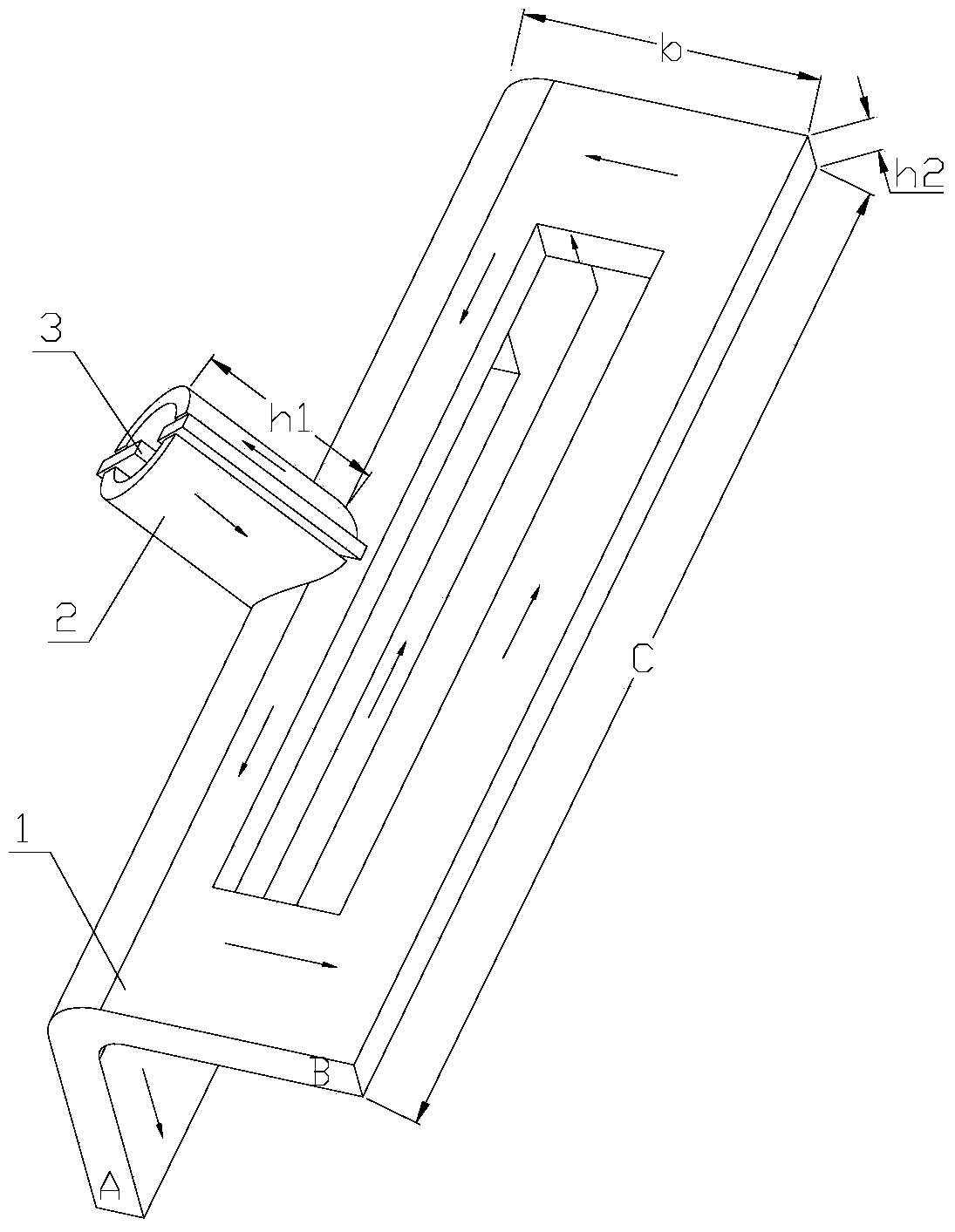

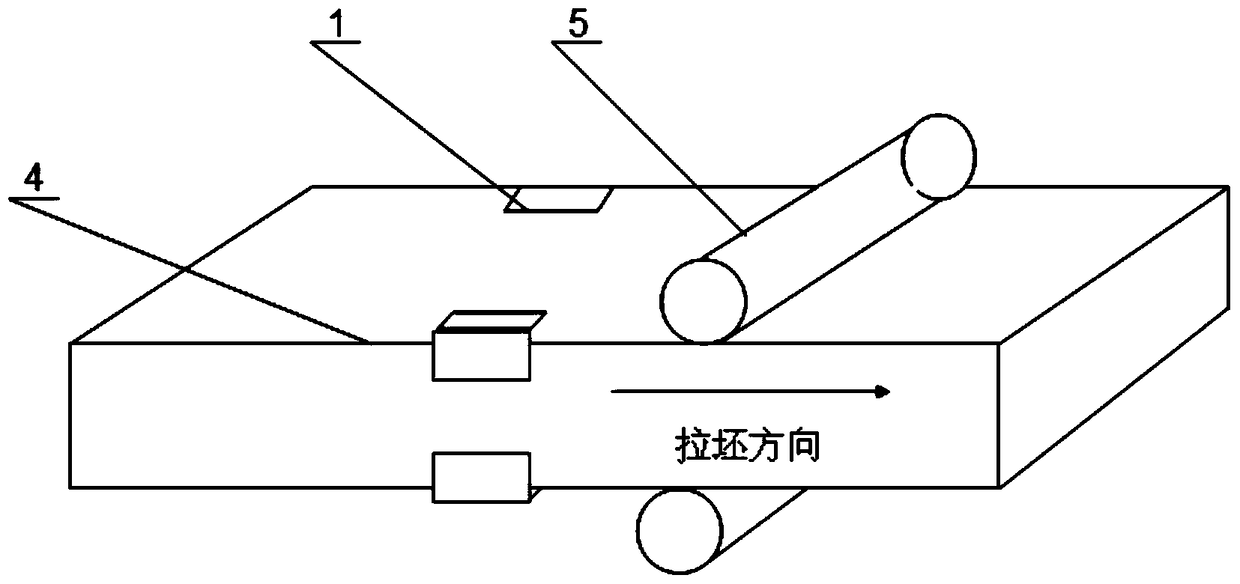

A device and method for reducing cracks at the corners of microalloyed slabs

A corner crack and micro-alloying technology, applied in the field of continuous casting, to achieve the effects of increasing metal yield, preventing overcooling, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]When heating the low-carbon steel slab containing Nb=0.005%, N=0.0031% and microalloyed, the precipitation temperature of NbN can be calculated according to the solubility product of NbN nitride in steel at 910°C. Before straightening, a large amount of NbN is precipitated on the austenite grain boundary to increase the crack sensitivity of the slab to prevent corner cracks, and finally adjust the power of the induction heating coil to 60kW to ensure that the temperature of the corner can be raised to 950 before straightening °C is enough. Since NbN is relatively sensitive to cracks, in order to achieve a good heating effect at the deeper corners of the slab, the frequency of the power supply is adjusted to a relatively low frequency mode of 5000 Hz.

Embodiment 2

[0044] When heating the micro-alloyed low-carbon steel slab containing V=0.01%, N=0.0035%, the precipitation temperature of VN can be calculated at 772°C according to the solubility product of VN nitrides in steel, because the precipitation temperature of VN Relatively low, the power of the induction heating coil is finally adjusted to 30kW to ensure that the temperature at the corner can be raised to 800°C before straightening. Since VN is less sensitive to cracks than NbN, it can be used at relatively low power 15000Hz high frequency heating mode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com