Patents

Literature

113results about How to "Good desulfurization and denitrification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulphurization and denitrification agent and preparation method thereof

InactiveCN107899596AIncrease profitImprove leaching rateGas treatmentPhysical/chemical process catalystsPowder mixtureRed mud

The invention discloses a desulfurization and denitrification agent and a preparation method thereof, and belongs to the technical fields of tailing recycling and industrial smoke gas treatment. The desulfurization and denitrification agent includes 5-45% of phosphate rocks or phosphate tailings, 5-25% of iron slag, 5-30% of manganese slag, 5-35% of zinc slag, 1-10% of copper slag, 5-15% of red mud, 10-35% of rare earth tailings and 1-10% of coal gangue. The preparation method of the desulfurization and denitrification agent comprises the following steps: respectively grinding above solid byproducts to about 200-300 meshes, mixing the crushed powders according to a certain ratio, calcining the obtained powder mixture in a muffle furnace at 800-1200 DEG C for 1-3 h to make a porous material, and crushing the porous material to form 80-100 mesh powder which is the novel desulfurization and denitrification agent. The method has the advantages of simple process, high desulfuration and denitrification efficiency, realization of slag recycling while achieving industrial smoke purification, and significant economic and environmental benefits.

Owner:KUNMING UNIV OF SCI & TECH

Production method of desulfur denitrate dust collecting active coke

The present invention relates to a method for producing desulfurization denitration dust-removing active coke by using brown coal as raw material. Said method includes the following steps: mixing brown coal and coking coal according to a certain mixing ratio, pulverizing them to obtain coal powder; adding coal tar and water base emulsifying agent to make them into coal paste; hydraulic strip-extruding to obtain strip granules, drying and charring in charring furnace, placing the above-mentioned material into activating furnace to make activation to obtain activated material, making natural oxidation so as to obtain the invented active coke.

Owner:长春惠工净化工业有限公司

Method for preparing smoke treating and water source purifying double-purpose active coke and products thereof

The present invention provides a preparing method of active coke for gas purification and water source purification, including following steps: 1) preparing coal powder, breaking raw material to coal powder which more than 90% can pass 200 mesh sieve; 2) preparing an adhesive, keeping warm after heating melt asphalt or mixer of asphalt and tar, evenly mixing; 3)adding the adhesive to coal powder, forming pelleting, charing, activation and sieving package after mixing evenly. The preparing method and its product have gas-liquid dual efficacies, further reduces cost and simple process, preparation by make the most of present equipment, do not large change equipment; the prepared product has better dynamic purifying effect, realizes desulfurization, denitration, demercuration and dechlorination, removing dioxin and dust removing integrated purifying functions; the prepared product saves water, electricity and location in the pratica; application of the gas desulfurization, also a lower investment, the source is recycled in the treating process, this can not cause secondary pollution.

Owner:邹炎

Desulphurization and denitration catalyst and preparation method thereof

InactiveCN101518736AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParaffin waxCopper nitrate

The invention discloses a desulphurization and denitration catalyst. The catalyst comprises the following components by mass percentage: 4 to 18 percent of CuO, 80 to 95 percent of gamma-Al2O3, and 1 to 2 percent of promoter. A method for preparing the catalyst comprises the following steps: (1) adding aluminum isopropoxide into distilled water, stirring the mixture, adding a nitric acid solution into the mixture dropwise, and carrying out the evaporation in the air to obtain a boehmite sol; (2) adding the promoter into a copper nitrate solution, then adding the mixture into the boehmite sol, then adding the nitric acid solution dropwise, stirring the mixed solution for ageing, and aggregating the mixed solution into a semi-gel; and (3) adding the semi-gel dropwise into a gel pool containing ammonia water and liquid paraffin through a dropper, and obtaining the catalyst after ageing, drying and baking. The prepared catalyst can be used for synchronous desulphurization and denitration, and can be regenerated and used cyclically with low raw material cost. As the byproducts can be reutilized, the catalyst brings about no secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

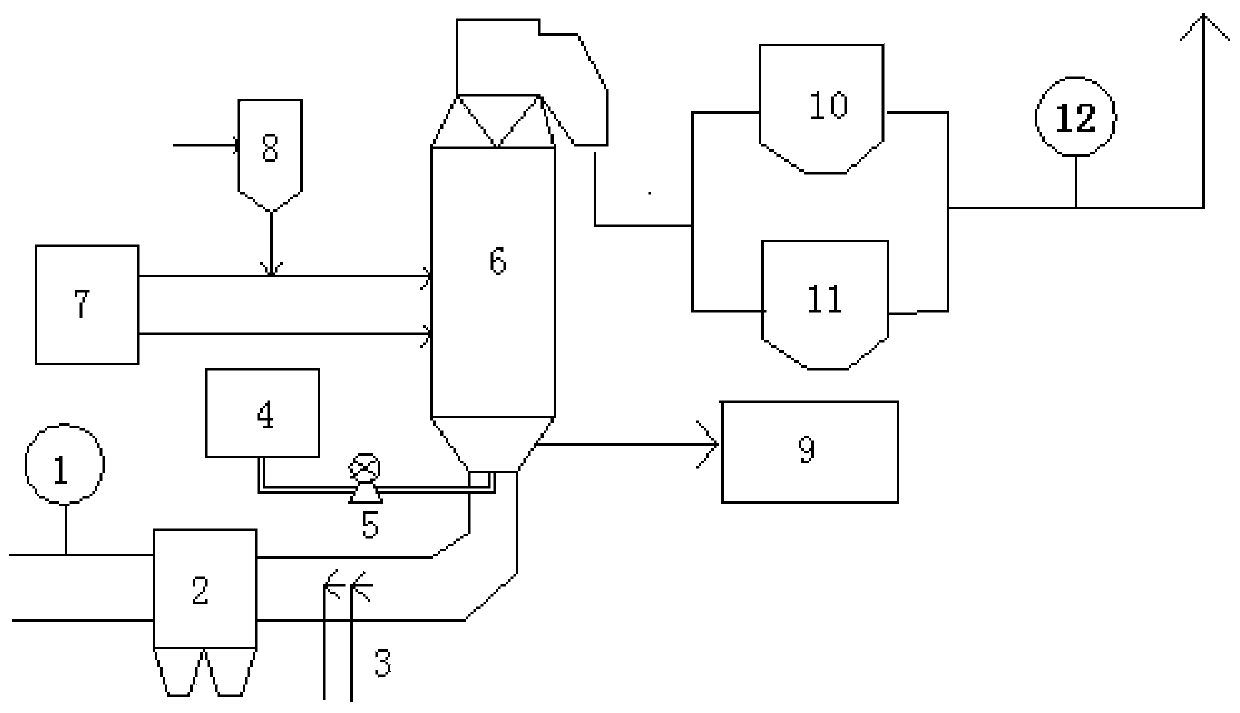

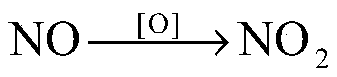

Method for simultaneously removing sulfur oxides and nitric oxides in flue gas

ActiveCN101632897AGood desulfurization and denitrificationLess investment in equipmentDispersed particle separationAir quality improvementFlueNitric oxide

The invention relates to a method for simultaneously removing sulfur oxides and nitric oxides in flue gas, which belongs to the technical field of flue gas purification. The method comprises the following steps: spraying water or steam into a flue before flue gas from burning equipment enters a fluidized bed reactor through the flue and controlling the temperature of the flue gas within a range of 90-200 DEG C, wherein the flue gas in the flue contains gas components of O2, H2O, SO2 and NOx; directly jetting CaO and / or Ca(OH)2 into the flue to oxidize NO; and controlling the temperature of the fluidized bed reactor to be between 50 DEG C and 90 DEG C for the flue gas to desulfurize and denitrate in the fluidized bed reactor. In the method, desulfurization and denitration can be simultaneously realized in the same system by adjusting processing steps and controlling a reaction condition. When a molar ratio Ca / (S+0.5N) of calcium to sulfur to nitrogen is 1.3, the removal rate of the SO2 can reach over 85 percent, and the removal rate of the NO can reach over 60 percent.

Owner:TSINGHUA UNIV

Treatment process for smoke gas produced by amino acid preparation process

ActiveCN104722183AImprove adsorption capacityGood desulfurization and denitrification effectCombination devicesAir quality improvementMicrobiologic agentChemical agents

The invention belongs to the field of smoke gas treatment and discloses a treatment process for smoke gas produced by an amino acid preparation process. The treatment process comprises the following steps: preparing a chemical preparation, preparing a microbial preparation, removing dust, defogging, desulfurizing, denitrating and preparing a compound fertilizer. The treatment process is simple, unique in design and capable of effectively removing various pollutants and preparing the fertilizer, so that dual purposes are achieved simultaneously.

Owner:内蒙古阜丰生物科技有限公司

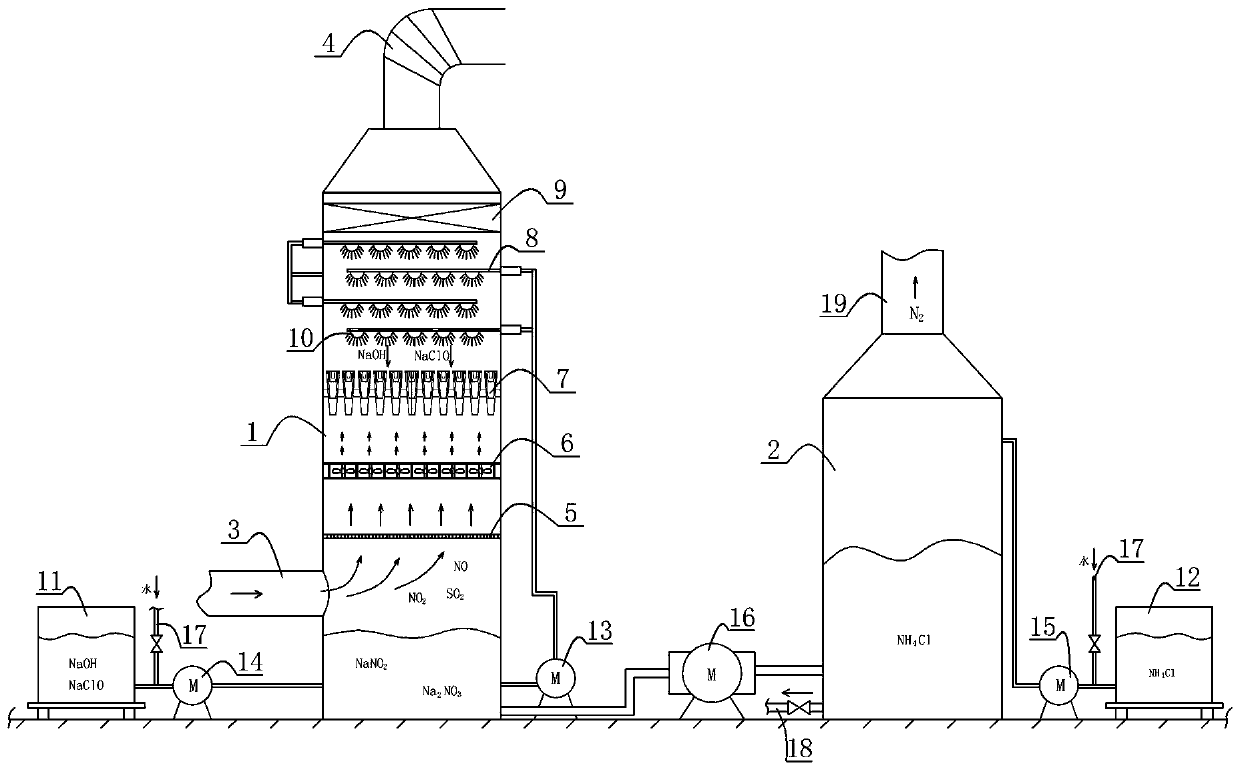

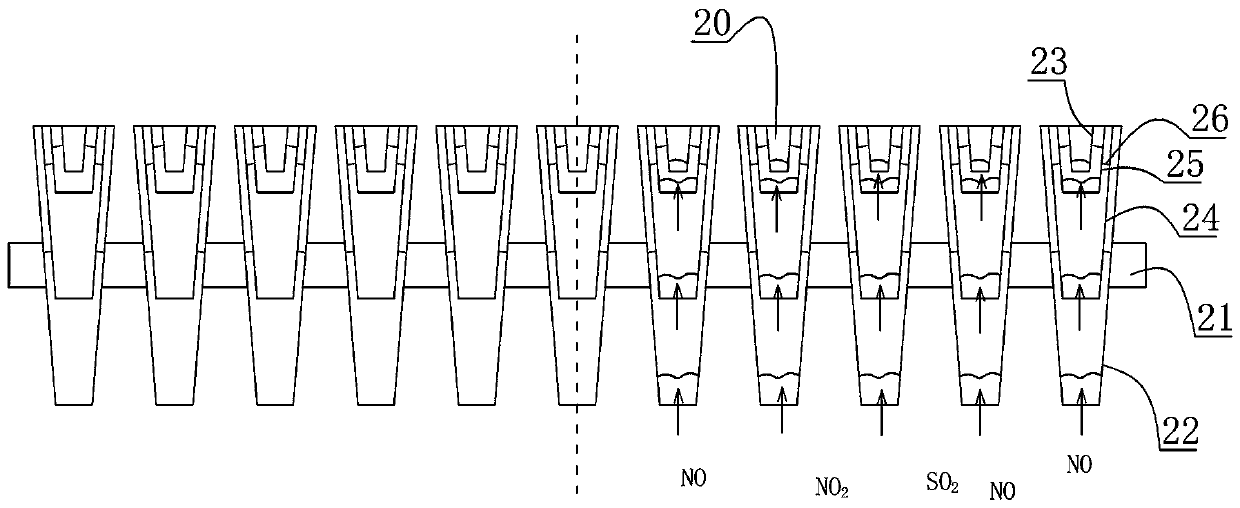

High-temperature and low-temperature gas-phase composite desulfurization and denitration method

PendingCN107754599AAvoid water pollutionGood desulfurization and denitrification effectGas treatmentDispersed particle separationNitrite ionGas phase

The invention provides a high-temperature and low-temperature gas-phase composite desulfurization and denitration method. The high-temperature and low-temperature gas-phase composite desulfurization and denitration method comprises the following steps: a) introducing flue gas; b) uniformly distributing the flue gas; c) carrying out flue gas turbulence; enabling the flue gas to penetrate through awater layer concentrated at the bottom of a catalytic contactor to realize sufficient contact between the water layer and a spraying solution; d) carrying out desulfurization and denitration treatment, wherein the spraying solution is a water solution containing NaClO and NaOH; e) removing nitric acid and nitrite in water and mixing the water with an ammonium chloride solution. The desulfurizationand denitration method provided by the invention comprises the following steps: firstly, absorbing NO, SO2 and less NO2 in the flue gas by utilizing the water solution containing the NaClO and the NaOH; then transforming the nitric acid and nitrite ions in the water into nitrogen gas through the ammonium chloride solution to be released. According to the high-temperature and low-temperature gas-phase composite desulfurization and denitration method, very good desulfurization and denitration effects can be realized under a high-temperature or low-temperature condition; the desulfurization anddenitration efficiency can reach 95 percent or more; the method has remarkable beneficial effects and is suitable for being popularized and applied.

