Desulfurization and low-temperature denitration system and process for clean flue gas emission

A low-temperature denitration and desulfurization system technology, applied in the field of desulfurization and low-temperature denitration systems, can solve the problems of high energy consumption and increase the resistance of flue gas, and achieve the effects of reducing emissions, high dust removal rate and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

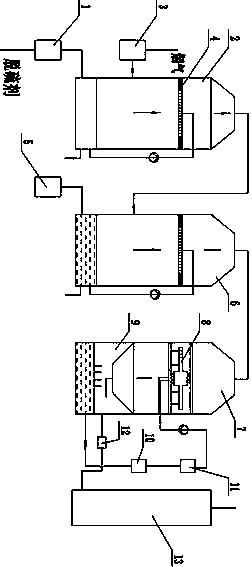

[0030] see figure 1 , the desulfurization and low-temperature denitrification system and process for clean flue gas discharge in the illustration are preferred embodiments of the present invention, including a desulfurization system, a denitrification system, a flue gas washing system and a flue gas discharge system. The desulfurization system consists of a desulfurization absorption tower, a desulfurization The denitrification system consists of a denitrification absorption tower, an ozone generator, etc. The flue gas washing system consists of a cooling scrubber and a washing water supply system, and the cooling scrubber is a water spray tower; the flue gas discharge system includes a chimney , the cleaned flue gas is finally discharged through the chimney.

[0031] In this example, flue gas desulfurization by magnesium method and denitrification by ozone oxidation method are adopted. The specific process is as follows:

[0032] After the purchased MgO powder is matured and...

example 1

[0048] Flue gas condition: 100000 Nm3 / h; SO 2 Concentration 800 mg / L; NO concentration 300mg / L; dust concentration 50 mg / L; boiler flue gas temperature: 120°C.

[0049] Measured after the steps of the foregoing examples:

[0050] The temperature after the absorption tower: 55°C and 43°C; the temperature after the low-temperature washing tower: 28°C;

[0051] SO after flue gas cleaning 2 Concentration 0.8mg / L; NO concentration 2.1mg / L; dust concentration 0.3mg / L.

[0052] Desulfurization efficiency: 99.8%; denitrification efficiency: 99.3%; dust removal efficiency: 99.8%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com