Flue gas treatment method

A technology for flue gas treatment and flue gas, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as high nitrogen oxide content, poor flue gas denitration effect, and failure to meet national standards, etc., to achieve strong adsorption Good performance, good desulfurization and denitrification effect, good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

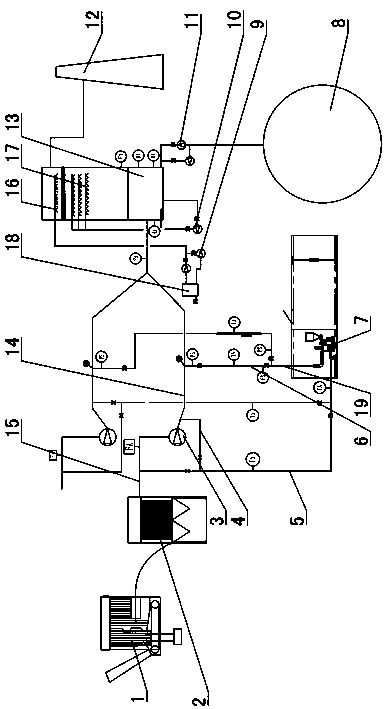

[0066] 1) Dedusting the flue gas of boiler 1;

[0067] The flue gas discharged from the boiler 1 first enters the dust collector 2 to remove the dust in the flue gas, so as to prevent the dust in the flue gas from hindering the mixing of the sodium bicarbonate powder and the flue gas, and affecting the mixing of the sodium bicarbonate powder and the flue gas. Nitrogen oxides and sulfur oxides react, which can also reduce the difficulty of subsequent dust reduction treatment;

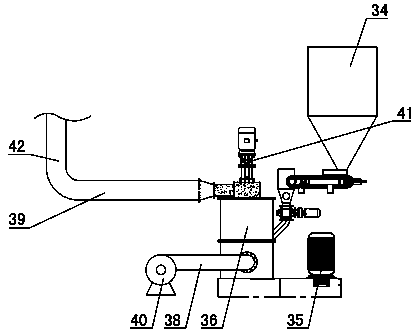

[0068] 2) Extract part of the flue gas, dehumidify the extracted flue gas and send it into the sodium bicarbonate grinding device 7;

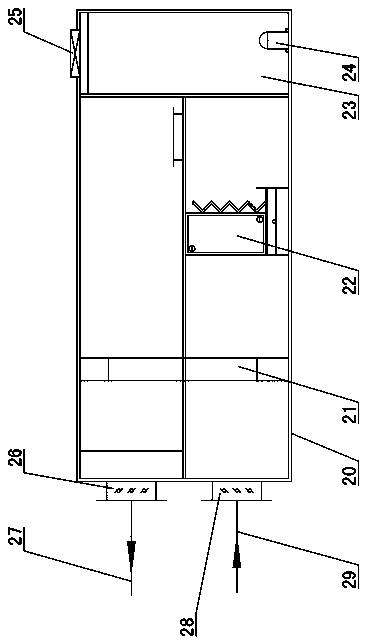

[0069] Part of the flue gas is drawn out of 5% of the flue gas volume through the auxiliary flue 5, and the drawn flue gas enters the dehumidification device, and the flue gas first enters the dehumidification chamber to exchange heat with the lower part of the heat exchanger 21, and then with the The cooler 22 exchanges heat and condenses to condense and liquefy the wat...

Embodiment 2

[0076] 1) Dedusting the flue gas of boiler 1;

[0077] The flue gas discharged from the boiler 1 first enters the dust collector 2 to remove the dust in the flue gas, so as to prevent the dust in the flue gas from hindering the mixing of the sodium bicarbonate powder and the flue gas, and affecting the mixing of the sodium bicarbonate powder and the flue gas. Nitrogen oxides and sulfur oxides react, which can also reduce the difficulty of subsequent dust reduction treatment;

[0078] 2) Extract part of the flue gas, dehumidify the extracted flue gas and send it into the sodium bicarbonate grinding device 7;

[0079] Part of the flue gas is drawn out of 3% of the flue gas volume through the auxiliary flue 5, and the drawn flue gas enters the dehumidification device, and the flue gas first enters the dehumidification chamber to exchange heat with the lower part of the heat exchanger 21, and then with the The cooler 22 exchanges heat and condenses to condense and liquefy the wat...

Embodiment 3

[0085] 1) Dedusting the flue gas of boiler 1;

[0086] The flue gas discharged from the boiler 1 first enters the dust collector 2 to remove the dust in the flue gas, so as to prevent the dust in the flue gas from hindering the mixing of the sodium bicarbonate powder and the flue gas, and affecting the mixing of the sodium bicarbonate powder and the flue gas. Nitrogen oxides and sulfur oxides react, which can also reduce the difficulty of subsequent dust reduction treatment;

[0087] 2) Extract part of the flue gas, dehumidify the extracted flue gas and send it into the sodium bicarbonate grinding device 7;

[0088] Through the secondary flue 5, part of the flue gas is drawn out of the flue gas with 7% of the flue gas volume, and the drawn flue gas enters the dehumidification device, and the flue gas enters the dehumidification chamber first to exchange heat with the lower part of the heat exchanger 21, and then with the The cooler 22 exchanges heat and condenses to condense ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com