Owner:山东中源节能环保科技有限公司

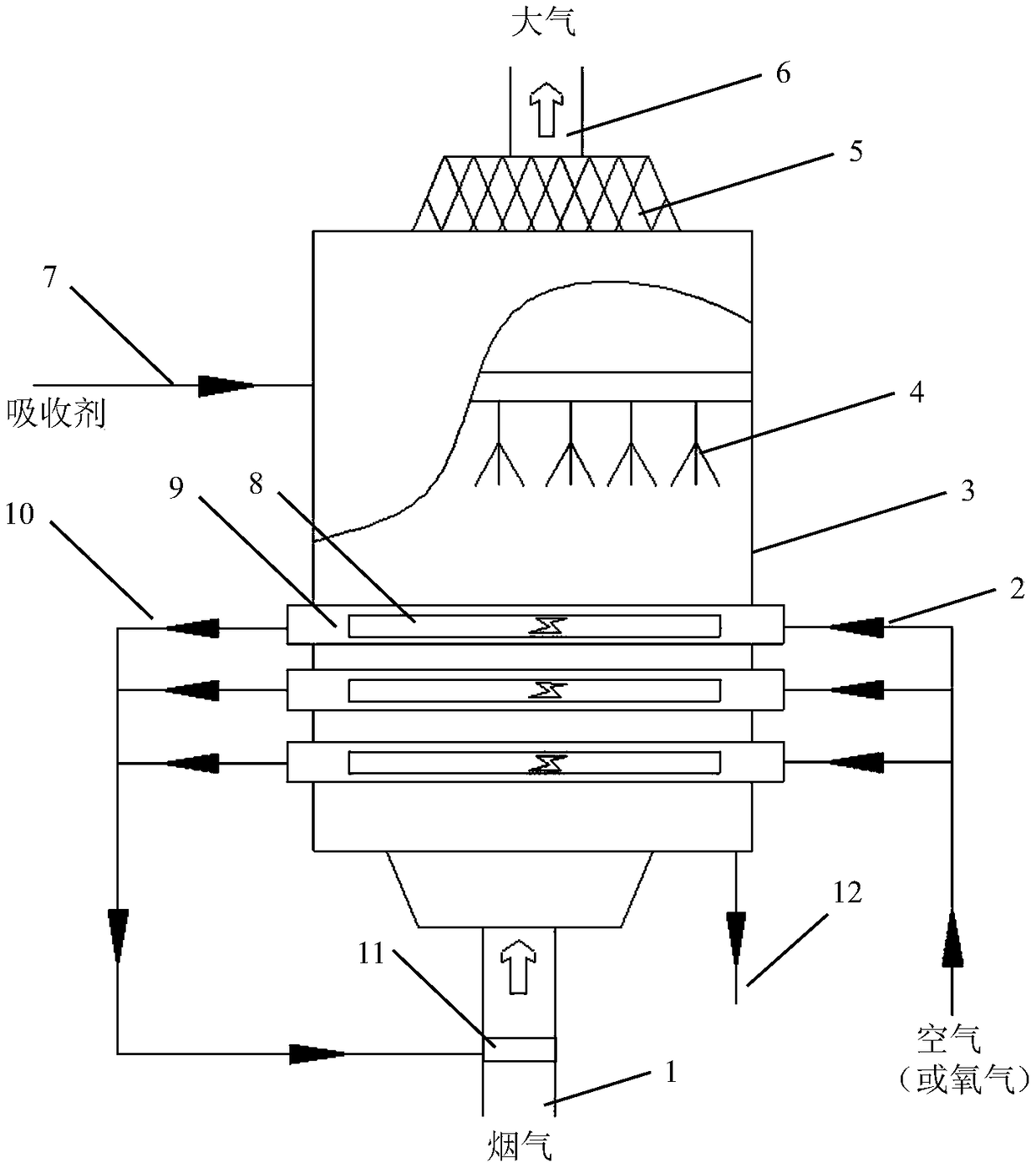

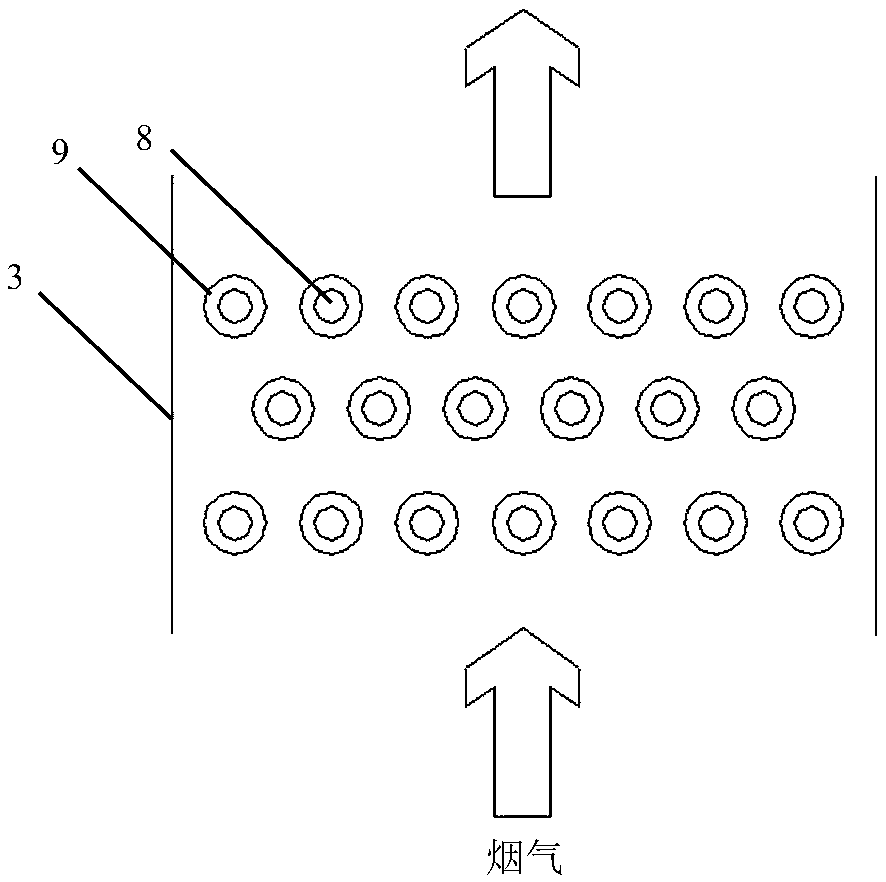

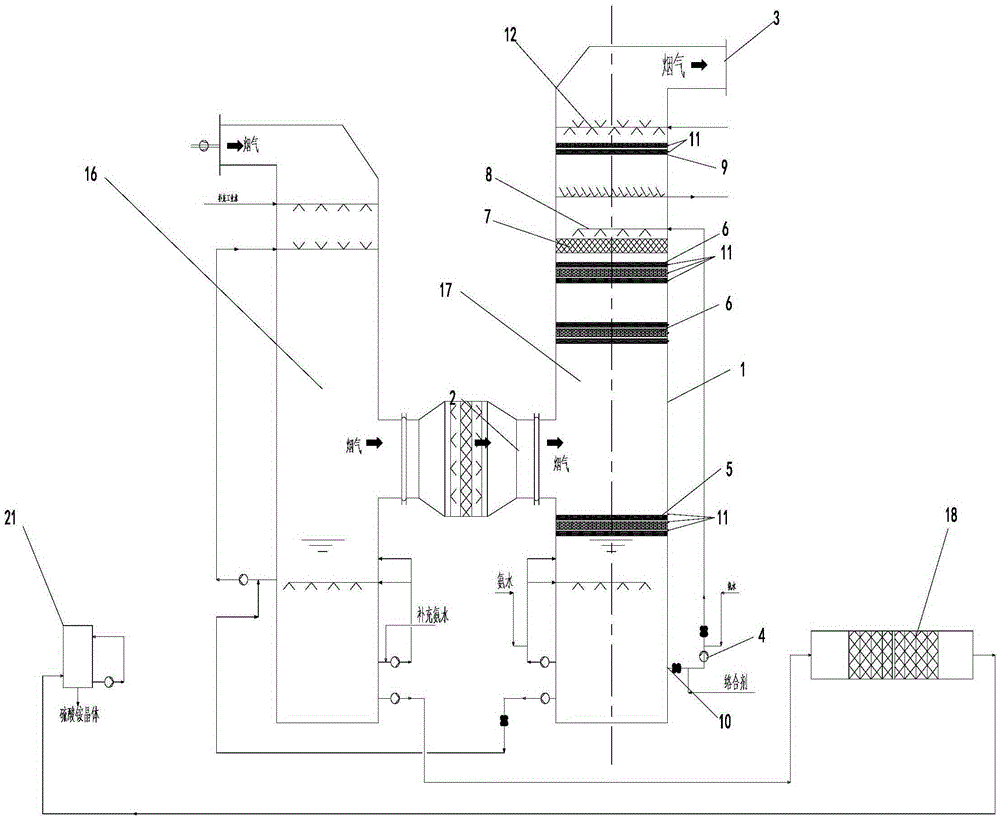

Ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration

ActiveCN105413422AEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationAmmonium sulfateFlue gas

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

Denitration-demercuration integrated device and method used in circulating fluidized bed desulfurization of sintering flue gas

ActiveCN110787606AWide variety of sourcesLow priceGas treatmentDispersed particle filtrationNitrogen oxidesFlue gas

The invention discloses a denitration-demercuration integrated device and method used in circulating fluidized bed desulfurization of sintering flue gas, belonging to the technical field of desulfurization and denitration of sintering flue gas. The device comprises a CFB reactor, an industrial water tank, a digestion tank, a denitration reduction absorbent tank, a cloth bag dust removal system, aflue gas monitoring system and an electrostatic dust removal system. The method comprises the following steps that firstly, a denitration oxidant component A of is sprayed into a flue located betweenan electrostatic dust collector and a CFB reactor, and can rapidly oxidize a part of NO in flue gas into a high-valence-state multi-nitrogen-oxide mixture easy to absorb by water vapor, and then the high-valence-state multi-nitrogen-oxide mixture enters the CFB reactor; and a denitration reduction absorbent component B is sprayed into the CFB reactor, lime is sprayed into the CFB reactor, and desulfurized and denitrated flue gas undergoes dust removal and is then discharged after being detected by the flue gas monitoring system. The method disclosed by the invention is simple, environment-friendly, circular and pollution-free, and has low operation cost and remarkable economic and environmental benefits.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

