Dry-method desulphurization denitration integrated treatment method

A treatment process, dry desulfurization technology, applied in gas treatment, auxiliary pretreatment, inorganic chemistry, etc., can solve problems such as inability to stimulate catalysts to release electrons and vacancy redox, high temperature, and difficult separation of desulfurization and denitrification products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

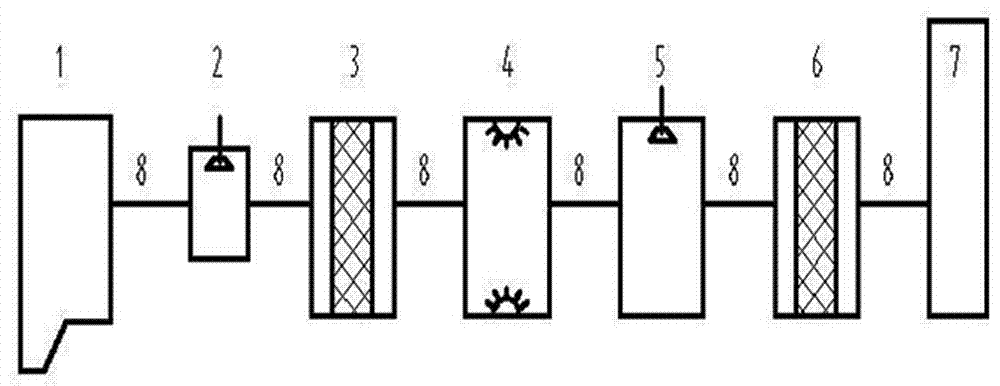

[0021] Integrated dry desulfurization and denitrification process (see figure 1 ),details as follows.

[0022] Step (1): After the flue gas passes through the dust collector, it is atomized and humidified by the atomizer.

[0023] Step (2), adsorption desulfurization: the humidified flue gas enters the desulfurization device equipped with a foamed adsorption block, after 0.5s, the sulfur dioxide is completely adsorbed.

[0024] Step (3), photocatalysis and decomposition: the flue gas after desulfurization enters the photocatalytic oxidation device to decompose the NOx in the flue gas into N 2 And O 2 , Will produce some O 3 ; There is also part of the NO produced by the photocatalytic process of O 3 Oxidized to NO 2 .

[0025] Step (4), adsorption and denitrification: the flue gas after photocatalytic decomposition is atomized and humidified and then enters the denitrification device equipped with a foamed adsorption block. After the nitrogen dioxide is completely adsorbed by the adso...

Embodiment 2

[0028] The raw materials of the foamed adsorption block are as follows by weight: 65% magnesium oxide, 10% magnesium sulfate, 10% magnesium chloride, 3% phosphoric acid, 10% glass fiber, 0.5% rubber powder, 1.5% hydrogen peroxide.

Embodiment 3

[0030] The raw materials of the foamed adsorption block are as follows by weight: 80% calcium carbonate and 20% high-fine cement.

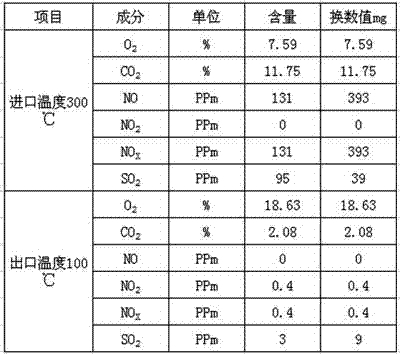

[0031] 1. After using the foamed adsorption block of Example 1 above to desulfurize and denitrate the flue gas of Dashiqiao Qinghua Group (the inlet and outlet flue gas velocity is 350m 3 / h), the test results are shown in Table 1.

[0032] Table 1. The content of sulfur and nitrogen compounds before and after flue gas treatment.

[0033]

[0034] It can be seen from the table that the dry high-efficiency desulfurization and denitrification process has high desulfurization and denitrification efficiency and meets the standard requirements for air pollutant emission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com