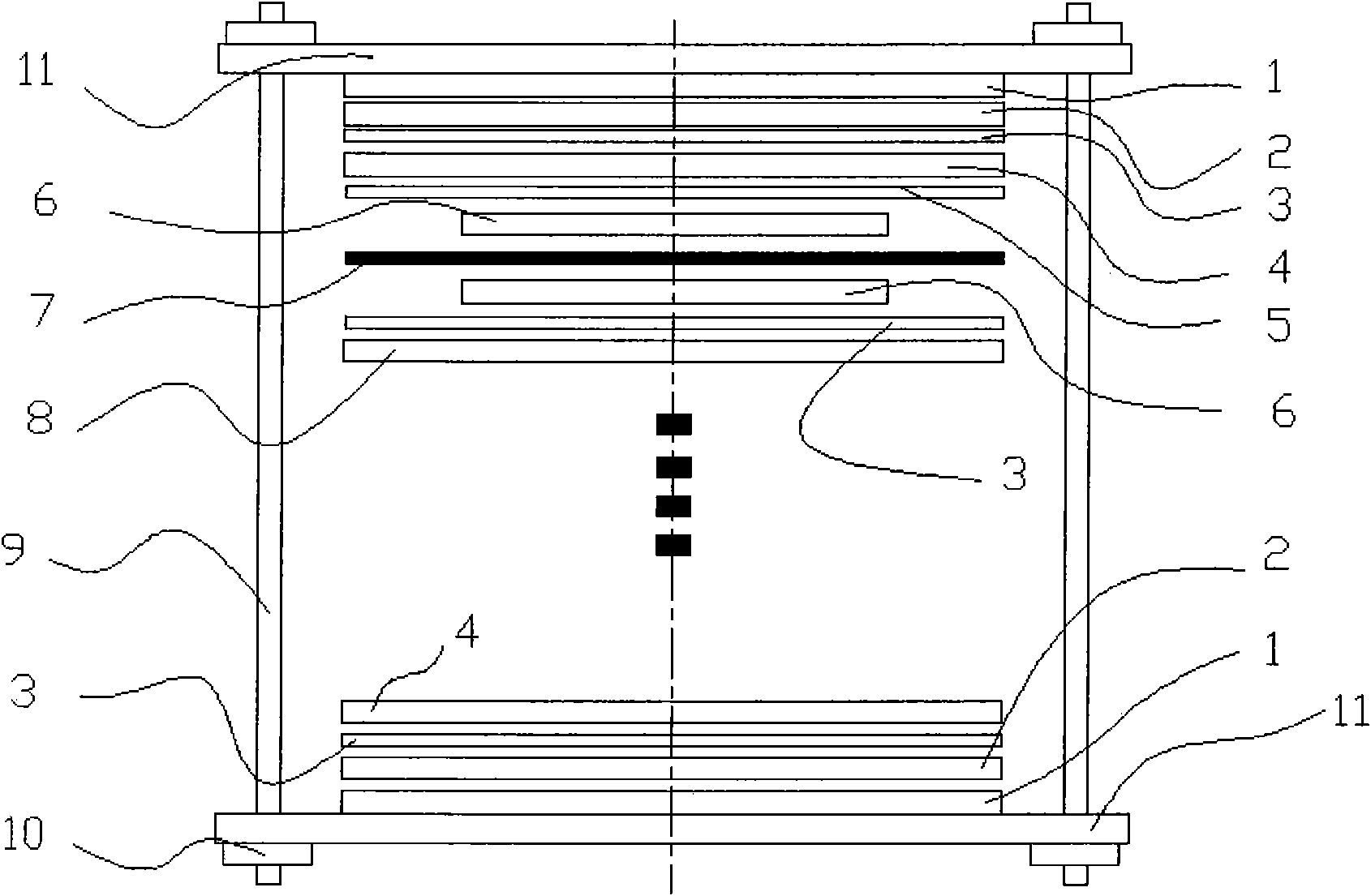

Electrode frame and all-vanadium redox flow battery pile

An electrode frame and electrode technology, applied in fuel cells, secondary batteries, hybrid batteries, etc., can solve problems such as increased electrolyte flow resistance, decreased charge and discharge energy efficiency, and uneven distribution of electrolytes to improve long-term operation stability and life, avoid partial clogging and resistance increase, and improve the effect of charging and discharging energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