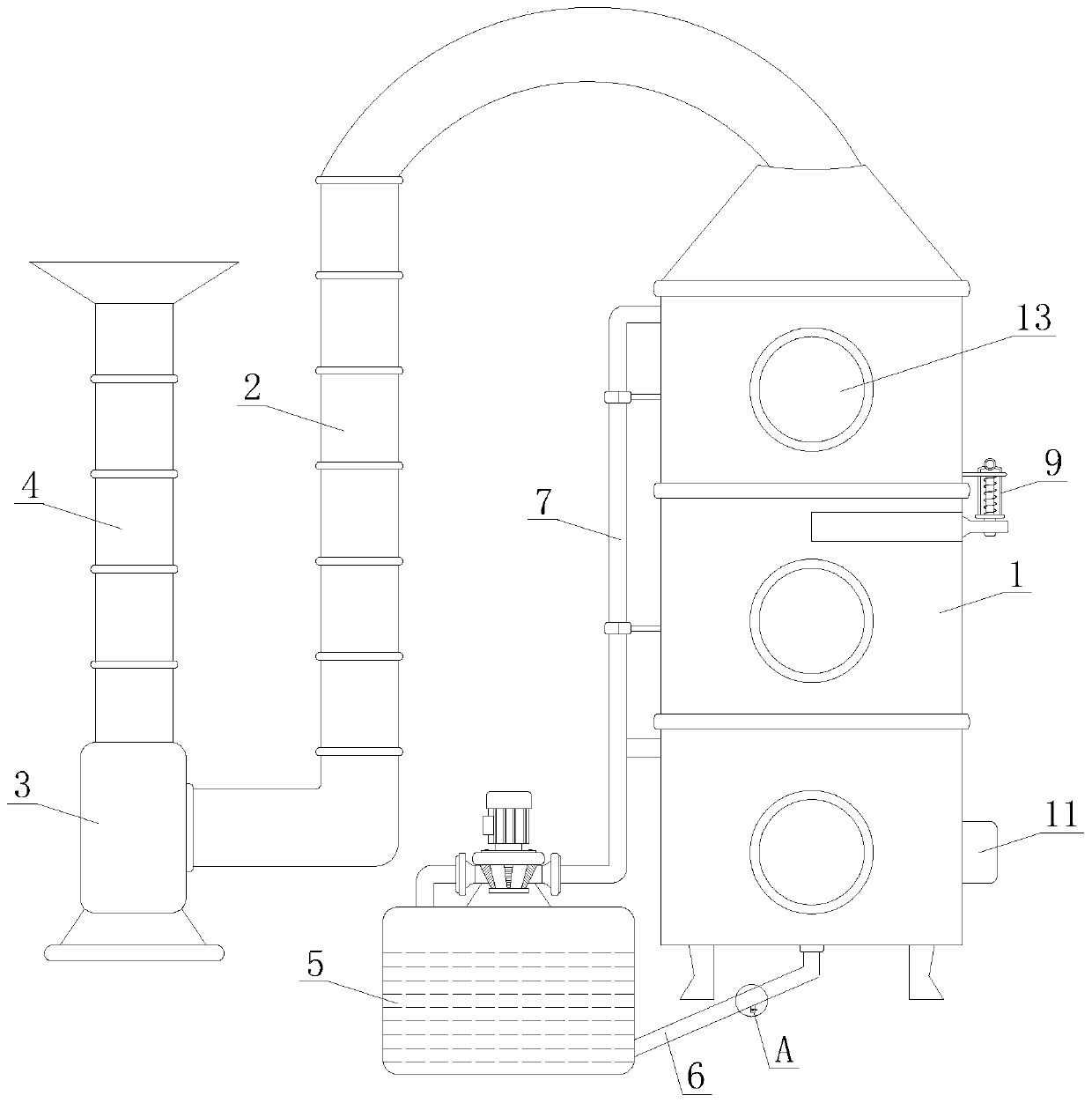

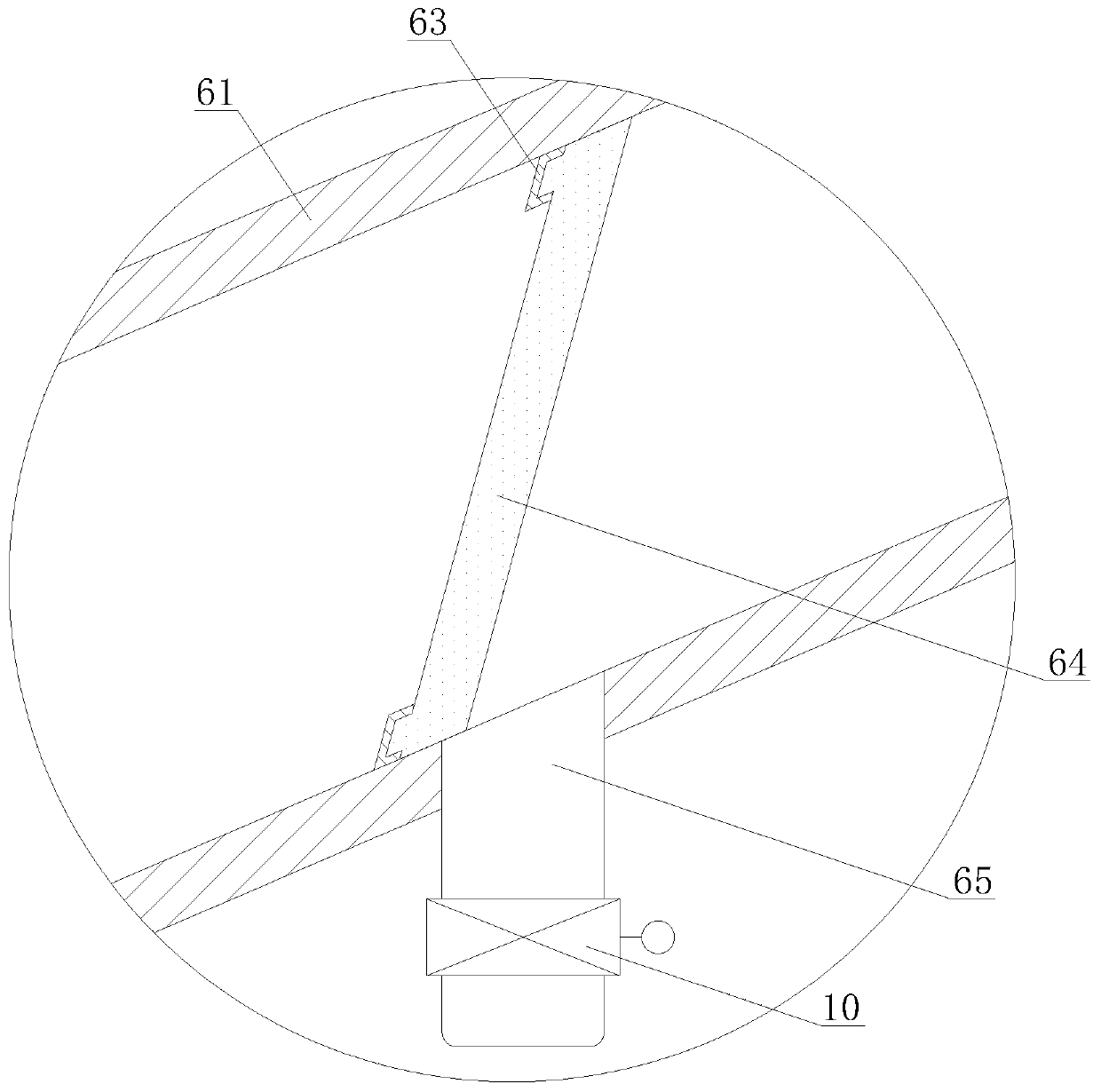

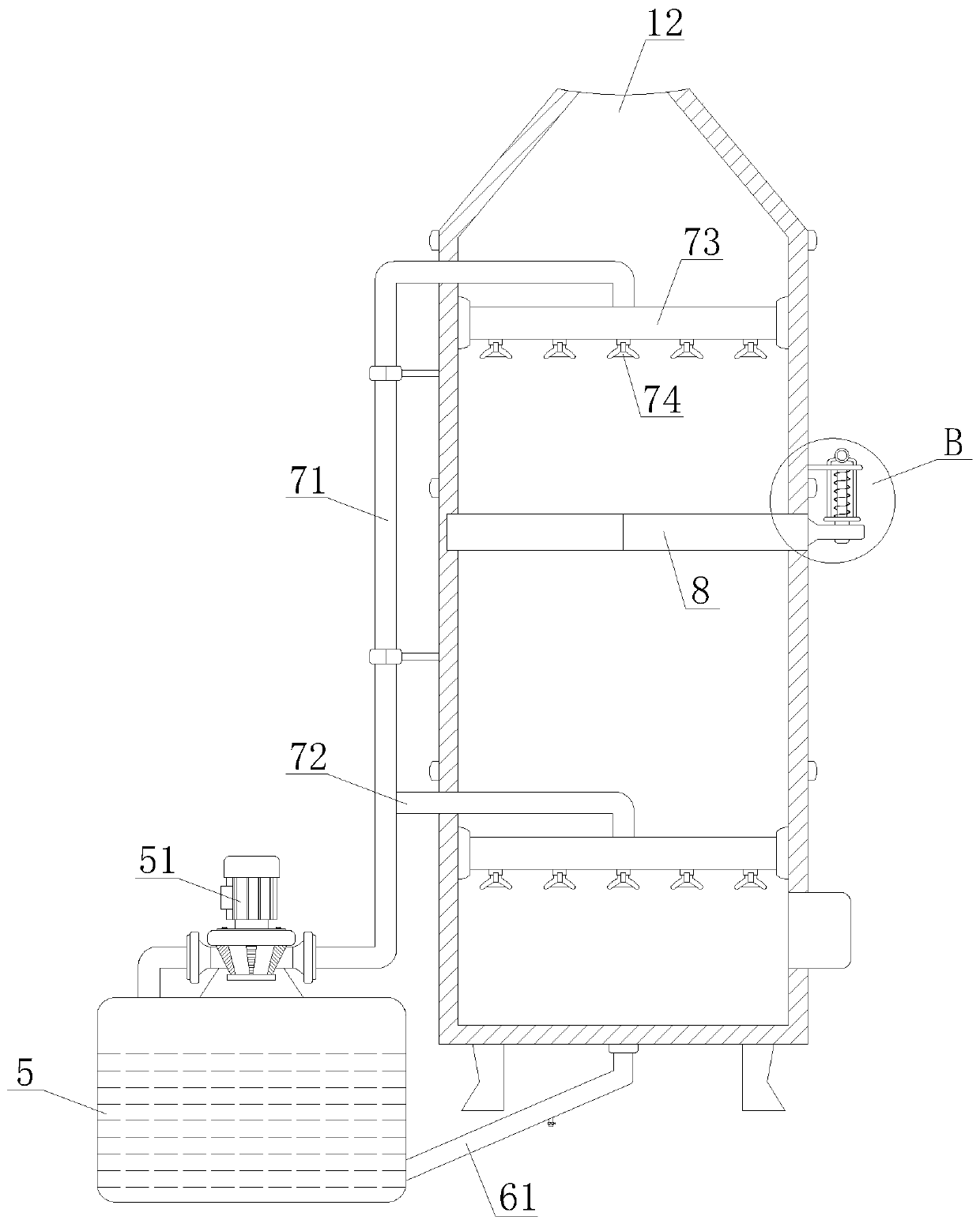

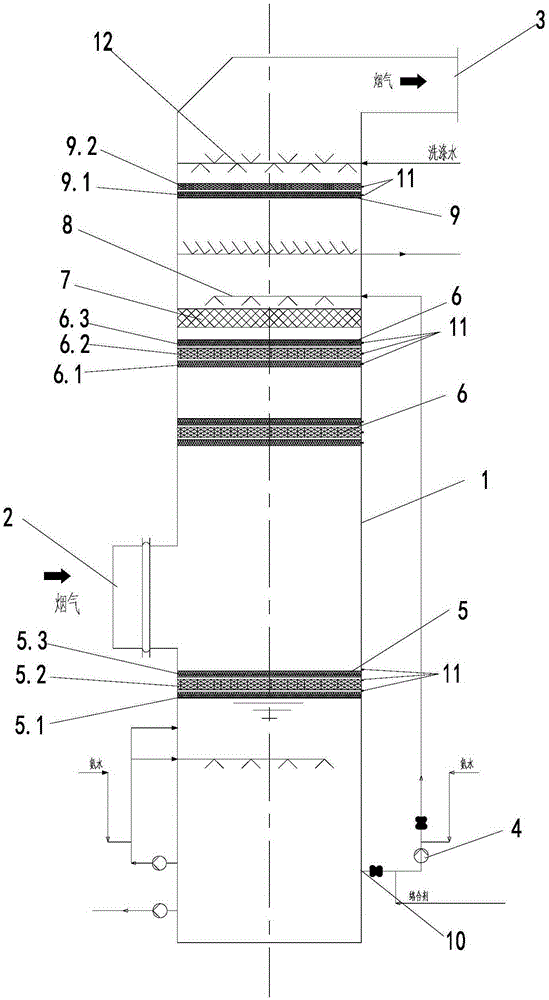

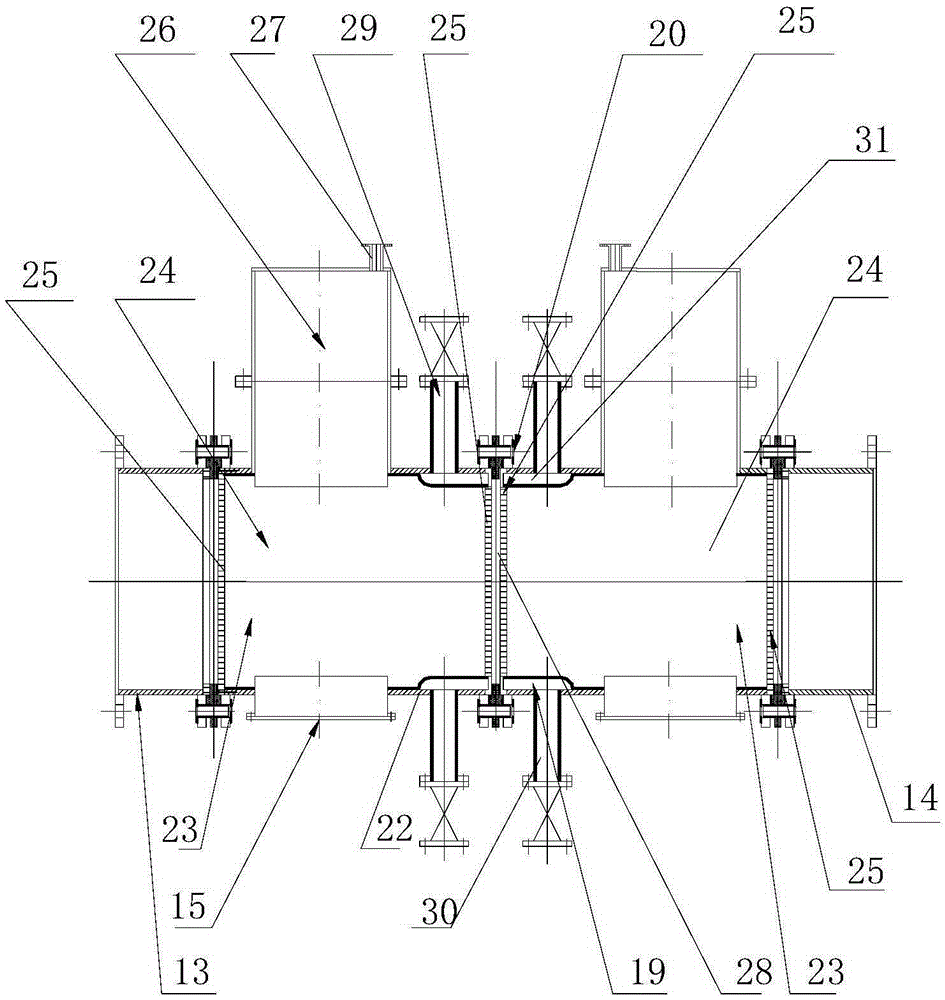

Wet desulfurization and denitrification device and process for high-sulfur-concentration flue gas

InactiveCN111495139AGood desulfurization and denitrification effectFully recycleGas treatmentDispersed particle separationPtru catalystFlue gas

The invention discloses a wet desulfurization and denitrification device and process for high-sulfur-concentration flue gas. A wet desulfurization and denitrification device belongs to the technical field of wet desulfurization and denitrification and comprises a treatment tower, wherein a water tank is arranged on one side of the treatment tower and connected to a water outlet of the treatment tower through a water inlet component, a water pump is mounted on the water tank, a spraying component is mounted at a water outlet of the water pump and mounted on the treatment tower, and a flue gas treatment mechanism is further arranged on the inner side of the treatment tower. The invention discloses a wet desulfurization and denitrification device and process for high-sulfur-concentration fluegas. The desulfurization and denitrification effects of the high-sulfur-concentration flue gas are good, wherein water circulation is formed by the water tank, the water pump, the water inlet assembly and the spraying assembly, so that water resource is fully utilized and saved. In addition, the flue gas treatment mechanism can be fixed in the treatment tower through the limiting mechanism, so that after desulfurization and denitrification, the outer frame body can be pulled out of the treatment tower through the limiting plate, and thereby a desulfurization and denitrification agent and a denitrification catalyst are convenient to replace. The device is convenient to use and replace.

