Desulfurization and denitrification device and method

A desulfurization, denitrification, and inlet technology, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve problems such as secondary pollution, difficulty in meeting discharge requirements, ammonia escape, etc., and meets environmental protection standards. effect, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

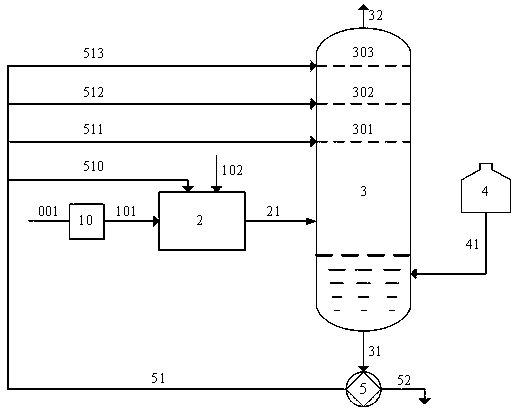

[0050] according to image 3 The device performs continuous desulfurization and denitrification of the gas to be treated. The solid-liquid separator 5 is a circulating pump.

[0051] The gas to be treated is a flue gas with a temperature of 800~1000°C, and the dioxin contained in it is 0.001ng / m 3 , NO is 400mg / Nm 3 , SO 2 6000mg / Nm 3 , particulate matter is 63.1mg / m 3 .

[0052] The absorbent is an aqueous solution of ferrous cysteine, its molar concentration is 0.1mol / L, the molar ratio between ferrous ions and cysteine is 1:4, and the lye is sodium hydroxide and sodium hydrosulfide A mixed aqueous solution in which the molar ratio between sodium hydroxide and sodium hydrosulfide is 1:0.5. The pH of the lye is 9.2.

[0053] The flue gas is continuously input into this desulfurization and denitrification device. The flue gas enters the refrigeration device 10 through the pipeline 001, the temperature of the flue gas is dropped to 80°C suddenly, and then enters the ...

Embodiment 2

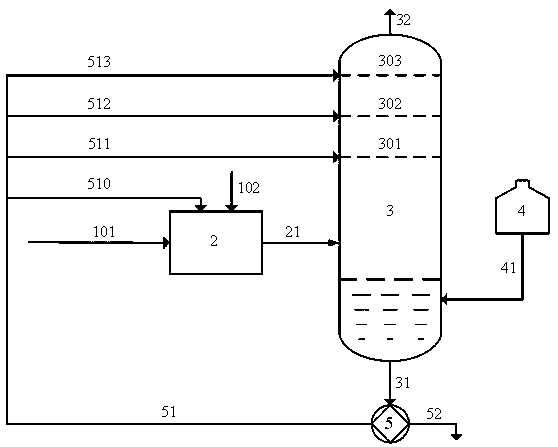

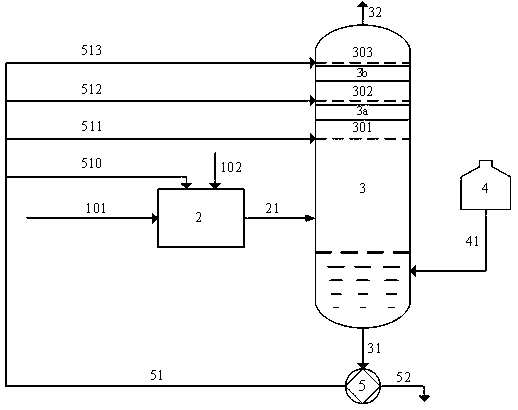

[0061] according to figure 2 The device performs continuous desulfurization and denitrification of the gas to be treated. figure 2 Activated carbon filler is used in the device, and its specific surface area is 1200m 2 / g.

[0062] The gas to be treated is a flue gas with a temperature of 800~1000°C, and the dioxin contained in it is 0.001ng / m 3 , NO is 400mg / Nm 3 , SO 2 6000mg / Nm 3 , particulate matter is 63.1mg / m 3 .

[0063] The absorbent is an aqueous solution of ferrous cysteine, its molar concentration is 0.1mol / L, the molar ratio between ferrous ions and cysteine is 1:4, and the lye is sodium hydroxide and sodium hydrosulfide A mixed aqueous solution in which the molar ratio between sodium hydroxide and sodium hydrosulfide is 1:0.5. The pH of the lye is 9.2.

[0064] The flue gas is continuously input into this desulfurization and denitrification device. The flue gas enters the absorption reactor 2 through the inlet 101, and the fresh absorbent enters the ...

Embodiment 3

[0067] according to Figure 5 The device performs continuous desulfurization and denitrification operation of flue gas to be treated. Figure 5 Activated carbon filler is used in the device, and its specific surface area is 1200m 2 / g.

[0068] The gas to be treated is a flue gas with a temperature of 800~1000°C, and the dioxin contained in it is 0.001ng / m 3 , NO is 400mg / Nm 3 , SO 2 6000mg / Nm 3 , particulate matter is 63.1mg / m 3 .

[0069] The absorbent is an aqueous solution of ferrous cysteine, its molar concentration is 0.1mol / L, the molar ratio between ferrous ions and cysteine is 1:4, and the lye is sodium hydroxide and sodium hydrosulfide A mixed aqueous solution in which the molar ratio between sodium hydroxide and sodium hydrosulfide is 1:0.5. The pH of the lye is 9.2.

[0070] The flue gas is continuously input into this desulfurization and denitrification device. The flue gas is divided into two branch inlets through the pipeline 001, one is the inlet 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com