Patents

Literature

51results about How to "Suppression of segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

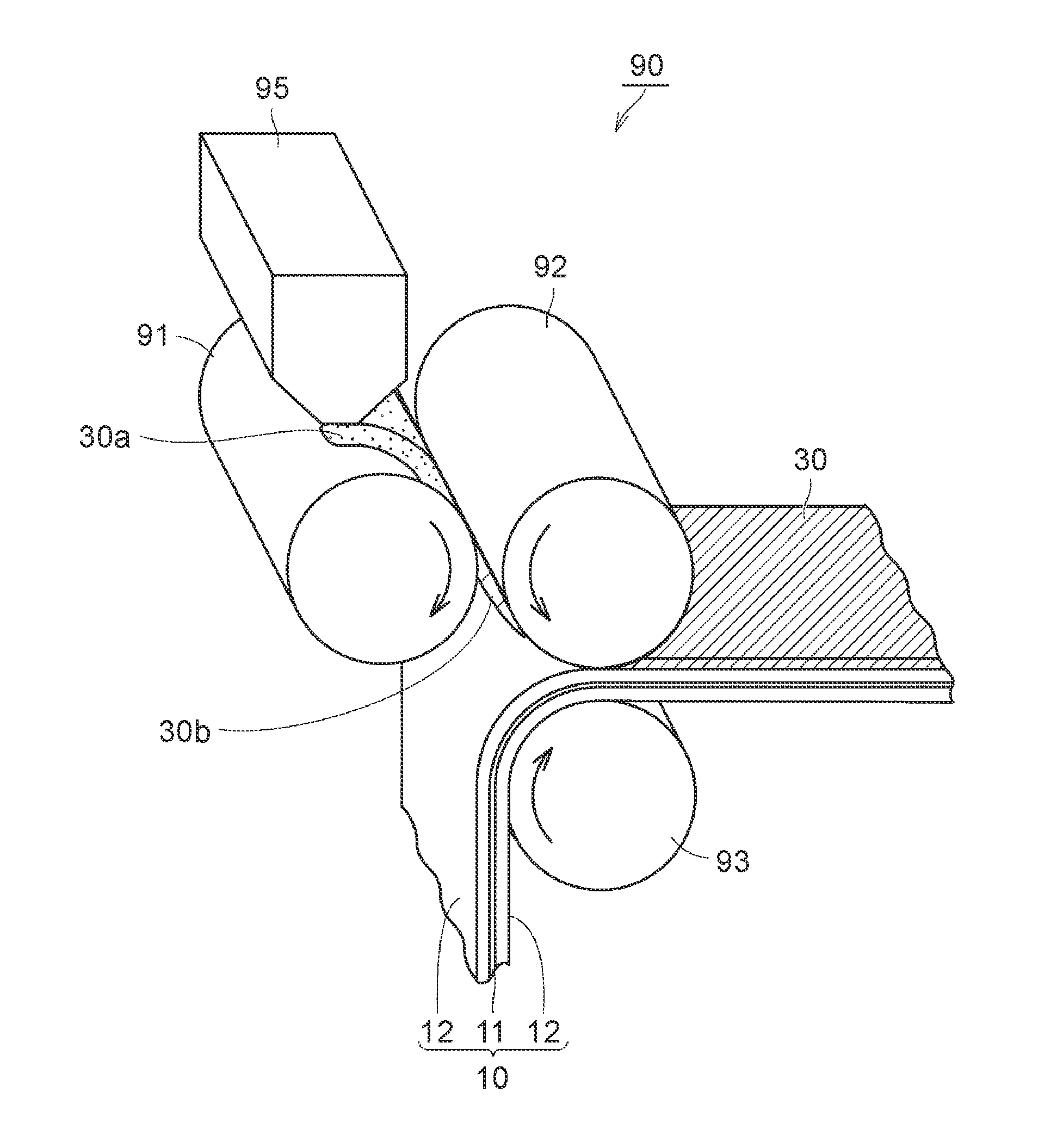

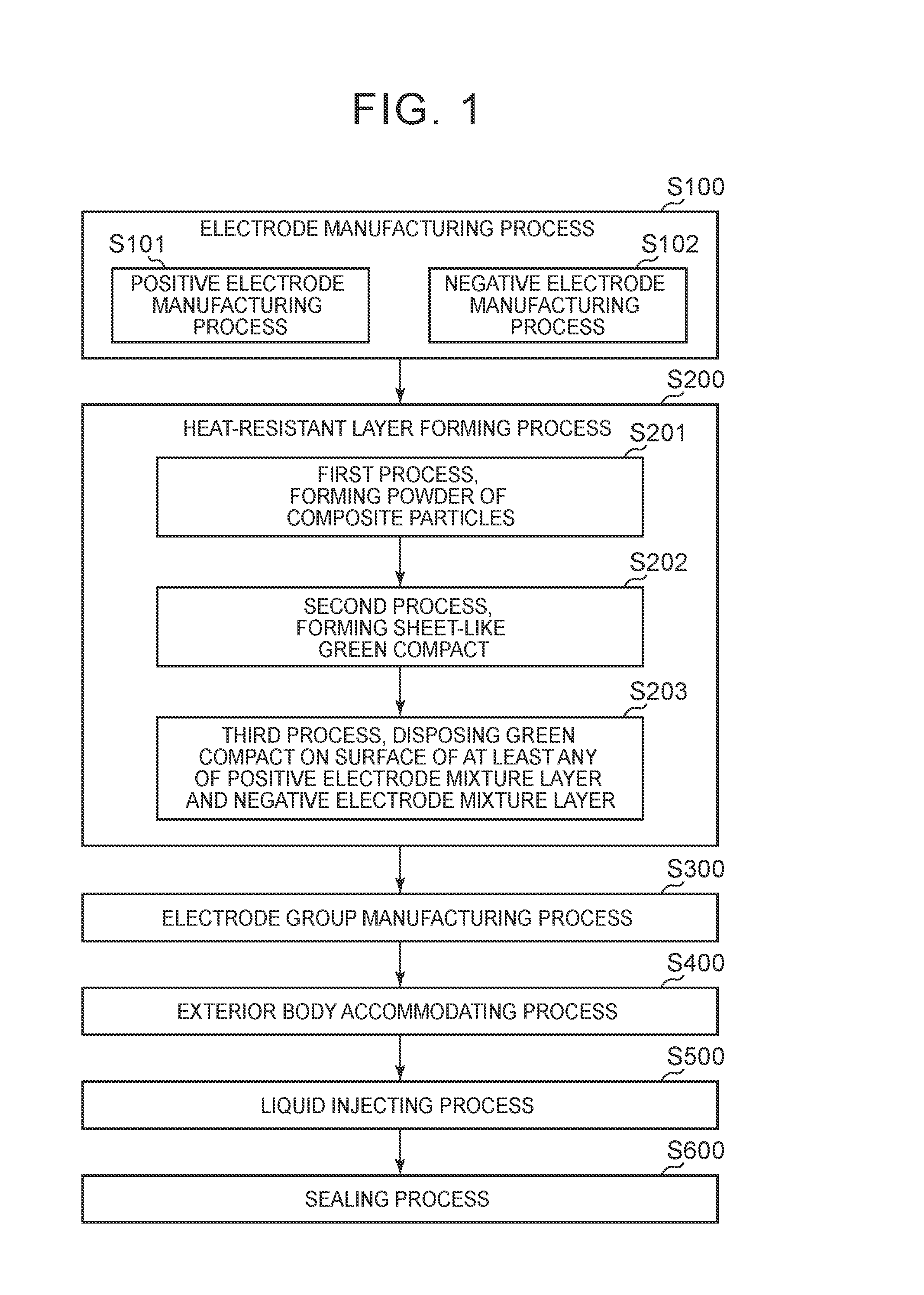

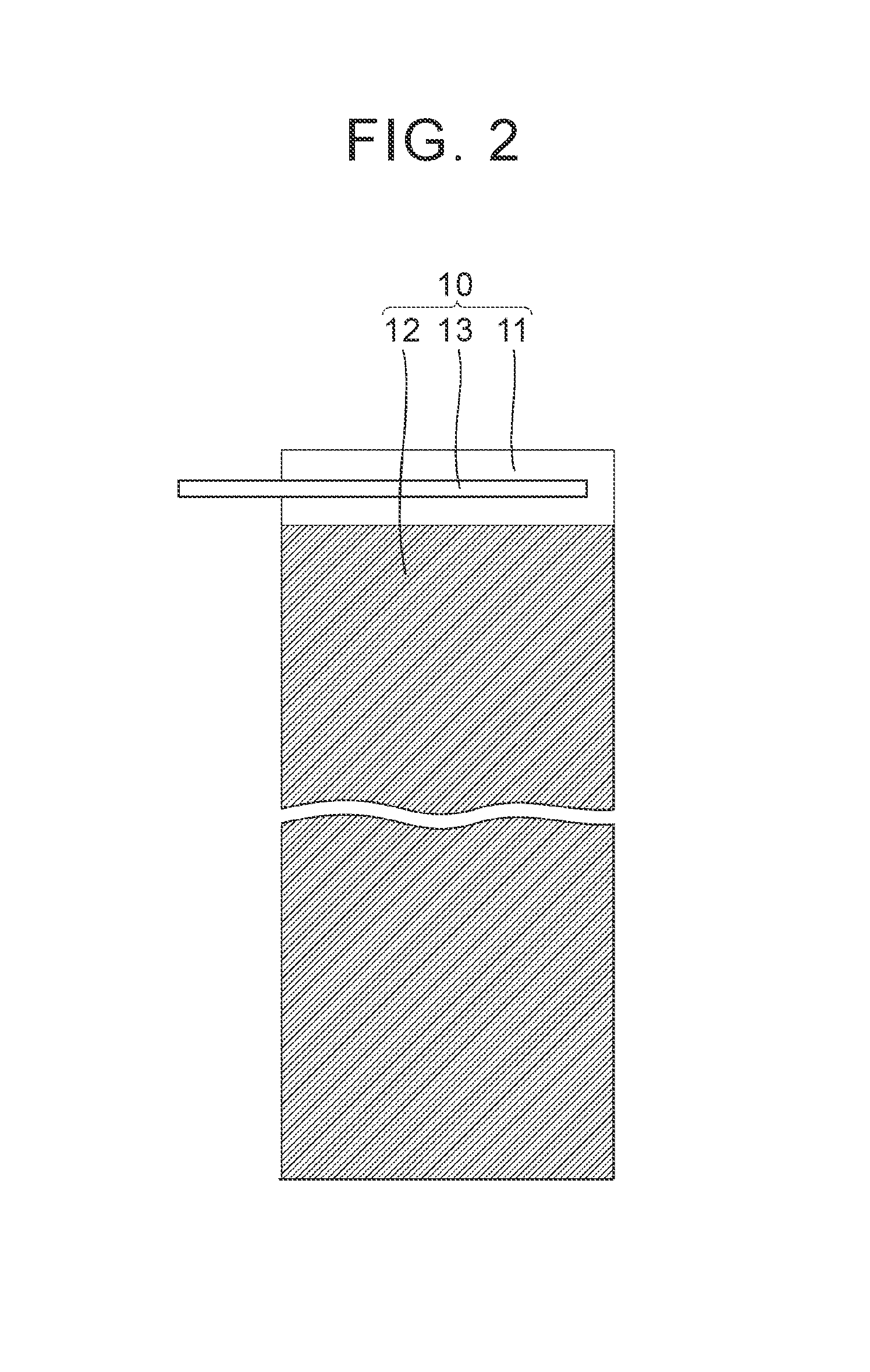

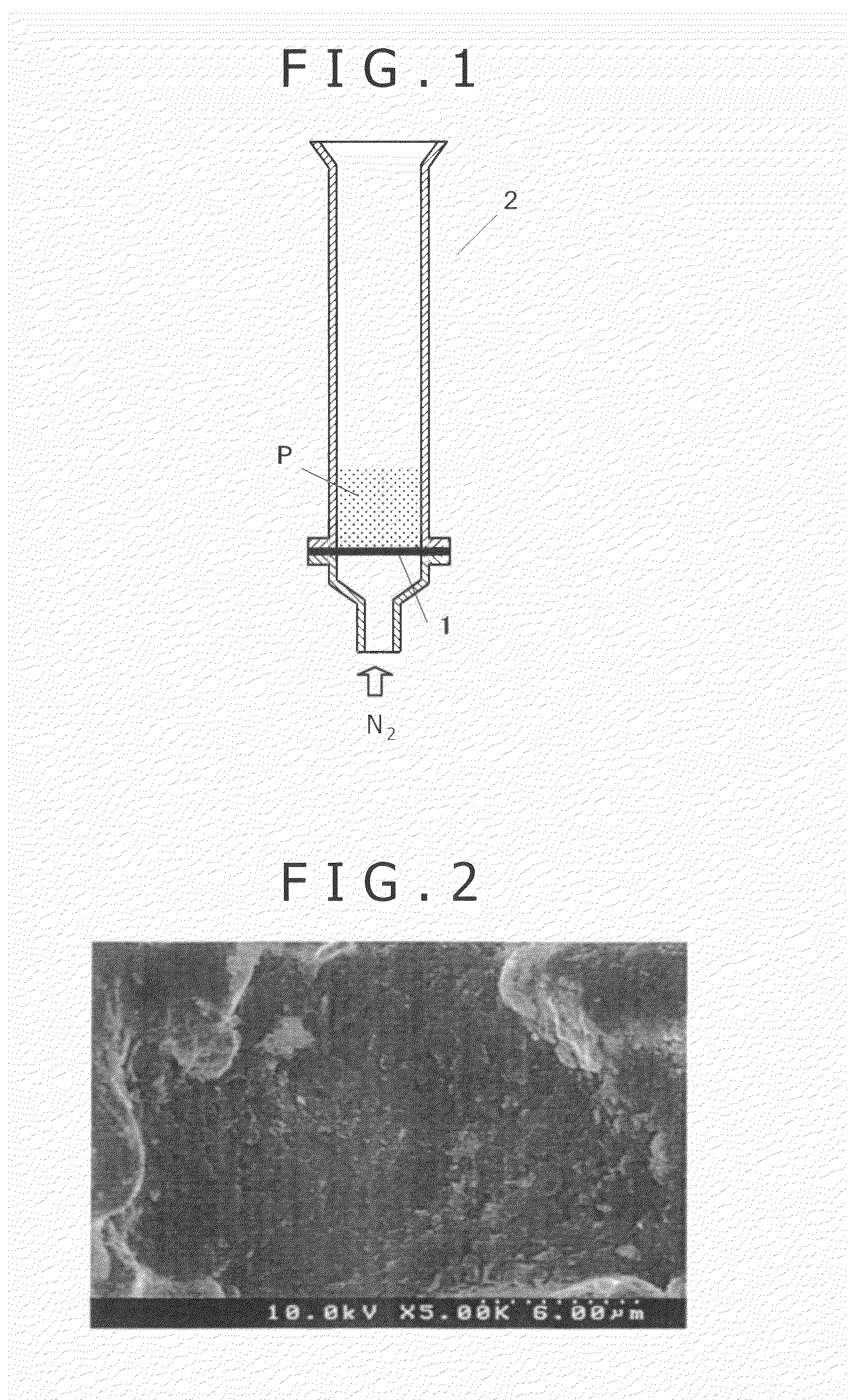

Manufacturing method for non-aqueous electrolyte secondary battery

ActiveUS20160240839A1Reduce the amount requiredHigh strengthElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsSolventInorganic filler

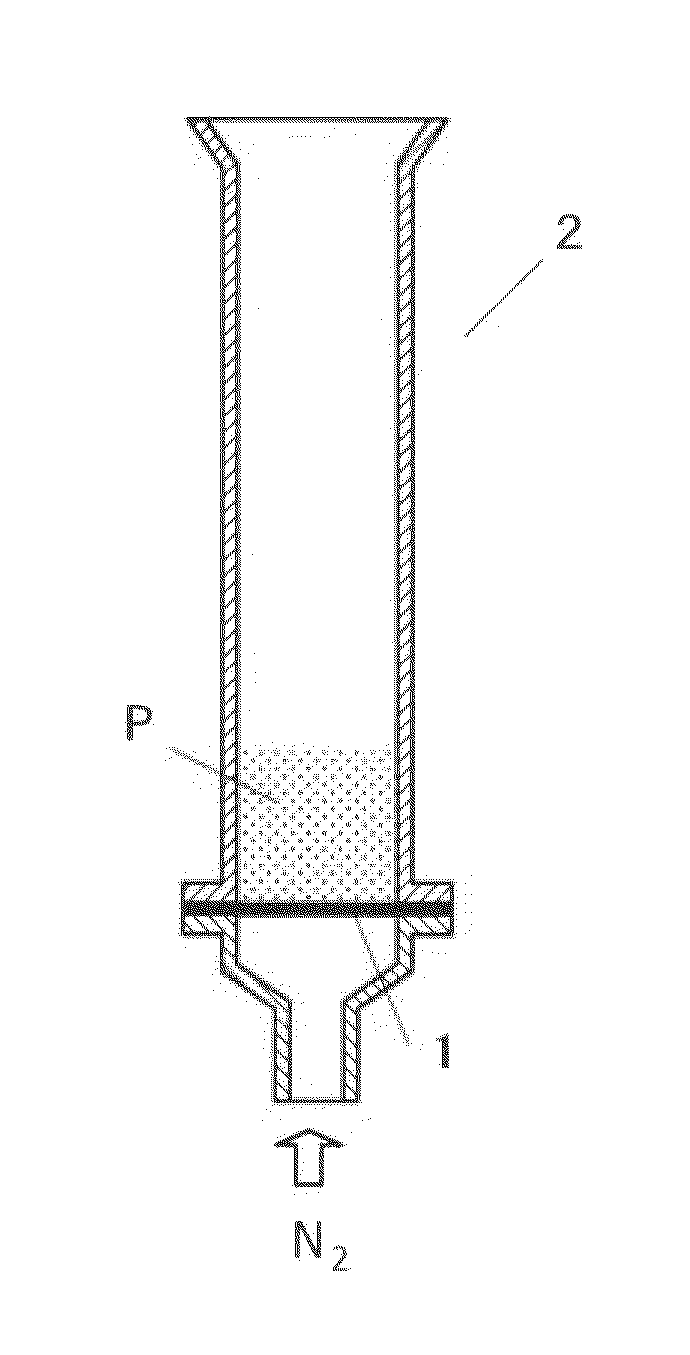

A manufacturing method for a non-aqueous electrolyte secondary battery includes: forming a powder; forming a sheet-like green compact; and forming a heat-resistant layer. The powder contains composite particles and a solvent. The composite particles contain inorganic filler particles and a binder. The green compact is formed by pressing the powder in a state in which the solvent remains. The heat-resistant layer is formed by disposing the green compact on a surface of at least any of a positive electrode mixture layer and a negative electrode mixture layer after the green compact is formed.

Owner:TOYOTA JIDOSHA KK

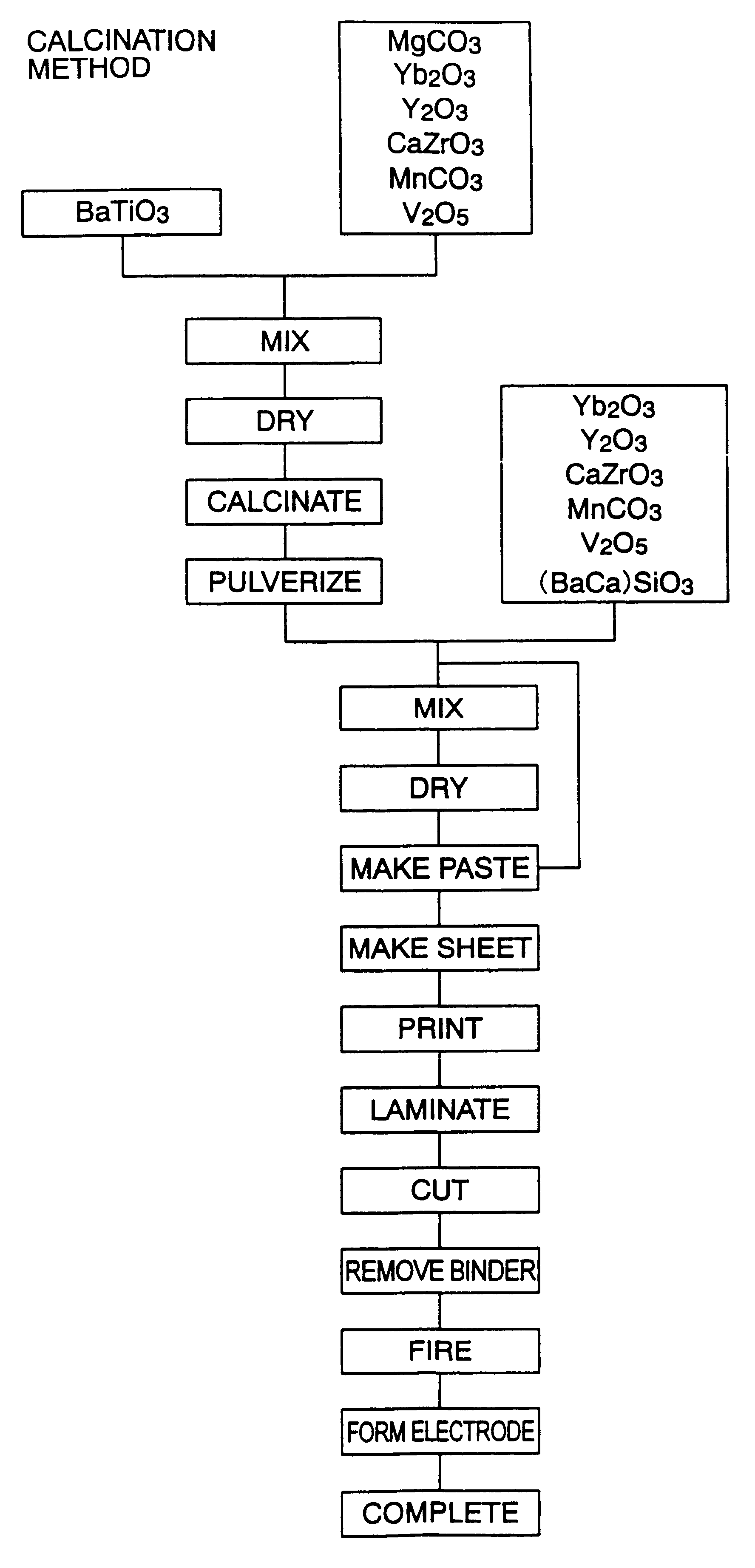

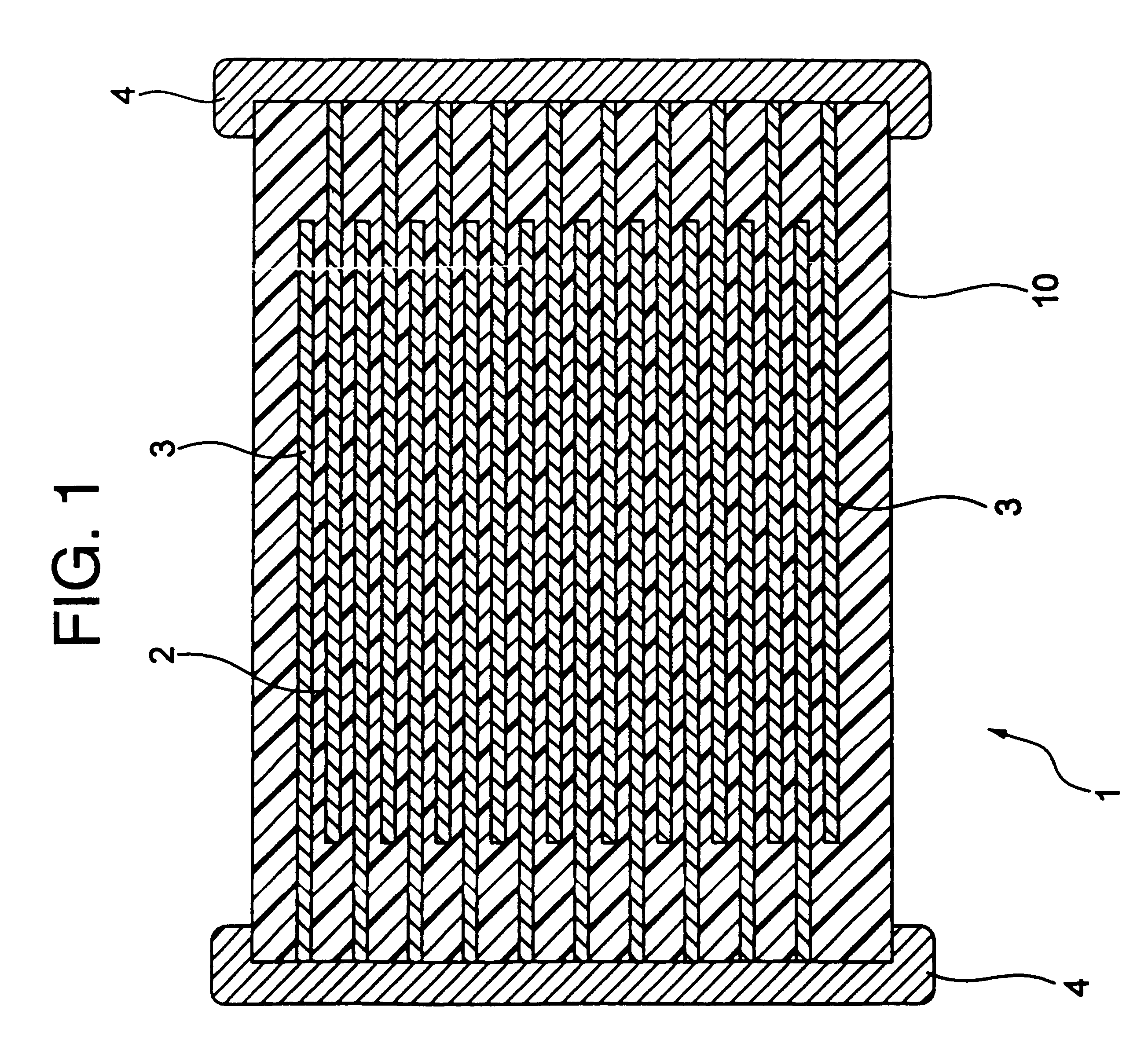

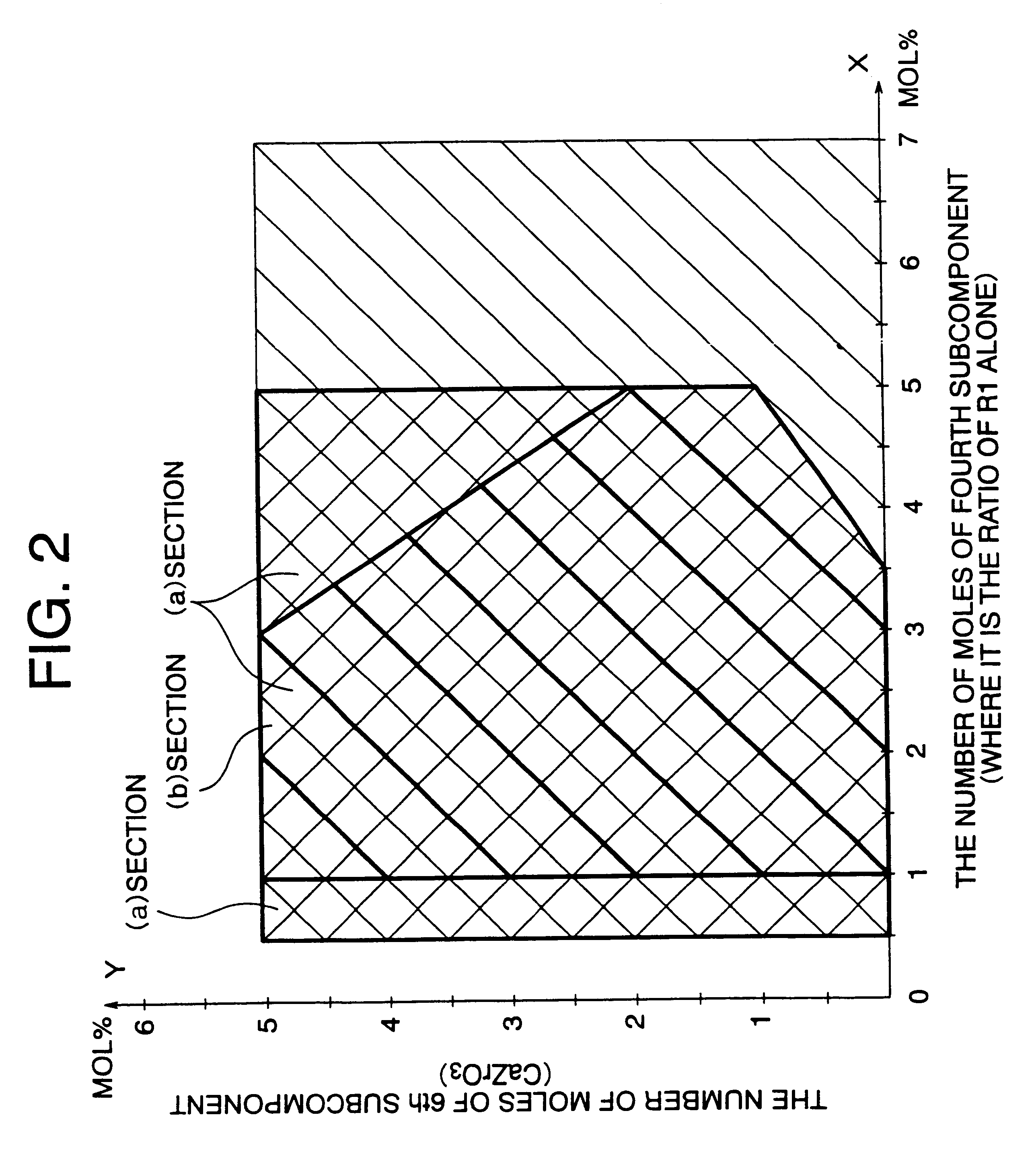

Manufacture method of dielectric ceramic composition

InactiveUS6544916B1Improve insulation performanceHigh relative permittivityFixed capacitor dielectricMetallurgyCalcination

A method of manufacturing a dielectric ceramic composition comprising at least BaTiO3 as a main component, a second subcomponent having SiO2 as a main component and at least one type selected from MO (note that M is at least one type of element selected from Ba, Ca, Sr and Mg), Li2O and B2O3 and other subcomponents, comprising the steps of mixing in the main component at least part of other subcomponents except for the second subcomponent to prepare a pre-calcination powder, calcining said pre-calcination powder to prepare a calcined powder, and mixing at least said second subcomponent in said calcined powder to obtain a dielectric ceramic composition having ratios of the subcomponents to BaTiO3 as the main component of predetermined molar ratios.