Owner:MAANSHAN SHUNDA ENVIRONMENTAL PROTECTION EQUIP

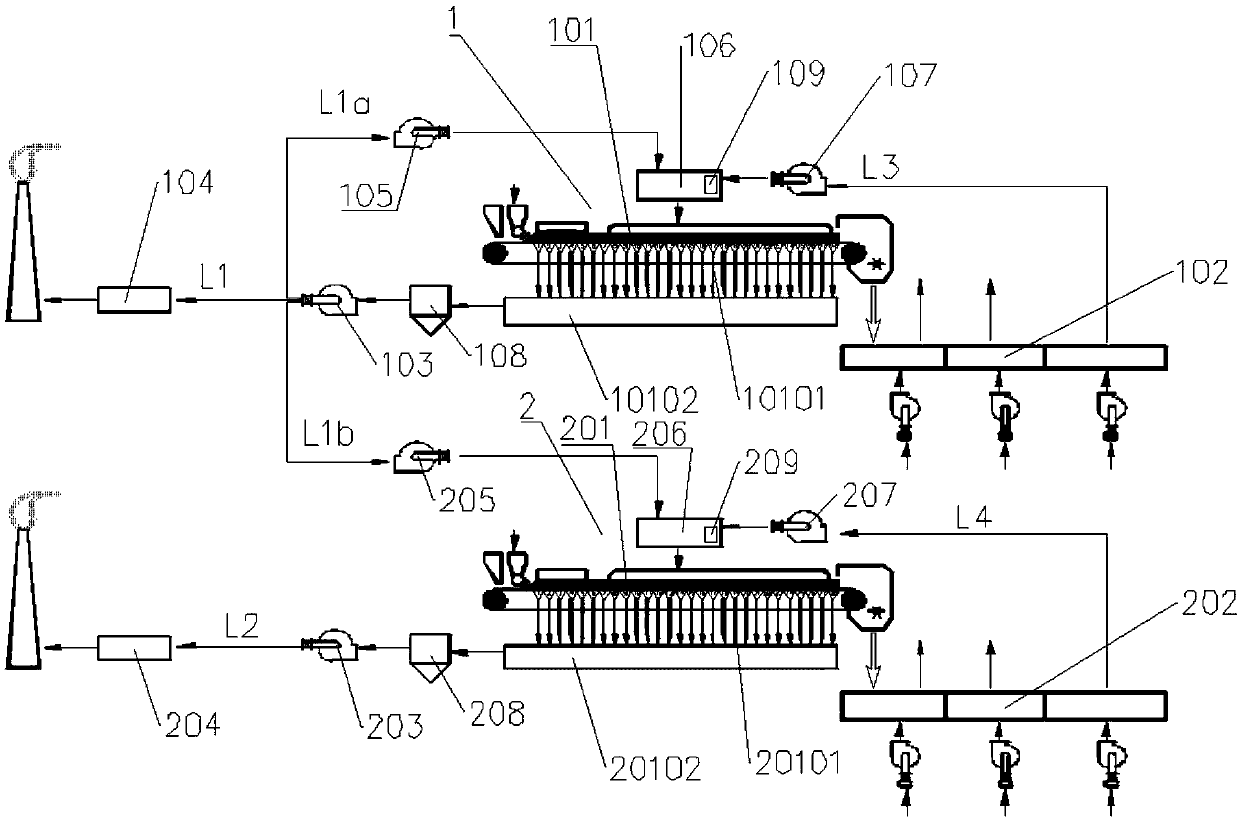

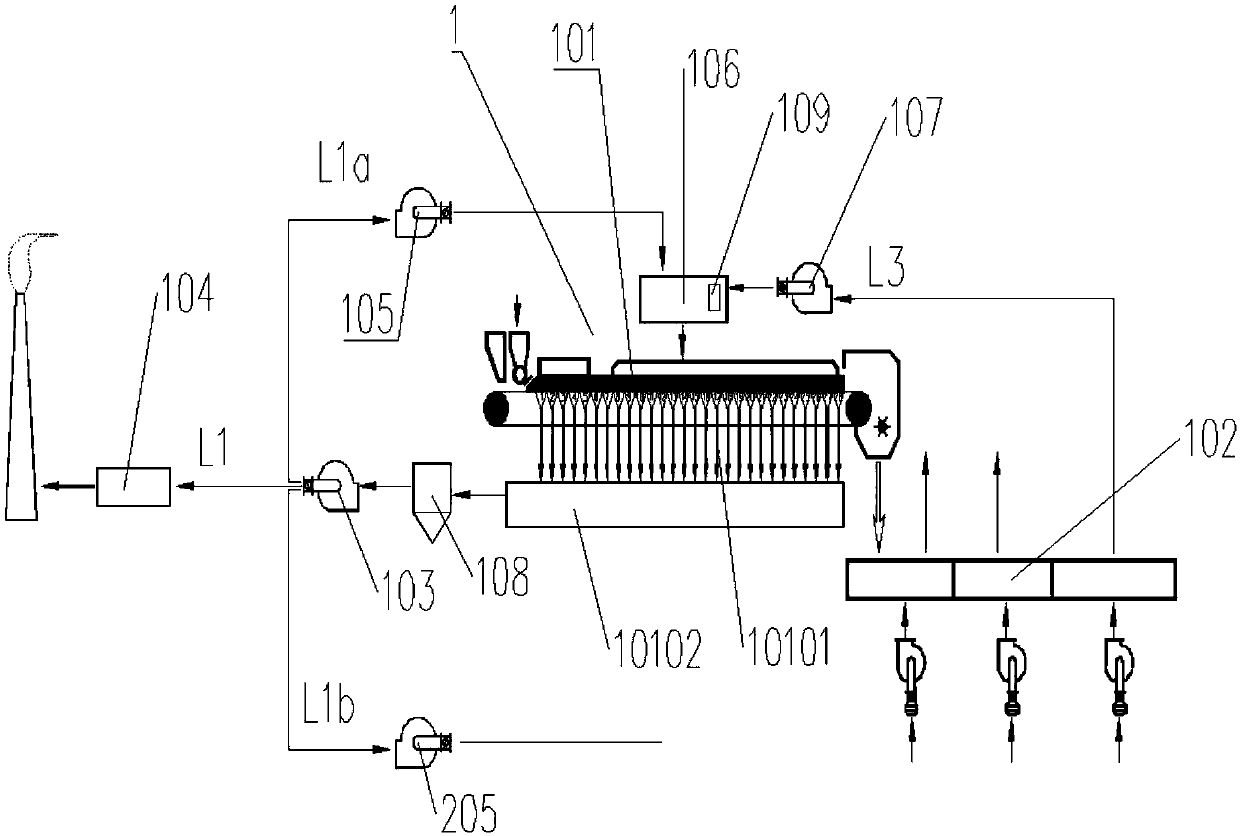

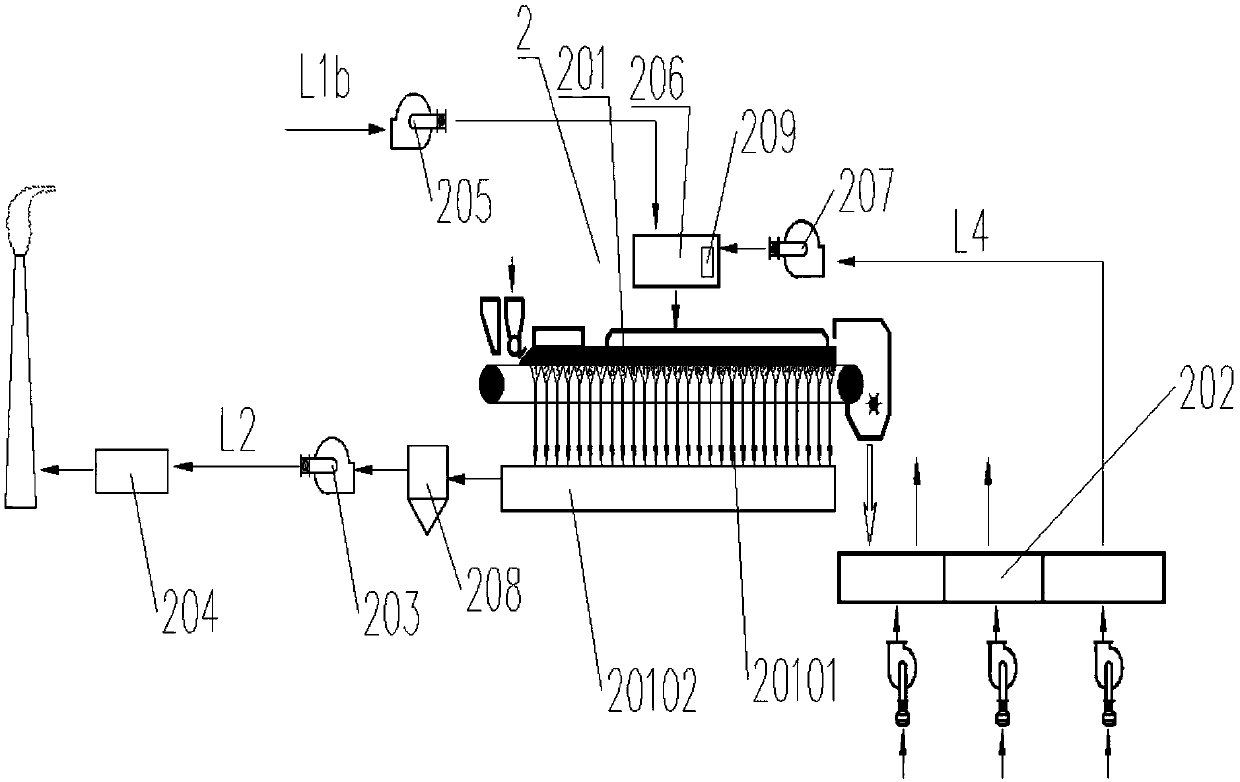

Flue gas comprehensive cyclic treatment method and treatment device for two series of sintering systems

ActiveCN109569183AEasy to transformGood desulfurization and denitrification effectGas treatmentLighting and heating apparatusActivated carbonFlue gas

A flue gas comprehensive cyclic treatment method for two series of sintering systems includes steps: 1) sintering, to be more specific, sintering raw materials in sintering machineS to generate sintering gas; 2) cooling, namely cooling the sintered raw materials in circular cooling machineS; 3) flue gas treatment, to be more specific, after the sintering gas passes through dedusting deviceS, entering a desulfurization and denitrification system to realize treatment, wherein a sintering system A is an activated carbon desulfurization and denitrification system, a system B is a wet desulfurization and denitrification system, and sintering flue gas of the sintering system A is fed into the sintering machine of the sintering system A and the sintering machine of the sintering system B throughtwo cyclic gas branch pipes respectively. In the dry desulfurization and denitrification system, the sulfide concentration is increased while the nitride concentration is reduced, and dry desulfurization and denitrification can be benefited; in the wet desulfurization and denitrification system, the sulfide concentration and the nitride concentration are reduced, and wet desulfurization and denitrification can be benefited. Therefore, energy consumption in industrial production is reduced, and production cost is saved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

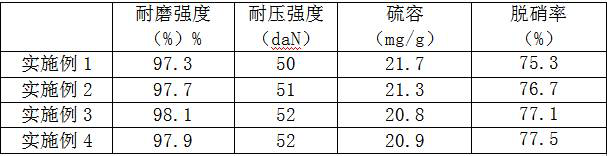

Preparation method of high-performance active coke for flue gas purification

PendingCN113233459AImprove adsorption capacityImprove wear resistanceGas treatmentCarbon compoundsCarbon fibersAcrylonitrile

The invention relates to the field of waste gas purification, in particular to a preparation method of high-performance active coke for flue gas purification, which comprises the following steps: mixing raw coal, activated semi-coke and rare earth elements according to the mass ratio of (20-80):(5-40):(0.02-0.1), and grinding until the particle size is 200 meshes to obtain raw material powder for later use; adding the raw material powder, nanoscale corn starch and water into a kneading machine for kneading to obtain a kneaded material; feeding the kneaded material into a granulator for granulation, drying until the moisture is 5-10%, then feeding the kneaded material into a carbonization and activation device for carbonization and activation, and cooling to obtain primary active coke; d anuniformly mixing and stirring the primary active coke, the graphene oxide solution, the polyacrylonitrile-based carbon fiber and the solid hydrogel particles, putting the mixture into a mold, tabletting by a tabletting machine, and drying, so as to obtain the composite material. The active coke obtained by the invention has relatively strong adsorption capacity, and has excellent wear resistance, pressure resistance and desulfurization and denitrification performance.

Owner:YULIN UNIV

Flue gas desulfurization and denitrification method

InactiveCN109499326AHigh removal rateHigh sulfur capacityGas treatmentDispersed particle separationFlue gasFlue-gas desulfurization

The invention relates to a flue gas desulfurization and denitrification method. Preparation raw materials are selected and a removal method comprises the following steps of S1, selecting materials: selecting distilled water and boiling the water; S2, selecting; selecting an FeCl3 solution; S3, dropwise adding the FeCl3 solution into the boiled water; continually boiling until reddish brown liquidis generated, so as to obtain a desulfurization agent; S4, cooling flue gas to 50 to 100 DEG C through a heat exchanger and introducing the flue gas into the obtained desulfurization agent; S5, introducing the flue gas into the obtained denitrification agent and carrying out denitrification reaction; S6, carrying out ultraviolet irradiation and electron beam irradiation on primary desulfurizationand denitrification flue gas at the same time, so as to obtain secondary desulfurization and denitrification flue gas; S7, carrying out water spraying treatment; S8, discharging denitrified coke ovenflue gas through an induced draft fan. By adopting two times of the desulfurization and denitrification method, the removal efficiency is high and pollutants including SO2, NOx and the like in the flue gas can be removed, so that pollutions to the air are reduced, damage to humans is reduced and the humans are healthier.

Owner:ZHEJIANG FEIDA ENVIRONMENTAL SCI & TECH CO LTD

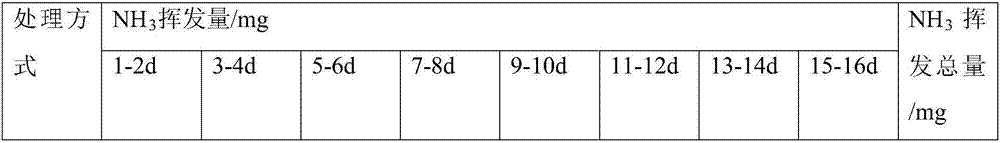

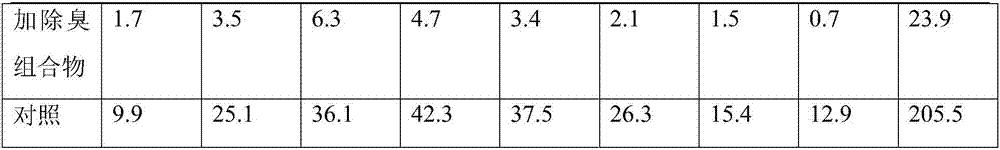

Deodorization composition used for processing breeding dung and application thereof

ActiveCN107029535AImprove bindingReduce volatilityGas treatmentDispersed particle separationActivated carbonOrganic fertilizer

The invention discloses a deodorization composition used for processing breeding dung and an application thereof. The deodorization composition is prepared from, by mass, 40%-55% of activated biomass supercritical liquidation residue, 15%-25% of activated carbon, 10%-15% of bran and 10%-15% of organic calcium. The deodorization composition can reduce the production of repugnant substances in an animal dung compost process, and the composition is suitable for usage and popularization in organic fertilizer factories and all large farms.

