Impregnation process biomass-based active coke and preparation method thereof

A technology based on activated coke and biomass, applied in the field of active coke, can solve the problems of various raw materials, high energy consumption and cost, environmental pollution, etc., and achieve reduction of production energy consumption and time cost, controllable pore structure size, comprehensive high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

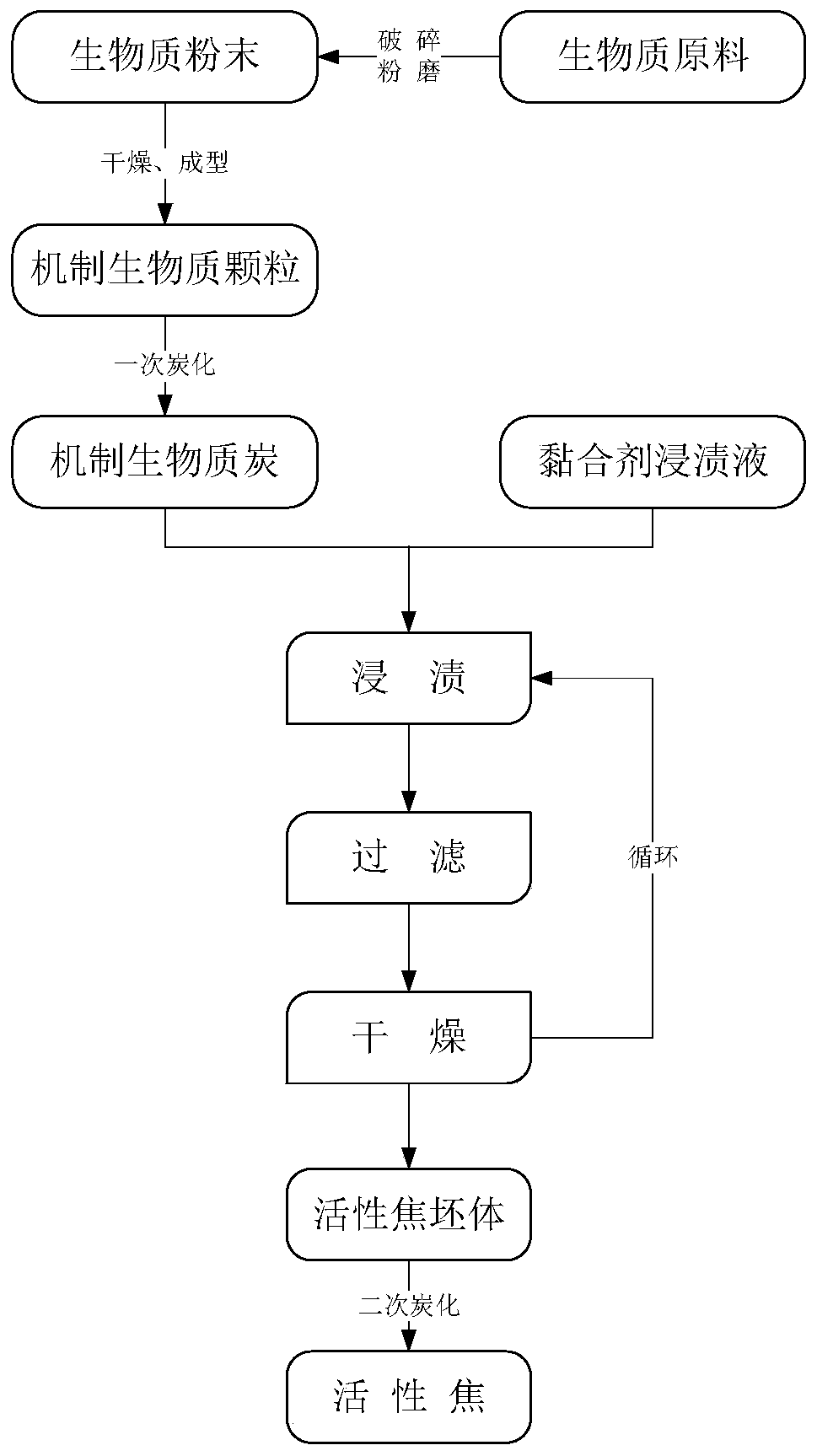

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Crushing and grinding coconut shells to coconut shell powder with a particle size of ≤1.25mm, and then drying until the moisture content is lower than 15%.

[0040] Step 2: The above-mentioned coconut shell powder is granulated and formed by a flat mill granulator to obtain mechanism coconut shell particles.

[0041] Step 3: Under the protection of a nitrogen atmosphere, the coconut shell particles of the above-mentioned mechanism are carbonized at a temperature increase rate of 5°C / min, and the final carbonization temperature is 550°C. The carbonization time maintained at the final carbonization temperature is 3.0h; After natural cooling, the mechanism coconut shell charcoal is obtained.

[0042] Step 4: Soak the above mechanism coconut shell charcoal in the phenolic resin emulsion with a solid content of 45wt% by the supersaturated impregnation method, wait for the adsorption to be saturated, filter and dry to obtain the active coke body, and repeat the impreg...

Embodiment 2

[0046] Step 1: crushing and grinding bamboo processing leftovers to bamboo powder with a particle size of ≤0.83mm, and then drying until the moisture content is lower than 25%.

[0047] Step 2: The above-mentioned bamboo powder is granulated by a ring mill granulator to obtain machine-made bamboo granules.

[0048] Step 3: Under the protection of a nitrogen atmosphere, the above-mentioned machine-made bamboo particles are carbonized at a heating rate of 2°C / min, and the final carbonization temperature is 600°C, and the carbonization time maintained at the final carbonization temperature is 1.0h; The machine-made bamboo charcoal is obtained after cooling.

[0049]Step 4: Soak the above-mentioned mechanism bamboo charcoal in an aqueous solution of sodium lignosulfonate with a concentration of 25wt% by supersaturated impregnation method, wait for the adsorption to be saturated, filter and dry to obtain an active coke body, and repeat the impregnation several times until the activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com