System and method for regenerating active coke

A technology of activated coke regeneration and regeneration tower, applied in the chemical industry, can solve the problems affecting the long-term stable operation of the regeneration fan, the difficulty of the regeneration tail gas treatment system, and the high content of coke powder in the regeneration tail gas, which is beneficial to long-term operation, stable flow and composition , The effect of reducing the temperature and tendency of salt formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

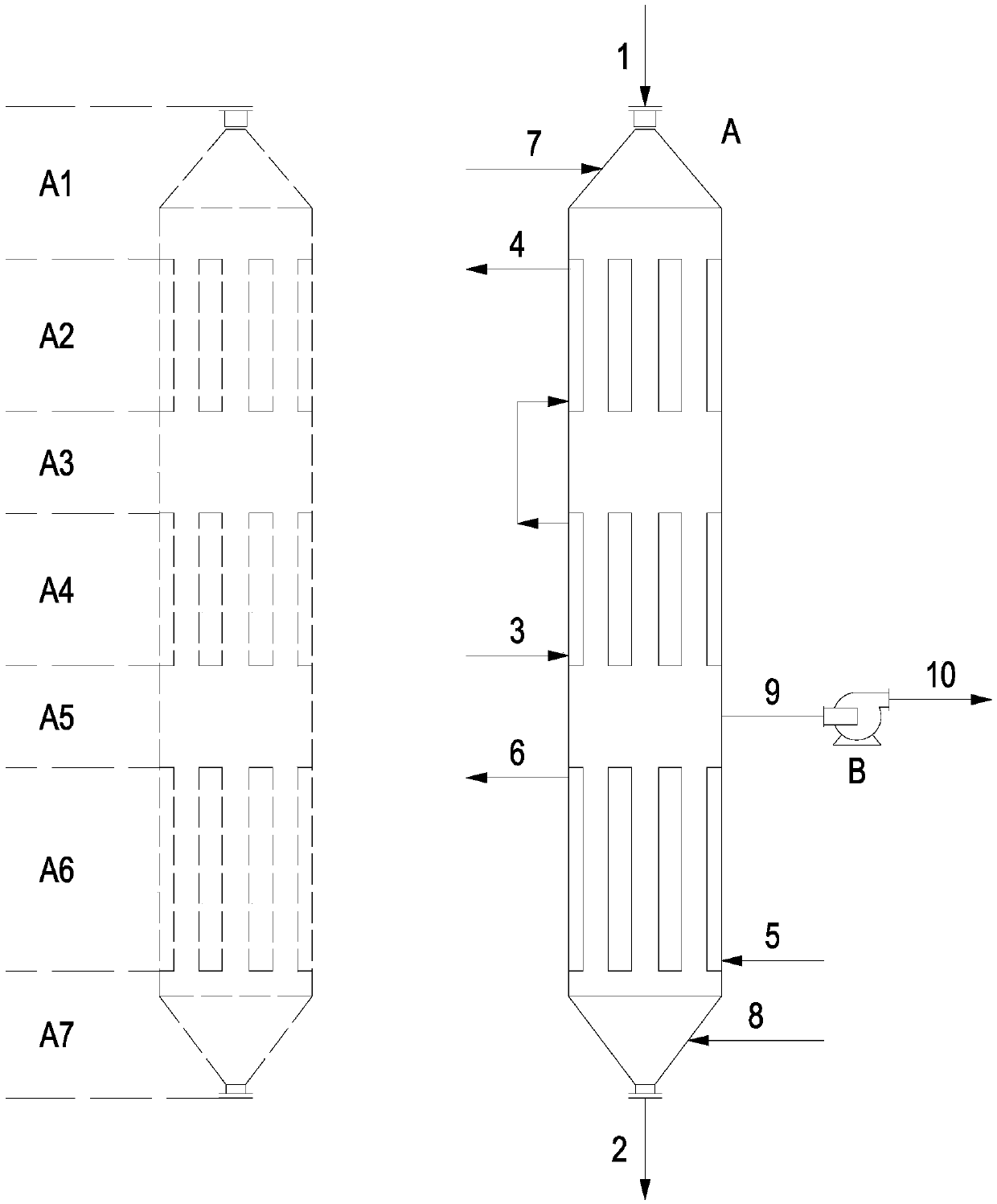

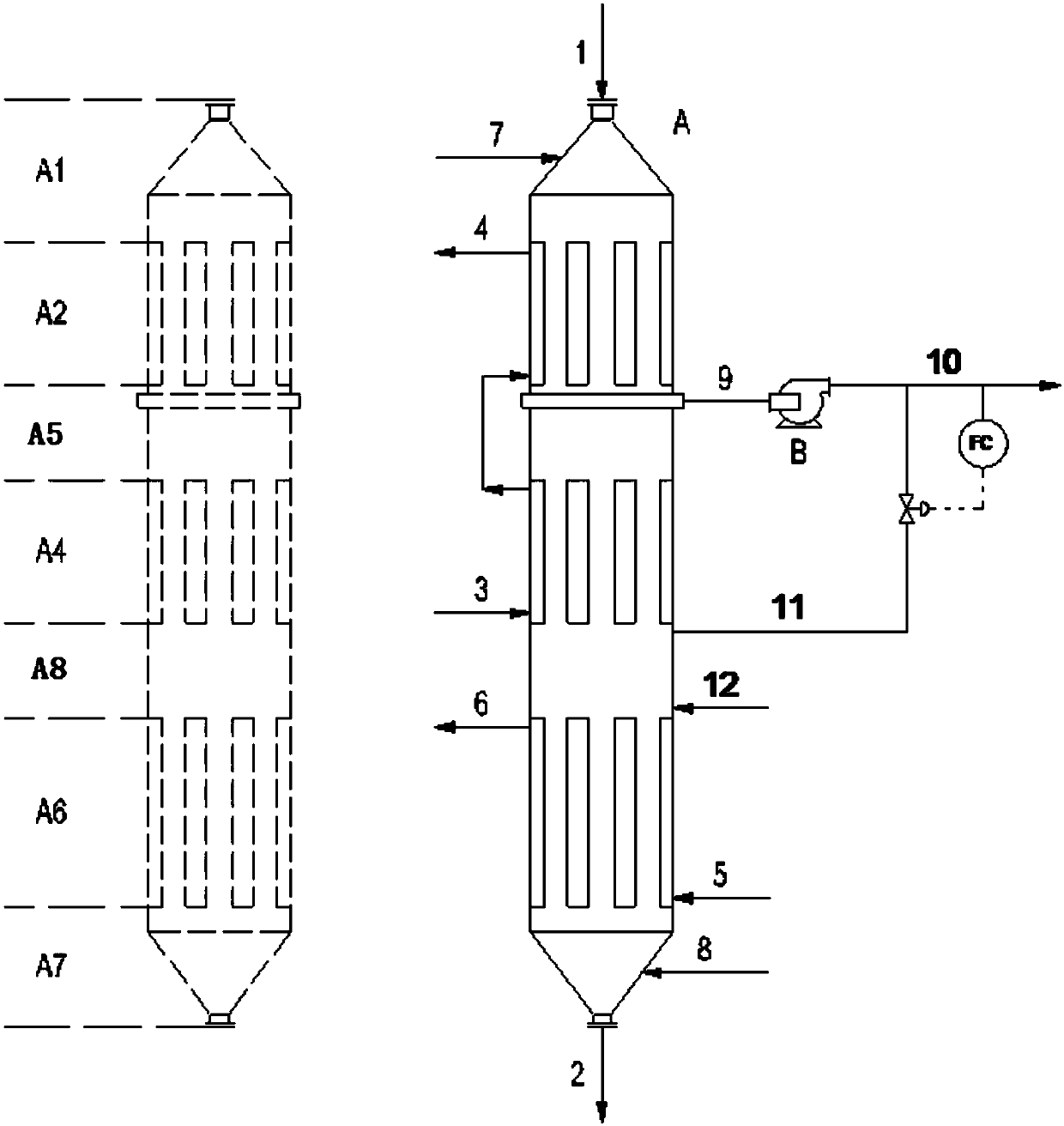

[0054] An active coke regeneration system such as figure 2 As shown, the active coke regeneration system includes: a regeneration tower A and a regeneration fan B; the regeneration tower A is sequentially provided with a feed distribution section A1, a preheating section A2, a regeneration exhaust gas extraction section A5, and a heating section A4 from top to bottom. , redistribution and activation section A8, cooling section A6, and outlet collection section A7; the top of the regeneration tower A is provided with an inlet for raw coke, and the bottom of the tower is provided with a regenerated coke outlet 2; wherein, the top of the feed distribution section A1 is provided with There is a sealed nitrogen inlet; the lower part of the outlet collecting section A7 is provided with a sealed nitrogen inlet.

[0055] Both the preheating section A2 and the heating section A4 are provided with a heating medium outlet at the top and a heating medium inlet at the bottom; the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com