Owner:沃邦环保有限公司

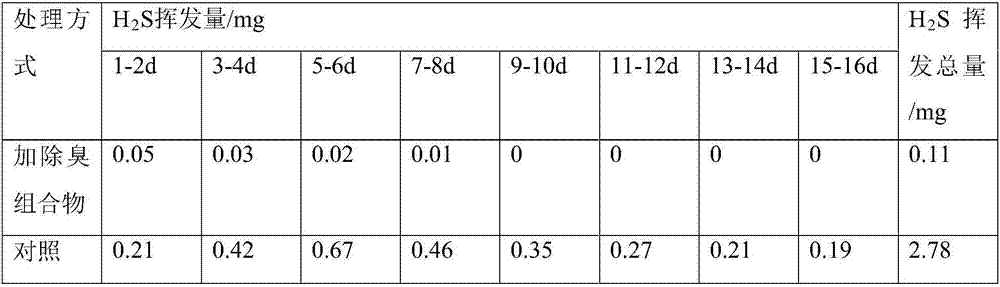

Desulfurization and low-temperature denitration system and process for clean flue gas emission

InactiveCN107913589AReduce or even eliminate the generation ofEliminate generationDispersed particle separationOzone generatorFlue gas

The invention discloses a desulfurization and low-temperature denitration system for clean flue gas emission. The desulfurization and low-temperature denitration system comprises a desulfurization system, a denitration system, a flue gas washing system and a flue gas emission system, wherein the desulfurization system is composed of a desulfurizing absorption tower, a desulfurizing solution preparation system and a desulfurizing solution circulating system; the denitration system is composed of a denitrating absorption tower, an ozone generator and a denitrating solution circulating system; the flue gas washing system comprises a scrubbing tower and a scrubbing water supply system; the flue gas emission system is a chimney; and flue gas from a boiler is sequentially subjected to desulfurization, low-temperature denitration and flue gas scrubbing. The desulfurization and low-temperature denitration system disclosed by the invention has excellent desulfurization, denitration and dust removal effects and can eliminate a 'white smoke' problem caused by the flue gas. Moreover, the system disclosed by the invention solves the problem of secondary pollution in the desulfurization and denitration process and offers help for reducing and eliminating haze.

Owner:北京亿玮坤节能科技有限公司

Device and method for simultaneous desulfurization and denitrification of flue gas under synergistic effect of vacuum ultraviolet and available chlorine

ActiveCN108704465AImprove cooling effectEasy maintenance and repairNitrous oxide captureGas treatmentOxygenPhotochemistry

The invention discloses a device and method for simultaneous desulfurization and denitrification of flue gas under a synergistic effect of vacuum ultraviolet and available chlorine. The method and thedevice are characterized in that an ultraviolet source is adopted for simultaneous radiation of VUV and UVC, and oxygen source gas is subjected to photolysis through VUV waveband photons to generateO3 and ROS; then, the generated O3 and ROS are guided into flue gas and returns near to the ultraviolet source along with the flue gas to take UVC irradiation; an available chlorine oxidation absorbent is mixed in the flue gas, and O3, ROS and the available chlorine oxidation absorbent synergistically play a role in oxidation of NOx and SOx in the flue gas; photochemical reaction of O3 and an available chlorine component in the available chlorine oxidation absorbent is excited through UVC waveband photons to generate more active free radicals to further have reaction with NOx and SOx in the flue gas, so that NO and SO2 in the flue gas can be oxidized into nitrate and sulfate to realize simultaneous desulfurization and denitrification of flue gas.

Owner:HUAZHONG UNIV OF SCI & TECH

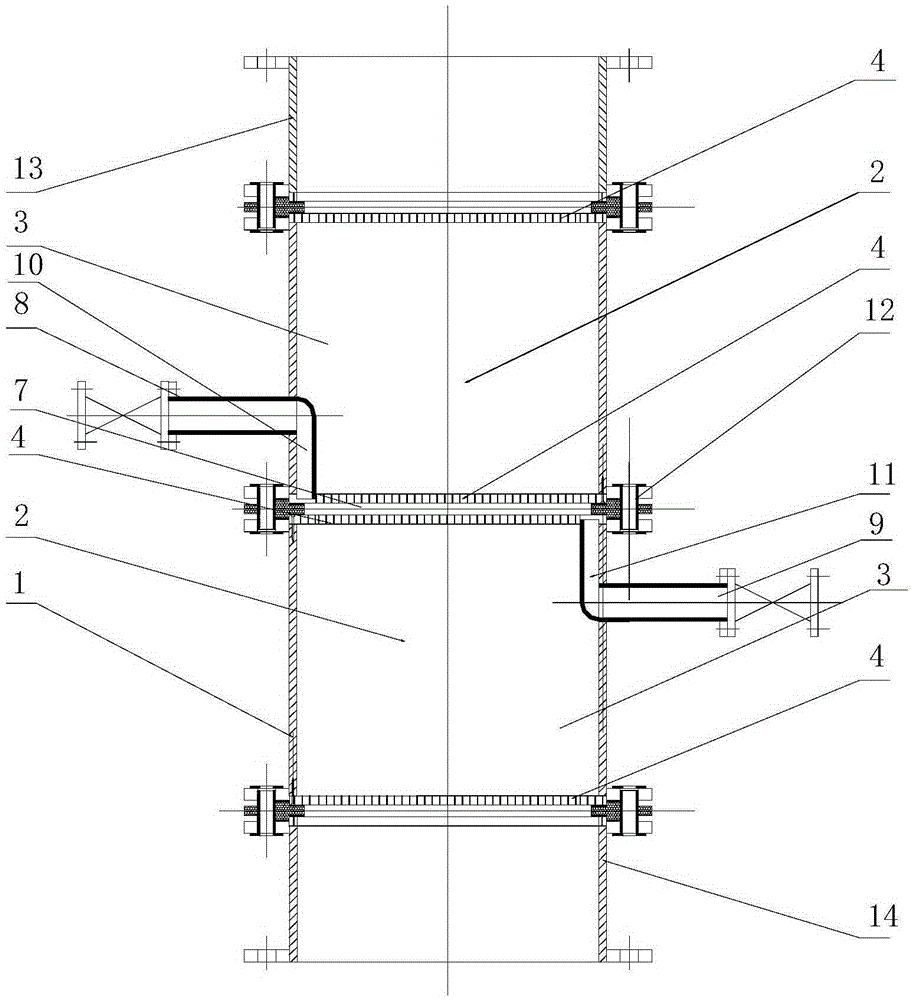

Flue gas pollutant cooperation removal technology based on electrolysis

InactiveCN105344215AImprove conversion rateSimple structureCombination devicesGas treatmentAmmonium sulfateElectrochemical response

The invention discloses a flue gas pollutant cooperation removal technology based on electrolysis. The problems are solved that technologies are complex, the pollutant treatment efficiency is low, investment and operation cost are high in present flue gas treatment. The technology comprises steps: flue gas is pressurized and sent to a concentration tower, a reaction is carried out, the flue gas going out from the concentration tower is sent to an absorbing tower and contacts and reacts with a circulating absorption solution sprayed from a spray layer at the upper part of the tower in a reverse manner, and the flue gas after reaction is discharged from the top of the absorbing tower; part of the concentrate at the tower bottom of the concentration tower is subjected to iron removal, then is sent to a ammonium sulfate crystallization system, the flue gas goes into the absorbing tower from a flue gas inlet at the middle part of the absorbing tower, goes through at least one absorbing and electrochemical reaction layer arranged at the upper part of the tower firstly, then contacts and reacts with a circulating absorption solution in a reverse manner, then goes through a filler layer and a spraying layer, and is discharged from a flue gas outlet. The technology is simple, the reaction efficiency is high, the operation and investment cost are low, the system land occupation area is small, and the technology is especially suitable for cooperation treatment of multiple pollutants of sulfur dioxide, nitrogen oxides, fine particles, dioxin and the like.

Owner:WUHAN WUTUO TECH +1

Dust removal, desulfurization and denitrification integrated tower and dust removal, desulfurization and denitrification integrated system

The invention provides a dust removal, desulfurization and denitrification integrated tower which sequentially comprises a water film dust removing layer, a denitration layer, a desulfuration layer and a steam-water separation layer from bottom to top; the positions of the denitration layer and the desulfuration layer can be exchanged. The invention also provides a dust removal, desulfurization and denitrification integrated system which comprises an air inlet device, a purification device and a recovery device, wherein the air inlet device is connected with the purification device; the purification device is connected with the recovery device. After the dust removal, desulfurization and denitrification integrated tower and the dust removal, desulfurization and denitrification integrated system are used for treating waste material, the pollution is reduced, the reaction raw material is saved, the device is easy to clean, the service life is prolonged, and the production cost is lowered.

Owner:江苏佳诣环保科技有限公司

Dry-method desulphurization denitration integrated treatment method

InactiveCN107042052AWon't happenGood desulfurization and denitrification effectGas treatmentAuxillary pretreatmentDecompositionFlue gas

The invention belongs to the field of flue gas processing, and especially relates to a dry-method desulphurization denitration integrated treatment method. The dry-method desulphurization denitration integrated treatment method comprises following steps: flue gas is delivered through a deduster for dedusting, and then an atomizer is used for atomization and humidification; after humidification, obtained flue gas is delivered into a desulphurization device containing absorption blocks for 0.5 to 2.5s of treatment so as to achieve complete absorption of SO2; after desulphurization, flue gas is delivered into a photocatalysis oxidation device so as to degrade NOx in flue gas into N2 and O2 and generate a part of O3; a part of NO is converted into NO2 via oxidation with O3 generated via photocatalysis; after photocatalysis decomposition, flue gas is delivered into a denitration device containing absorption blocks, wherein NO2 is absorbed by the absorption blocks completely, and left trace amount of NOx (the concentration of the NOx is 100mg / m<3> or lower), NO2, and O2 are discharged through a chimney. According to the dry-method desulphurization denitration integrated treatment method, low temperature photocatalysis is adopted to reduce waste flue gas treatment cost, and realize high efficiency desulphurization denitration.

Owner:LIAONING BEIHUAN PURIFICATION TECH

Flue gas treatment method

ActiveCN108114591AAvoid pollutionReduce the temperatureGas treatmentDispersed particle separationChemical reactionFlue gas

The invention provides a flue gas treatment method, and belongs to the technical field of environmental protection equipment. The flue gas treatment method comprises the following treatment steps that: discharged flue gas is dedusted by a deduster and then enters a main flue, and the flue gas accounting for 3-7% of the volume of the dedusted flue gas is drawn out and is cooled and dehumidified tohave a temperature of 60-80 DEG C and a relative humidity of less than 3.5%, and then the flue gas preheats sodium bicarbonate in a grinding device; the preheated sodium bicarbonate powder is heated to 120-200 DEG C and then sprayed directly into the main flue to have a chemical reaction with nitrogen oxides and sulfur oxides in the flue gas; and the flue gas is discharged after washing. The fluegas treatment method can well solve the problems of desulfurization and denitration of low-temperature flue gas, is low in energy consumption, low in equipment cost and wide in application range, andcan not only realize the treatment of low-temperature flue gas, but also can adapt to the treatment of high-temperature flue gas, and sodium bicarbonate powder is directly mixed with the flue gas, sothat compared with spraying a solution, the requirement on equipment is low, and the reaction efficiency is high.

Owner:山东义丰环保机械股份有限公司

Efficient desulfurization and denitration absorbing agent and preparation method thereof

InactiveCN108654311ANo pollutionEfficient desulfurization and denitrificationDispersed particle separationNitratePotassium alum

The invention discloses an efficient desulfurization and denitration absorbing agent and a preparation method thereof. The efficient desulfurization and denitration absorbing agent comprises, by weight, 5-15 parts of ammonium sulfate, 2-6 parts of urea, 2-10 parts of white alum, 1.2-2.6 parts of magnesium hydroxide, 3.0-4.5 parts of complexing agents, 1.0-2.0 parts of sodium borate and 4.5-6.5 parts of molding solution. According to the efficient desulfurization and denitration absorbing agent and the preparation method thereof, the absorbing agent lower precipitated mixture powder dispersed in the molding solution and the sodium borate, the lower precipitated mixture powder comprises the ammonium sulfate, the urea, the white alum and the magnesium hydroxide, raw materials are complexed through the complexing agents, dried and crushed to prepare the absorbing agent, the absorbing agent is uniform in shape and stable in nature, sulfate and nitrate can be rapidly, efficiently and thoroughly removed, and environments cannot be polluted.

Owner:DSP TECH DEV WENZHOU CO LTD

Preparation method of simultaneous desulfurization and denitrification Al2O3@TiO2 core-shell structure adsorbent

ActiveCN108176349ALow priceThe synthesis method is simpleGas treatmentOther chemical processesSorbentActivated Aluminum Oxide

The invention relates to a preparation method of simultaneous desulfurization and denitrification Al2O3@TiO2 core-shell structure adsorbent, belonging to the field of environmental protection. the simultaneous desulfurization and denitrification Al2O3@TiO2 core-shell structure adsorbent is prepared by using mesoporous activated aluminum oxide as a core and anatase titanium dioxide as a shell, grinding a certain amount of aluminum oxide into nanoparticles, dispersing the nanoparticles in ethanol by ultrasonication, stirring, and the like, and adding the ethanol into a titanium dioxide preparation sol. When being used in a simultaneous desulfurization and denitrification process, the simultaneous desulfurization and denitrification Al2O3@TiO2 core-shell structure adsorbent is found that thespecial structure of the simultaneous desulfurization and denitrification Al2O3@TiO2 core-shell structure adsorbent can effectively weaken the competitive adsorption of SO2 and NOx, and improves the simultaneous desulfurization and denitration performance. The simultaneous desulfurization and denitrification Al2O3@TiO2 core-shell structure adsorbent prepared by the method has stable properties andlarge adsorption capacity, can reduce the competitive adsorption of the SO2 and the NOx, achieves simultaneous desulfurization and denitrification, and has good economic, environmental and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

