Dust removal, desulfurization and denitrification integrated tower and dust removal, desulfurization and denitrification integrated system

A desulfurization, denitrification, and denitration technology, applied in chemical instruments and methods, using liquid separation agents, and dispersing particle separation, can solve the problems of high waste treatment costs, short service life, and easy damage to equipment, and achieve extended service life and reduced Production cost, effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

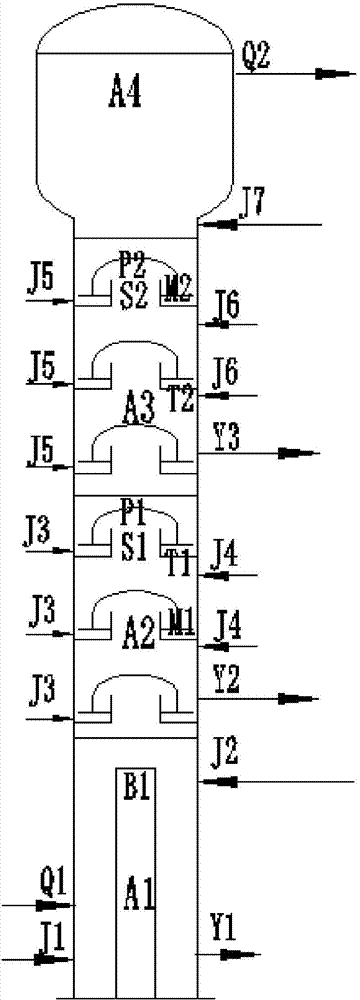

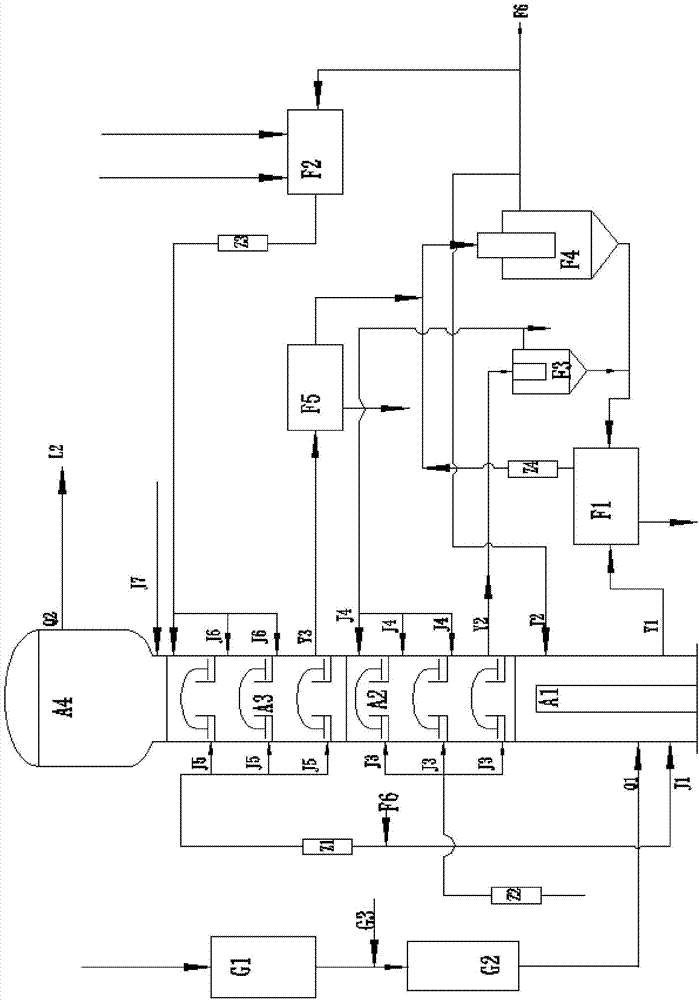

[0041] The dust removal, desulfurization and denitrification integrated tower of the present invention includes a denitrification layer, a desulfurization layer and a steam-water separation layer in sequence from the bottom of the tower, and the positions of the denitrification layer and the desulfurization layer can also be exchanged, that is, from the bottom of the tower upwards Including the desulfurization layer, denitrification layer and steam-water separation layer, but the most preferred structure is that the denitrification layer is on the bottom and the desulfurization layer is on the top, because the product produced by the denitration layer can be mixed with the ash emulsion in the desulfurization layer The reaction is carried out to prevent the release of substances such as nitric acid from the chimney into the atmosphere. At the bottom of the dust removal, desulfurization and denitrification integrated tower, a water film dust removal layer can be set for prelimina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com