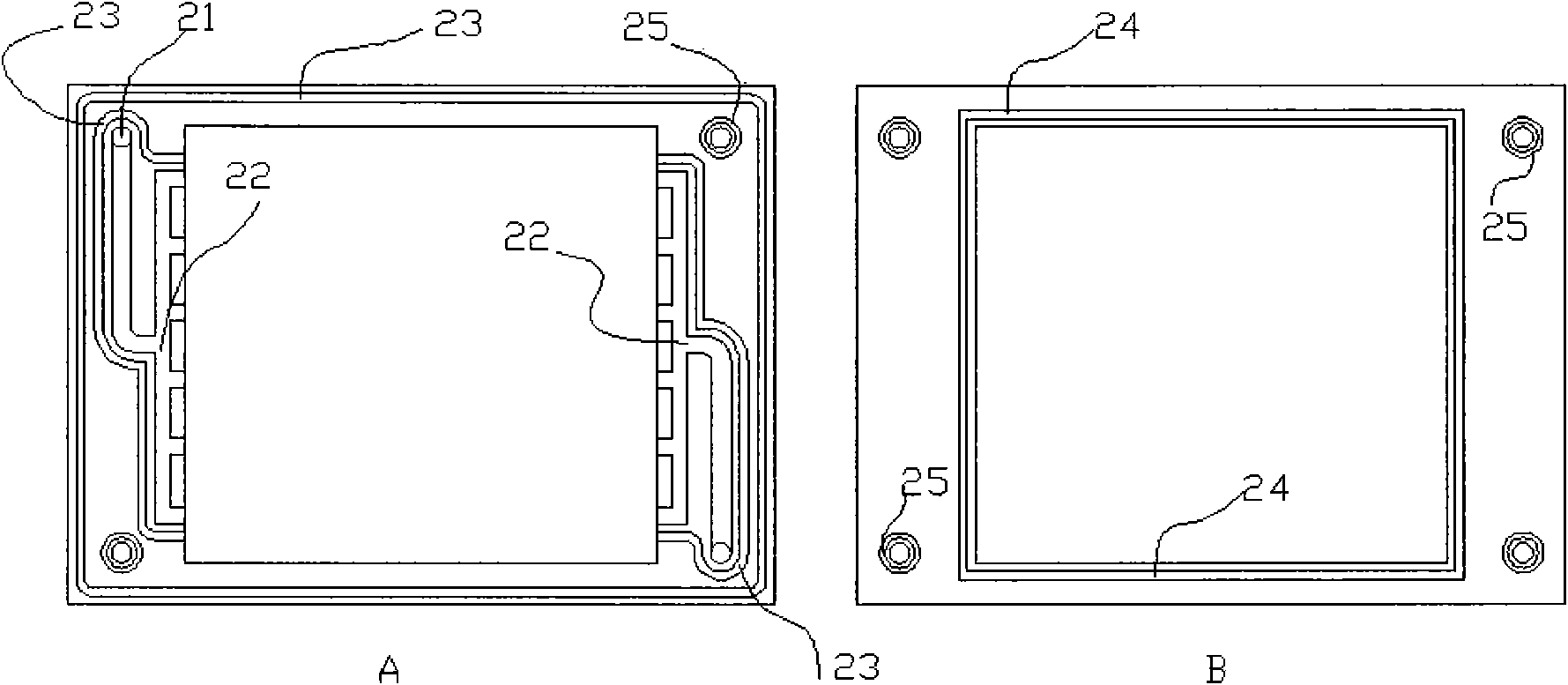

[0026] Electrode frame size: the outer edge of the electrode frame is 1000mm long, 800mm wide, and 5mm thick; the inner edge of the electrode frame is 800mm long and 700mm wide.

[0027] The side of the electrode frame that is in contact with the bipolar plate:

[0028] Adopt line sealing method. Sealing groove size: groove depth 1mm, groove width 3mm. The dimension between the center of the sealing groove and the outer edge of the electrode frame is 6.5mm.

[0029] Sealant strip size: section diameter is 1.5mm.

[0030] The side of the electrode frame that is in contact with the ion exchange membrane:

[0031] Sealing groove size: the groove depth is 1mm, the groove width is 3mm, and the distance between the center of the sealing groove and the inner edge of the electrode frame is 5.5mm.

[0032] Sealant strip size: section diameter is 1.5mm.

[0033] Ion exchange membrane size: length is 810mm, width is 710mm.

[0034] The bipolar plate is a hard graphite plate with a ...