Owner:TDK CORPARATION

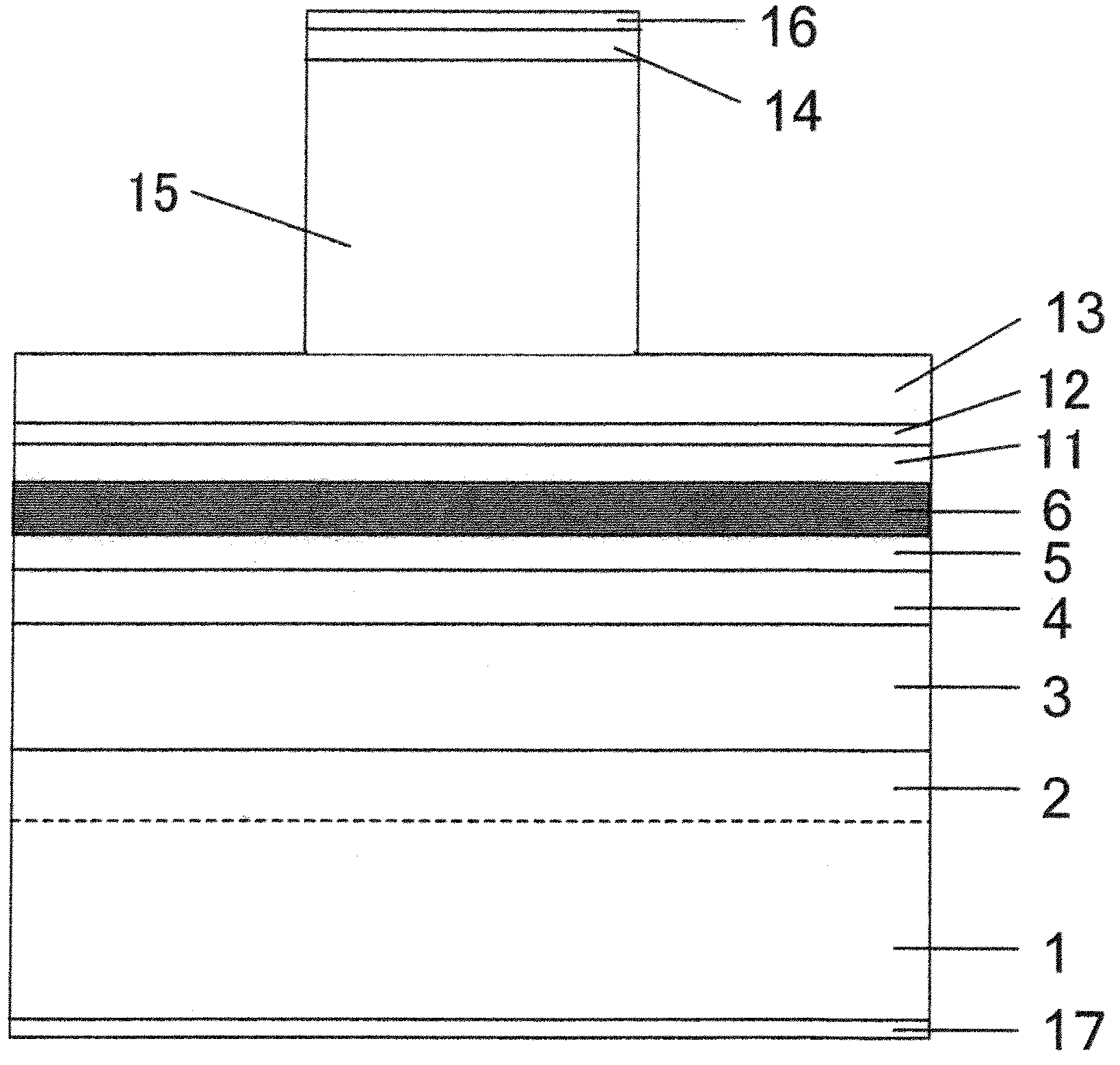

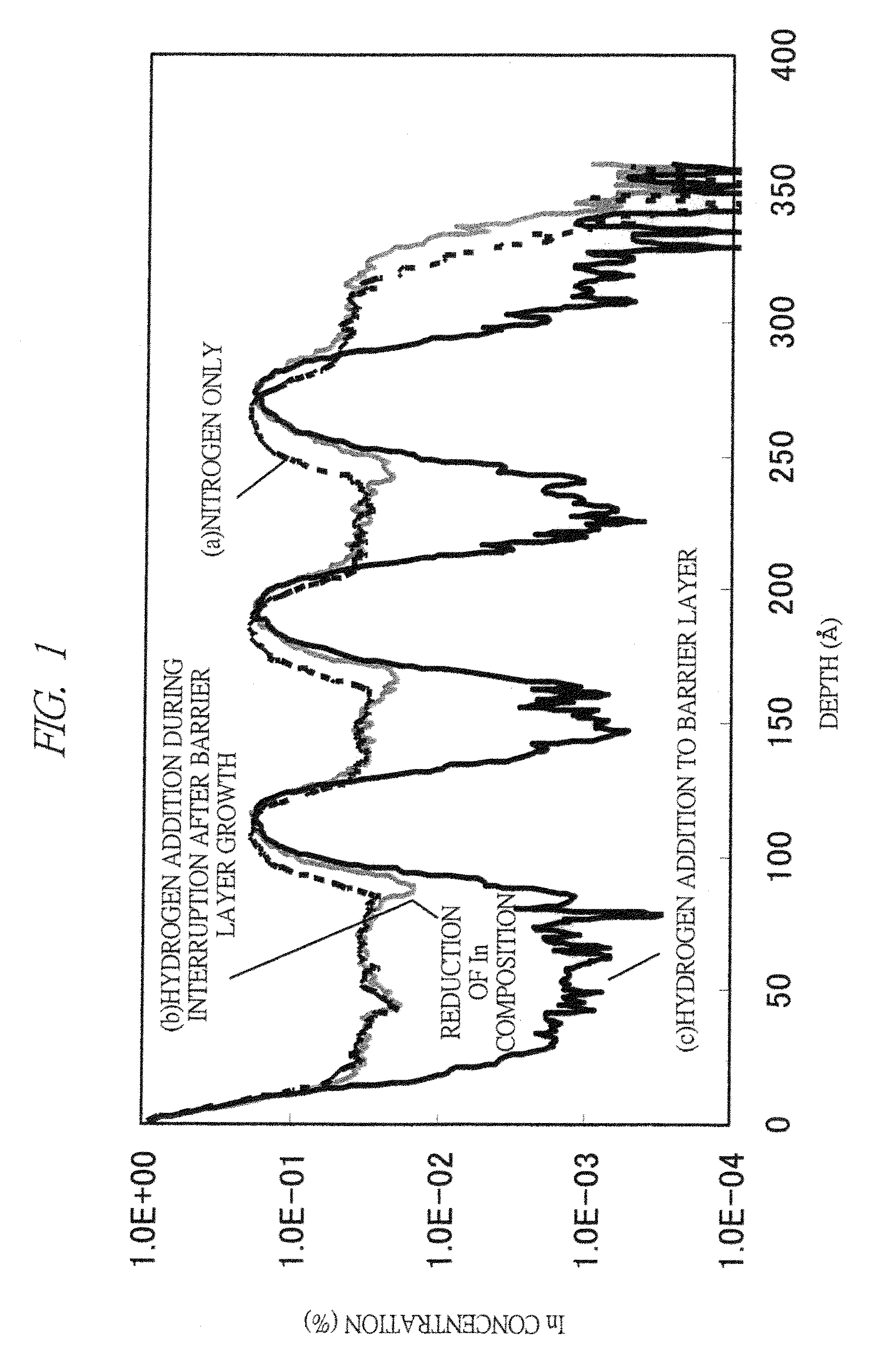

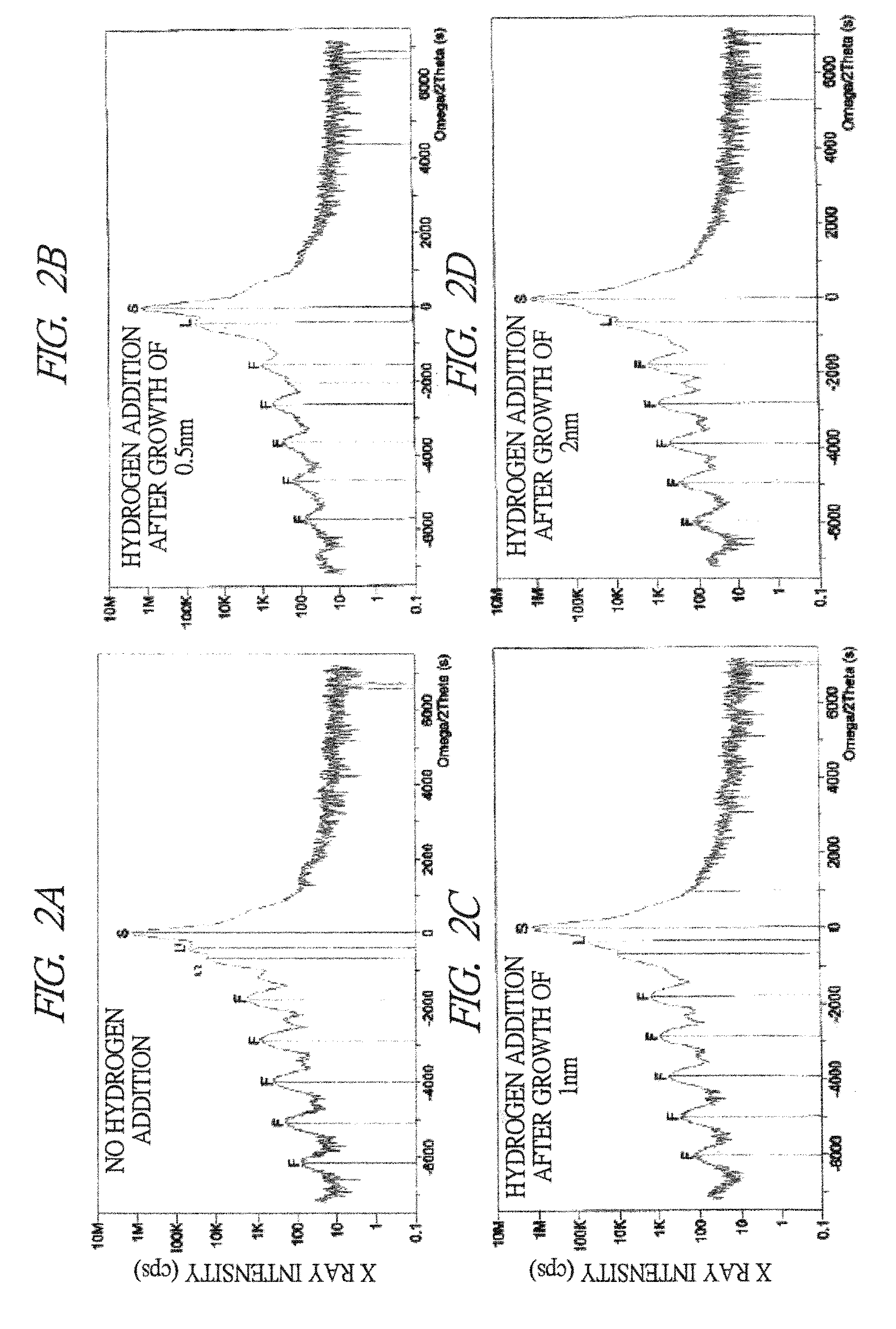

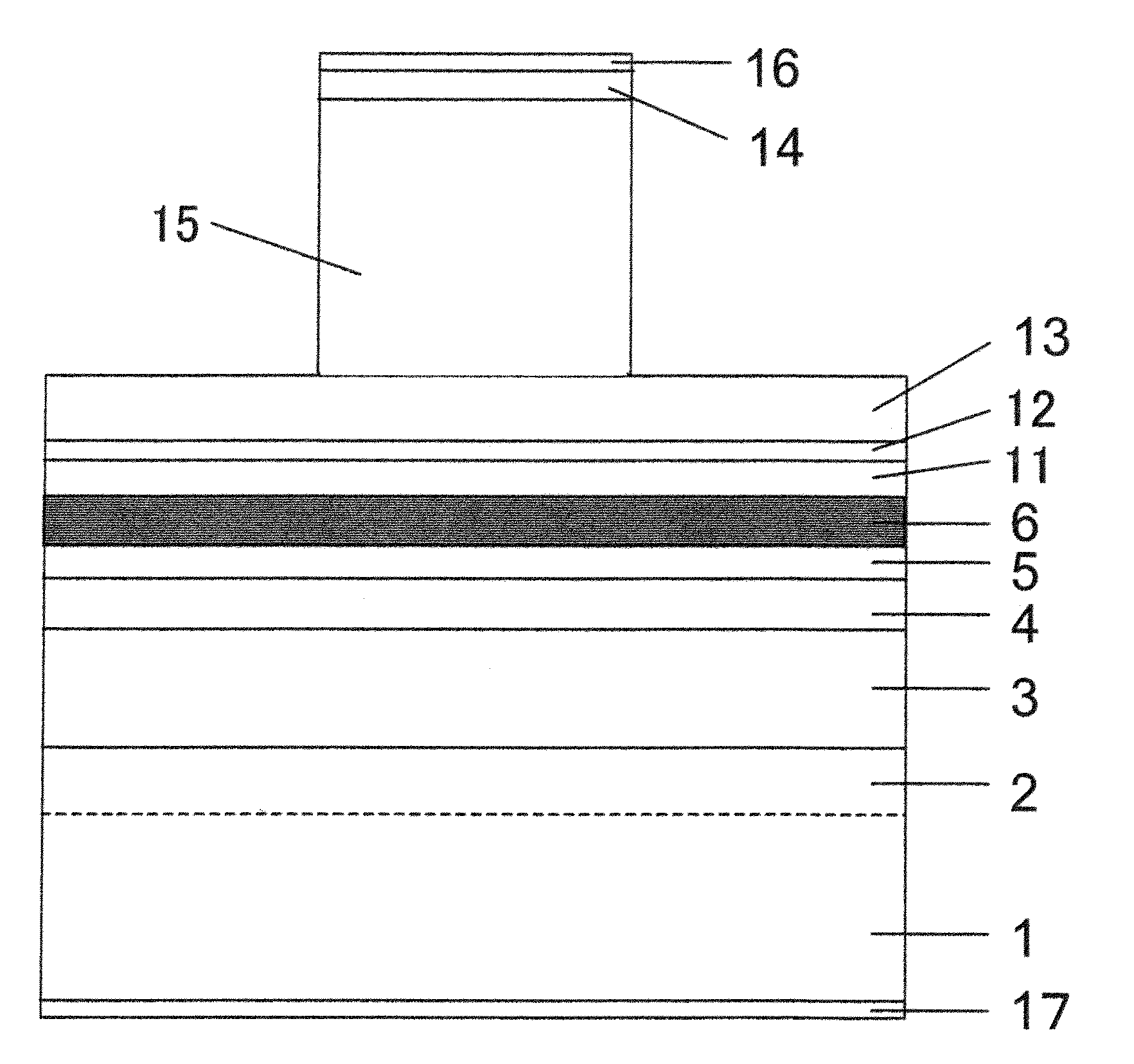

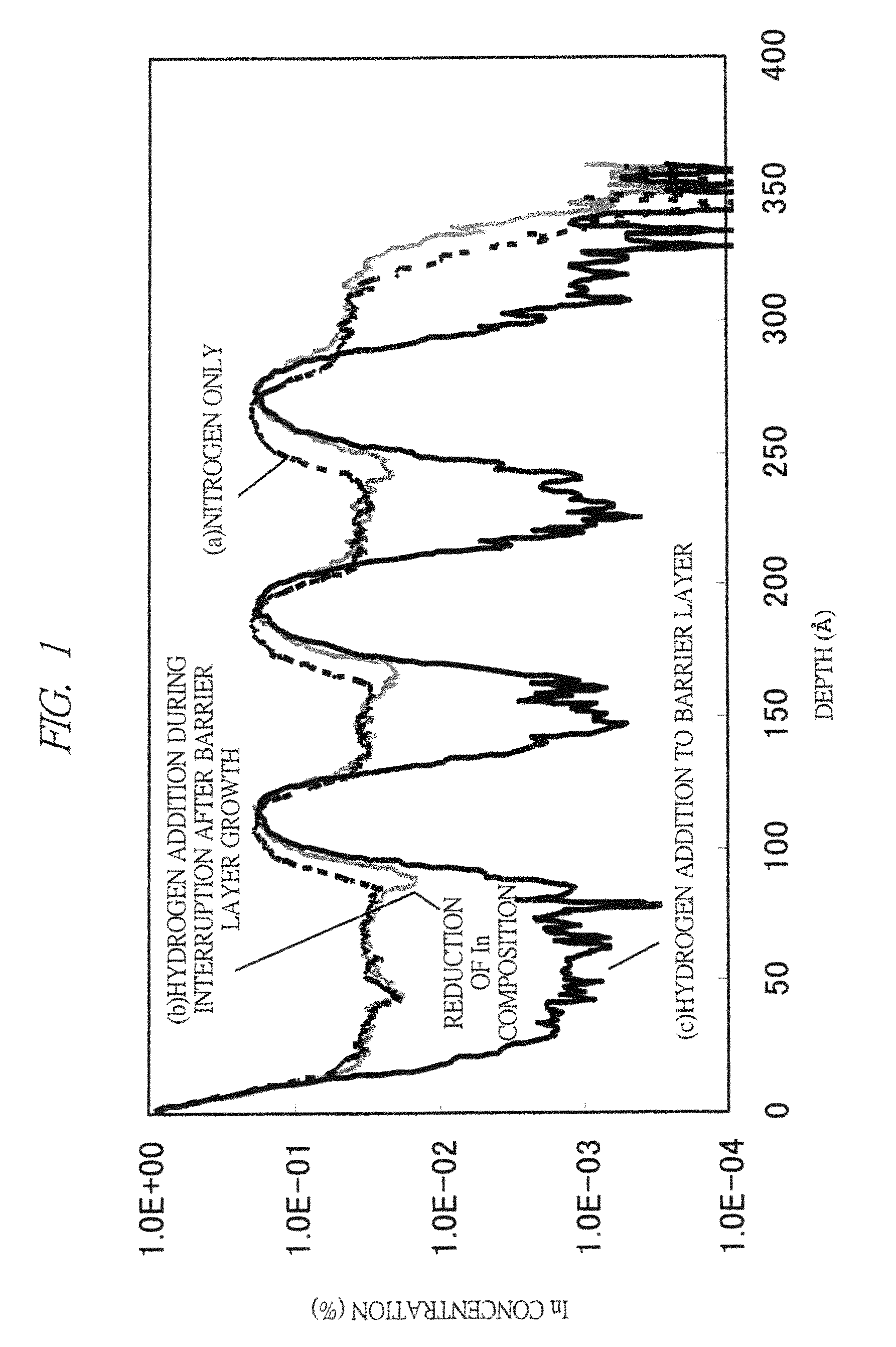

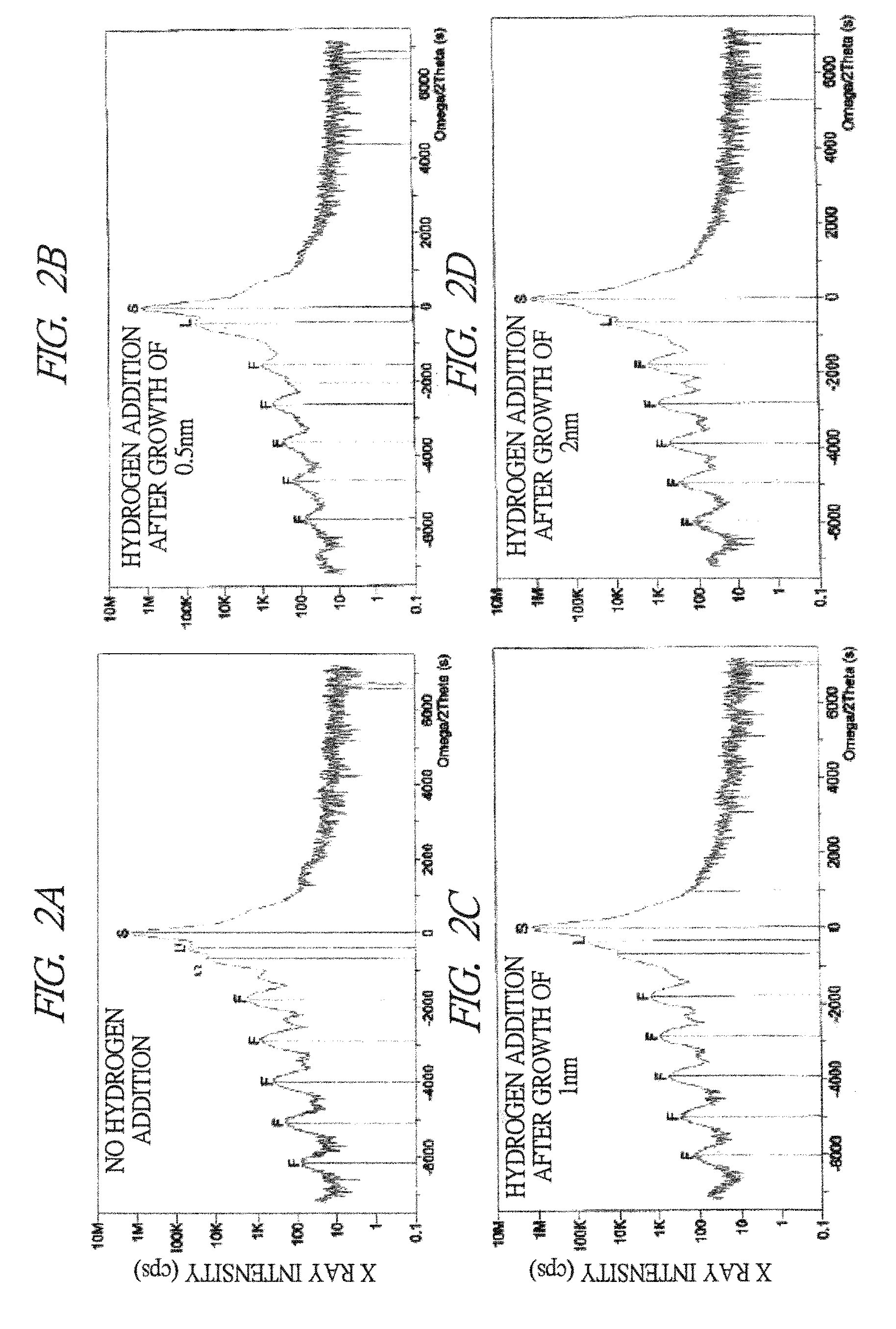

Nitride semiconductor optical element and manufacturing method thereof

ActiveUS20100150194A1High crystallinityEliminate segregationLaser detailsLaser active region structureIndiumHydrogen

In an InGaN-based nitride semiconductor optical device having a long wavelength (440 nm or more) equal to or more than that of blue, the increase of a wavelength is realized while suppressing In (Indium) segregation and deterioration of crystallinity. In the manufacture of an InGaN-based nitride semiconductor optical device having an InGaN-based quantum well active layer including an InGaN well layer and an InGaN barrier layer, a step of growing the InGaN barrier layer includes: a first step of adding hydrogen at 1% or more to a gas atmosphere composed of nitrogen and ammonia and growing a GaN layer in the gas atmosphere; and a second step of growing the InGaN barrier layer in a gas atmosphere composed of nitrogen and ammonia.

