Preparation process of a nickel-based superalloy with high content of refractory elements

A nickel-based superalloy and preparation process technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve problems such as abnormal compositional segregation, tissue heritability, etc. The effect of the uniform problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

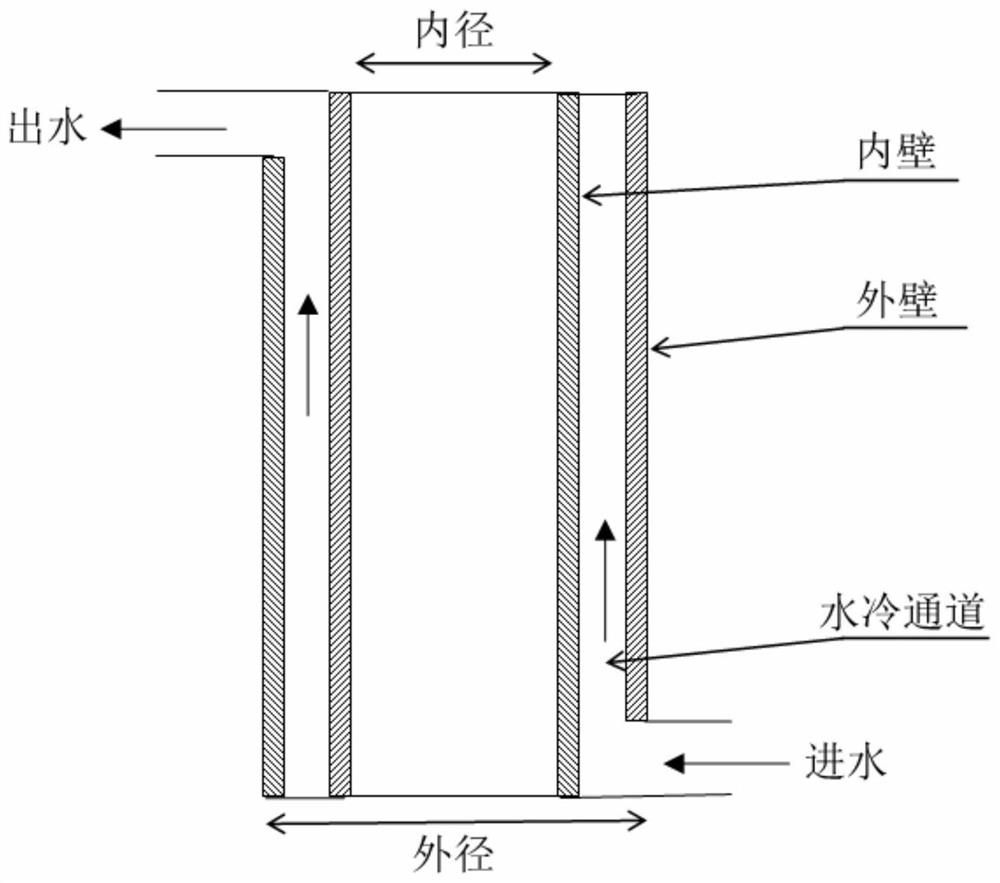

[0044] In this example, a high-W alloyed nickel-based superalloy was prepared by the VIM+ESR process. The composition of the alloy ingredients is shown in Table 1, wherein the W element is a refractory element with a content of 16wt.%. In this embodiment, an alloy material ingot (master alloy ingot) is firstly prepared by a vacuum induction melting process, and then electroslag remelting (ESR) is performed on the master alloy ingot to obtain the nickel-based superalloy with a high content of refractory elements; the The process specifically includes the following steps:

[0045] (1) Feeding to ensure stable carbon alloying and preliminary deoxidation:

[0046] Clean the inside of the crucible, add carbon element raw materials to the bottom of the crucible, then add all other element raw materials (cobalt, chromium, nickel, niobium, hafnium) except aluminum, titanium and W, and finally add refractory element W to the upper part of the crucible It is added in the form of master...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com