Embodiment 2

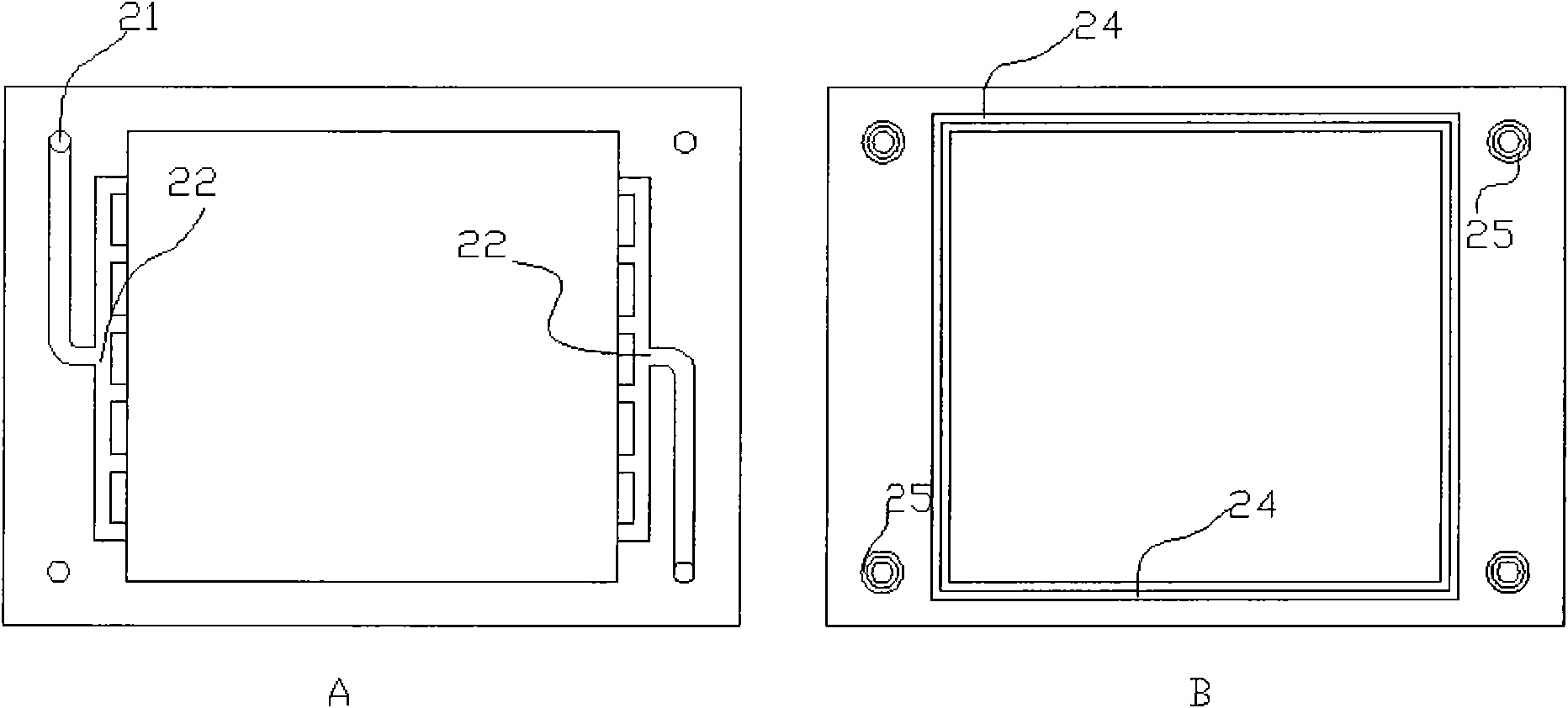

[0039] Electrode frame size: the outer frame is 1000mm long, 800mm wide, and 6mm thick; the inner frame is 800mm long and 700mm wide.

[0040] The side of the electrode frame that is in contact with the bipolar plate:

[0041] The surface sealing method is adopted, and the size of the sealing material and the position of the hole are the same as that of the electrode frame.

[0042] The side of the electrode frame that is in contact with the ion exchange membrane:

[0043] Sealing groove size: the groove depth is 1mm, the groove width is 3mm, and the distance between the center of the sealing groove and the inner edge of the electrode frame is 5.5mm.

[0044] Sealing line size: section diameter is 1.5mm, length is 3036mm.

[0045] Ion exchange membrane size: length is 810mm, width is 710mm.

[0046] The bipolar plate is a hard graphite plate with a length of 1000mm and a width of 800mm.

[0047] The electrode material is carbon felt with a length of 800 mm and a width of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com