Casting device and casting method for large-section castings

A large-section, casting technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of segregation component removal, casting performance degradation, etc., to reduce the aspect ratio, shorten the feeding distance, easy to find and The effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

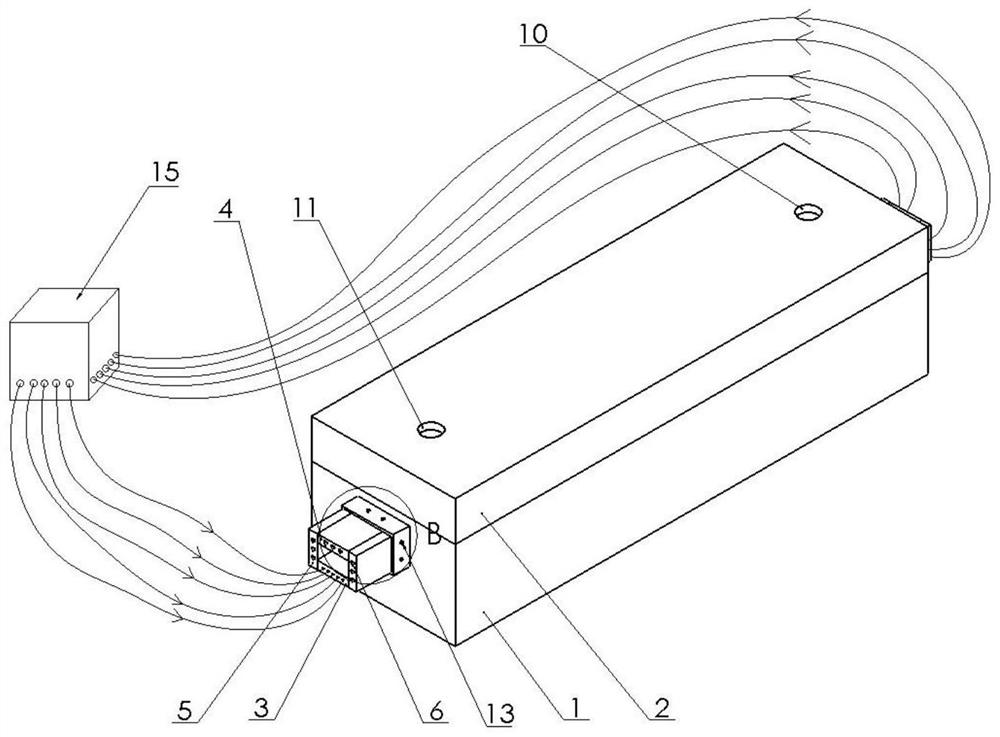

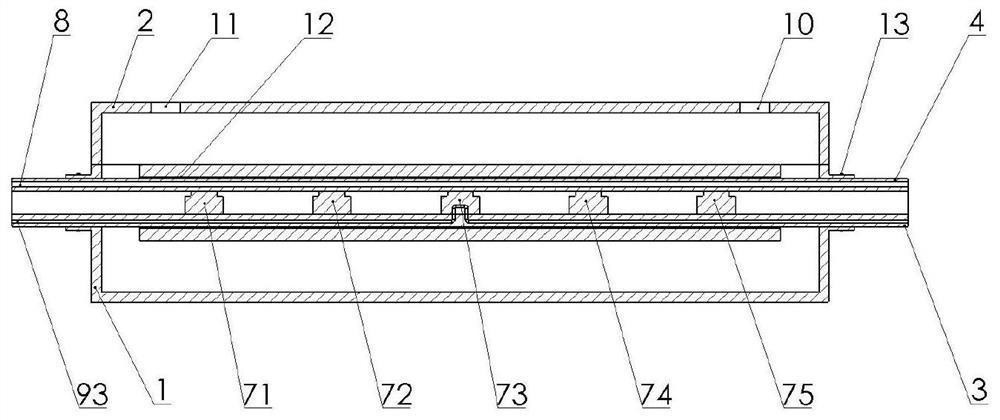

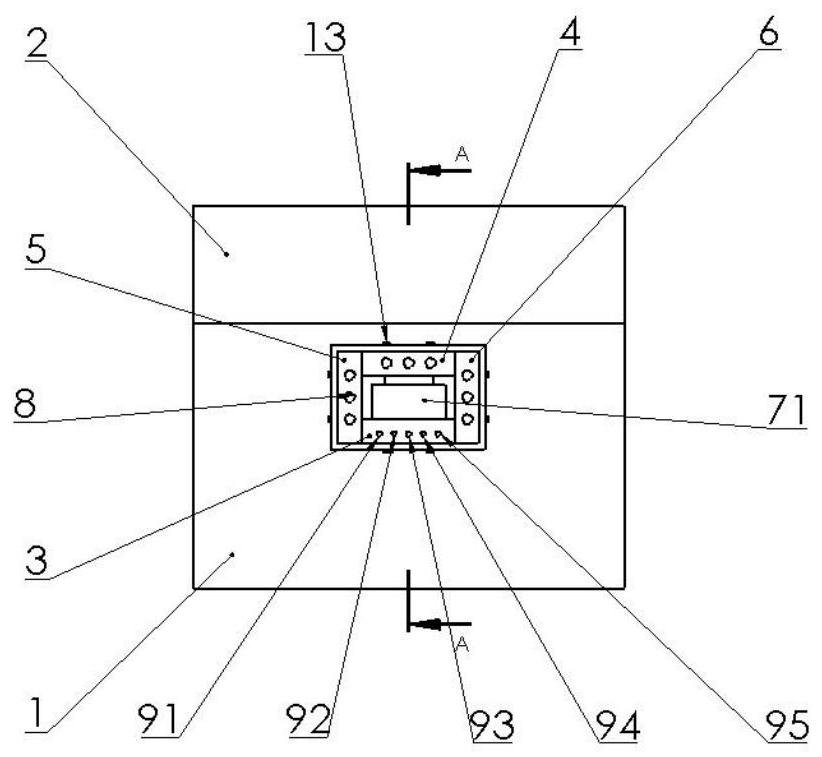

[0038] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

[0039] Casting devices for large-section castings, such as figure 1 and figure 2 As shown, it includes a sandbox, a hydraulic metal plate 3, a water-cooled metal plate, a hydraulic jack, a water-cooled pipeline, a hydraulic oil pipeline, a right runner 10, a left riser 11, a heat-resistant coating 12, a fixing component 13, and a controller and casting 16.

[0040] like figure 1 As shown, the sandbox, which includes an upper sandbox 2 and a lower sandbox 1, is composed of a bottom plate and an enclosure plate. The bottom plate and the enclosure plate of the lower sandbox 1 form a concave box with an upward opening, and the enclosure plates at the left and right ends of the lower sandbox 1 Respectively provide rectangular holes, the rectangular holes are fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com