Owner:USHIO OPTO SEMICON

Sputtering target for phase-change memory, film for phase change memory formed by using the target, and method for producing the target

InactiveUS20050115829A1Improving rewriting propertyImprove crystallization speedCellsElectrical apparatusPhase-change memoryTe element

The present invention provides a sputtering target for a phase change memory and a phase change memory film formed with such a target, and the manufacturing method thereof, characterized in that the sputtering target is composed from elements of not less than a three component system and has as its principal component one or more components selected from stibium, tellurium and selenium, and the compositional deviation in relation to the intended composition is ±1.0 at % or less. This sputtering target for a phase change memory is capable of reducing, as much as possible, impurities that cause the reduction in the number of times rewriting can be conducted as a result of such impurities segregating and condensing in the vicinity of the boundary face of the memory point and non-memory point; in particular, impurity elements that affect the crystallization speed, reducing the compositional deviation of the target in relation to the intended composition, and improving the rewriting properties and crystallization speed of the phase change memory by suppressing the compositional segregation of the target.

Owner:JX NIPPON MINING& METALS CORP

Sputtering target for phase-change memory, film for phase change memory formed by using the target, and method for producing the target

InactiveUS7156964B2Improving rewriting property and crystallization speedReduce deviationCellsElectrical apparatusPhase-change memoryTe element

The present invention provides a sputtering target for a phase change memory and a phase change memory film formed with such a target, and the manufacturing method thereof, characterized in that the sputtering target is composed from elements of not less than a three component system and has as its principal component one or more components selected from stibium, tellurium and selenium, and the compositional deviation in relation to the intended composition is ±1.0 at % or less. This sputtering target for a phase change memory is capable of reducing, as much as possible, impurities that cause the reduction in the number of times rewriting can be conducted as a result of such impurities segregating and condensing in the vicinity of the boundary face of the memory point and non-memory point; in particular, impurity elements that affect the crystallization speed, reducing the compositional deviation of the target in relation to the intended composition, and improving the rewriting properties and crystallization speed of the phase change memory by suppressing the compositional segregation of the target.

Owner:JX NIPPON MINING & METALS CORP

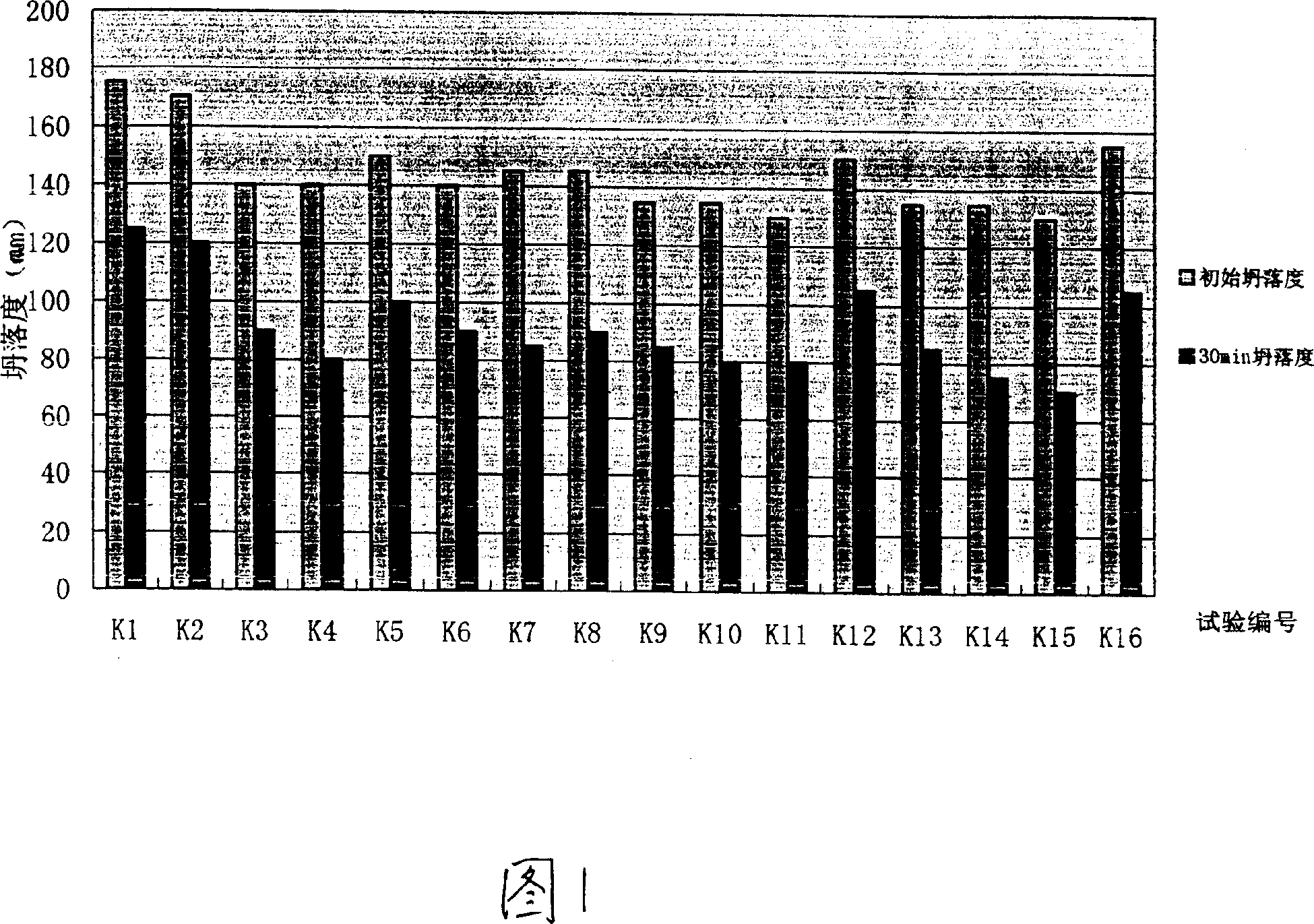

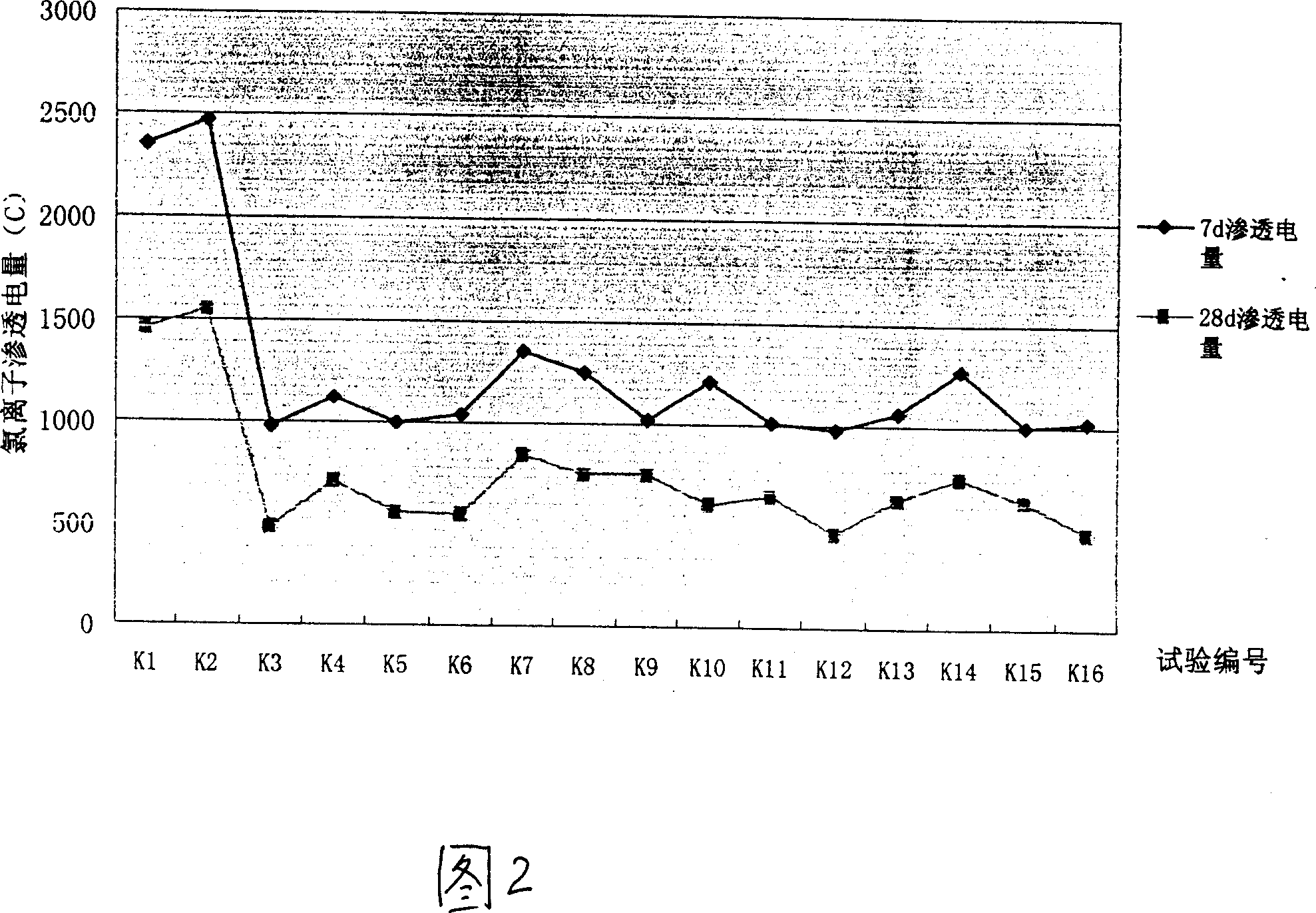

Formula of seaport engineering concrete chloride ion penetration resistant reinforcing agent

InactiveCN101134649AImprove permeabilityReduce penetration rateSolid waste managementFiberMicro structure

The present invention provides the recipe of chlorine ion penetration resisting reinforcer for concrete in harbor engineering. The chlorine ion penetration resisting reinforcer consists of superfine silica powder 15-20 wt%, washed and calcined kaolin 20-25 wt%, high grade fly ash 20-25 wt%, ground blast furnace slag 20-25 wt%, nanometer fiber 5-10 wt%, superplasticizer 6 wt%, slump keeping agent 0.09 wt%, air entraining agent 0.09 wt%, and organic active excitant 0.12 wt%. The chlorine ion penetration resisting reinforcer has inorganic components as main functional materials dispersed homogeneously in concrete cementing material, and can improve the micro structure and hydration product composition inside concrete, raise compactness, adsorb and fix chlorine ion and lower the penetration of chlorine ion in hardened concrete, so as to improve the chlorine ion penetration resisting capacity of hardened concrete.

Owner:LETS HLDG GRP CO LTD +1

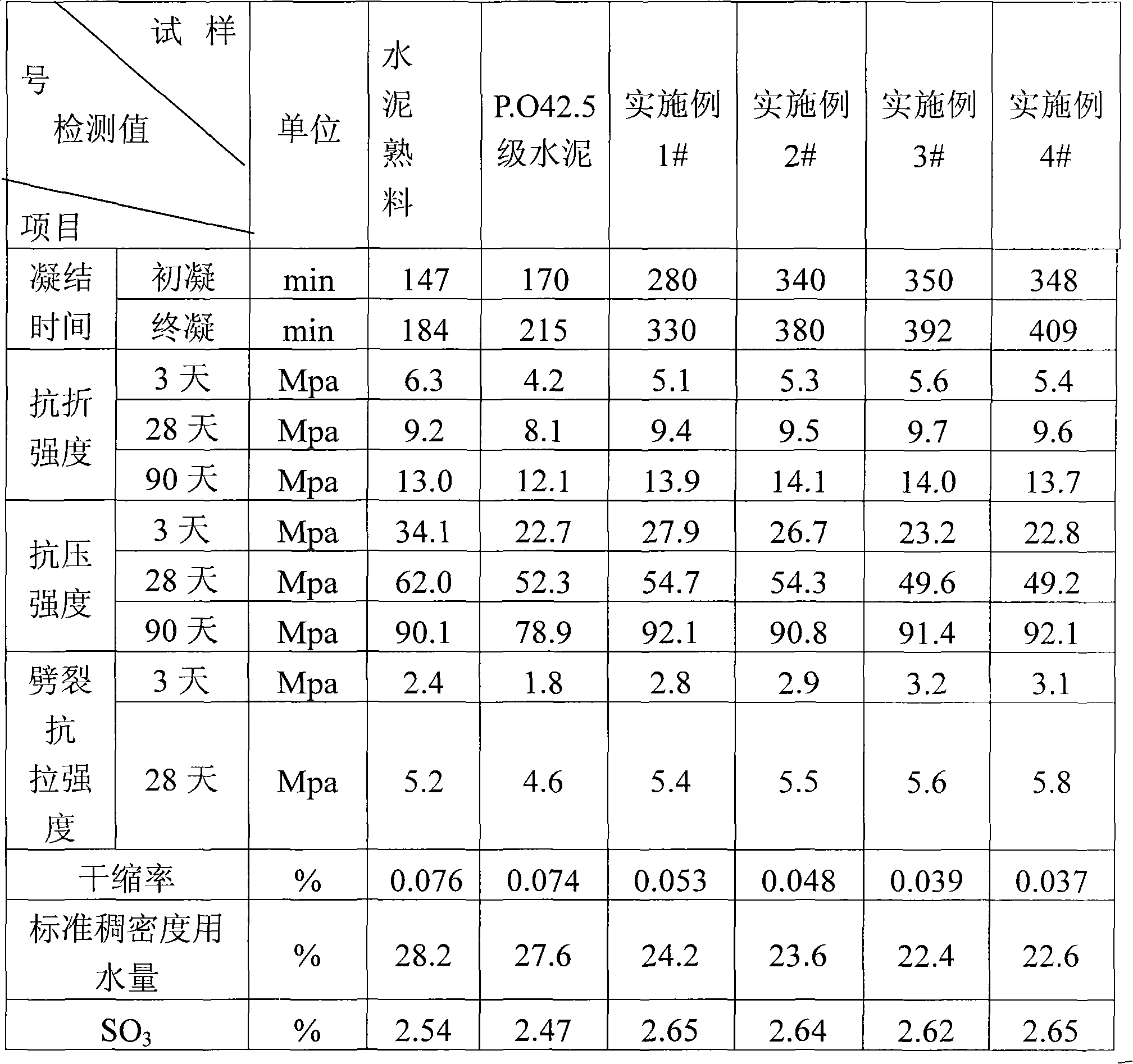

Anti-cracking reinforced ecological cement

InactiveCN101134645AProlong initial setting timeReduce early thermal cracksSolid waste managementGypsumFiber

The anticracking high strength ecological cement is produced with Portland clinker 35-80 wt%, fly ash 5-30 wt%, ferroalloy slag 1.0-30 wt%, boiler slag 5-40 wt%, gangue 10-40 wt%, grinding aid 0.1-2.0 wt%, gypsum 0.5-10 wt%, reinforcing fibrous inorganic mineral material 1-20 wt% and polymer fiber 0.01-10 wt%, and through grinding and mixing. Compared with available technology, the anticracking high strength ecological cement of the present invention has the advantages of low hydration heat, low shrinkage, low water demand, high early strength, etc.

Owner:JIANGXI GANFENG CEMENT

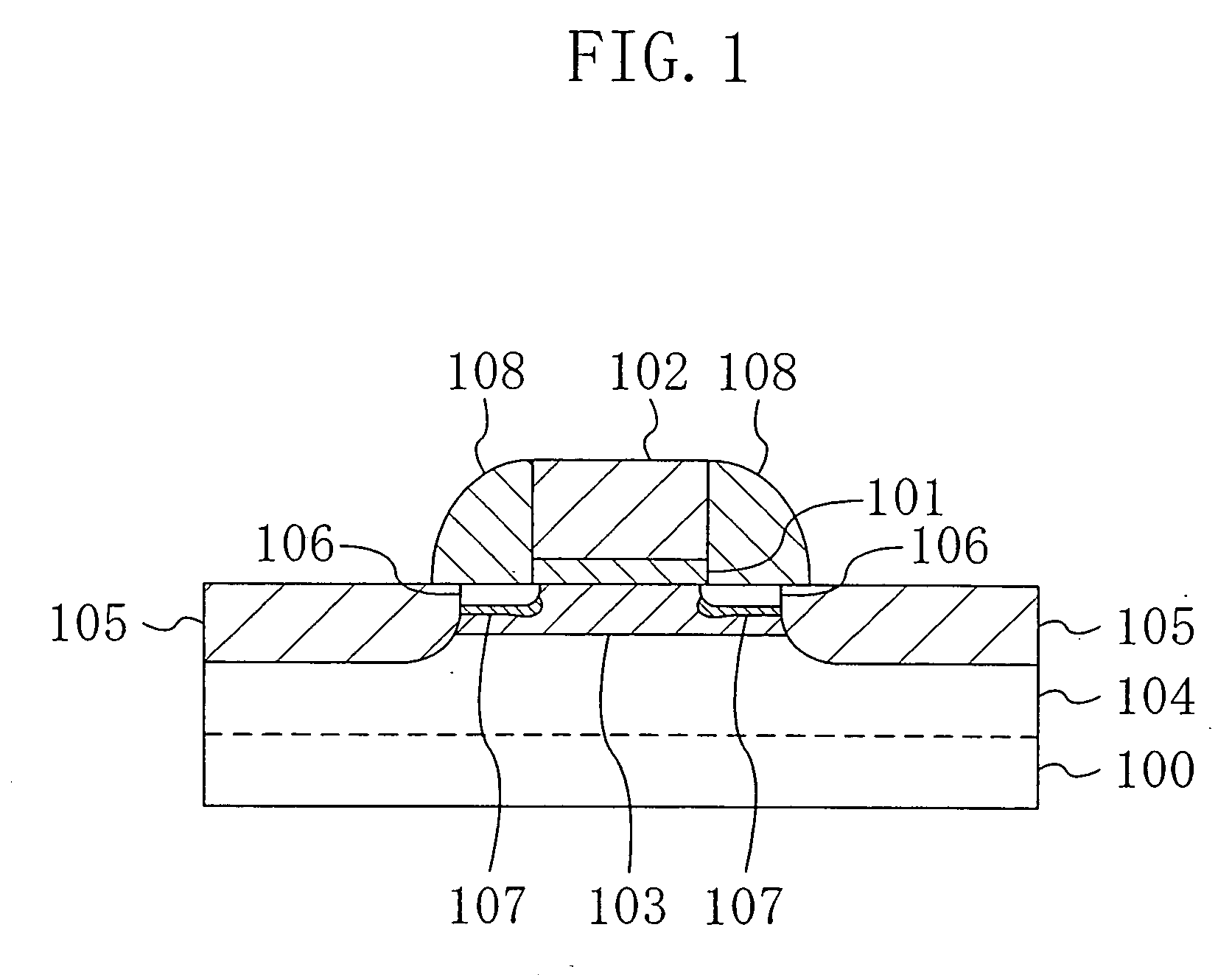

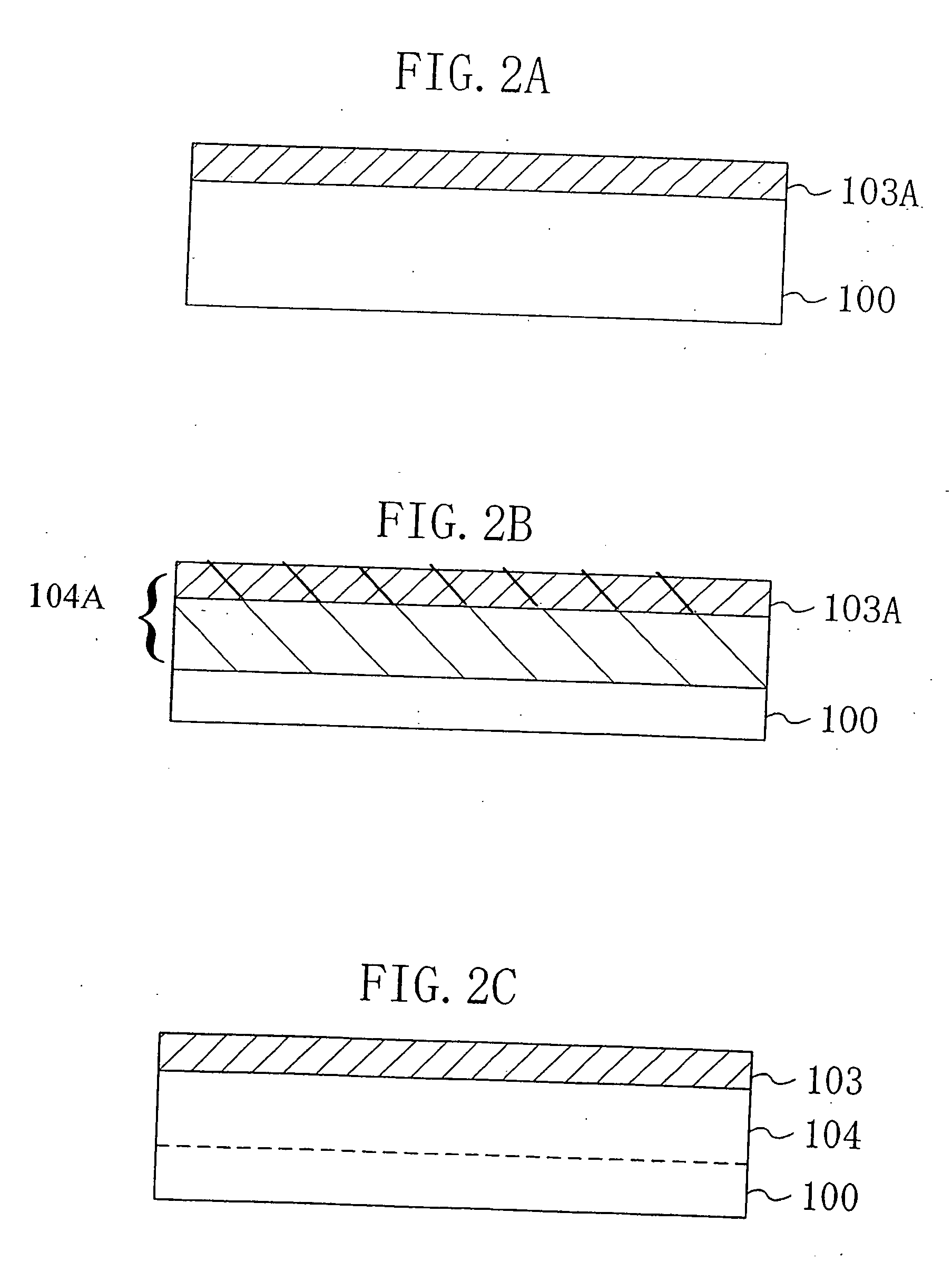

Semiconductor device and method for fabricating the same

InactiveUS7141477B2Increase the doping concentrationAvoid problemsTransistorSemiconductor/solid-state device manufacturingIndiumP type silicon

Into a channel formation region of a semiconductor substrate of p-type silicon, indium ions are implanted at an implantation energy of about 70 keV and a dose of about 5×1013 / cm2, thereby forming a p-doped channel layer. Next, germanium ions are implanted into the upper portion of the semiconductor substrate at an implantation energy of about 250 keV and a dose of about 1×1016 / cm2, thereby forming an amorphous layer in a region of the semiconductor substrate deeper than the p-doped channel layer.

