Deodorization composition used for processing breeding dung and application thereof

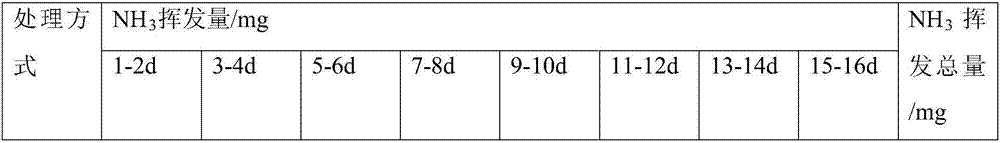

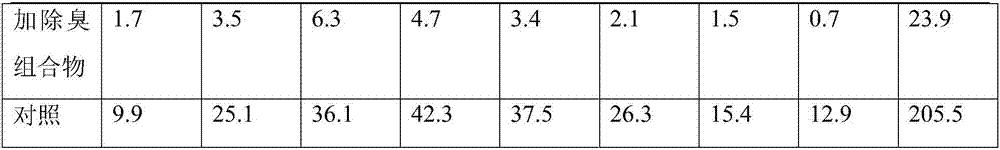

A technology for excrement treatment and composition, which is applied in the field of deodorizing compositions for the treatment of aquaculture excrement, can solve the problems of unstable adsorption performance, single adsorption effect, secondary pollution, etc., and achieves high binding capacity and binding stability and strong reaction. Activity, the effect of reducing the volatilization of NH3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A deodorizing composition for the treatment of farmed excrement, comprising the following components in mass percent:

[0025] Activated biomass supercritical liquefaction residue 55%, activated carbon 15%, bran 15%, calcium acetate 15%.

[0026] Wherein, the preparation method of activated biomass supercritical liquefaction residue comprises the following steps:

[0027] (1) Add pulverized camphor wood chips, ether and sodium carbonate in the high-pressure airtight reactor, the ratio of camphor wood chips, ether and sodium carbonate is 5g: 30mL: 0.03g, carry out liquefaction reaction under nitrogen atmosphere, the liquefaction temperature is 300 ℃, the pressure is 8MPa, and the time is 1h. After the liquefaction is completed, the residue left after filtering off the liquefied oil is the biomass supercritical liquefaction residue;

[0028] (2) Lay the biomass supercritical liquefaction residue obtained in step (1) on a circulating fluidized bed, and bake it under a nit...

Embodiment 2

[0037] A deodorizing composition for the treatment of farmed excrement, comprising the following components in mass percent:

[0038] Activated biomass supercritical liquefaction residue 50%, activated carbon 20%, bran 15%, calcium acetate 15%.

[0039] Wherein, the preparation method of activated biomass supercritical liquefaction residue comprises the following steps:

[0040] (1) Add pulverized Chinese fir chips, acetone and sodium carbonate in the high-pressure airtight reactor, the ratio of Chinese fir chips, acetone and sodium carbonate is 5g: 50mL: 0.03g, carry out liquefaction reaction under nitrogen atmosphere, the liquefaction temperature is 300 ℃, the pressure is 10MPa, and the time is 30min. After the liquefaction is completed, the residue left after filtering off the liquefied oil is the biomass supercritical liquefaction residue;

[0041](2) Lay the biomass supercritical liquefaction residue obtained in step (1) on a circulating fluidized bed, and bake it under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com