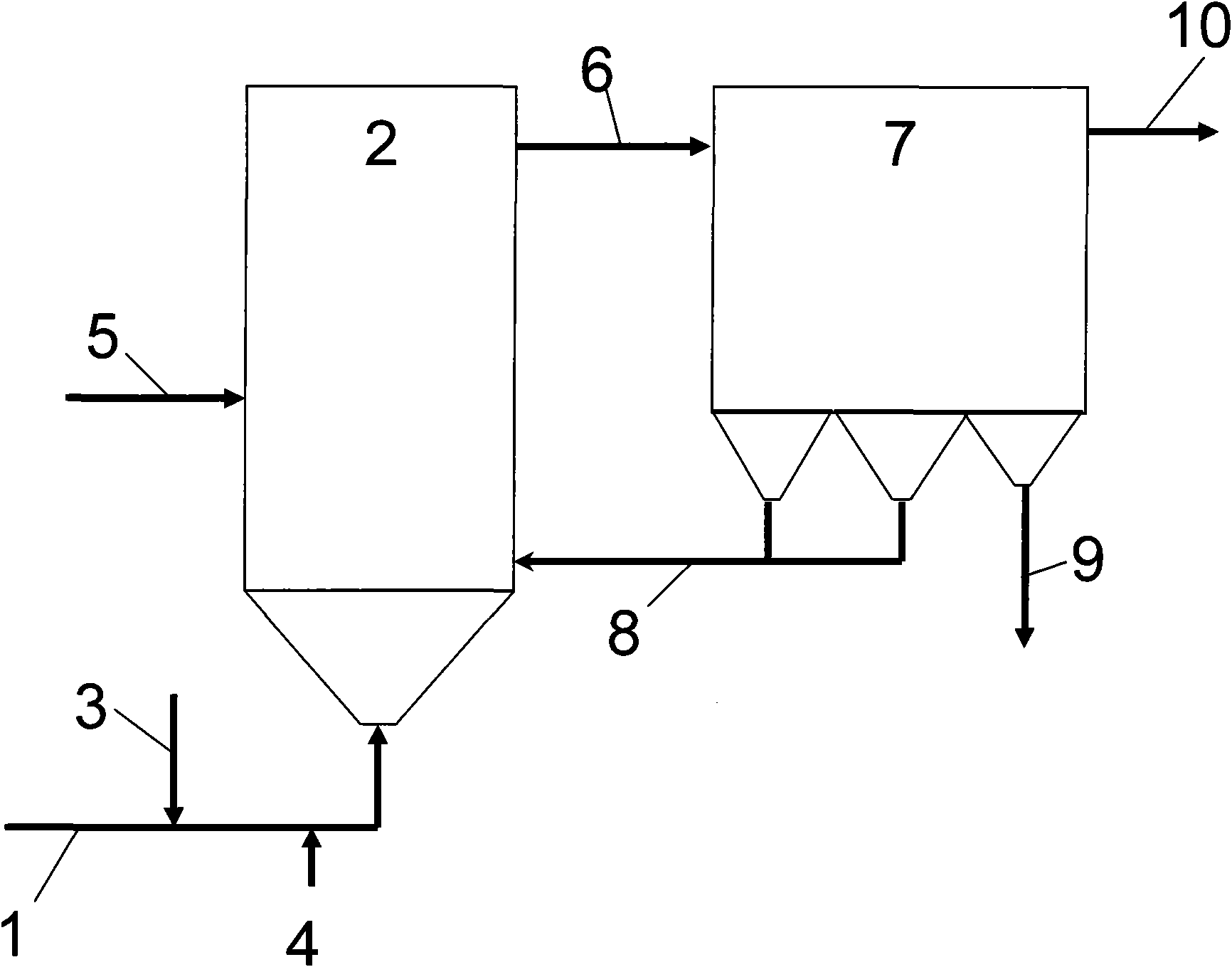

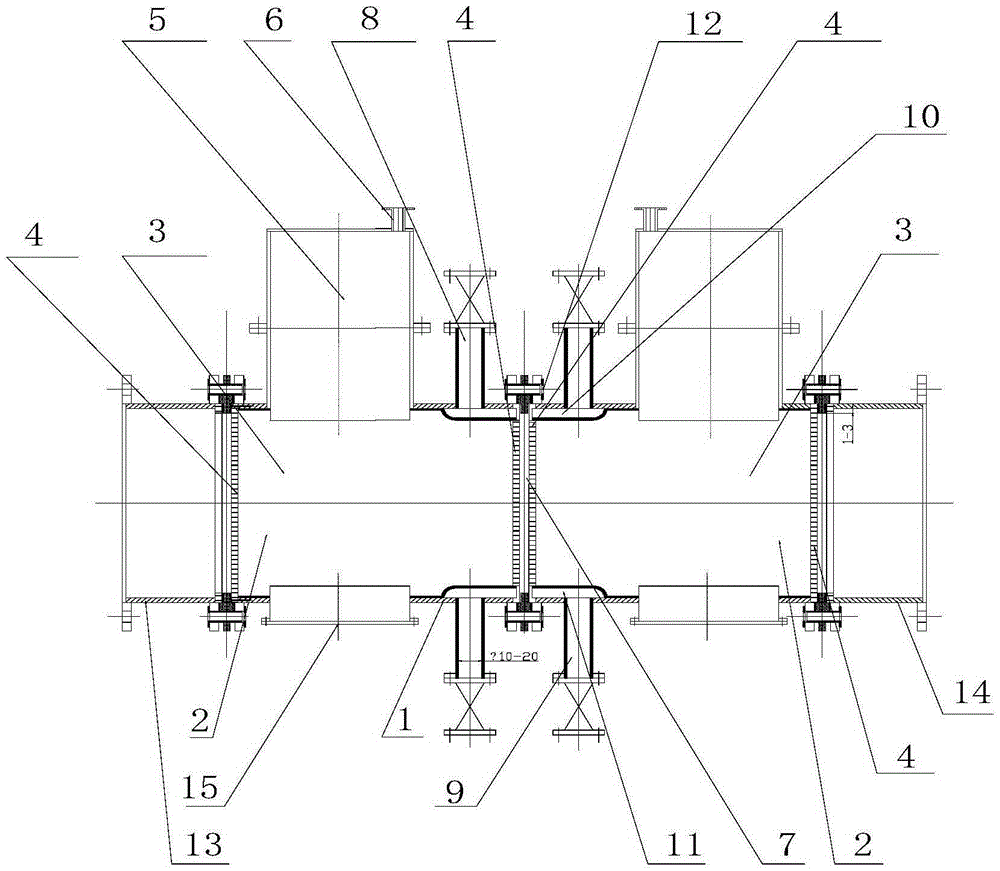

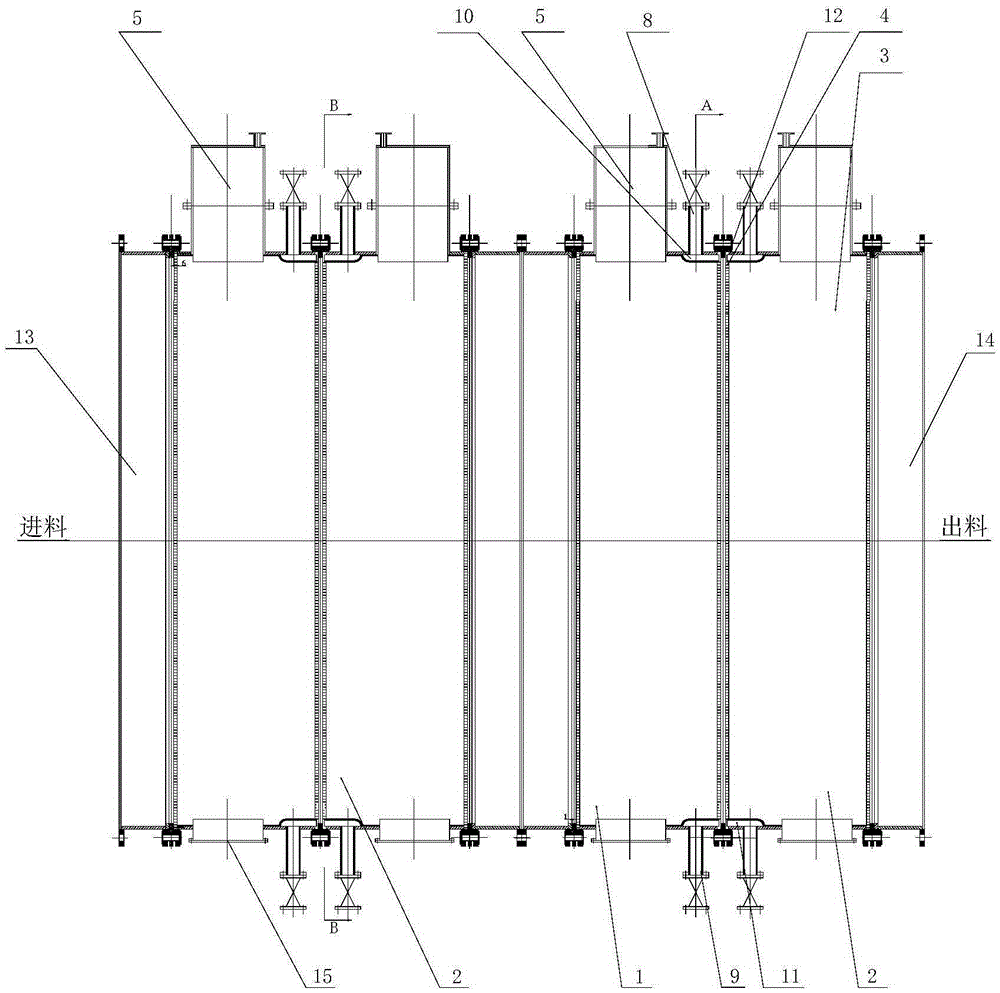

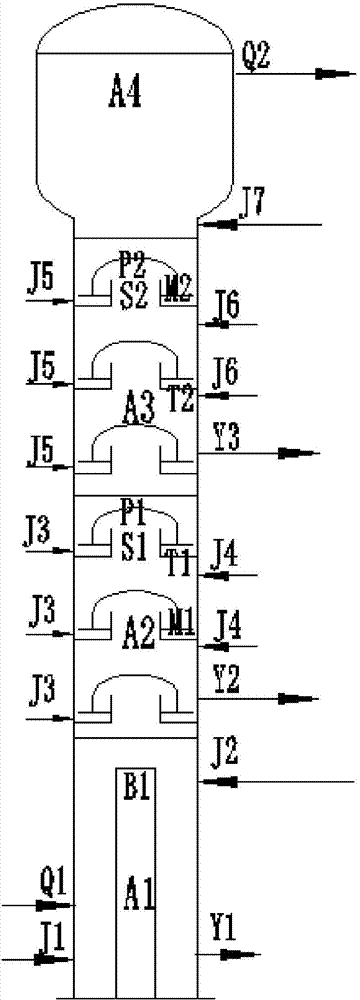

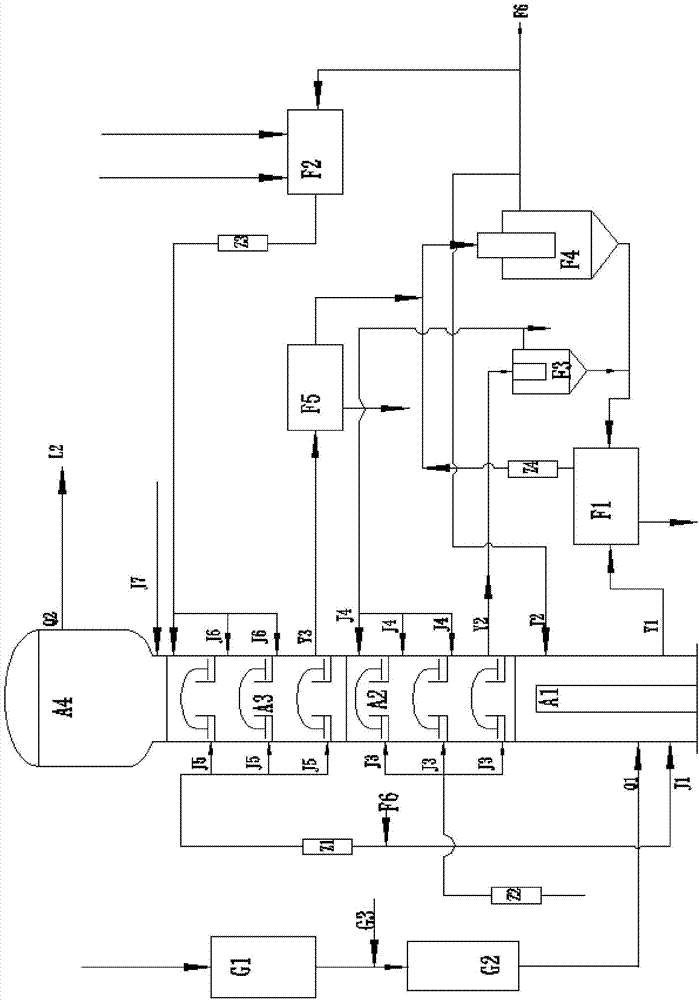

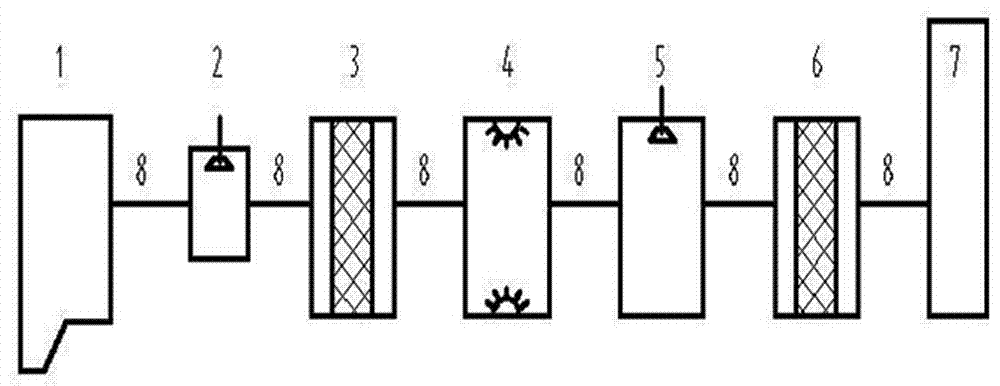

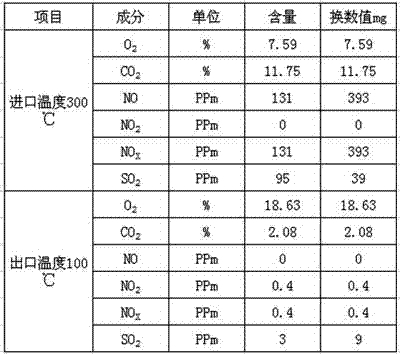

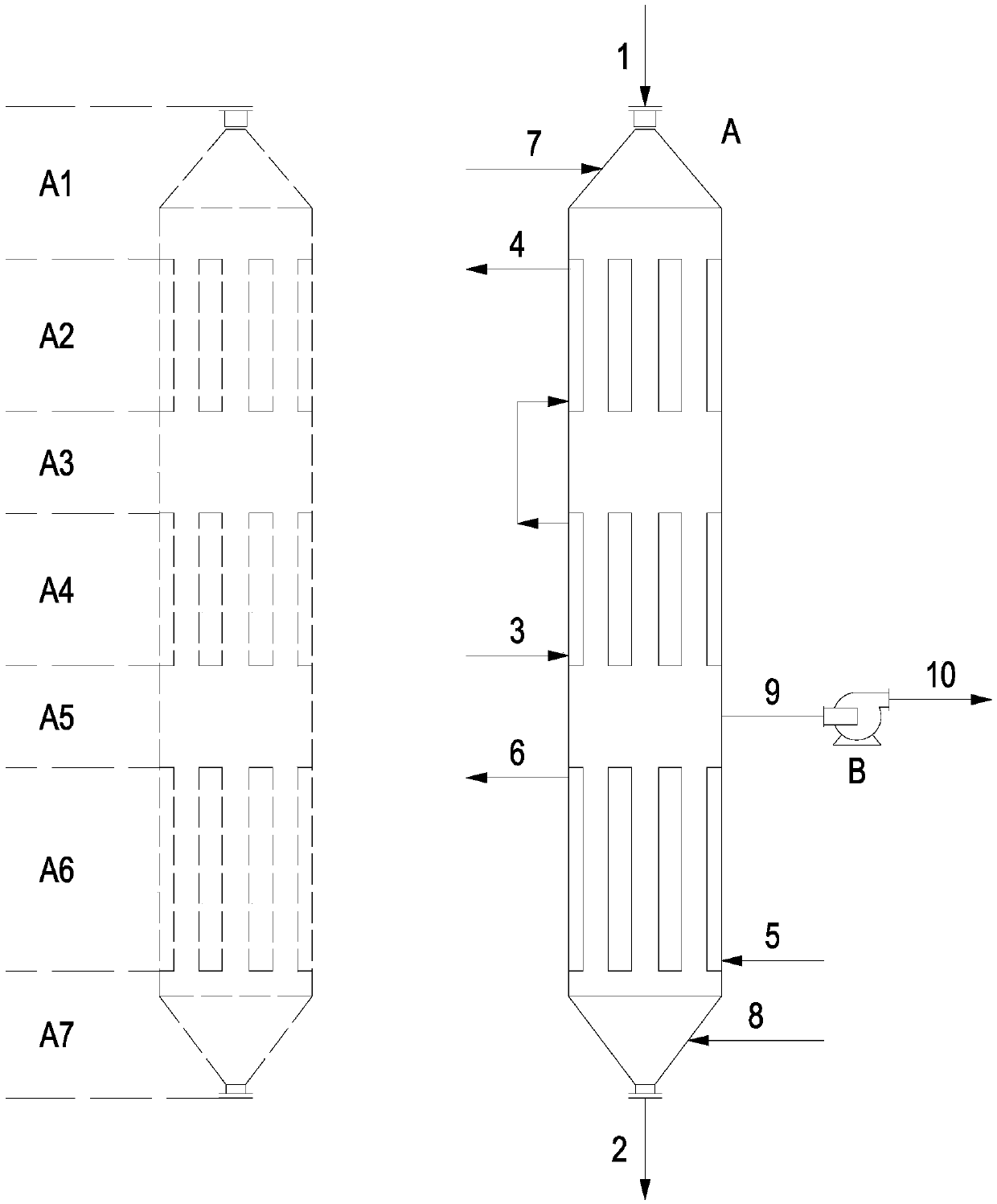

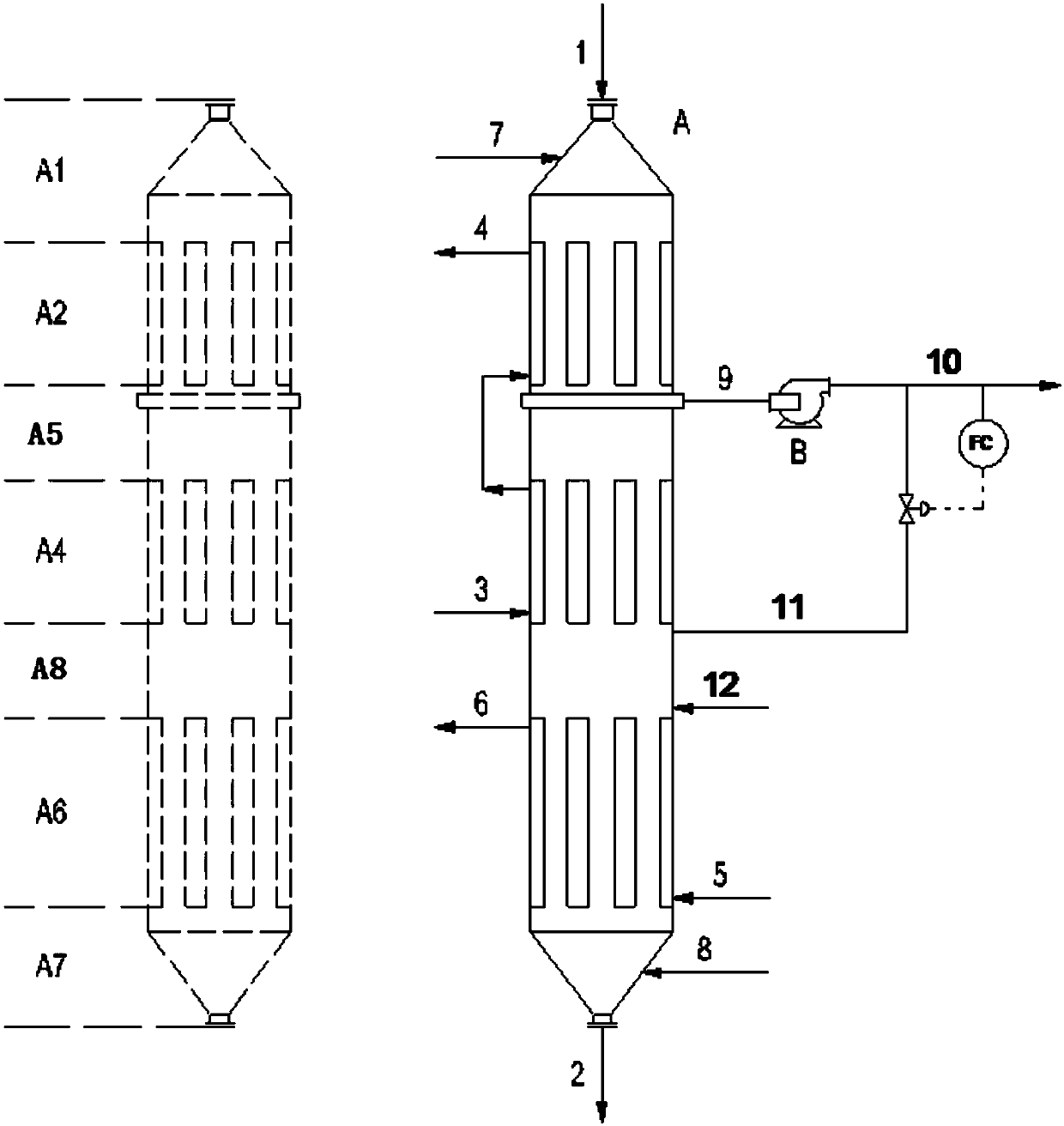

System and method for regenerating active coke

ActiveCN110624525AReduce contentStable flowGas treatmentDispersed particle separationDeposition temperatureEngineering

The invention belongs to the field of chemical engineering, and discloses a system and a method for regenerating active coke. The system for regenerating active coke comprises a regeneration tower anda regeneration fan, and the regeneration tower is sequentially provided with a feeding distribution section, a preheating section, a regeneration tail gas extraction section, a heating section, a redistribution and activation section, a cooling section and an outlet collection section from top to bottom. A process flow of circulating the regeneration tail gas to the bottom of the heating sectionis adopted to generate new oxygen-containing and nitrogen-containing functional groups on the surface of the active coke and improve the desulfurization and denitrification performance of the active coke; the flow and composition stability of regeneration tail gas can be guaranteed, the flow and the SO3 content of the regeneration tail gas can be reduced, the SO2 concentration is improved, the salt deposition temperature of a regeneration tail gas system is reduced, and the salt deposition tendency is reduced, so stable operation of a downstream regeneration tail gas treatment system is facilitated; and the process flow is simple, and is safe and reliable to operate, so the stability and reliability of the active coke regeneration technology are improved.

Owner:SINOPEC ENG +1

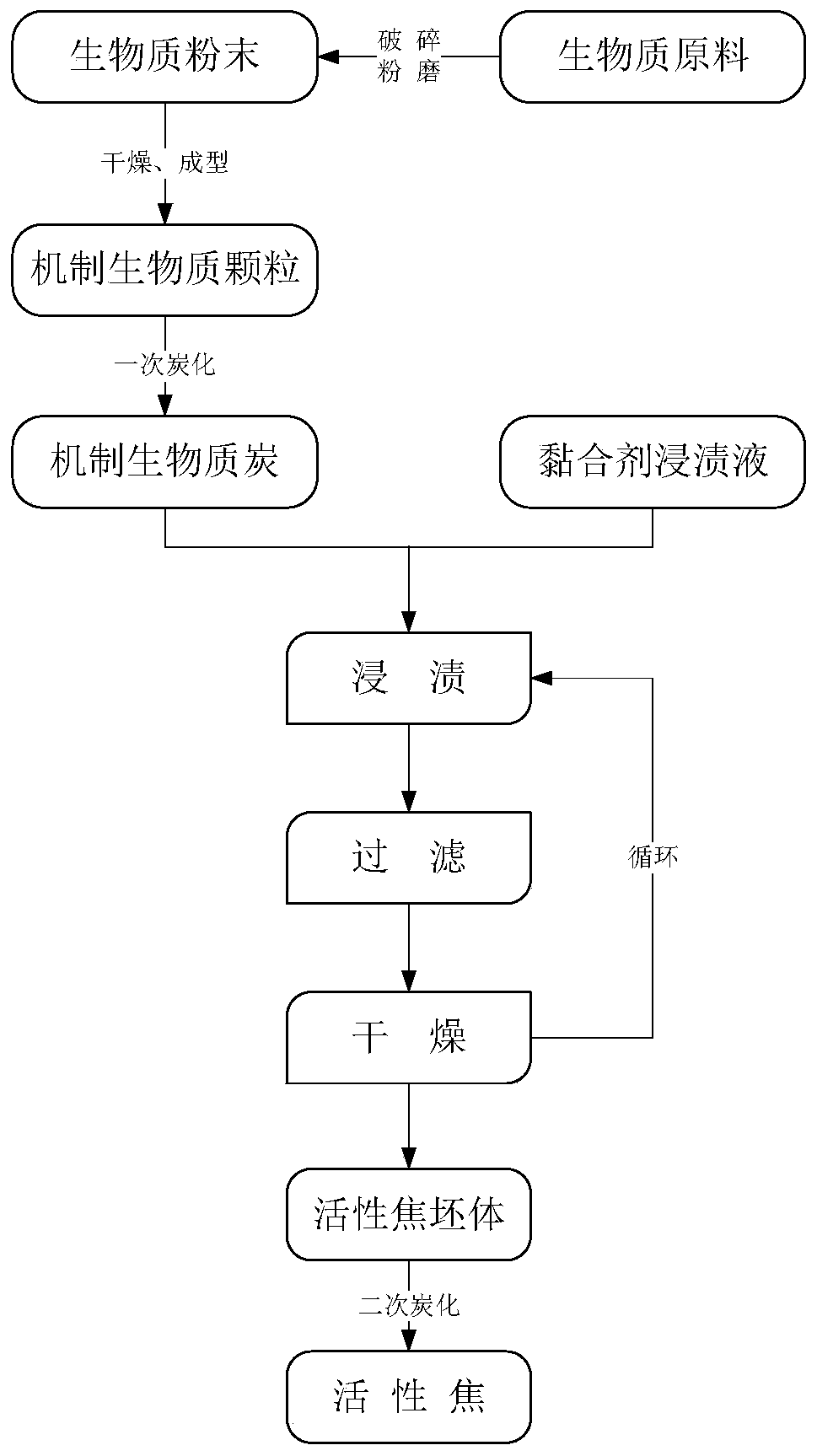

Impregnation process biomass-based active coke and preparation method thereof

ActiveCN110577218AThe size of the pore structure can be controlledEvenly distributedPhysical/chemical process catalystsOther chemical processesAdhesiveCarbonization