Owner:RPX CORP

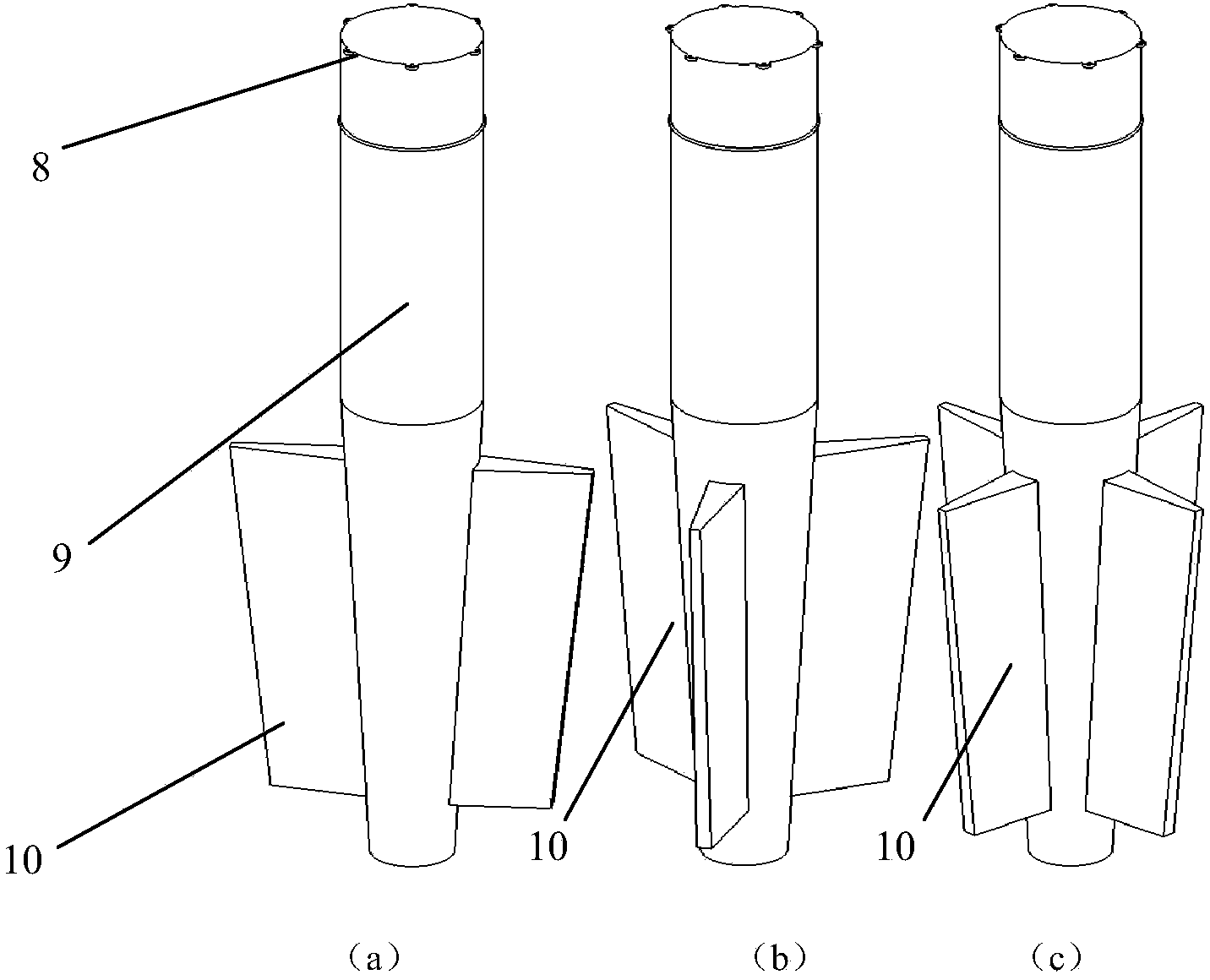

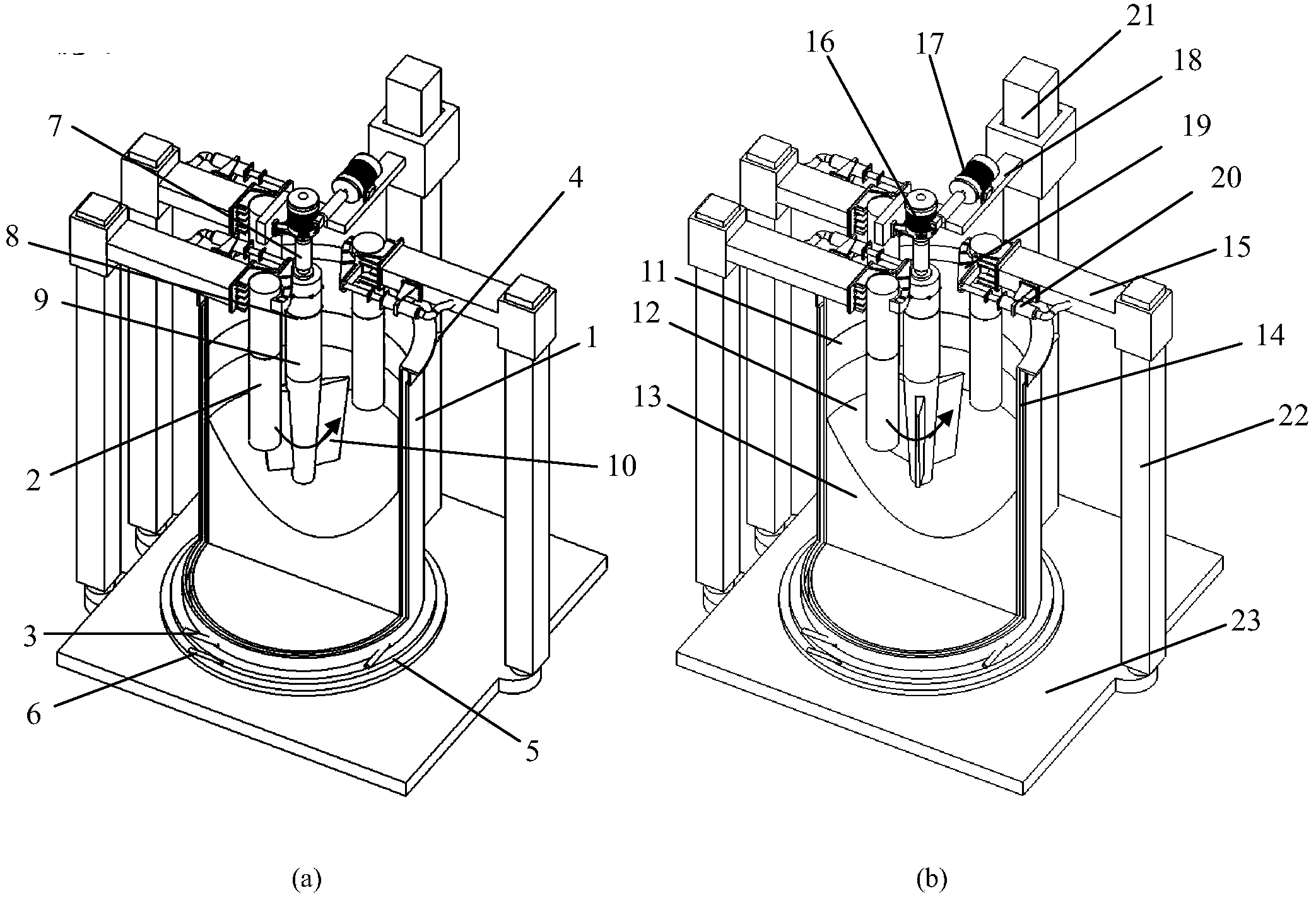

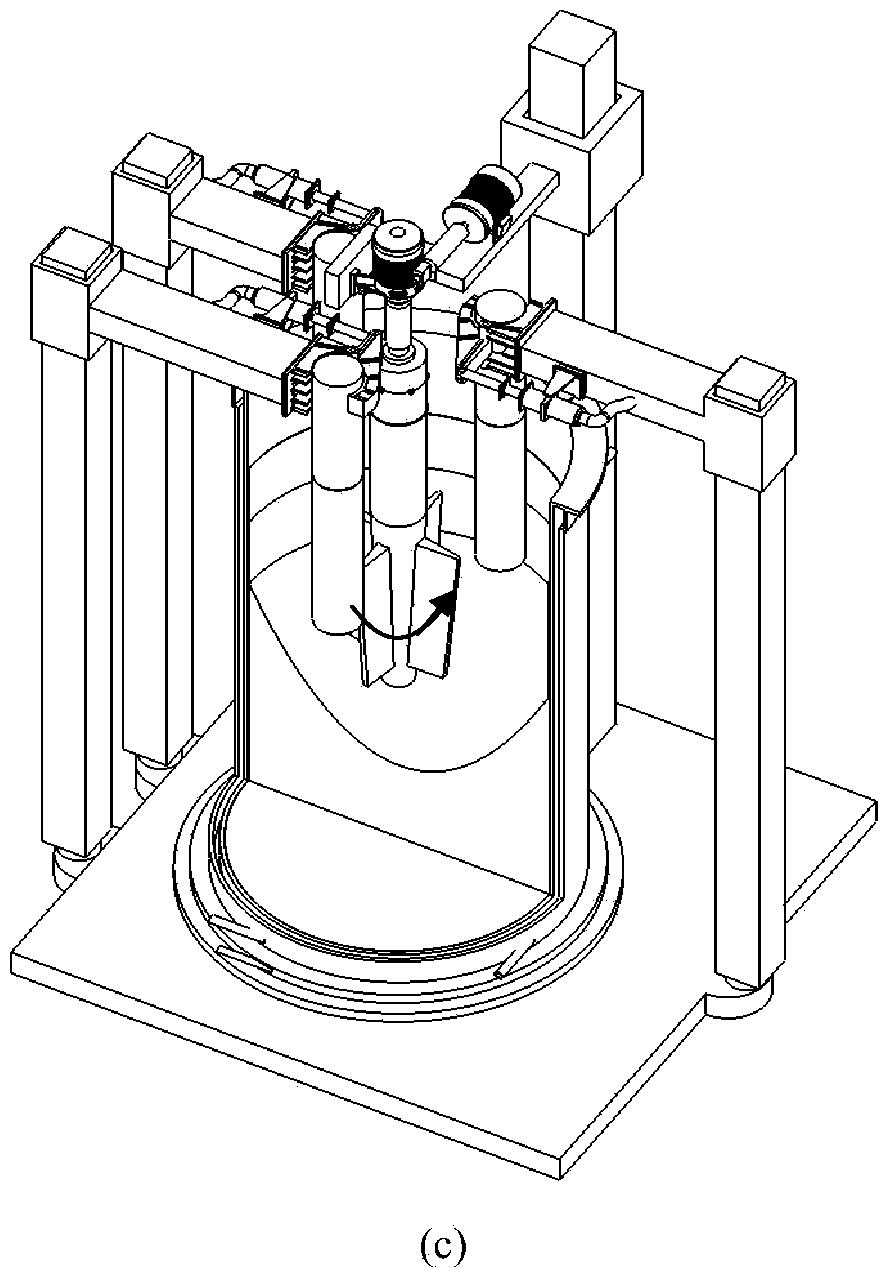

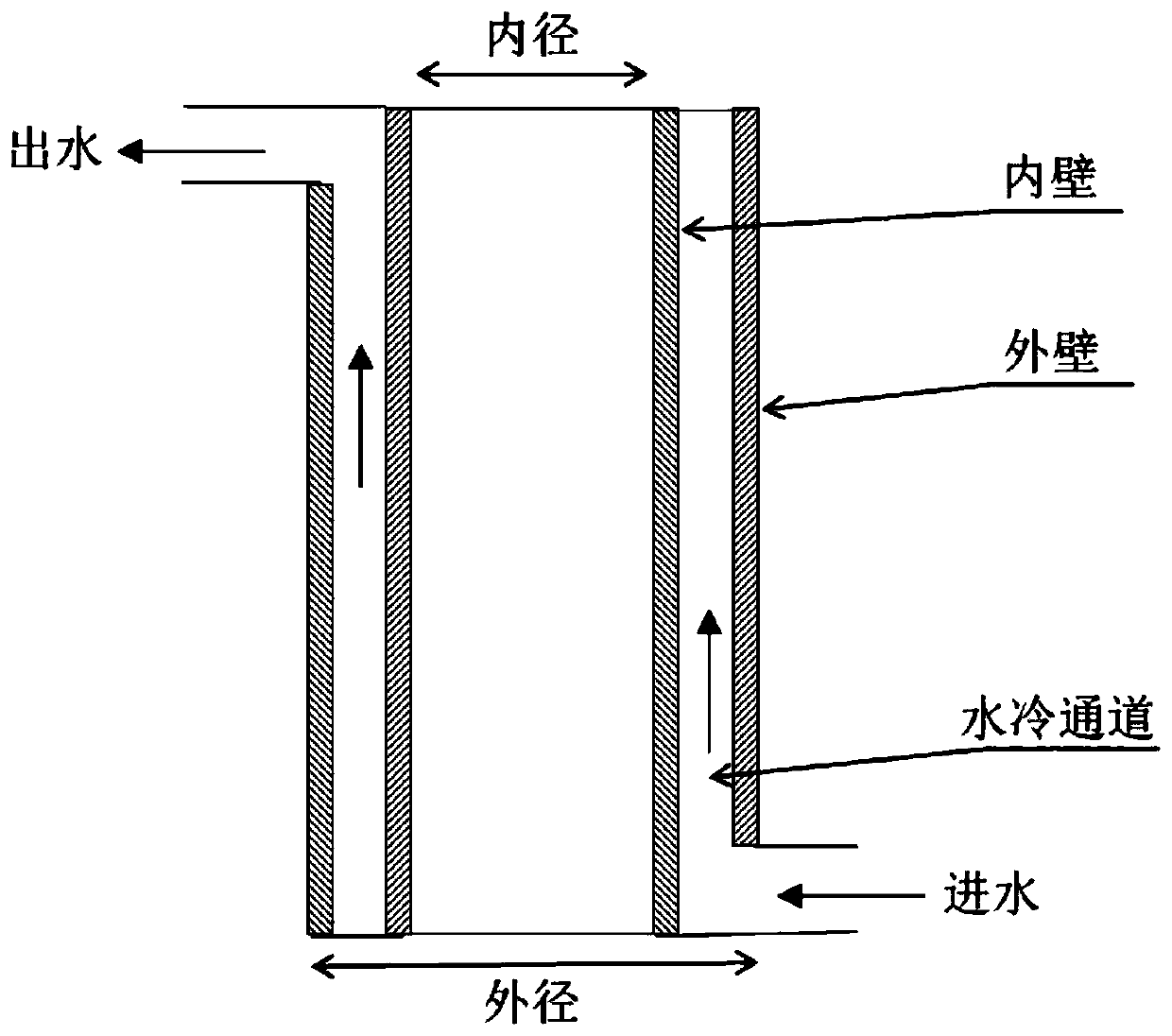

Consumable stirrer added device and method for producing large homogeneous electro-slag re-melting steel ingots

InactiveCN103406520ASpeed up cooling and heat transferShorten the setting timeSlagWater circulation

The invention discloses a consumable stirrer added device and method for producing large homogeneous electro-slag re-melting steel ingots. The device comprises a crystallizer, consumable electrodes, a cooling water circulation system, a lifting cross arm, an electronic control unit, a consumable electrode control unit and a consumable stirrer. The consumable stirrer comprises a stirring shaft and stirring blades which are fixedly connected onto the stirring shaft, and materials of the stirrer are identical to materials of the finally produced large homogeneous electro-slag re-melting steel ingot finished products. The stirring shaft is connected with an output shaft of a speed reducer through a coupling unit, the stirring blades are in sheet structures which thicken from the tops of the blades to the roots of the blades, the stirring blades are fixedly connected onto the stirring shaft in a single-layer multi-sheet mode, and the consumable stirring is controlled by the lifting cross arm to enter and exit the crystallizer. According to the device and the method, rotary flow of molten steel of the steel ingot solidification front is driven by the rotation of the consumable stirrer, so that primary dendrites of the solidification front are fractured to enter melts to form novel crystal nucleuses, the structure compactness is enhanced, and segregation of metal elements are restrained.

Owner:NORTHEASTERN UNIV

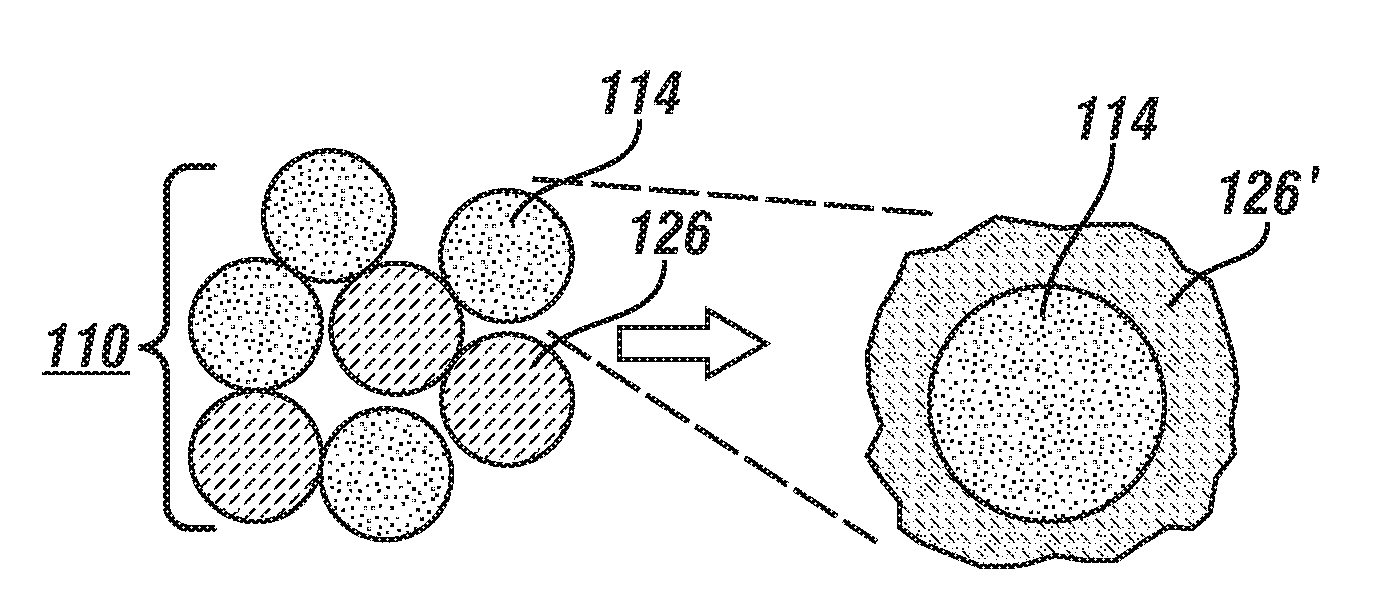

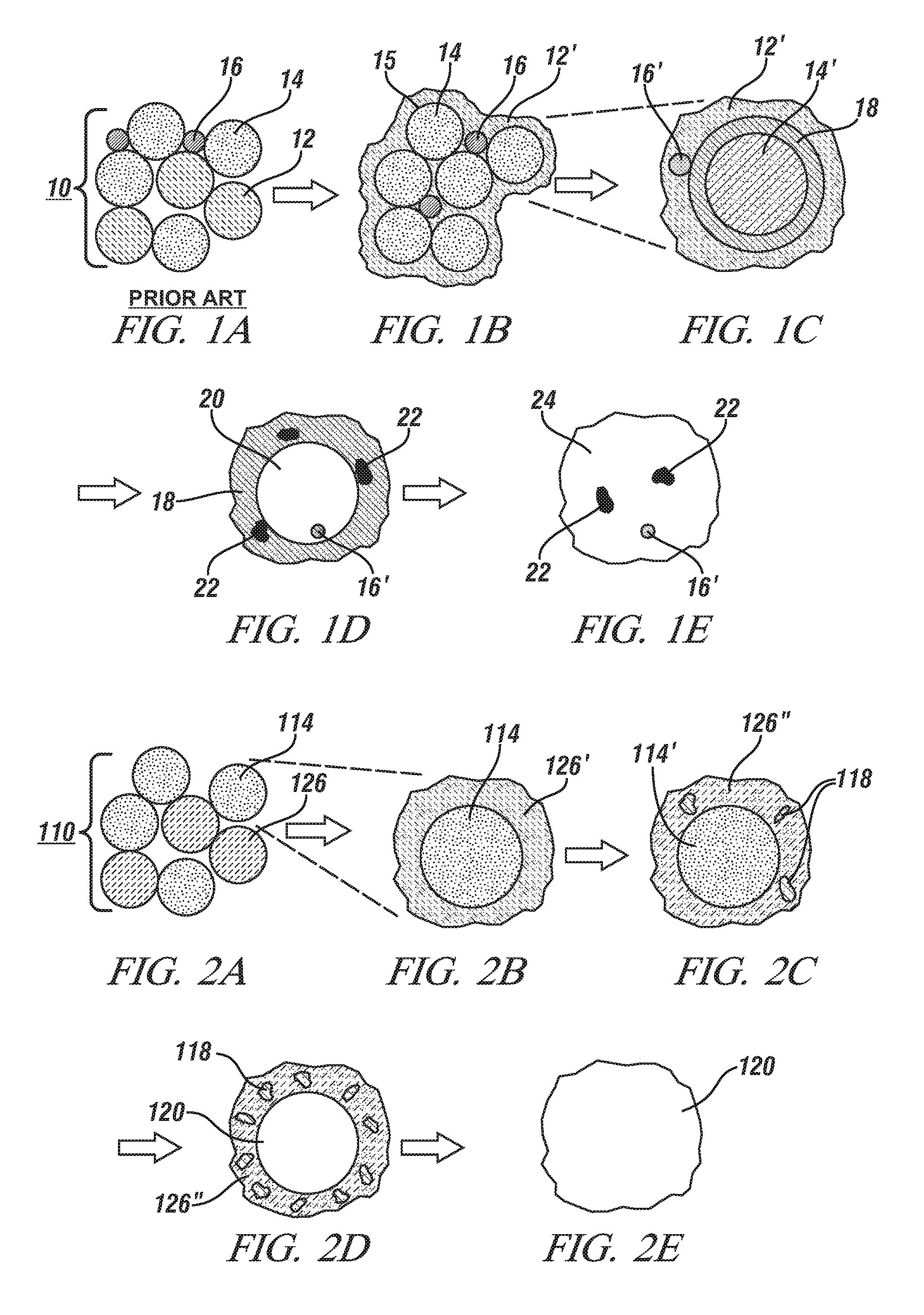

Multicomponent titanium aluminide article and method of making

ActiveUS20130121869A1Increase temperatureRapid and effective inter-diffusionMachines/enginesLift valveEngine valveAlonizing

A process for fabricating sintered, substantially pore-free titanium aluminide articles with minor alloying element additions is disclosed. Such articles may find application as automobile engine valves and connecting rods and may be fabricated by rapidly sintering intimately mixed powders of substantially pure titanium and rapidly-cooled particles of aluminum alloyed with the minor alloying element(s).

