Dust suppression device and dust suppression method during molten iron open-air transportation

A molten iron and open-air technology, which is applied in cleaning methods and appliances, chemical instruments and methods, and dust removal, etc., can solve the problems of reducing the yield of molten iron metal, high initial investment of dust removal system, high operating cost of dust removal system, etc., and achieves good results Dust suppression effect, low manufacturing and installation costs, and improved metal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

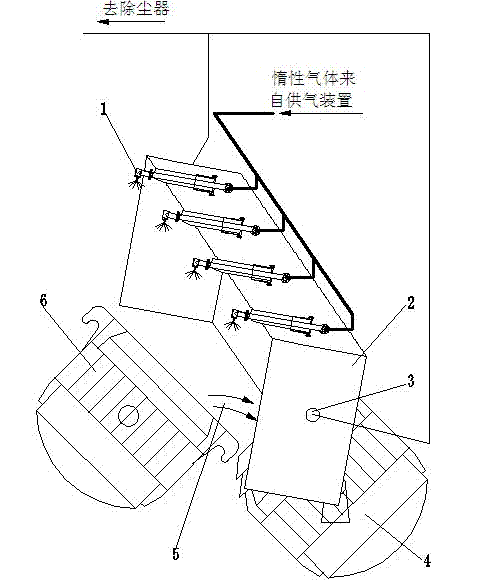

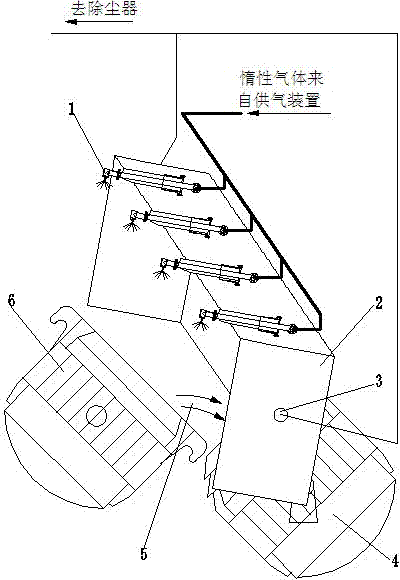

[0019] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the dust suppression device for open-air transfer of molten iron in this embodiment includes an inert gas nozzle 1 and a gas supply device that provides pressure inert gas for the inert gas nozzle 1, and the inert gas nozzle is facing The open-air flow area 5 of molten iron is distributed on the upper part of the molten iron transfer port.

[0020] In this embodiment, it also includes a dust removal cover 2 covering the upper part of the molten iron flow-through area 5, and the inert gas nozzle 1 is fixedly arranged on the dust removal cover 2; the structure of the dust removal cover 2 is adopted to make the molten iron flow-through area 5 relatively closed, It can significantly reduce the consumption of inert gas, and is conducive to generating sufficient positive pressure in the cover to prevent the entry of outside air and improve the dust suppression effect.

[0021] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com