The invention discloses an impregnation process biomass-based active coke and a preparation method thereof. The preparation method comprises the following steps: crushing, grinding and drying a biomass raw material to obtain a biomass powder with a certain moisture content; pressing the biomass powder through a pressure forming machine to obtain machine-made biomass particles; carbonizing and cooling the machine-made biomass particles in an oxygen-free or low-oxygen environment to obtain machine-made biomass charcoal; impregnating the machine-made biomass charcoal in an adhesive impregnation solution, and then filtering and drying the impregnated machine-made biomass charcoal to obtain an active coke body; and carrying out secondary carbonization and cooling on the activated coke body in the oxygen-free or low-oxygen environment to obtain the active coke. The method has the advantages of simple process, low cost and low energy consumption, and the active coke product has the advantagesof high specific surface area, low ash content, high comprehensive strength, high adsorbability and the like.

Owner:浙江微松冷链科技有限公司

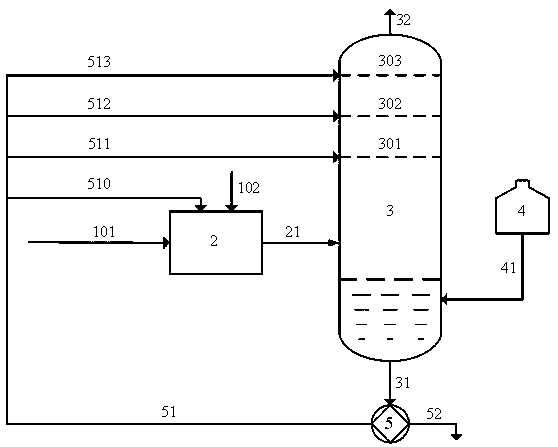

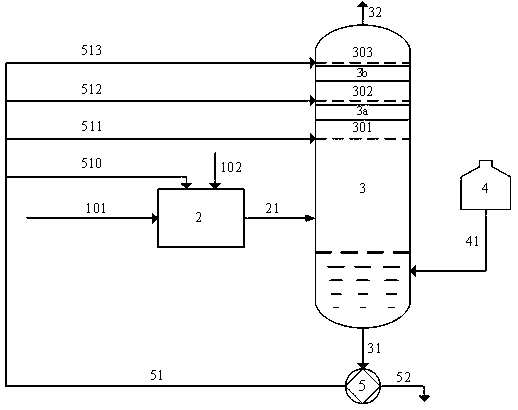

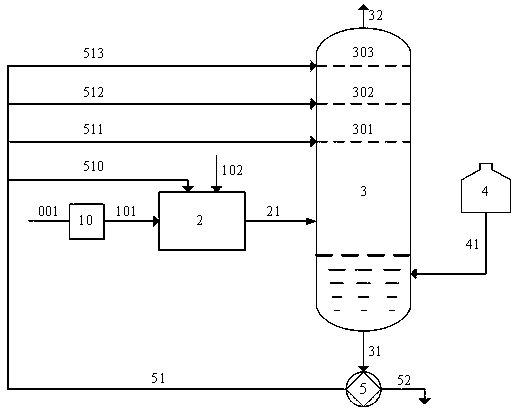

Desulfurization and denitrification device and method

InactiveCN110075677ARealize multi-stage desulfurization and denitrification treatmentGood desulfurization and denitrification effectGas treatmentUsing liquid separation agentEngineeringSolid particle

The invention provides a desulfurization and denitrification device and method. The desulfurization and denitrification device comprises a to-be-treated gas inlet (101), a fresh absorbent inlet (102),an absorption reactor (2), an absorption and regeneration mixed reactor (3), an alkali liquor tank (4) and a solid-liquid separator (5). By means of the desulfurization and denitrification device andmethod, continuous desulfurization and denitrification of to-be-treated gas can be realized, solid particles in the to-be-treated gas can be removed, the treatment efficiency is high, content of NOxand SOx in discharged gas is low, no dioxin is produced, and the national environmental protection standard can be met.