Owner:GM GLOBAL TECH OPERATIONS LLC

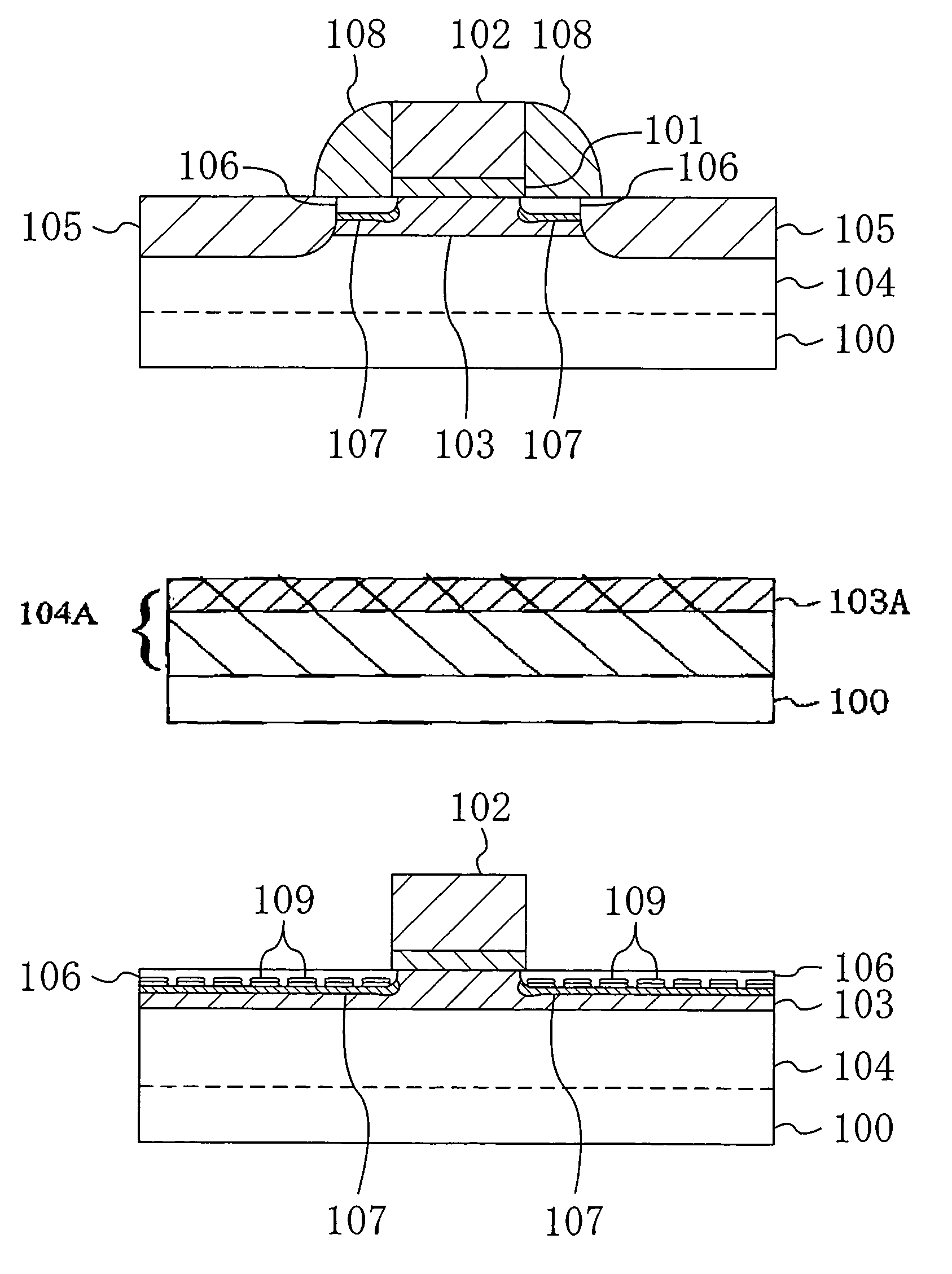

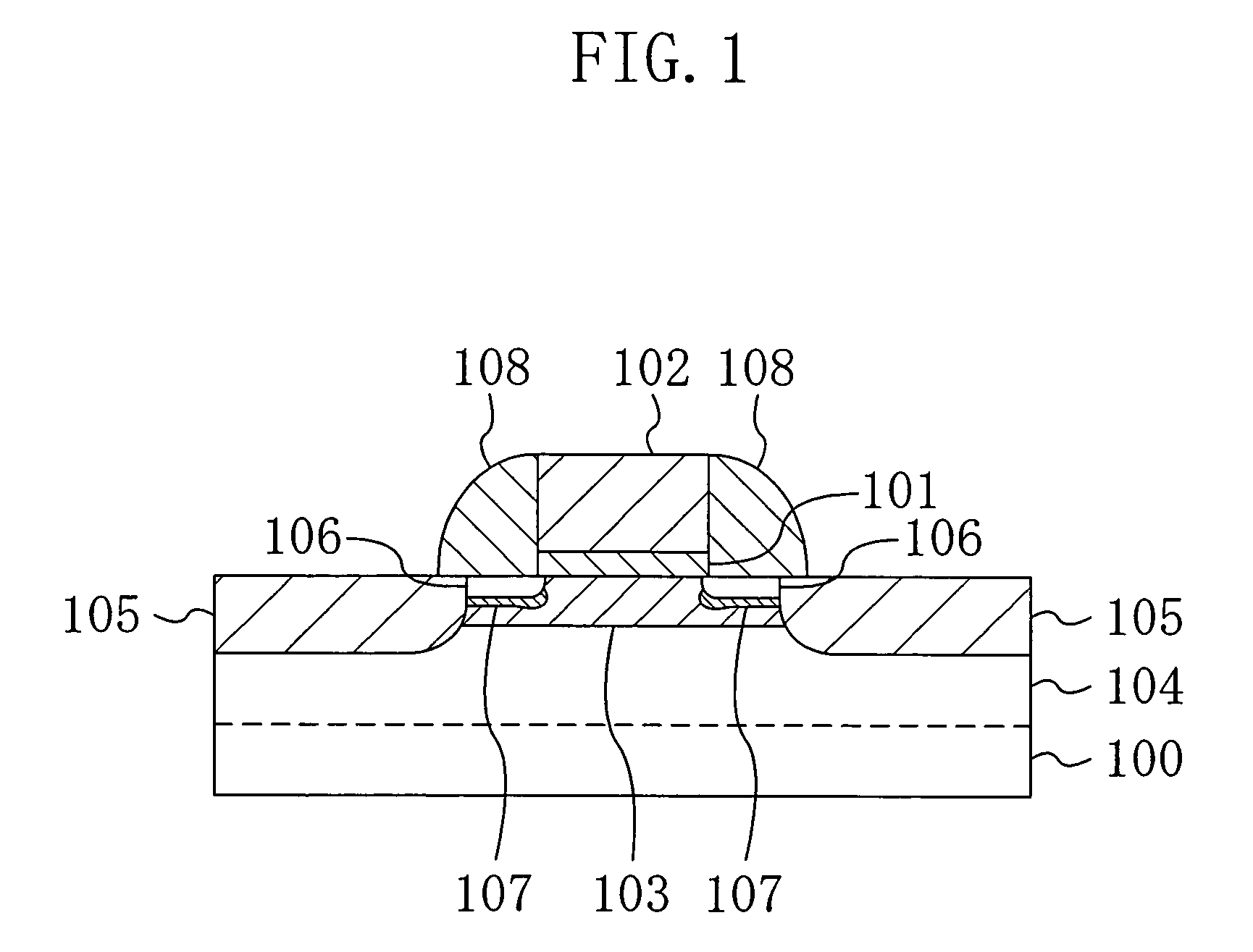

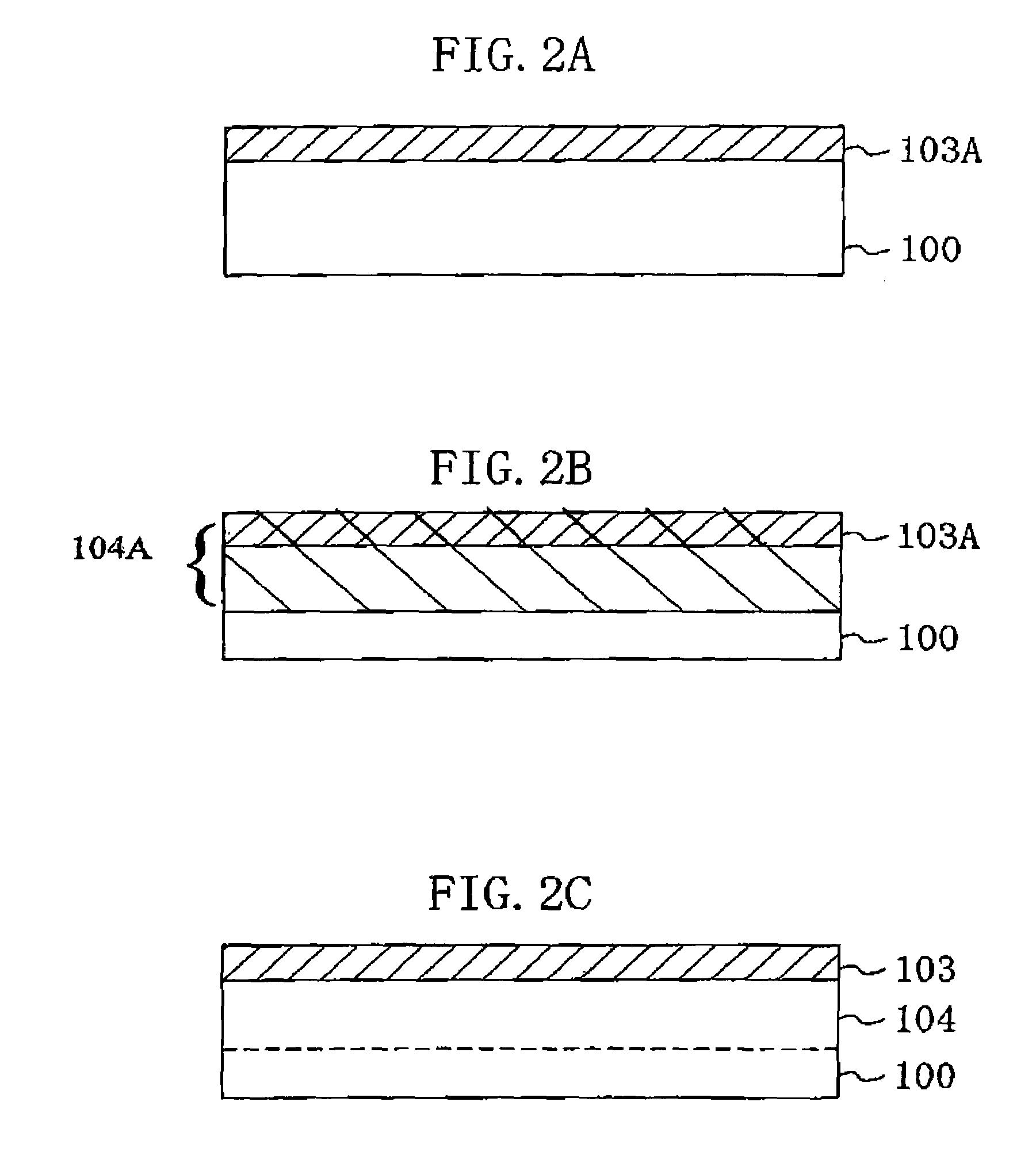

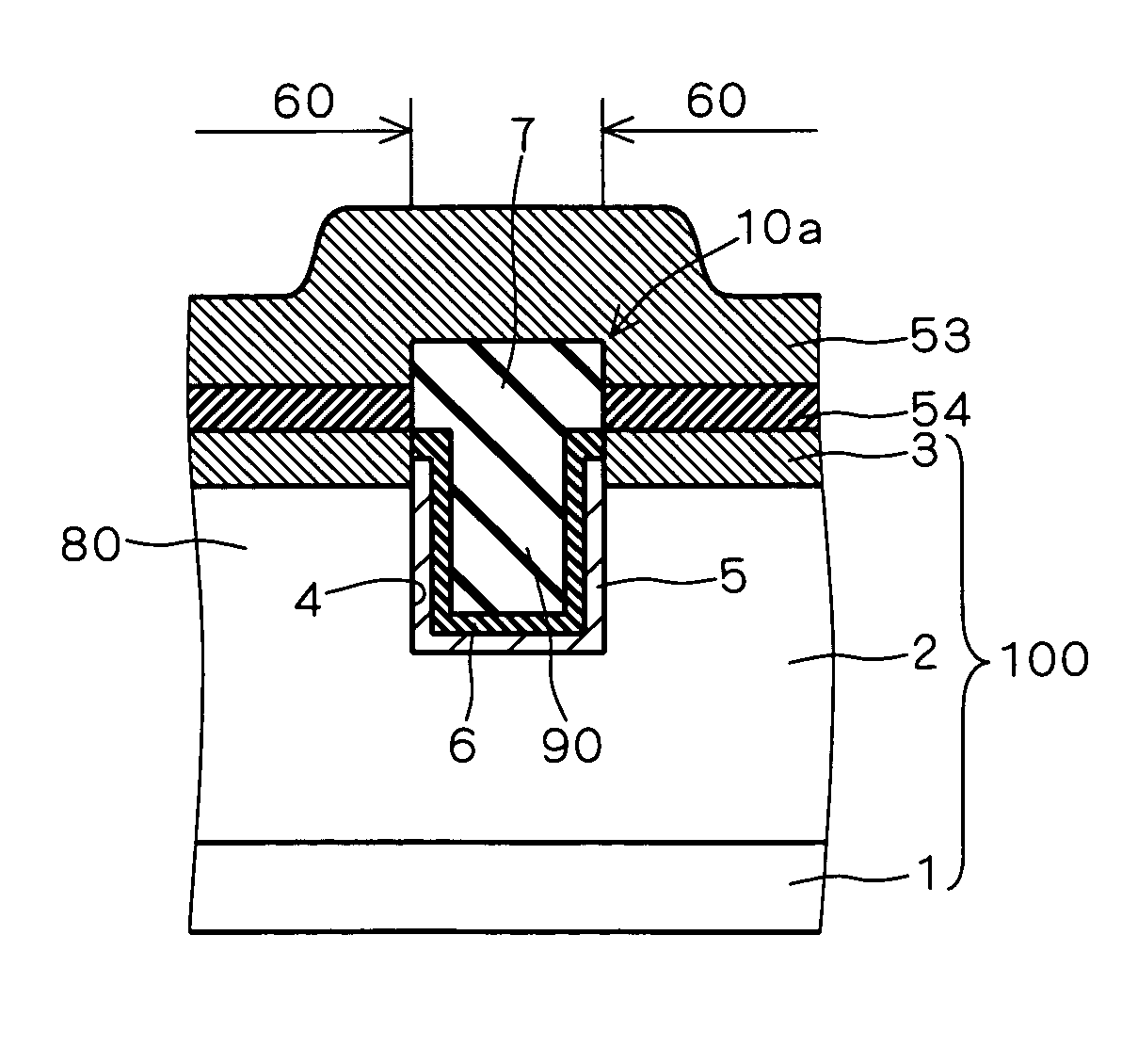

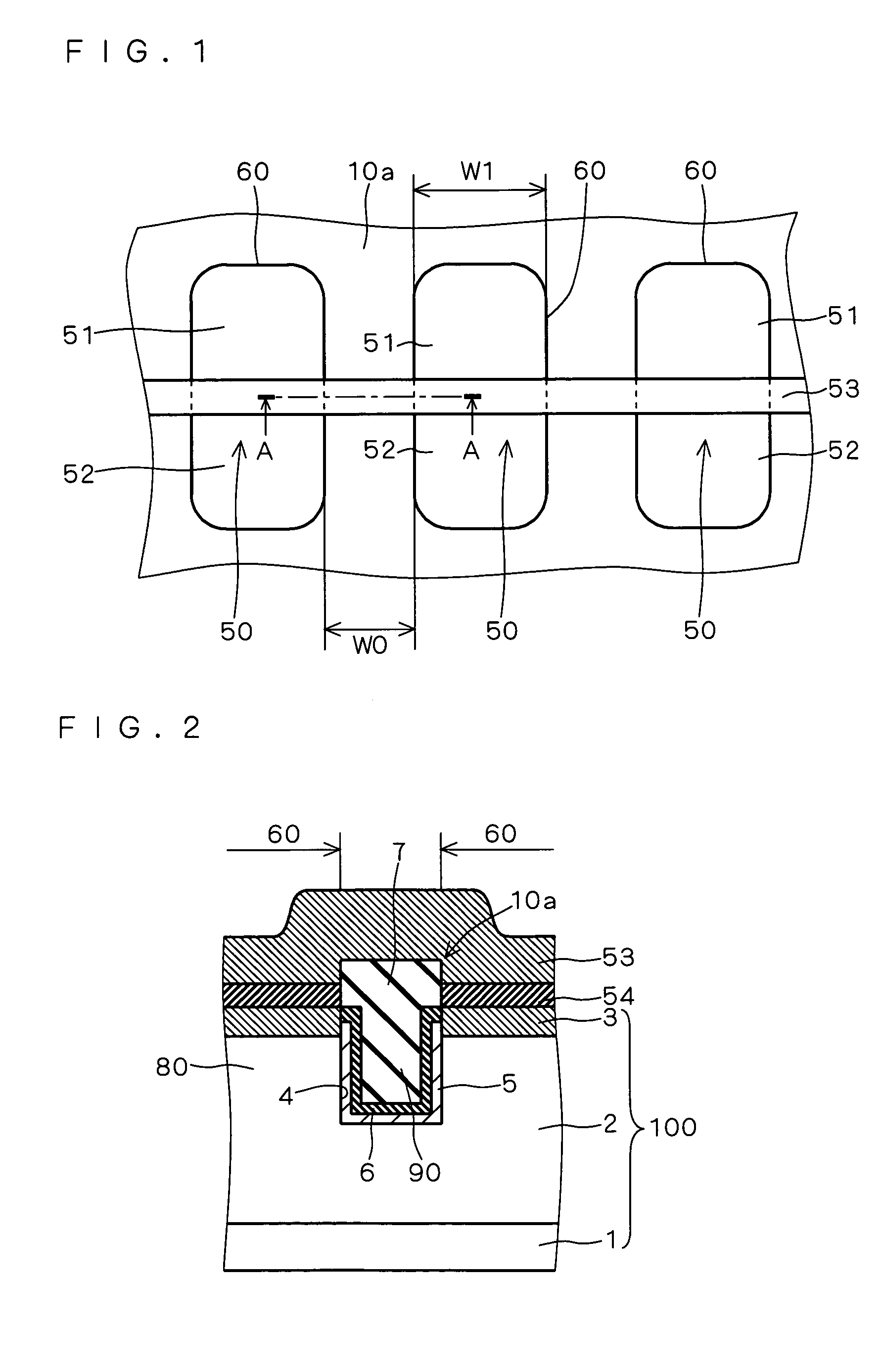

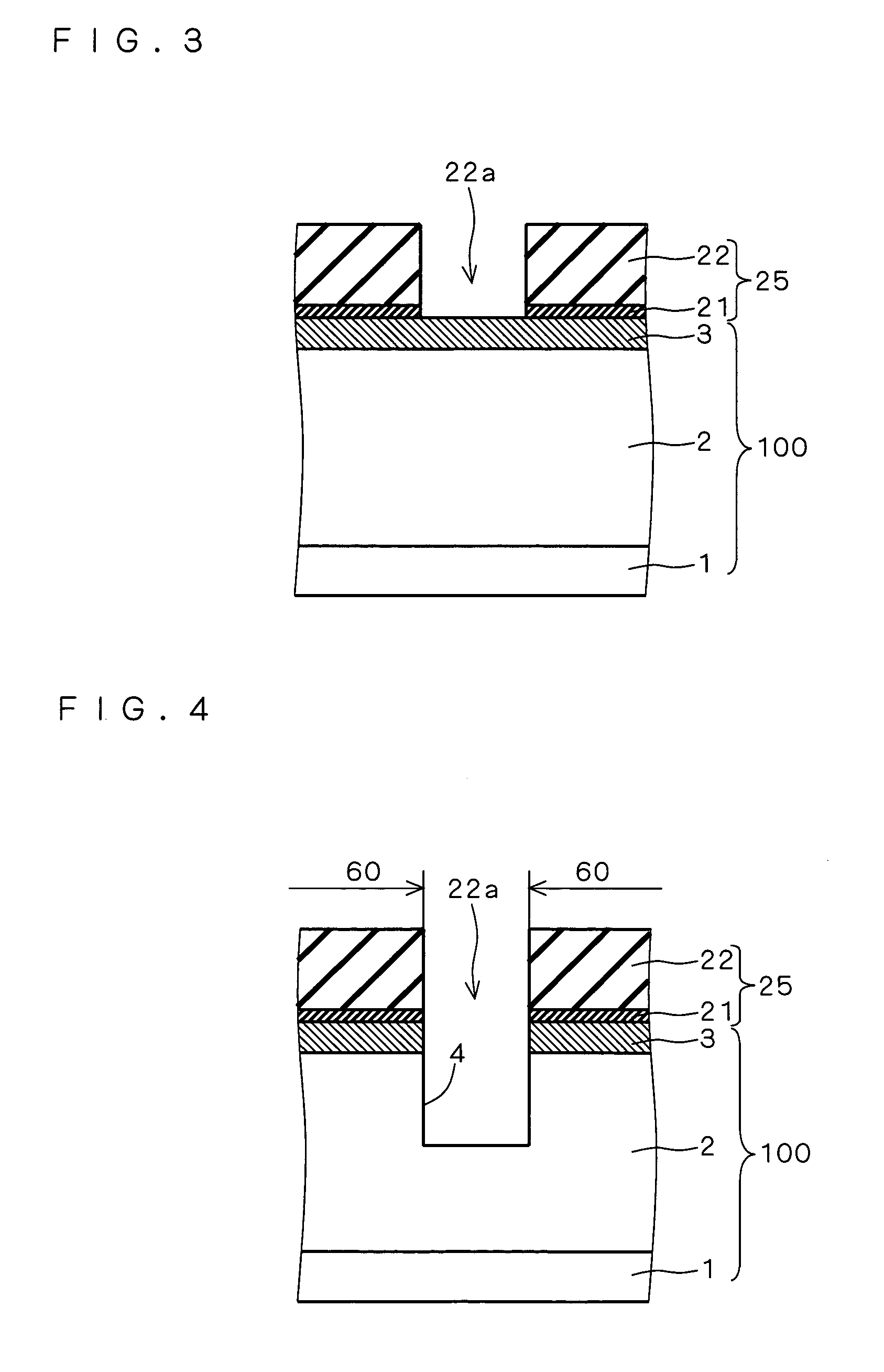

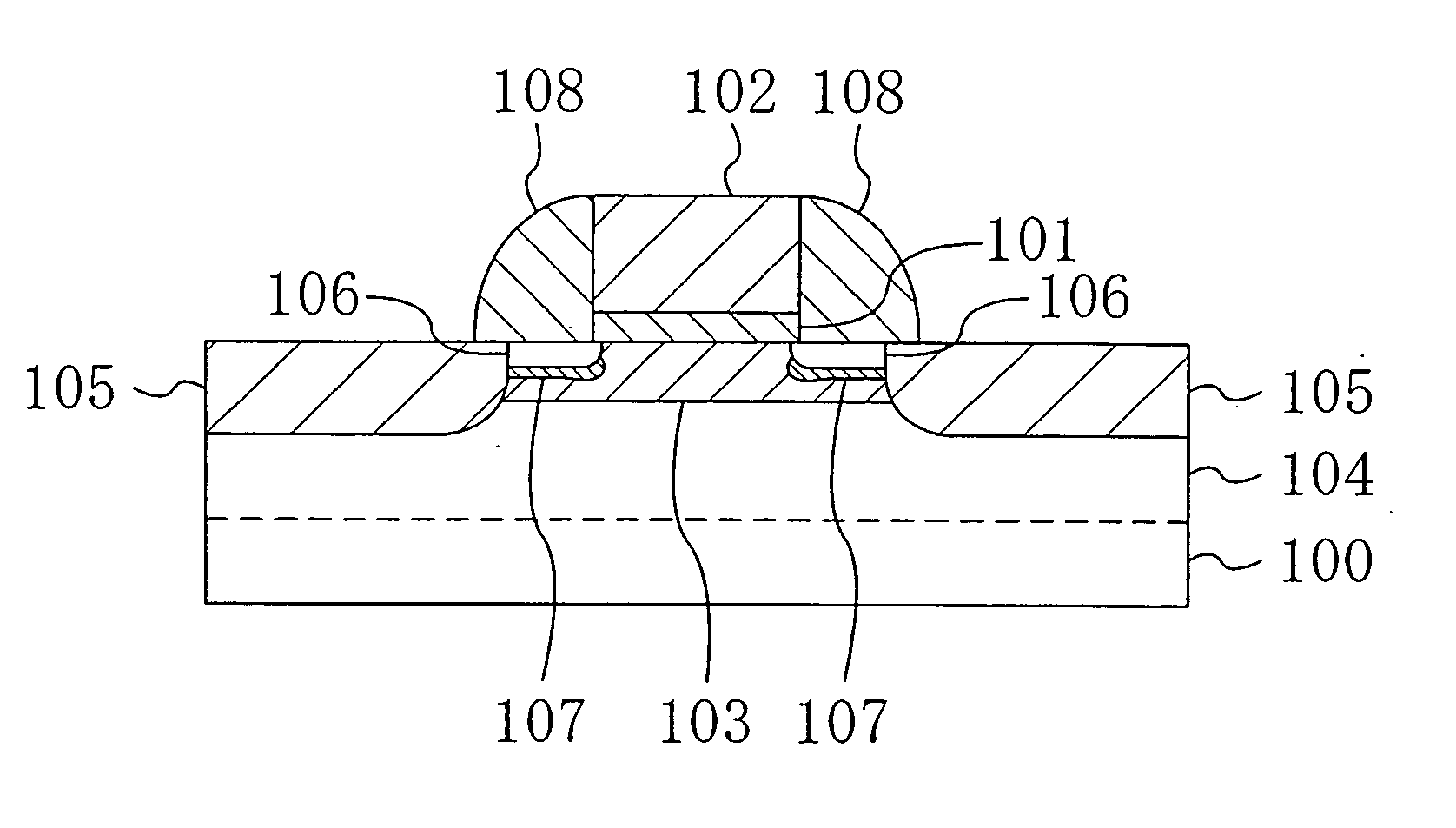

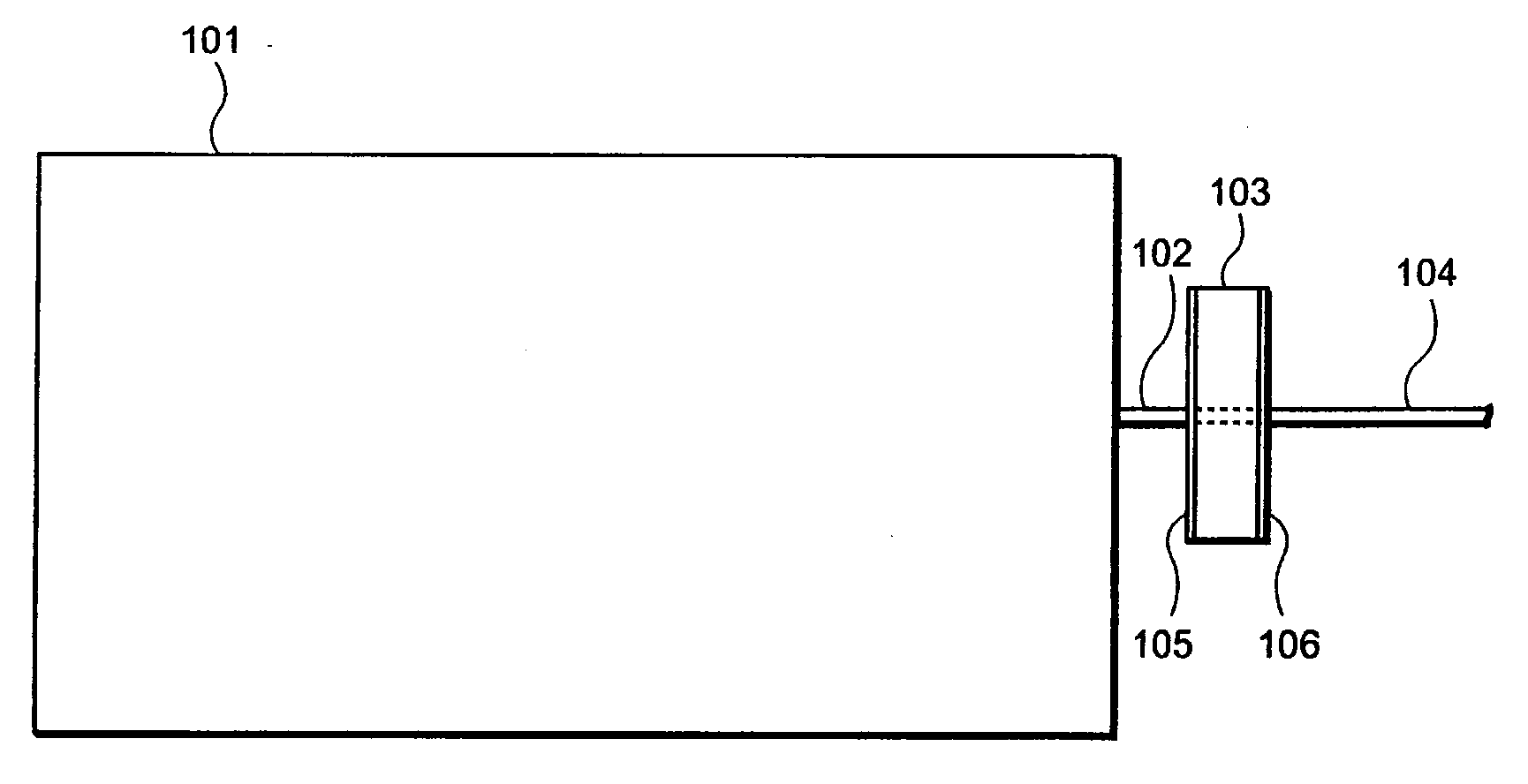

Heterojunction semiconductor device with element isolation structure

InactiveUS7170109B2Total current dropImprove featuresTransistorSemiconductor/solid-state device detailsHeterojunctionSemiconductor package

A technique enabling to improve element isolation characteristic of a semiconductor device is provided. An element isolation structure is provided in a semiconductor substrate in which a silicon layer, a compound semiconductor layer and a semiconductor layer are laminated in this order. The element isolation structure is composed of a trench, a semiconductor film, and first and second insulating films. The trench extends through the semiconductor layer and extends to the inside of the compound semiconductor layer. The semiconductor film is provided on the surface of the trench, and the first insulating film is provided on the semiconductor film. The second insulting film is provided on the first insulating film and fills the trench. Since the semiconductor film is interposed between the compound semiconductor film which is exposed by the trench and the first insulating film, there is no possibility that the compound semiconductor layer is directly thermally oxidized even if the semiconductor film is thermally oxidized to form the first insulating film.

