Casting equipment and method for steel ingots for wide and thick plates

A technology of casting equipment and wide and thick plates, which is applied in the field of metallurgy and casting, can solve the problems of insufficient cap mouth feeding capacity, long cap mouth feeding distance, and reduced metal yield, so as to improve thermal insulation capacity and reduce cap capacity Ratio, the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

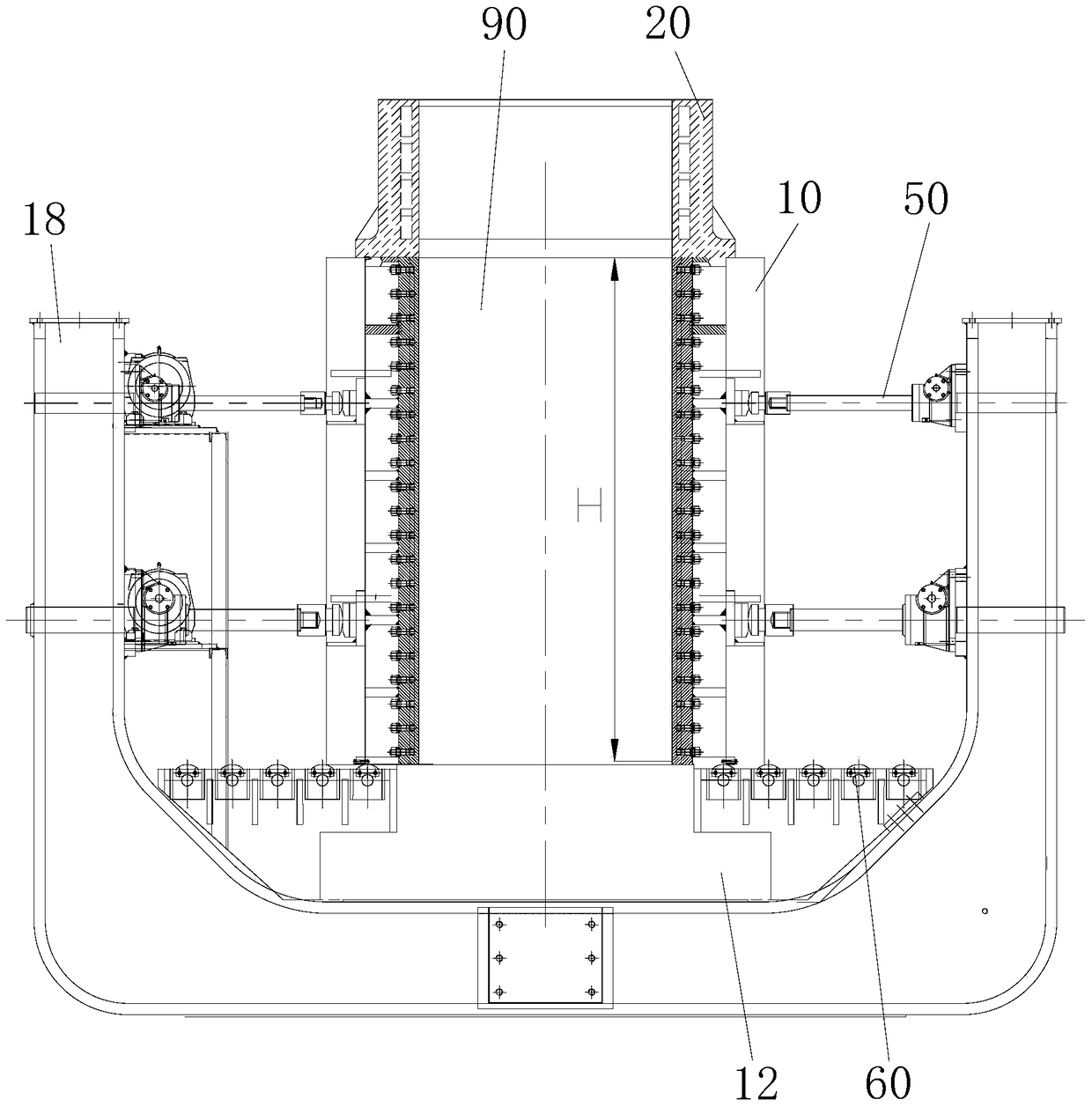

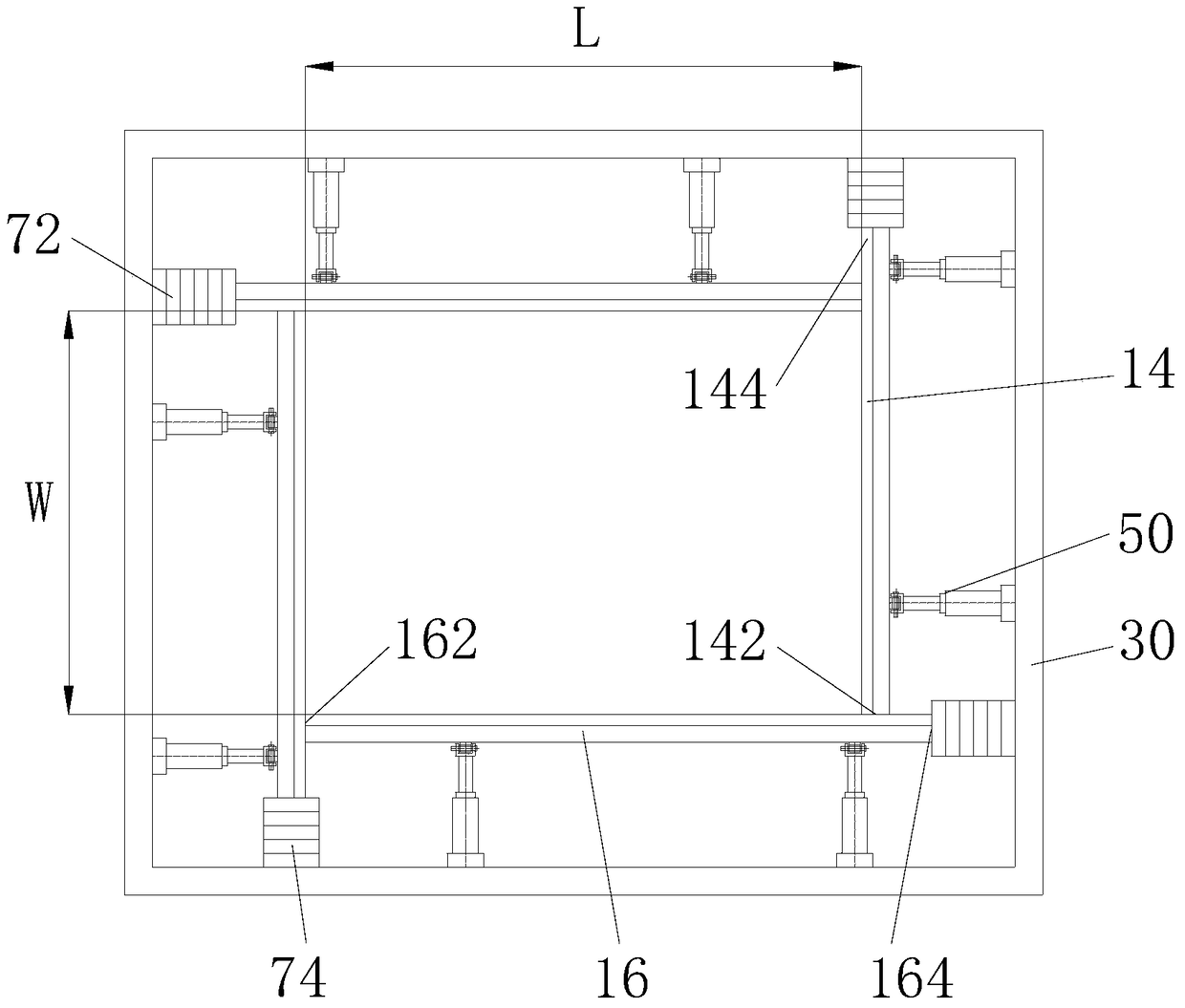

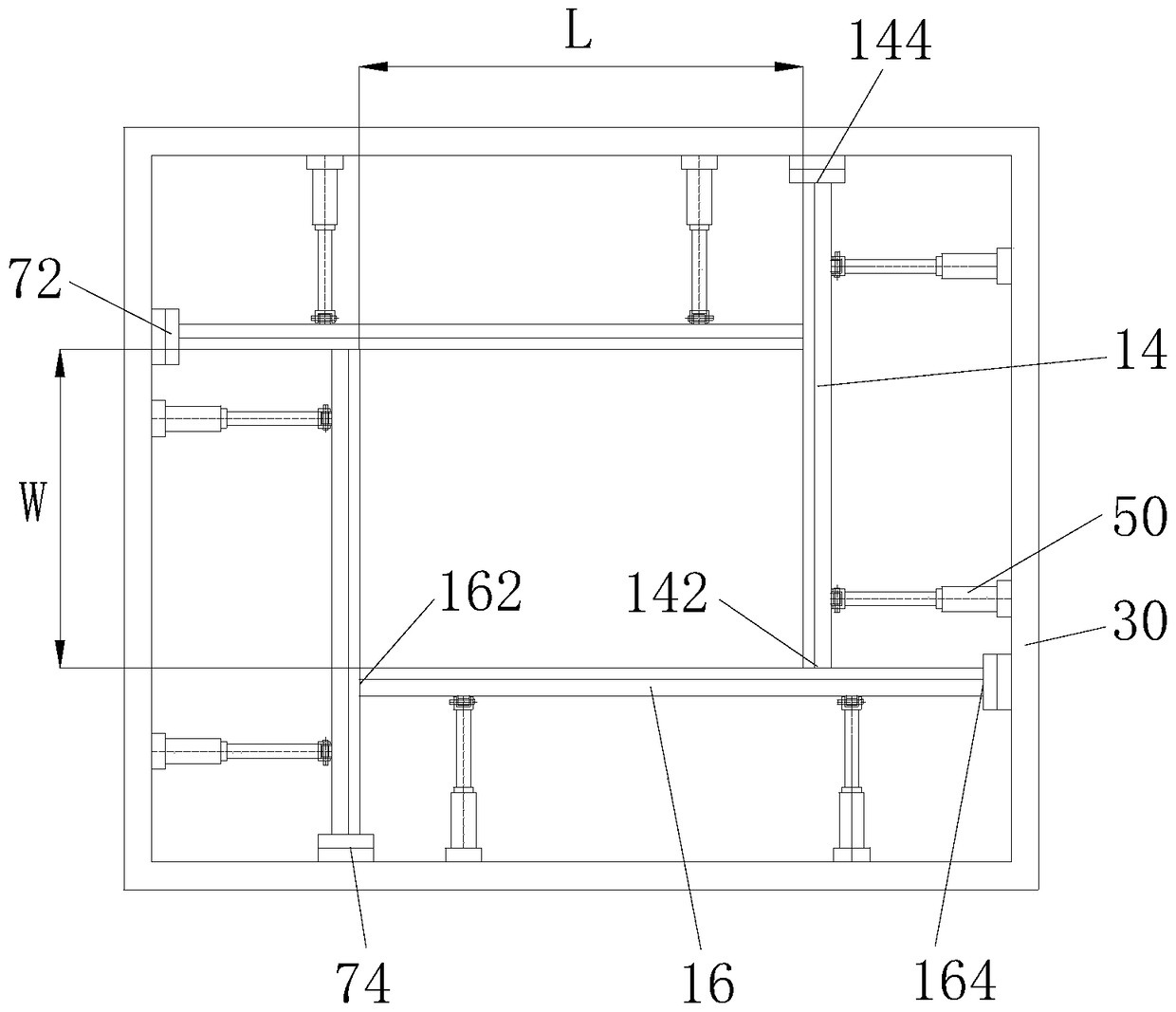

[0051] see figure 1 As shown, a casting equipment for steel ingots for wide and thick plates of the present invention includes a mold body 10 for accommodating and solidifying steel ingots 90, please refer to figure 2 with image 3 As shown, the mold body 10 includes: a pouring chassis 12 with a runner and an enclosing wall vertically connected to the pouring chassis 12, and the enclosing wall and the pouring chassis 12 are sealed to form a casting cavity with an upper opening. The enclosing wall includes two first vertical plates 14 and two second vertical plates 16 arranged at intervals relative to each other, and the first vertical plates 14 and the second vertical plates 16 abut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com