Owner:苏州华加星光新能源科技有限公司

Process for synergic removal of flue gas pollutants through complexing absorption synchronous electrolytic reduction

InactiveCN105289254ASimple processing methodImprove controllabilityDispersed particle separationExternal electric electrostatic seperatorComing outElectrolysis

The invention discloses a process for synergic removal of flue gas pollutants through complexing absorption synchronous electrolytic reduction. The technical scheme is that the process comprises the steps that flue gas is pressurized and then fed into a concentrating tower to react; the flue gas coming out of the concentrating tower is fed into an absorption tower to be in reverse contact reaction with circulating absorption liquid sprayed out of a spraying layer on the upper portion of the tower and then is discharged out of the top of the absorption tower; part of concentrated solution at the bottom of the concentrating tower undergoes iron removal and then is fed into an ammonium sulfate crystallization system; the circulating absorption liquid sprayed out of the spraying layer is in reverse contact reaction with the flue gas downwards and then enters the bottom of the absorption tower through an electrolytic regeneration layer below a flue gas inlet, and a cathode layer, an anode layer and a cathode layer are sequentially arranged on the electrolytic regeneration layer from top to bottom. Each electrode layer is of a net structure made of a conductive material, every two adjacent electrode layers are insulated from each other, and the electrolytic regeneration layer is connected with a power supply through a binding post installed on the tower wall. The process is simple, high in reaction efficiency, low in running and investment cost, small in occupied space and particularly suitable for coordinating management of multiple flue gas pollutants.

Owner:WUHAN UNIV OF SCI & TECH +1

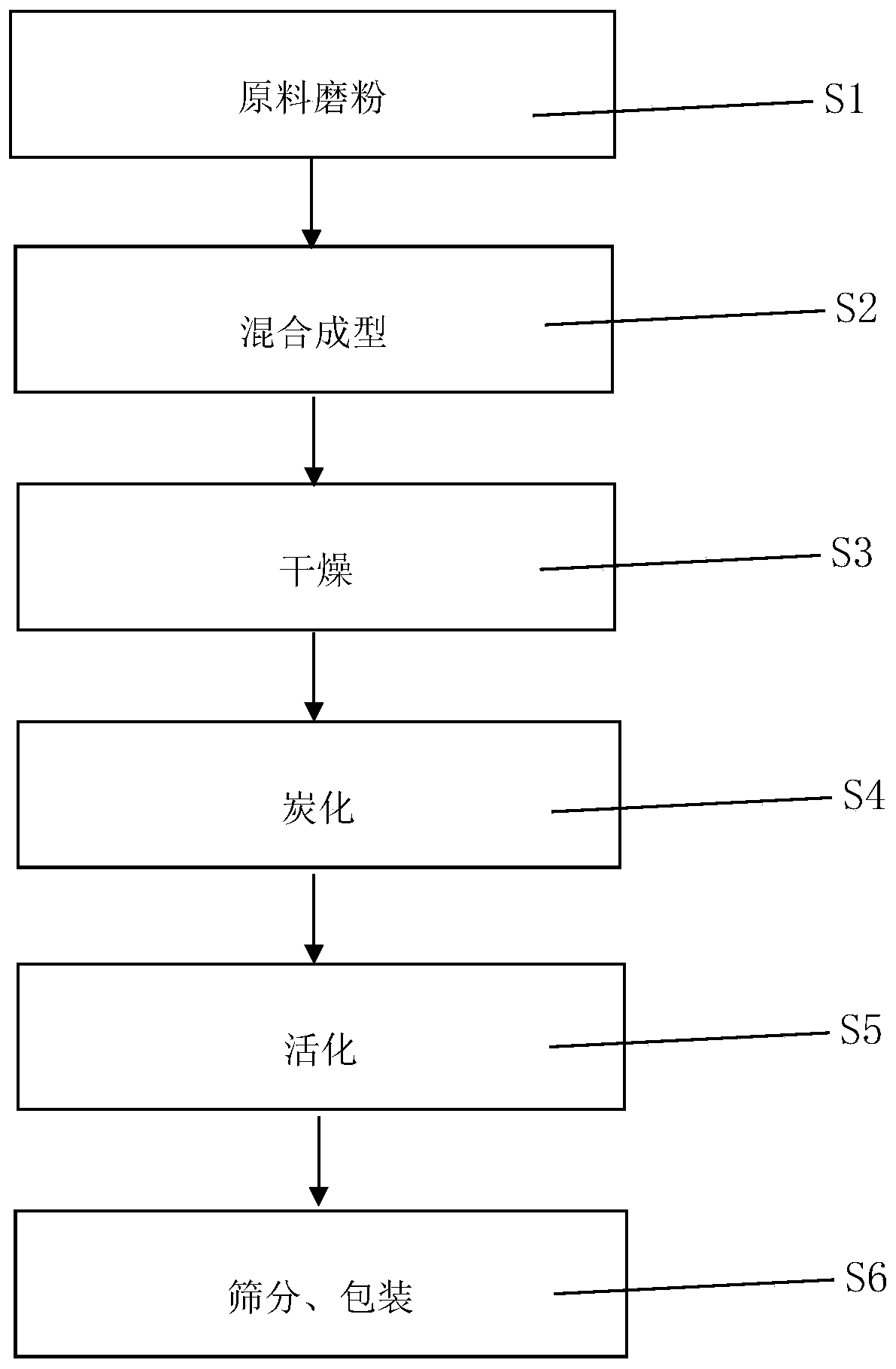

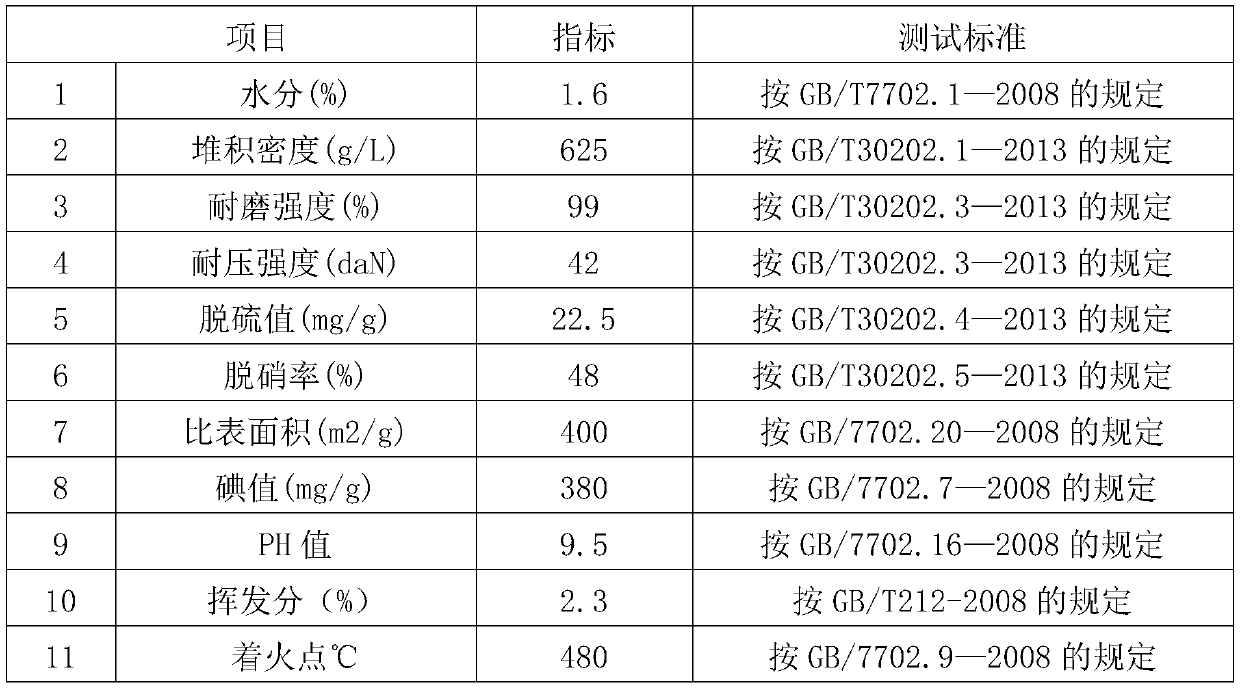

Novel desulfurization and denitrification activated carbon

PendingCN110255554AImprove featuresImprove removal effectGas treatmentCarbon compoundsHazardous substanceHigh pressure

The invention discloses novel desulfurization and denitrification activated carbon, which mainly comprises pulverized coal, bentonite, aluminum oxide and starch, the weight percentage ratio of the components being 1:(0.08-0.2):(0.01-0.2):(0.01-0.2) correspondingly. A preparation method comprises the following steps: grinding the raw materials according to the mixing ratio, mixing and molding the powders, drying, carbonizing and activating the mixture, and sieving and packaging the mixture to produce the novel desulfurization and denitrification activated carbon. The product has high pressure resistance, impact resistance and wear resistance in actual use; the activated carbon has the advantages of high sulfur dioxide adsorption capacity, high desulfurization speed and obvious desulfurization and denitrification effects, can be repeatedly recycled, and has favorable removal effects on various harmful substances such as SO2, NO, mercury, dioxin, dust and the like and harmful substances such as SO3 which are difficult to remove by the conventional wet process.

Owner:尹金彦

Nano composite type coal-saving desulfurization and denitrification additive

InactiveCN103666634AReduce contentExtended active reaction temperature rangeSolid fuelsFiberWater dispersible

The invention discloses a nano composite type coal-saving desulfurization and denitrification additive and belongs to the environmental-friendly coal-saving field. The coal-saving desulfurization and denitrification additive is water dispersible solution and consists of solute and a solvent, wherein the solute comprises the following components in parts by weight: 15-45 parts of nano titanium dioxide, 2-8 parts of rare earth lanthanum and high-alumina bauxite, 1-3 parts of triethanolamine acetate, 25-35 parts of nitrate and 5-10 parts of active carbon fiber; the solvent is deionized water, and the mass percentage concentration of the coal-saving desulfurization and denitrification additive is 10-35%. The nano composite type coal-saving desulfurization and denitrification additive disclosed by the invention has the beneficial effects that the burning condition of coal can be effectively improved, the coal consumption can be reduced, and the emission of main pollutants such as SO2 and NOx is reduced, and also has the advantages of stable performance, convenience in storage, good coal-saving effect, obvious emission reduction, simple use and fast investment return and the like.

Owner:MAANSHAN CHINASEA NEW MATERIAL

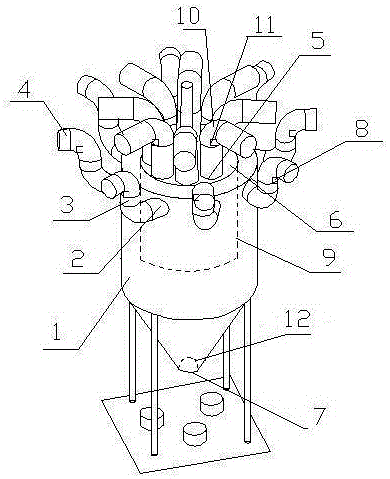

Multipoint centralized dedusting desulphurization denitration apparatus

ActiveCN106000059AAvoid resistanceIncrease intake speedDispersed particle separationSpray nozzleWastewater

The invention relates to a multipoint centralized dedusting desulphurization denitration apparatus. According to the invention, a cylindrical shell is arranged, a cover plate is arranged at the top of the cylindrical shell, a dust discharging port is arranged at the bottom of the cylindrical shell, a loop of air inlets is arranged on the upper part of the cylindrical shell, an air inlet pipe which is tangent to the cylinder wall of the cylindrical shell is arranged at the air inlets, the air inlet pipe is connected with a tail gas discharge pipe through a bend pipe arranged towards, a spray nozzle I for sprinkling desulphurization denitration liquid is arranged on the upper part of the bend pipe, a guide shell is arranged at the bottom of the cover plate, a lower end of the guide shell is arranged in the cylindrical shell which keeps 40-60 cm from the lower part of the air inlet to the air inlet, several air outlets communicated to the guide shell are arranged on the cover plate, and the caliber of the air outlet is greater than the caliber of the air inlet. According to the invention, the bend pipe is arranged at the outboard of the air inlet of the cylindrical shell, desulphurization and denitration are carried out in the bend pipe, waste water after desulphurization and denitration is discharged from the dust discharging port along the side wall of the cylindrical shell, then desulphurization and denitration are carried out on the tail gas, dust accumulated on the inner wall of the cylindrical shell is cleaned, several air inlets and air outlets are arranged, spraying resistance is overcome, and the air inlet speed is accelerated.

Owner:连云港泓聚莱釉料有限公司

Combined desulfurization and denitration method for novel dry-process cement production line

InactiveCN110981239ARealization of desulfurization and denitrificationLow costGas treatmentDispersed particle separationPtru catalystProcess engineering

A combined desulfurization and denitration method for a novel dry-process cement production line is disclosed. The method includes adding a raw material modifier and a liquid desulfurization and denitration agent which are two parts into the cement production line. The raw material modifier is added at a raw material elevator, and the liquid desulfurization and denitration agent is added at a windpipe among cyclone preheaters C1-C3. The raw material modifier includes 10-98% of a SO2 absorbent, 0.01-30% of an active component promoting SO2 absorption, 0.01-30% of an active component promotinglimestone decomposition, and 0.01-30% of a denitration catalyst adopting clay as a carrier. The liquid desulfurization and denitration agent includes 0.1-25% of ammonia water, 0.1-40% of a urea solution, or a solution mixture of both. The method has technical advantages of good desulfurization and denitration effects, low cost and no secondary pollution.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com