Owner:RENESAS TECH CORP

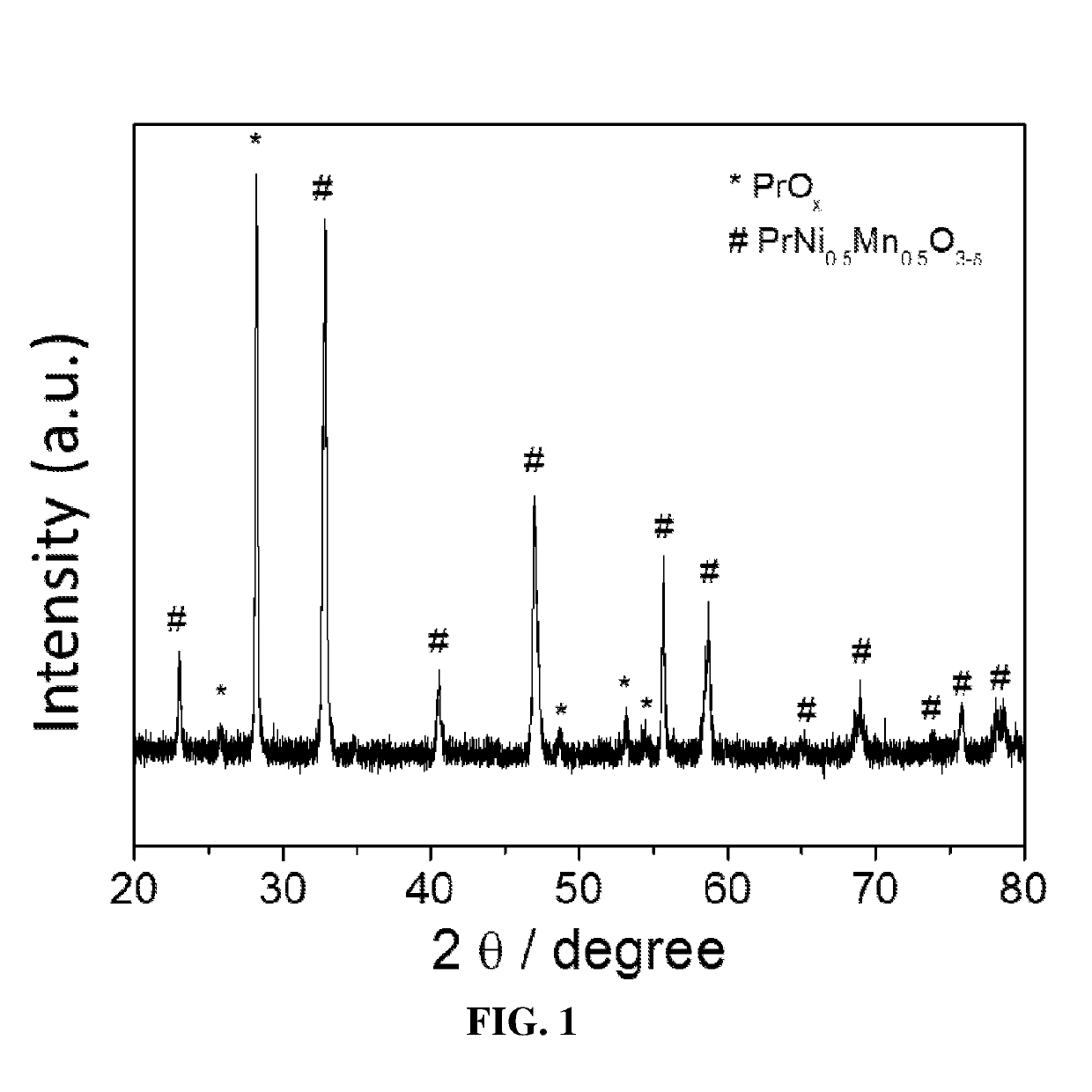

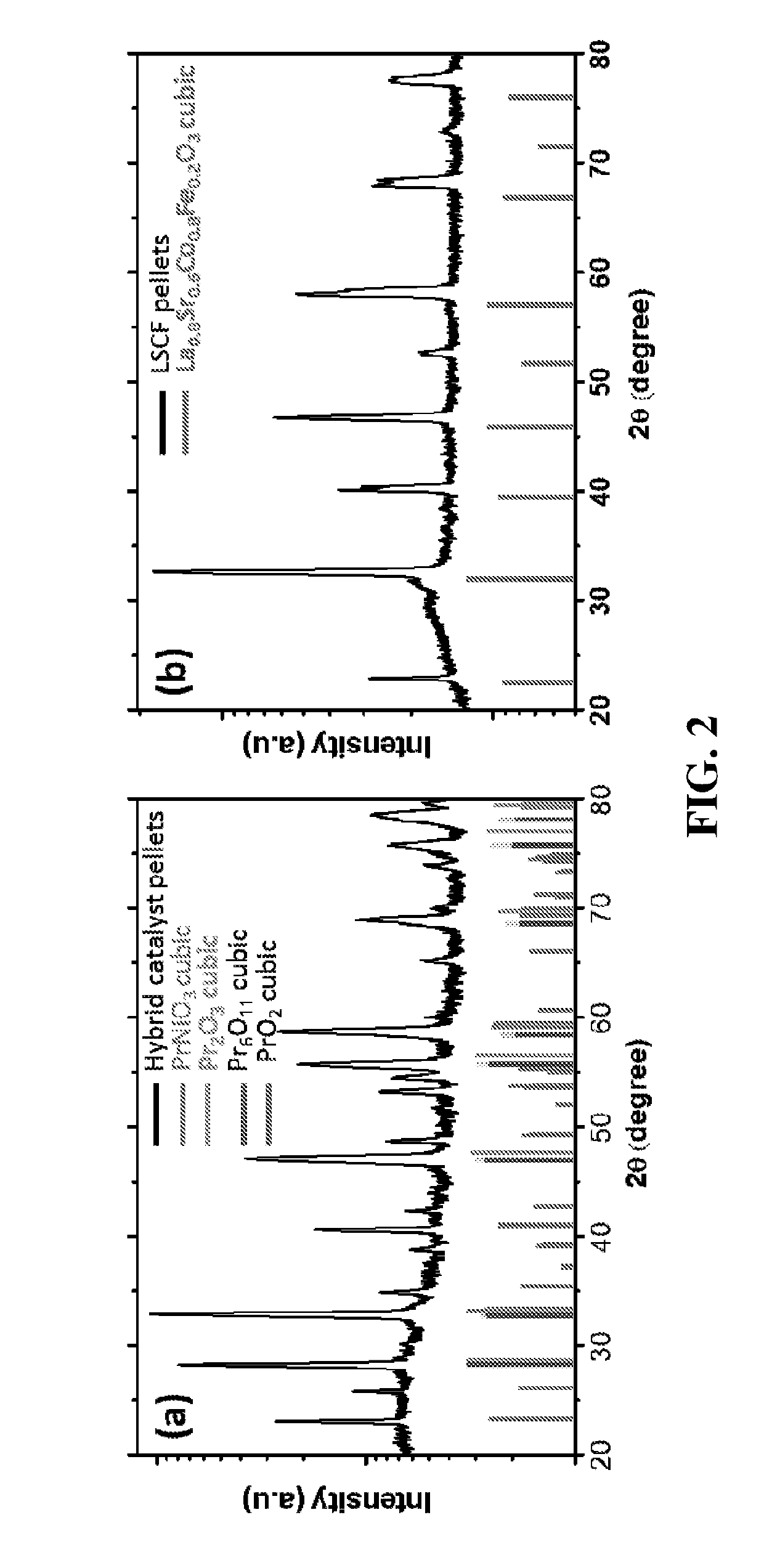

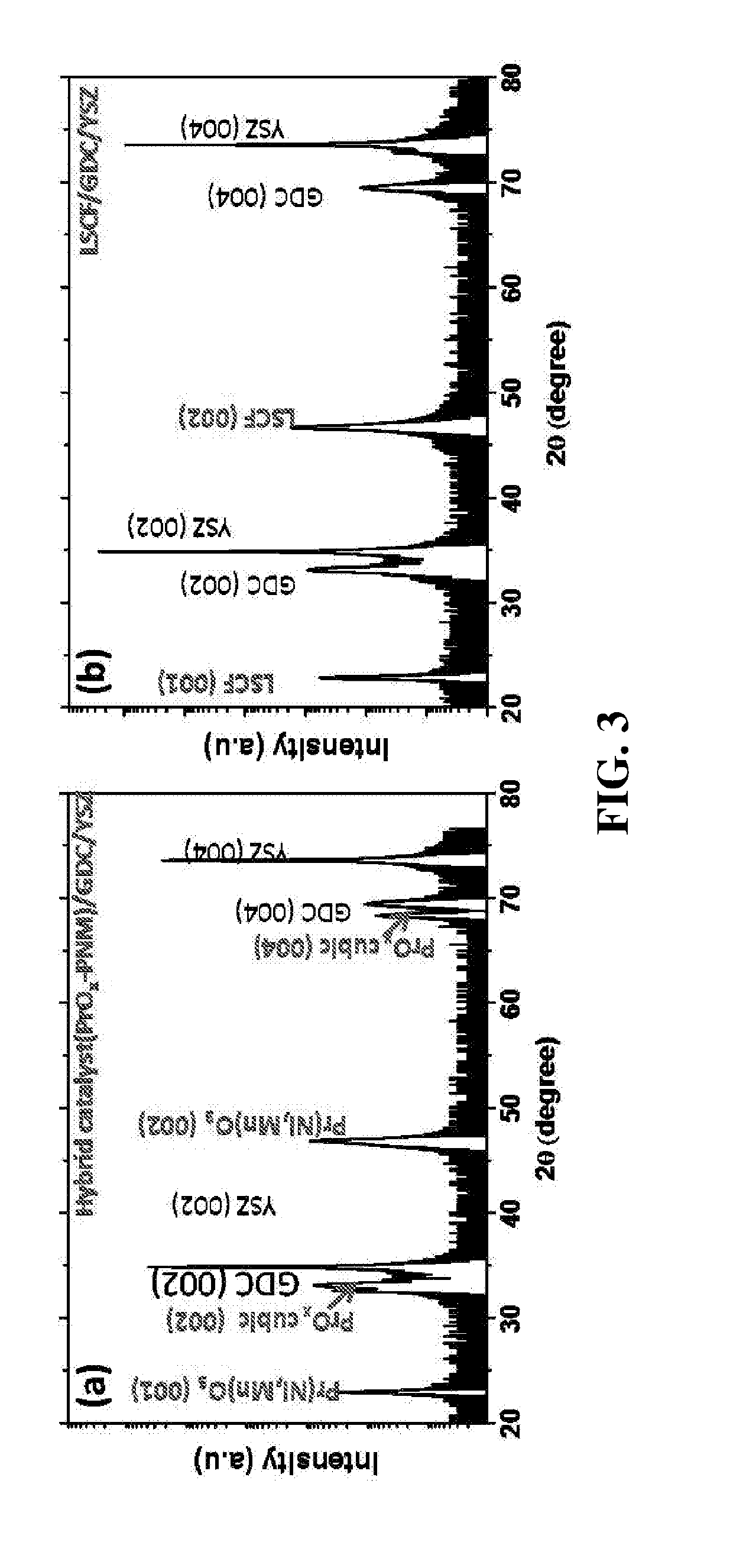

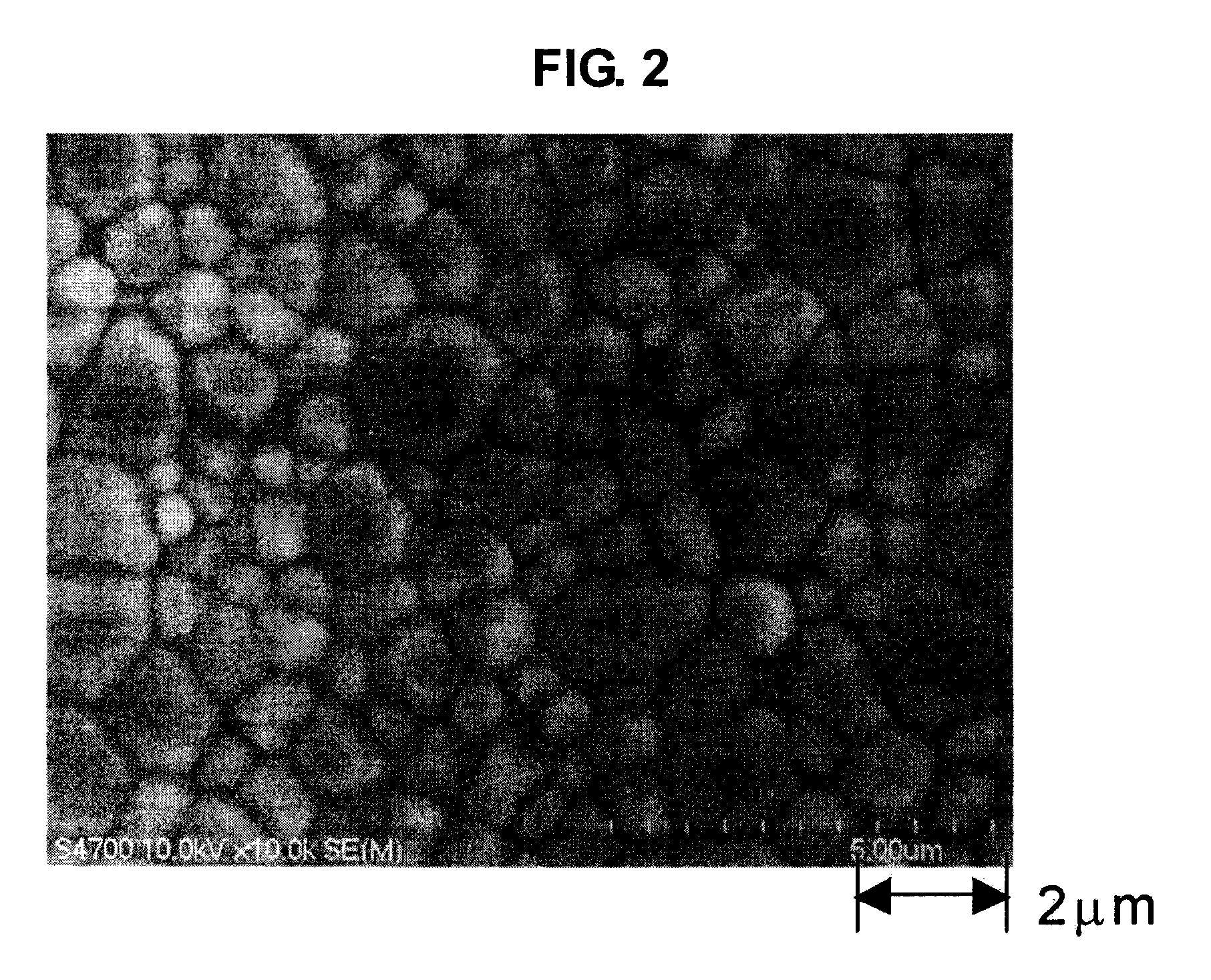

Catalyst coating of a perovskite film and particles exsoluted from the perovskite film

ActiveUS20190140287A1Increase orr rateCost reductionCell electrodesFuel cellsOxygen vacancyChemistry

A hybrid catalyst coating composed of a conformal thin film with exsoluted PrOx nano-particles. The conformal PNM thin film can be a perovskite composition of PrNi0.5Mn0.5O3 (PNM). The PrOx nano-particles dramatically enhance the oxygen reduction reaction kinetics via a high concentration of oxygen vacancies while the thin PNM film effectively suppresses strontium segregation from the cathode of an intermediate-temperature solid oxide fuel cell.

