Multipoint centralized dedusting desulphurization denitration apparatus

A technology for desulfurization, denitrification, and centralized dust removal, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of exhaust gas being discharged into the atmosphere, photochemical smog, and separation, and achieves simple structure and improved desulfurization and denitrification efficiency. , the effect of overcoming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

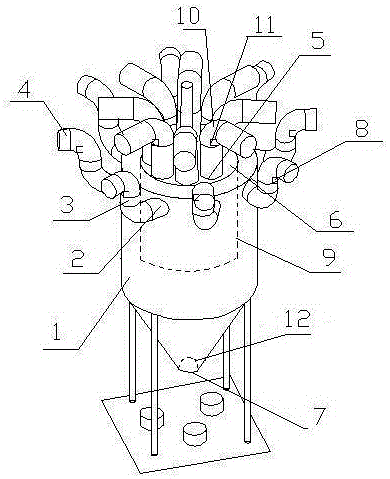

[0017] refer to figure 1 , a multi-point centralized dust removal, desulfurization and denitrification device is provided with a cylinder body 1, a cover plate 6 is provided on the top of the cylinder body 1, a dust discharge port 7 is provided at the bottom of the cylinder body 1, and a circle of air intake is provided on the upper part of the cylinder body 1 Inlet 2 and air inlet 2 are provided with an air intake pipe tangent to the cylinder wall of the cylinder body, the air intake direction of the air intake pipe is set in the same direction along the circumference of the cylinder body 1, and the air intake pipe is connected with the exhaust gas through the upwardly arranged elbow pipe 3. The discharge pipes 4 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com