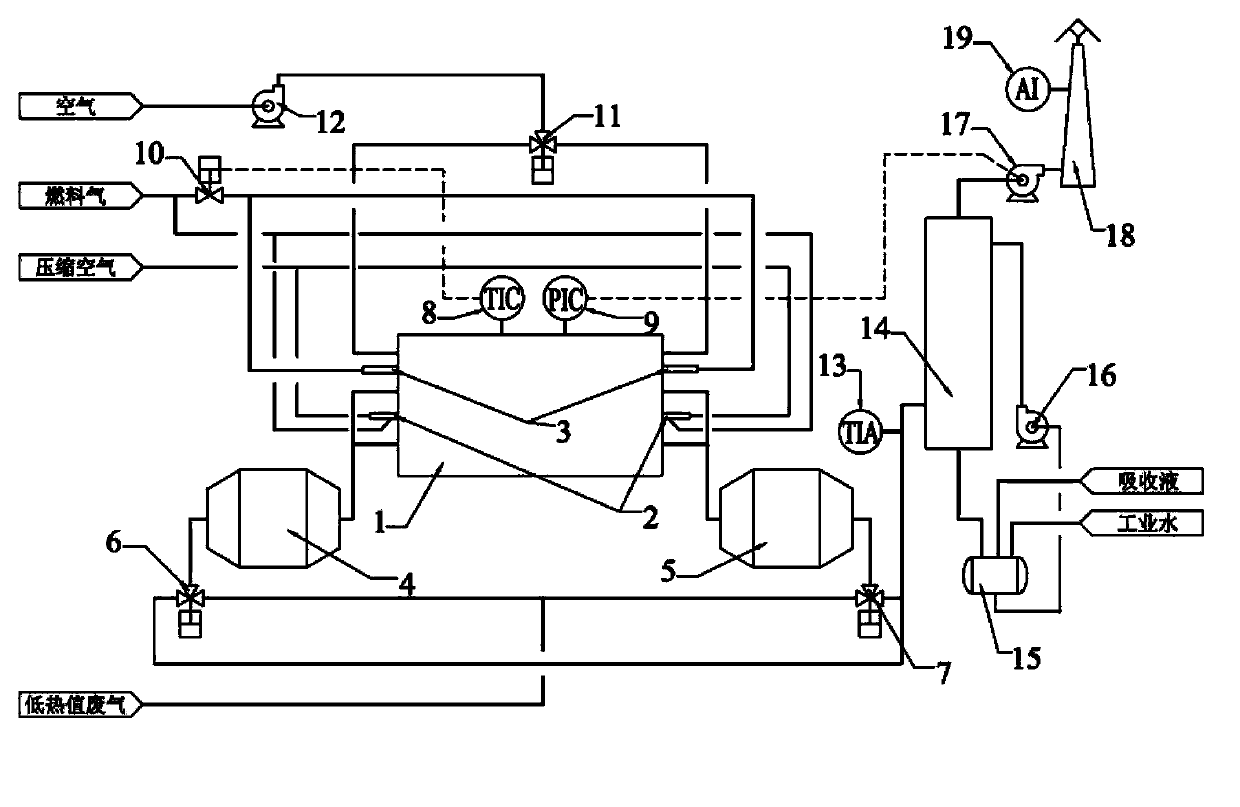

[0024] The following is an introduction to a large-flow low-calorific-value harmful waste gas incineration treatment process provided by the present invention in conjunction with the accompanying drawings and examples:

[0025] Such as figure 1 As shown, a large-flow low calorific value harmful waste gas incineration treatment process includes the following steps:

[0026] (1) The exhaust gas enters the regenerator A through the reversing valve A, and the heat stored in the regenerator in the regenerator during the previous cycle increases the temperature of the exhaust gas;

[0027] (2) The high-temperature exhaust gas after heating enters the incinerator and is incinerated under the action of the permanent lamp of the rigid flame;

[0028] (3) The furnace temperature of the incinerator is determined according to the temperature required for the decomposition of harmful components in the waste. The temperature of the furnace is measured by a temperature detection instrument....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com