Owner:GEORGIA TECH RES CORP

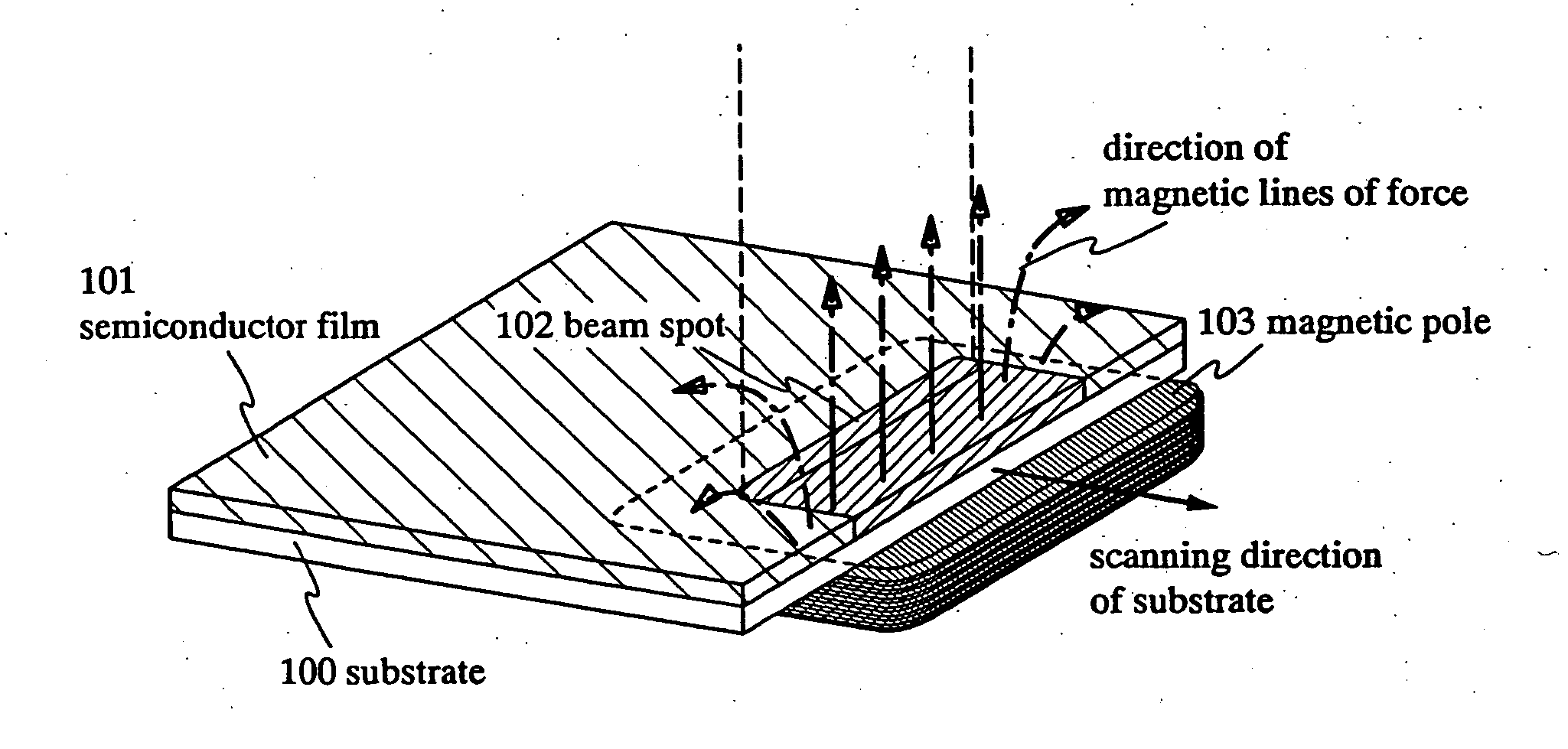

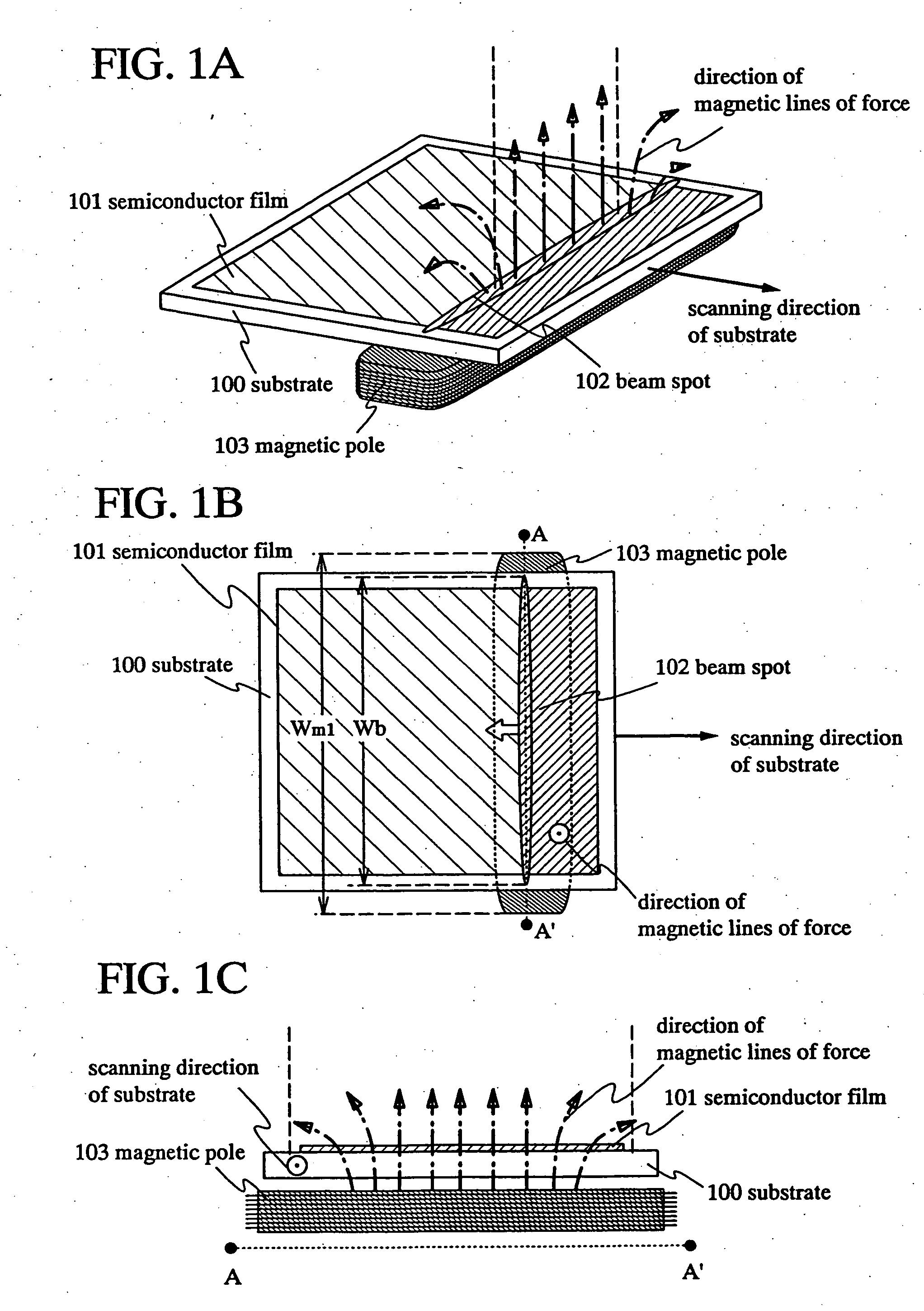

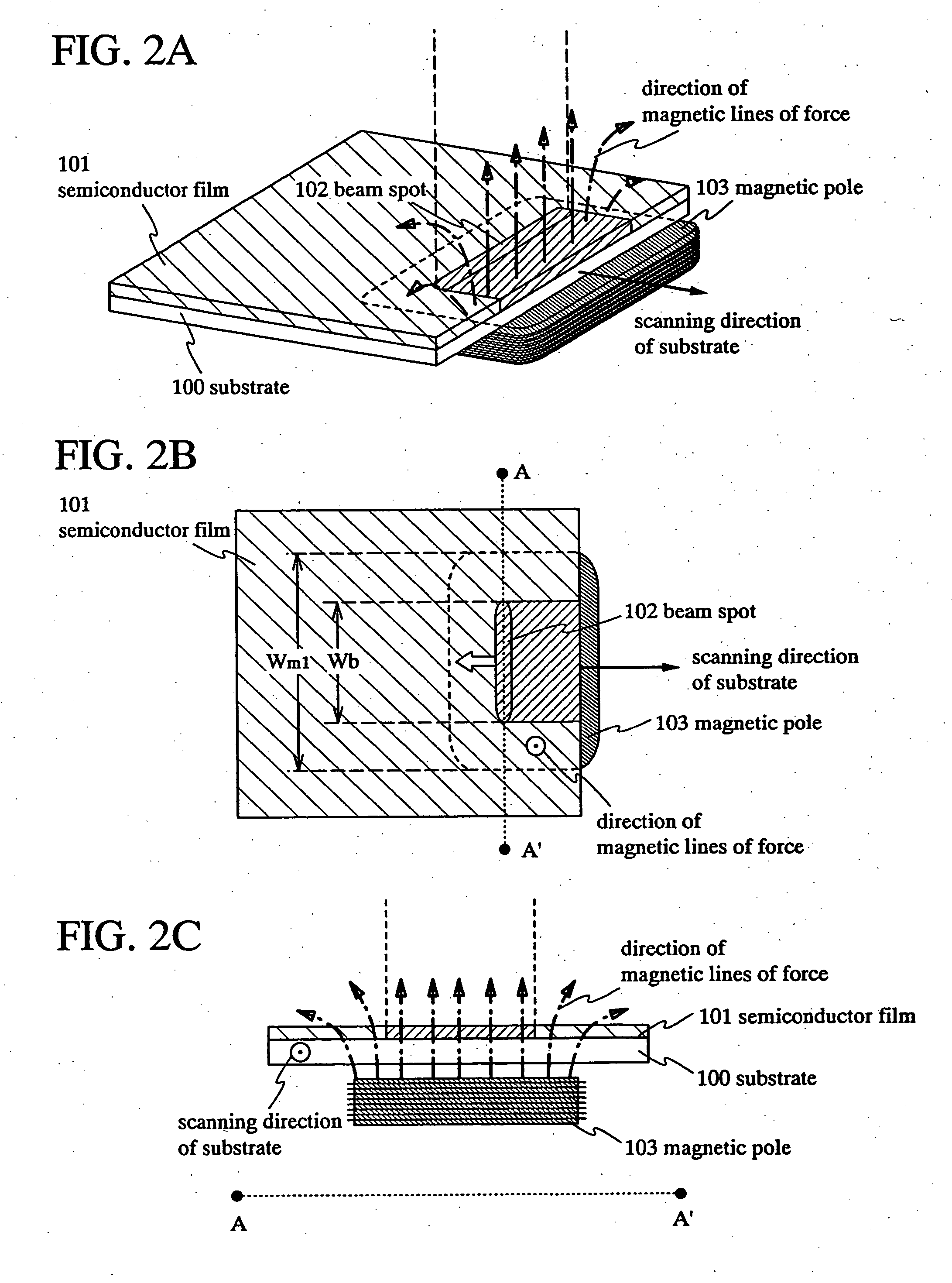

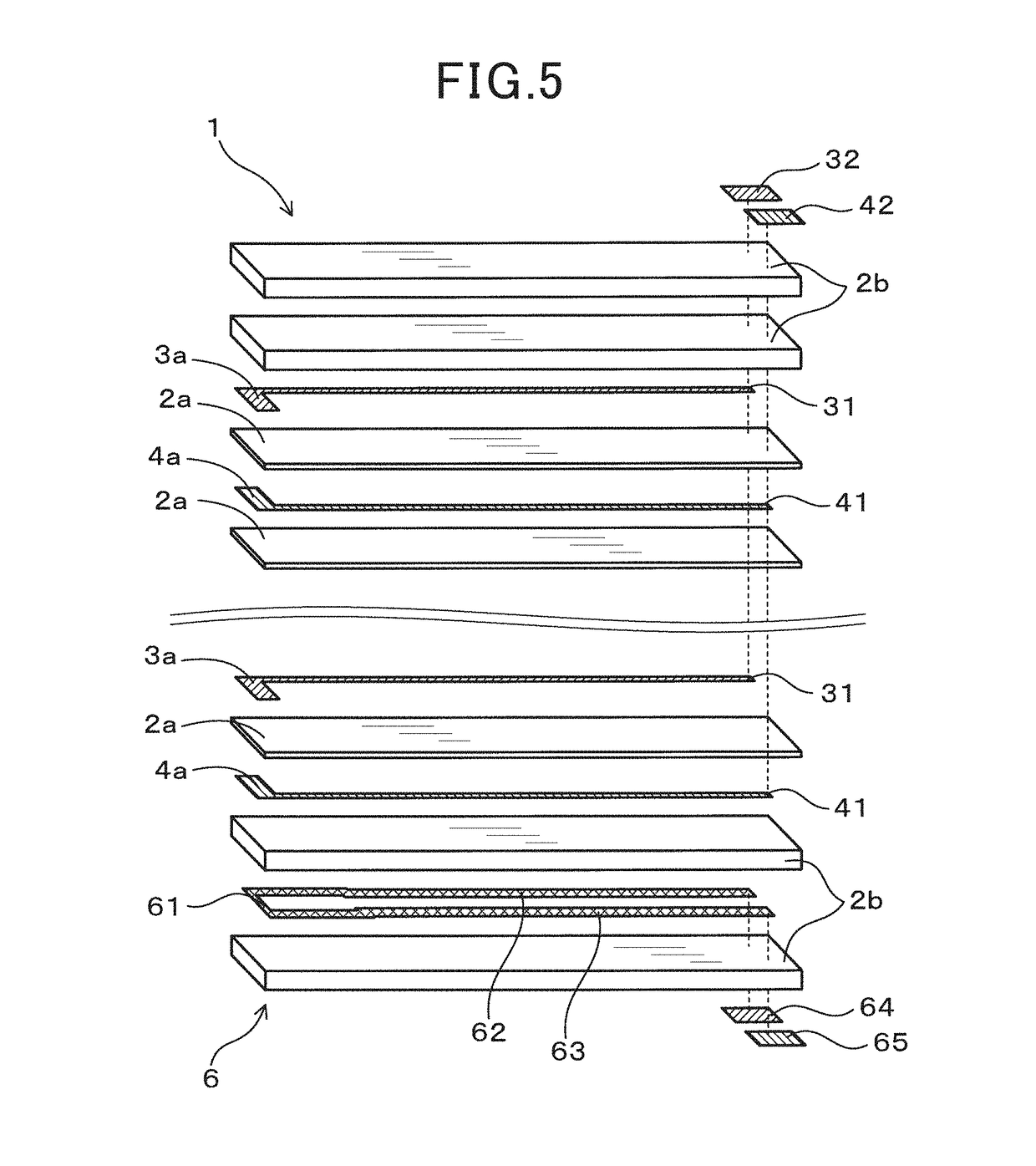

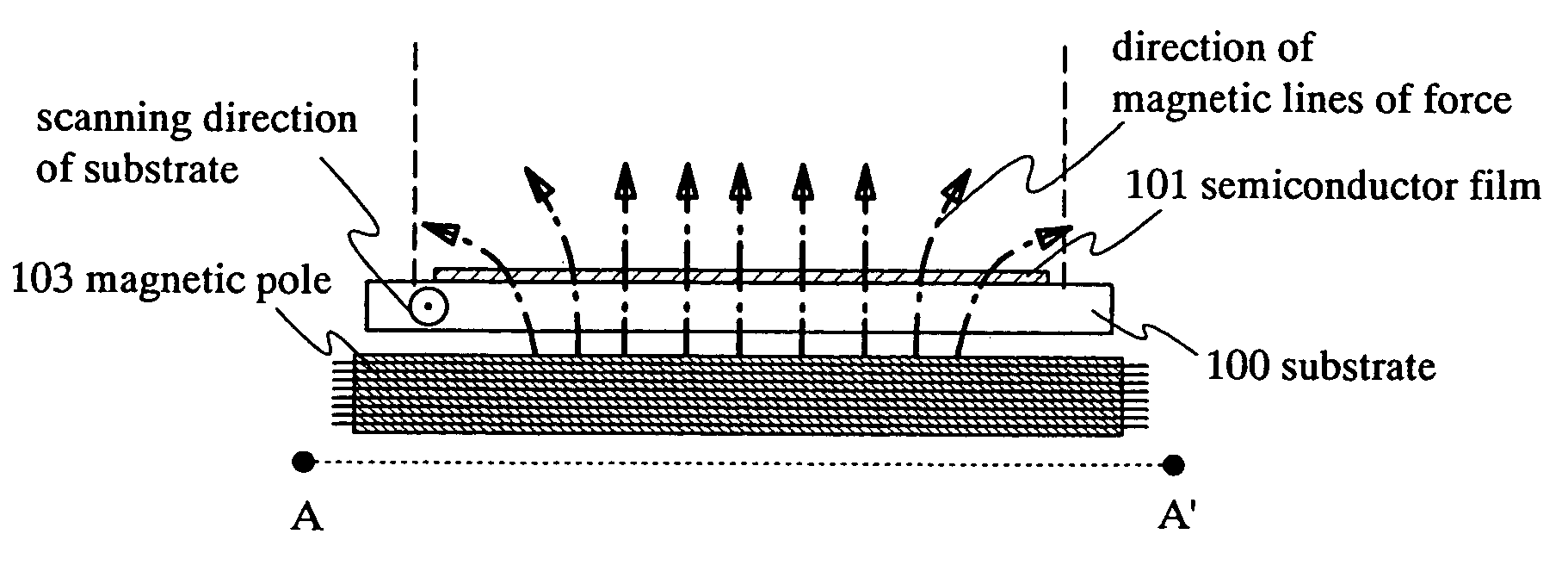

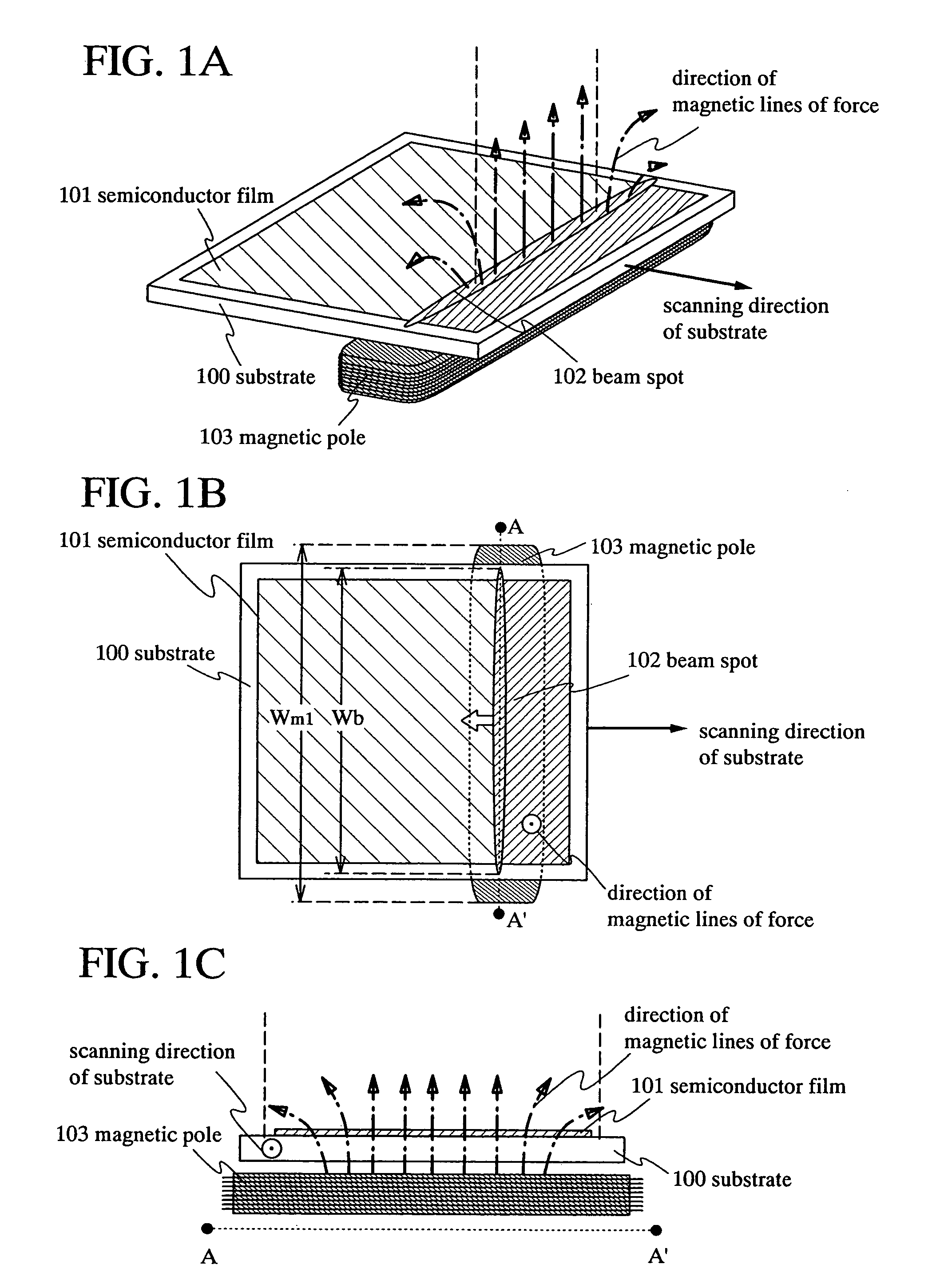

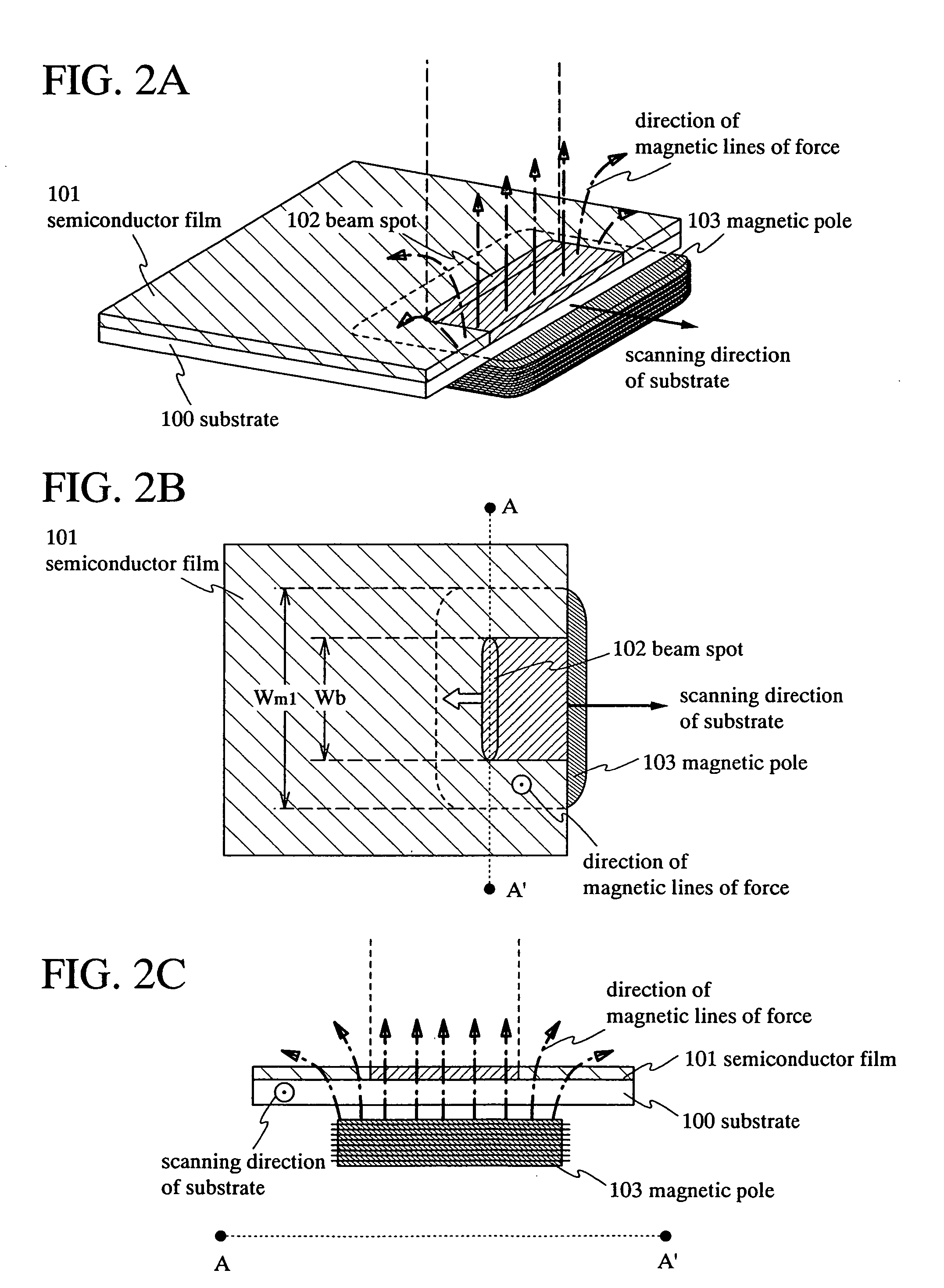

Method for manufacturing semiconductor device, semiconductor device, and laser irradiation apparatus

InactiveUS20070099440A1Avoid mixingVariation can be suppressedPolycrystalline material growthFrom solid stateNoble gasDevice material

[Object]It is an object of the present invention to provide a laser irradiation apparatus being able to crystallize the semiconductor film homogeneously while suppressing the variation of the crystallinity in the semiconductor film and the unevenness of the state of the surface thereof. It is another object of the present invention to provide a method for manufacturing a semiconductor device using the laser irradiation apparatus which can suppress the variation of on-current, mobility, and threshold of TFT, and to further provide a semiconductor device manufactured with the manufacturing method. [Solution]A method for manufacturing a semiconductor device comprising the steps of adding the first noble gas to the semiconductor film formed over the insulating surface with the ion doping method and irradiating the semiconductor film with the first noble gas added therein with the laser light in an atmosphere of second noble gas, wherein the magnetic field is applied to the semiconductor film with the first noble gas added when the laser light is irradiated.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method for fabricating the same

InactiveUS20070063275A1Increase the doping concentrationReduce leakage currentTransistorSemiconductor/solid-state device manufacturingIndiumDevice material

Owner:PANASONIC CORP

Laser oscillator and laser beam oscillation method

By using a ceramics laser medium such as Nd:YAG ceramics or Yb:YAG ceramics, division of a lateral mode pattern to a local mode is suppressed so that single frequency, linear polarization oscillation are achieved in TEM00 mode. A laser oscillator comprising a laser light source for oscillating the pumping light, and a laser medium of Nd:YAG ceramics or Yb:YAG ceramics having an average grain size of 5 μm or less upon which the pumping light impinges is provided. The laser medium may have a first surface having a first dielectric multilayer film, and a second surface having a second dielectric multilayer film.

