Preparation method of high-performance active coke for flue gas purification

A flue gas purification and activated coke technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of excessive NOx emissions, denitrification performance of activated coke, poor adsorption performance, wear resistance and pressure resistance, and affect the operation of activated coke Cost and other issues, to achieve the effect of excellent wear resistance, strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

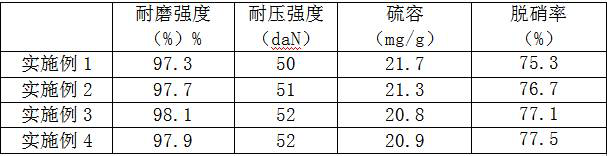

Examples

Embodiment 1

[0024] A method for preparing high-performance activated coke for flue gas purification, characterized in that it comprises the following steps:

[0025] S1. After mixing coking coal with a caking index greater than 60, activated semi-coke, and rare earth elements in a mass ratio of 20:5:0.02, grind them to a particle size of 200 mesh to obtain raw material powder for later use;

[0026] S2. Add raw material powder, nano-grade cornstarch, and water to a kneader in a mass ratio of 1:10%:5% to obtain a kneaded material;

[0027] S3. Send the kneaded material into a granulator for granulation, dry it until the water content is 5%, then send it into a carbonization activation device for carbonization activation, and cool to obtain primary activated coke;

[0028] S4. Mix and stir primary activated coke, graphene oxide solution (0.01mg / mL), polyacrylonitrile-based carbon fiber, and solid hydrogel particles in a mass ratio of 10:3:0.2:0.01, and place in In the mould, the tablet mac...

Embodiment 2

[0030] A method for preparing high-performance activated coke for flue gas purification, characterized in that it comprises the following steps:

[0031] S1. After mixing bituminous coal, activated semi-coke, and rare earth elements according to the ratio of 80: 40: 0.1 in mass ratio, grind to a particle size of 200 mesh to obtain raw material powder, and set aside;

[0032] S2. Add raw material powder, nano-grade cornstarch, and water to a kneader in a mass ratio of 1:40%:20% to obtain a kneaded material;

[0033] S3, sending the kneaded material into a granulator for granulation, drying until the water content is 10%, and then sending it into a carbonization activation device for carbonization activation, and cooling to obtain primary activated coke;

[0034] S4. Mix primary activated coke with graphene oxide solution (0.01mg / mL), polyacrylonitrile-based carbon fiber, and solid hydrogel particles in a mass ratio of 20: 5: 1: 0.1. In the mould, the tablet machine compresses ...

Embodiment 3

[0036] A method for preparing high-performance activated coke for flue gas purification, characterized in that it comprises the following steps:

[0037] S1. After mixing the 1:1 mixture of bituminous coal and anthracite, activated semi-coke, and rare earth elements according to the ratio of 60:22.5:0.06 in mass ratio, grind to a particle size of 200 mesh to obtain raw material powder, and set aside;

[0038] S2. Add raw material powder, nano-grade cornstarch, and water to a kneader in a mass ratio of 1:25%:12.5% to obtain a kneaded material;

[0039] S3. Send the kneaded material into a granulator for granulation, dry it until the water content is 7.5%, then send it into a carbonization activation device for carbonization activation, and cool to obtain primary activated coke;

[0040] S4. Mix and stir primary active coke, graphene oxide solution (0.01mg / mL), polyacrylonitrile-based carbon fiber, and solid hydrogel particles in a mass ratio of 15:4:0.6:0.055, and place In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com