Owner:TOKAI UNIV

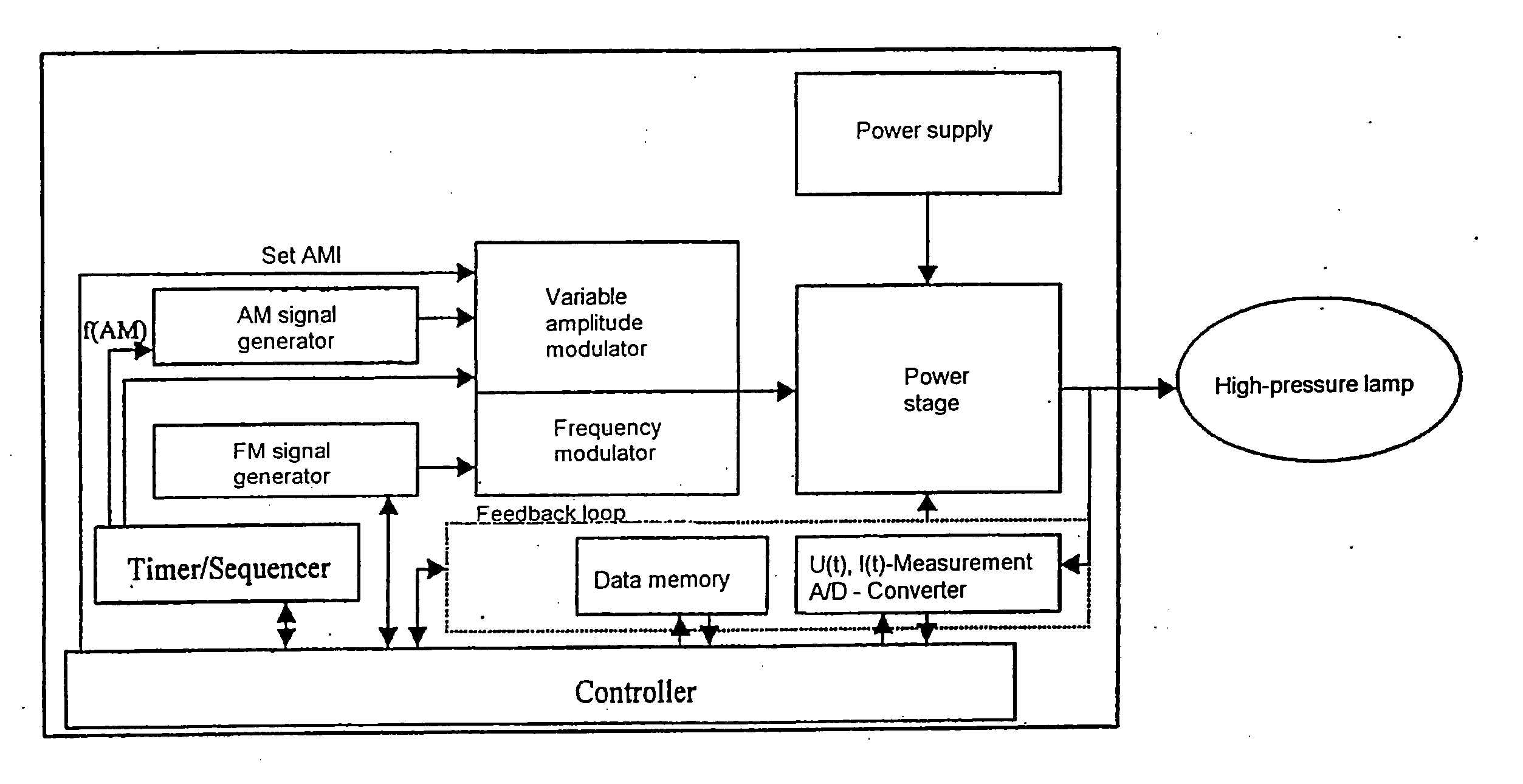

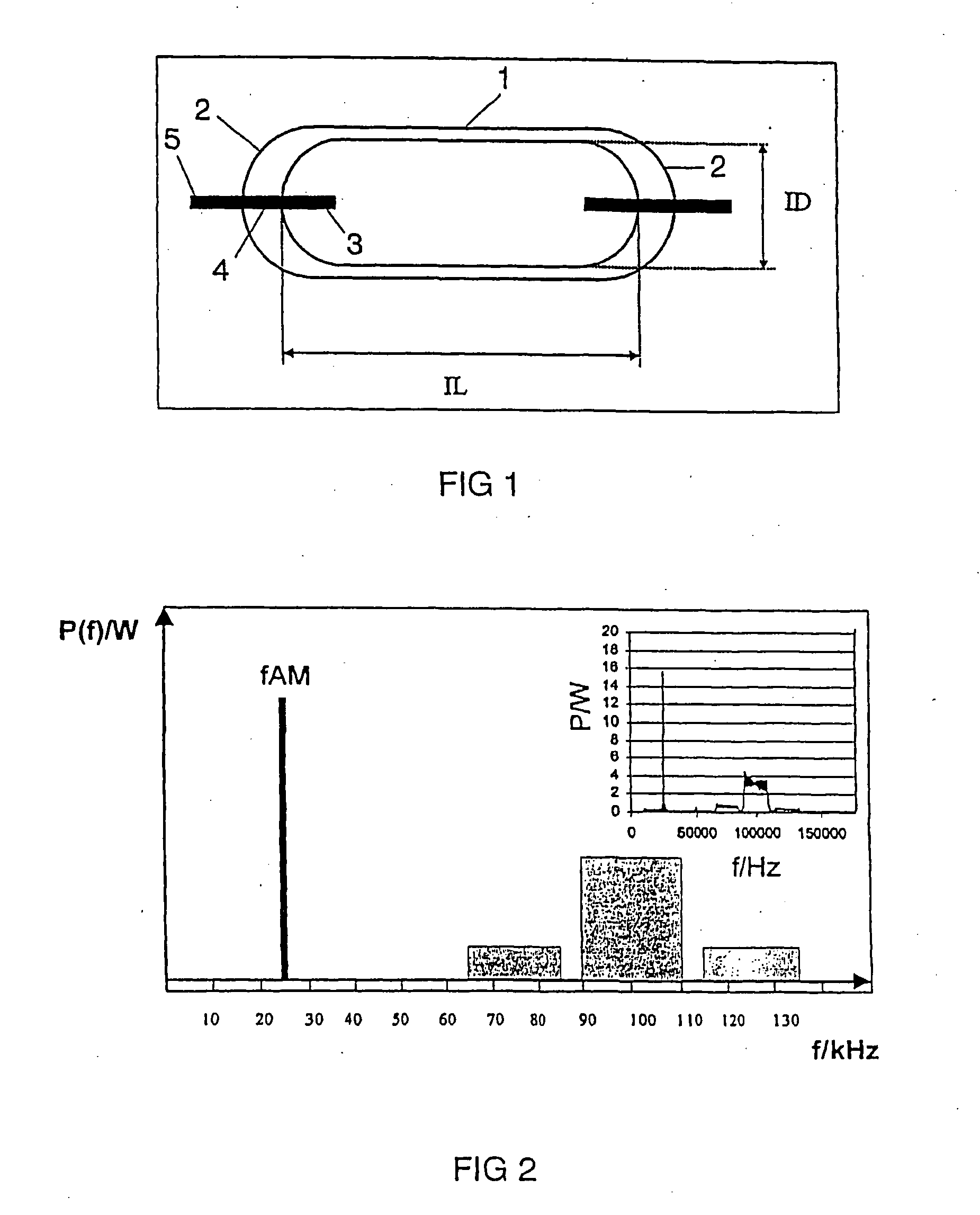

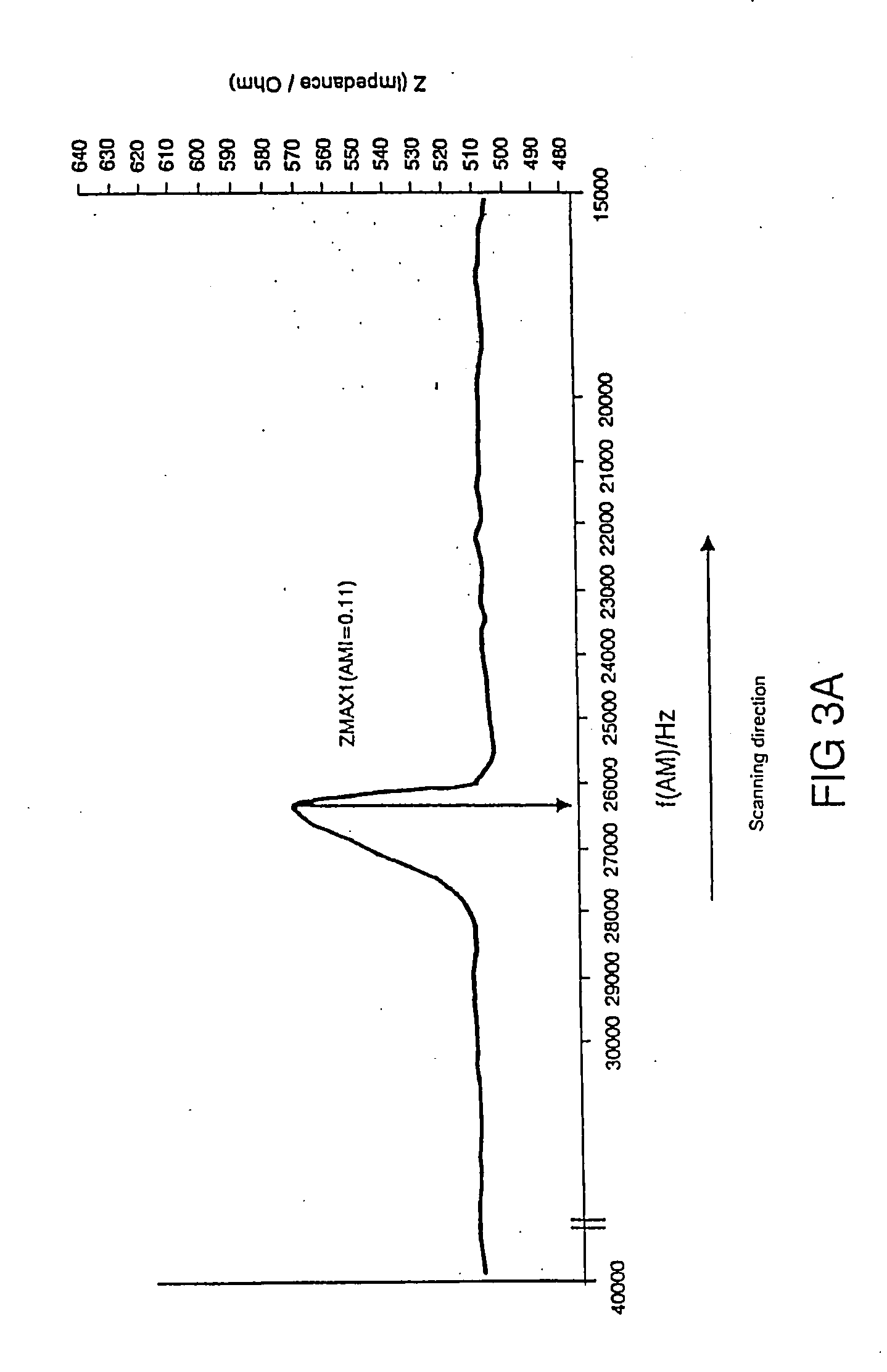

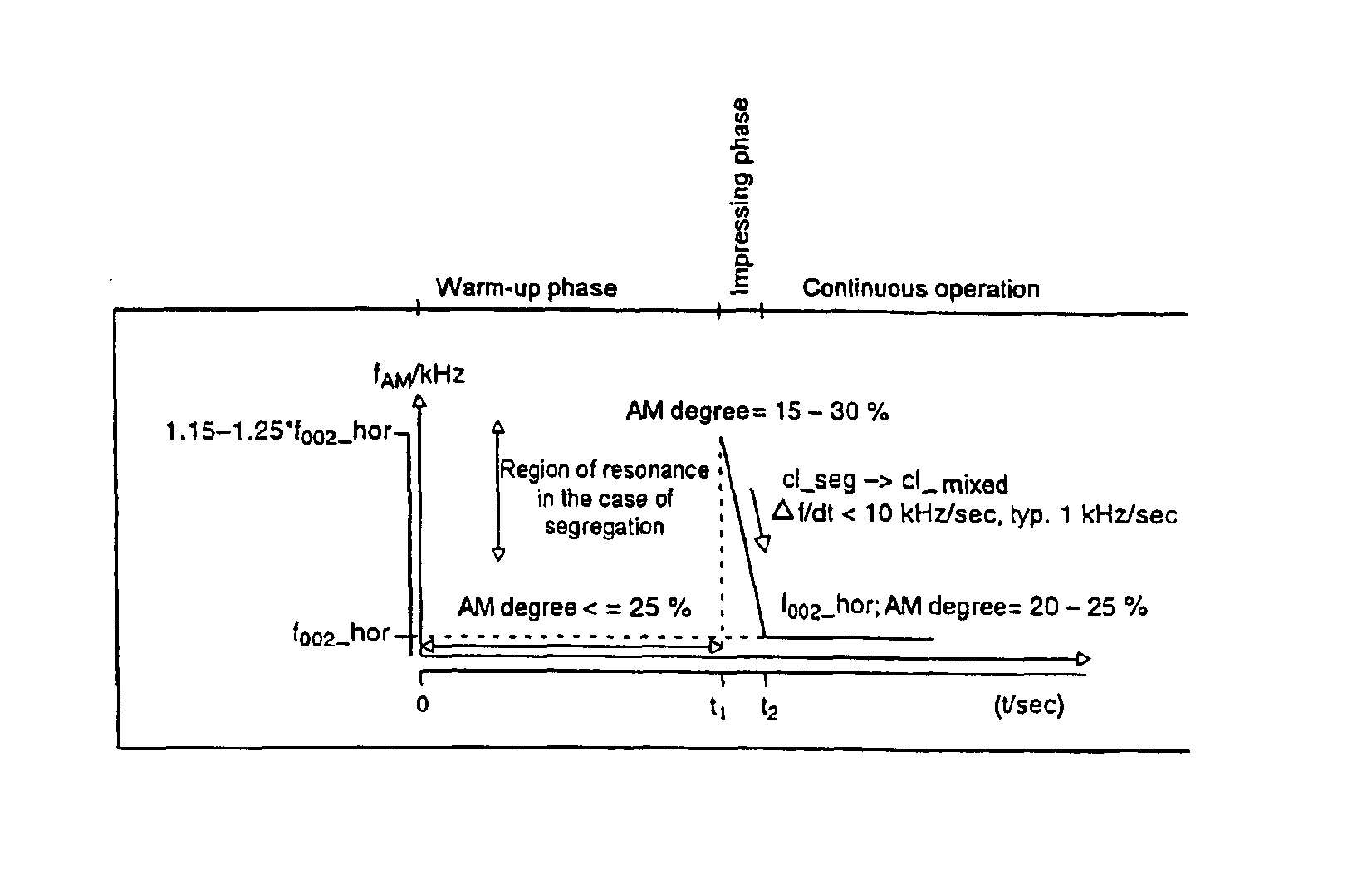

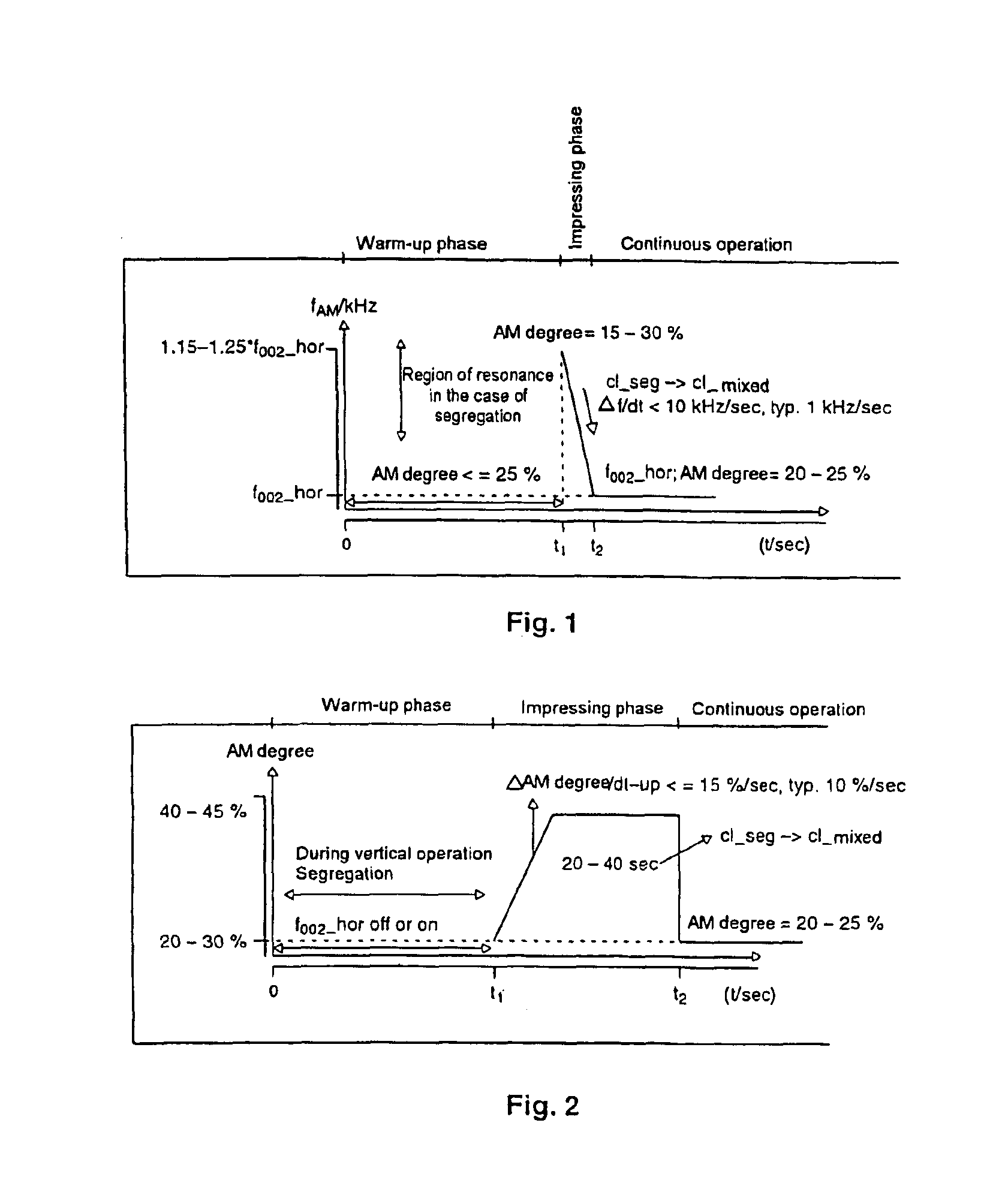

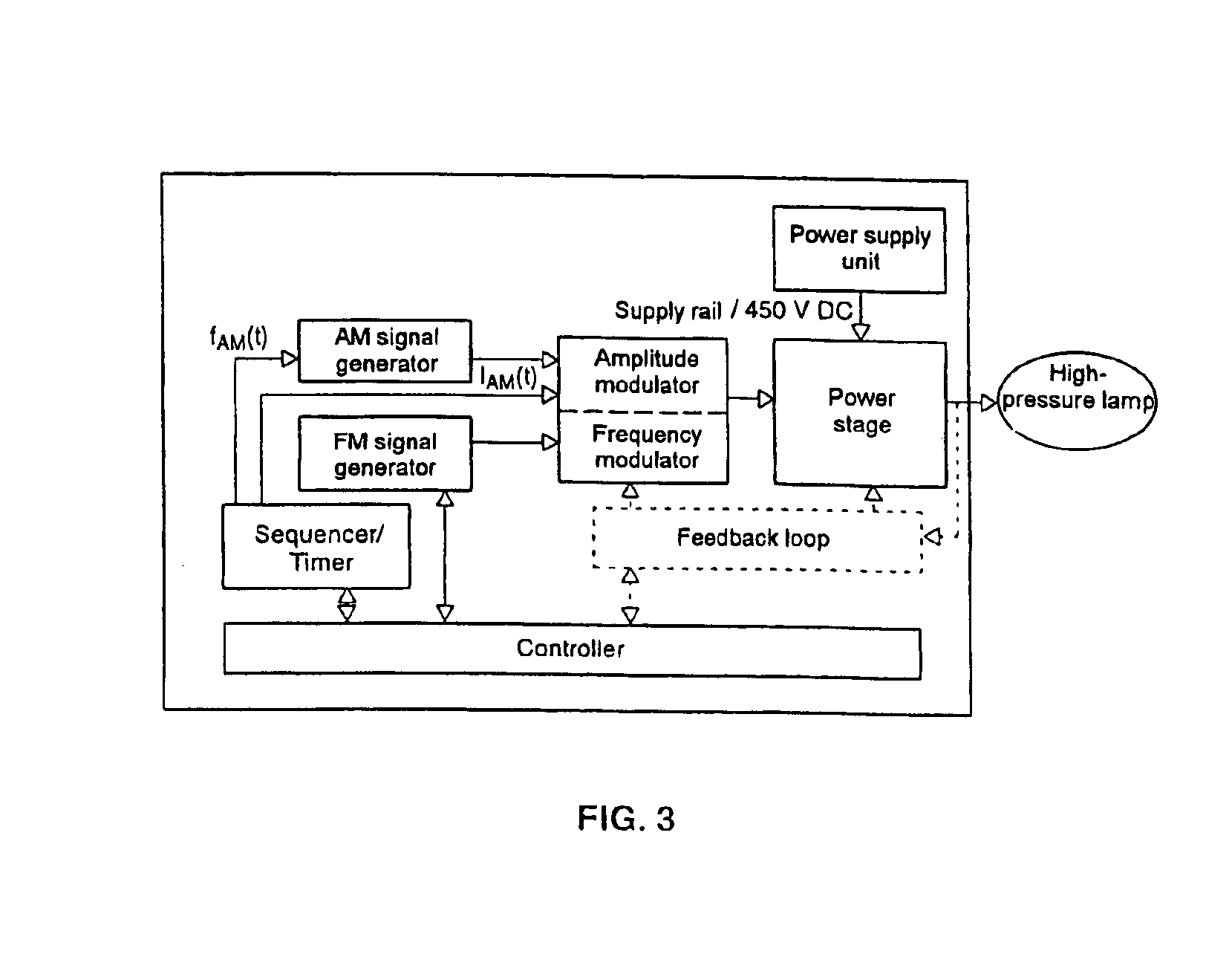

Operating method, electronic ballast and system for resonant operation of high pressure lamps in the longitudinal mode

InactiveUS20050168176A1Promotes thorough mixingInhibit coloringGas discharge lampsElectric light circuit arrangementHigh pressureLongitudinal mode

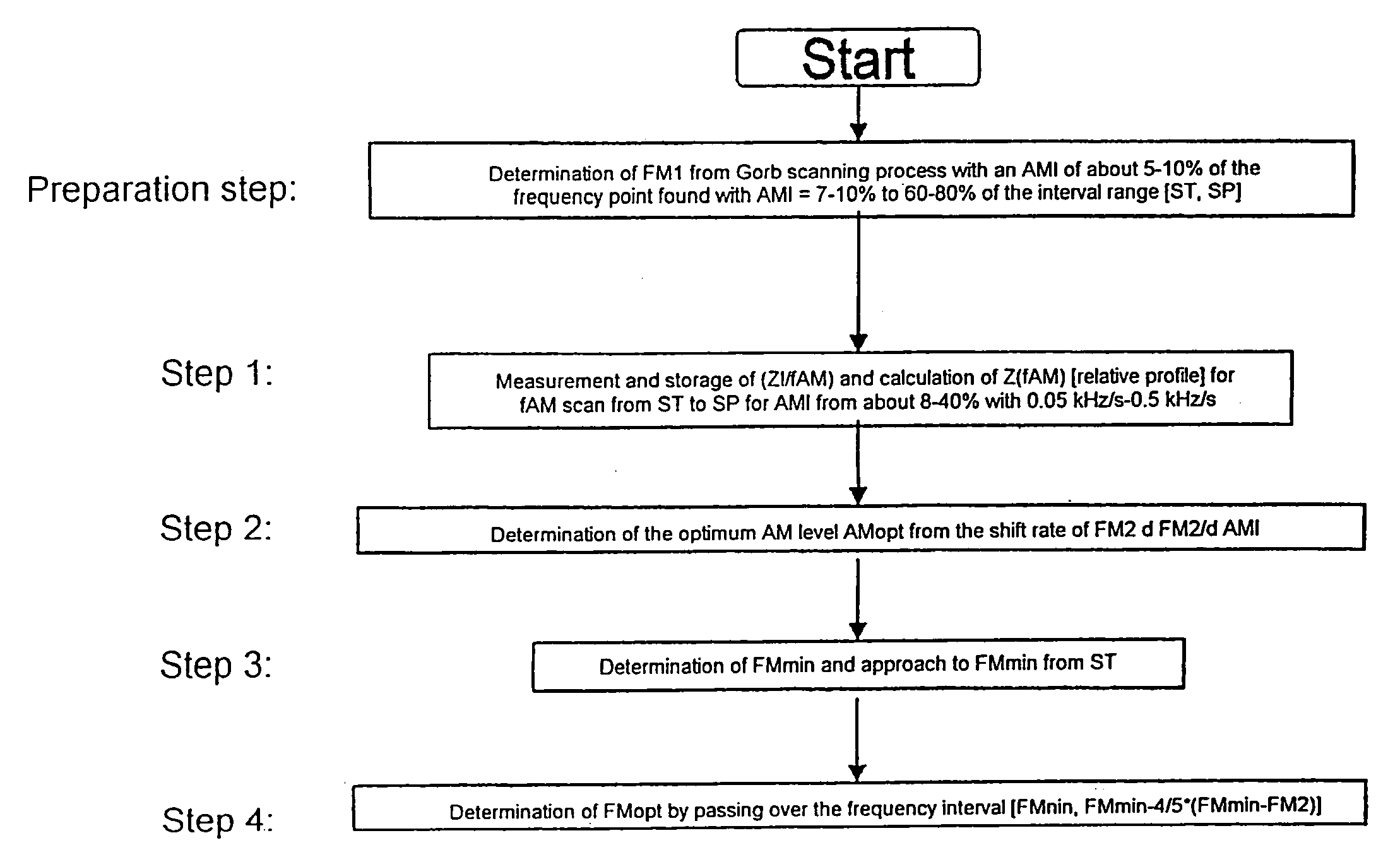

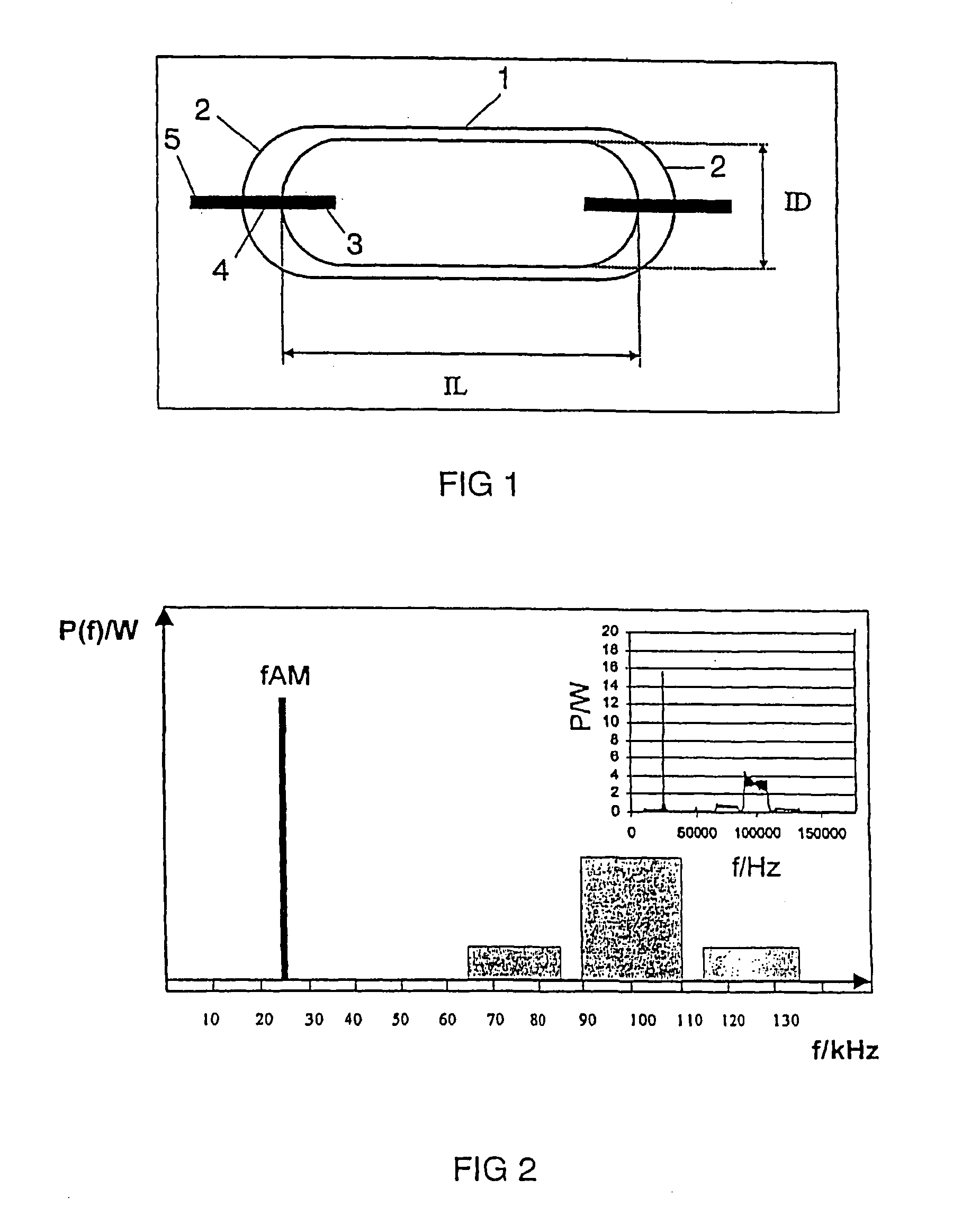

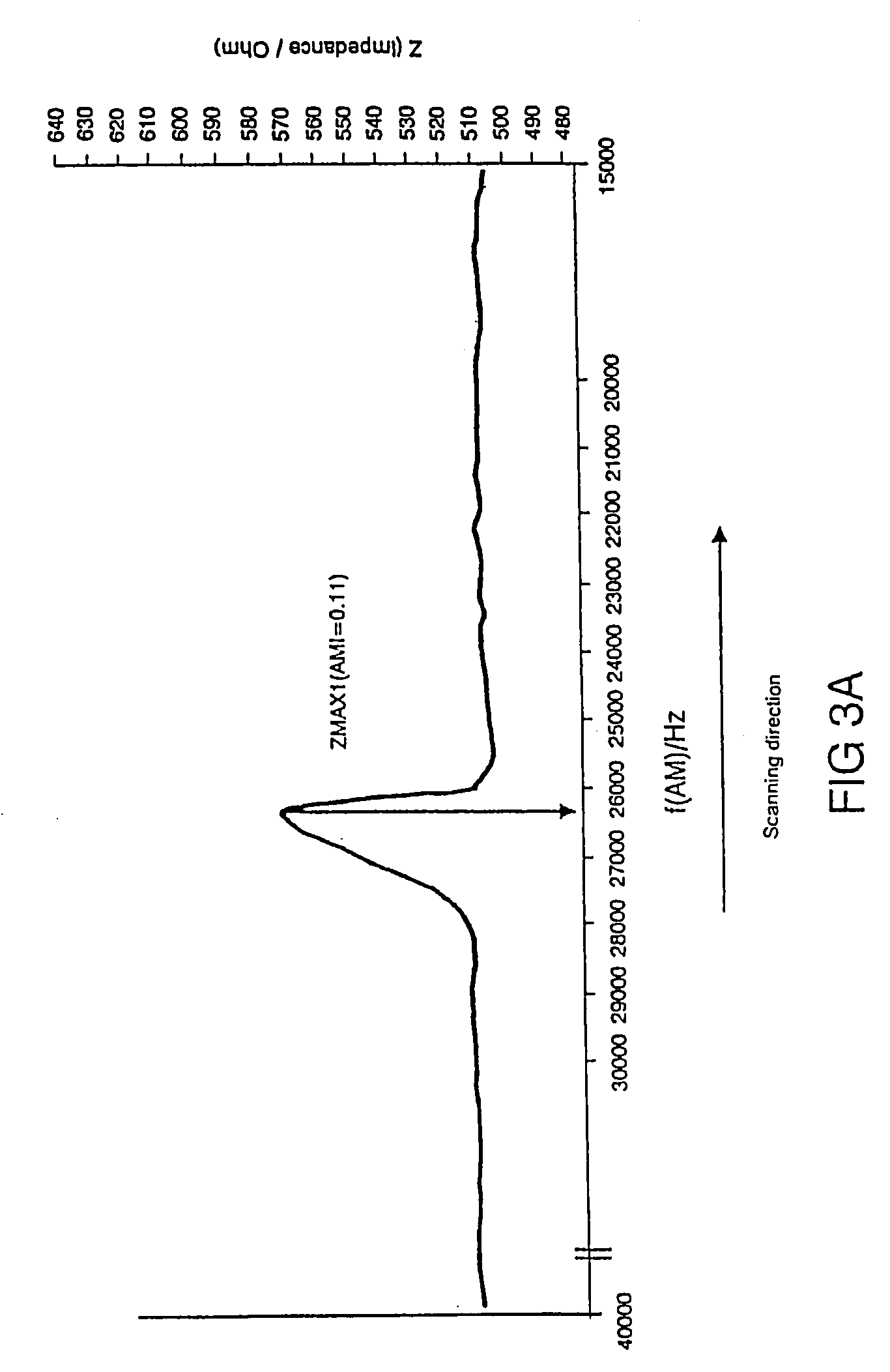

Operating method, electronic ballast and system for resonant operation of high-pressure lamps in the longitudinal mode The operating method is based on the simultaneous use of FM and AM and is distinguished by passing through a number of steps which are used to find an optimum frequency for the AM and, in addition, to define an optimum AM level. An electronic ballast which has a memory module which can be overwritten is used for implementation.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Operating method, electronic ballast and system for resonant operation of high pressure lamps in the longitudinal mode

InactiveUS7157867B2Promotes thorough mixingInhibit coloringGas discharge lampsElectric light circuit arrangementEngineeringHigh pressure

The operating method is based on the simultaneous use of FM and AM and is distinguished by passing through a number of steps which are used to find an optimum frequency for the AM and, in addition, to define an optimum AM level. An electronic ballast which has a memory module which can be overwritten is used for implementation.

Owner:PATENT TREUHAND GESELLSCHAFT FUER ELECTRIC GLUEHLAMPEN M B H

Mixed powder for powder metallurgy and manufacturing method thereof

ActiveUS20150151361A1Less scatteringImprove liquidityTransportation and packagingMetal-working apparatusGraphiteFullerene

This mixed powder for powder metallurgy, the powder having excellent fluidity and minimal graphite powder scattering, can be obtained relatively conveniently by mixing fine graphite having an average grain diameter of 4 μm or less with an iron based powder. The process is performed without the addition of a binder and while shearing force is applied. It is preferable that the fine graphite have an average grain diameter of 2.4 μm or less and be wet-milled. A portion of the fine graphite is preferably added in place of at least one constituent selected from the group consisting of carbon black, fullerene, carbon compounds carbonized by baking, and graphite having an average grain diameter of 5 μm or more.

Owner:KOBE STEEL LTD

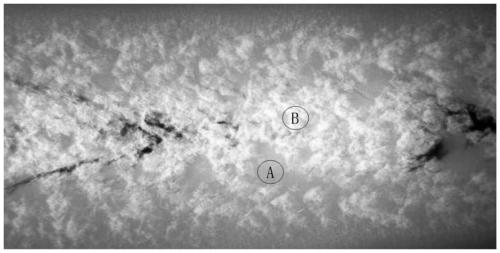

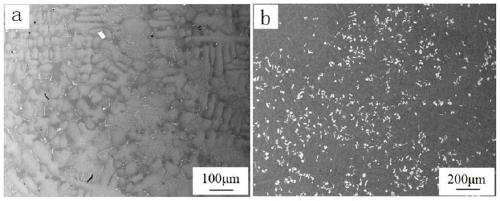

Preparation process of nickel-based high temperature alloy with high-content refractory elements

ActiveCN109913702AImprove melting efficiencyImproves ingredient uniformityIncreasing energy efficiencyRefractoryLow density

The invention discloses a preparation process of a nickel-based high temperature alloy with high-content refractory elements, and belongs to the technical field of alloy preparation. According to theprocess, a vacuum induction melting (VIM) and electroslag remelting (ESR) process is adopted for preparing the alloy containing the high-content refractory elements. During the vacuum induction melting stage, by controlling the feeding mode, increasing the refining temperature, prolonging the refining time, accelerating the solidification rate and the like, the segregation phenomena of refractorymetal and low-density alloy elements are effectively suppressed, and the composition uniformity of upper and lower parts of a parent alloy ingot is improved. Through electroslag remelting, secondary shrinkage in the alloy ingot is eliminated, the impurity content is reduced, and the metallurgical quality is improved. The preparation process can significantly reduce the microsegregation and macrosegregation phenomena of the high-content refractory elements and can effectively reduce the content of harmful gas elements such as O and N in the high-temperature alloy, the purity of the alloy is improved, the degree of segregation of the high-specific gravity elements is reduced, the heredity of alloy anomalous tissues is improved, and the overall mechanical properties of the alloy are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Operating method and system for the resonant operation of high-pressure lamps in longitudinal mode

ActiveUS6922114B2Well mixedReliably foundElectric lighting sourcesAngle to amplitude modulation conversionFundamental frequencyHigh pressure

The operating method is based on the simultaneous application of FM and AM, and is distinguished by passing through three operating states, specifically a warm-up phase, an impressing phase and the continuous operation.In the warm-up phase, the f002_hor is selected as fundamental frequency of the AM, or an AM is dispensed with. The impressing phase is distinguished by a temporally changing AM deviating from the conditions of the continuous operation and having an AM degree different from zero. In the continuous operation, constant conditions of the AM in the case of which the f002_hor is reached as fundamental frequency of the AM, and the AM degree is at 20 to 25% are characteristic.

Owner:LEDVANCE GMBH

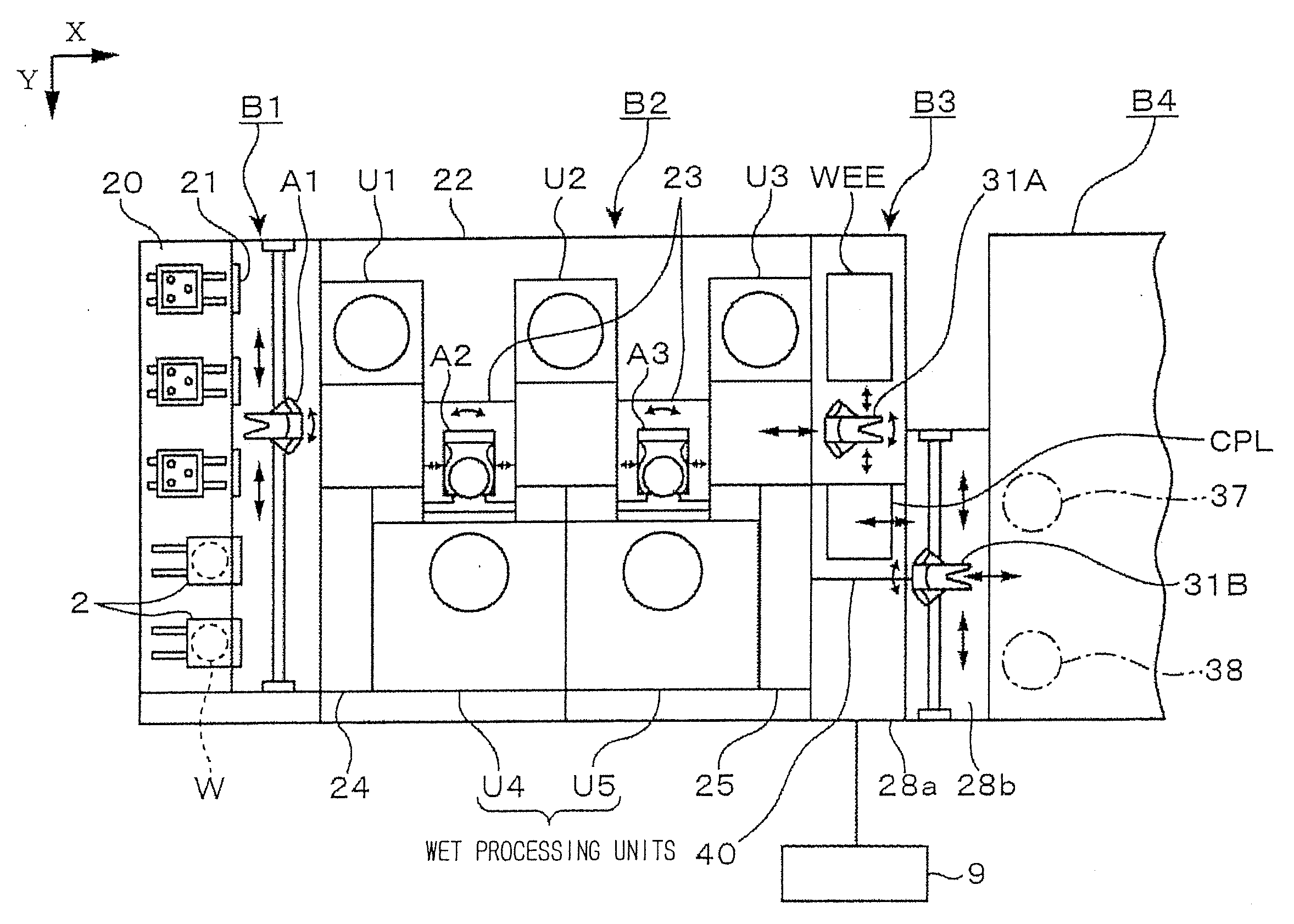

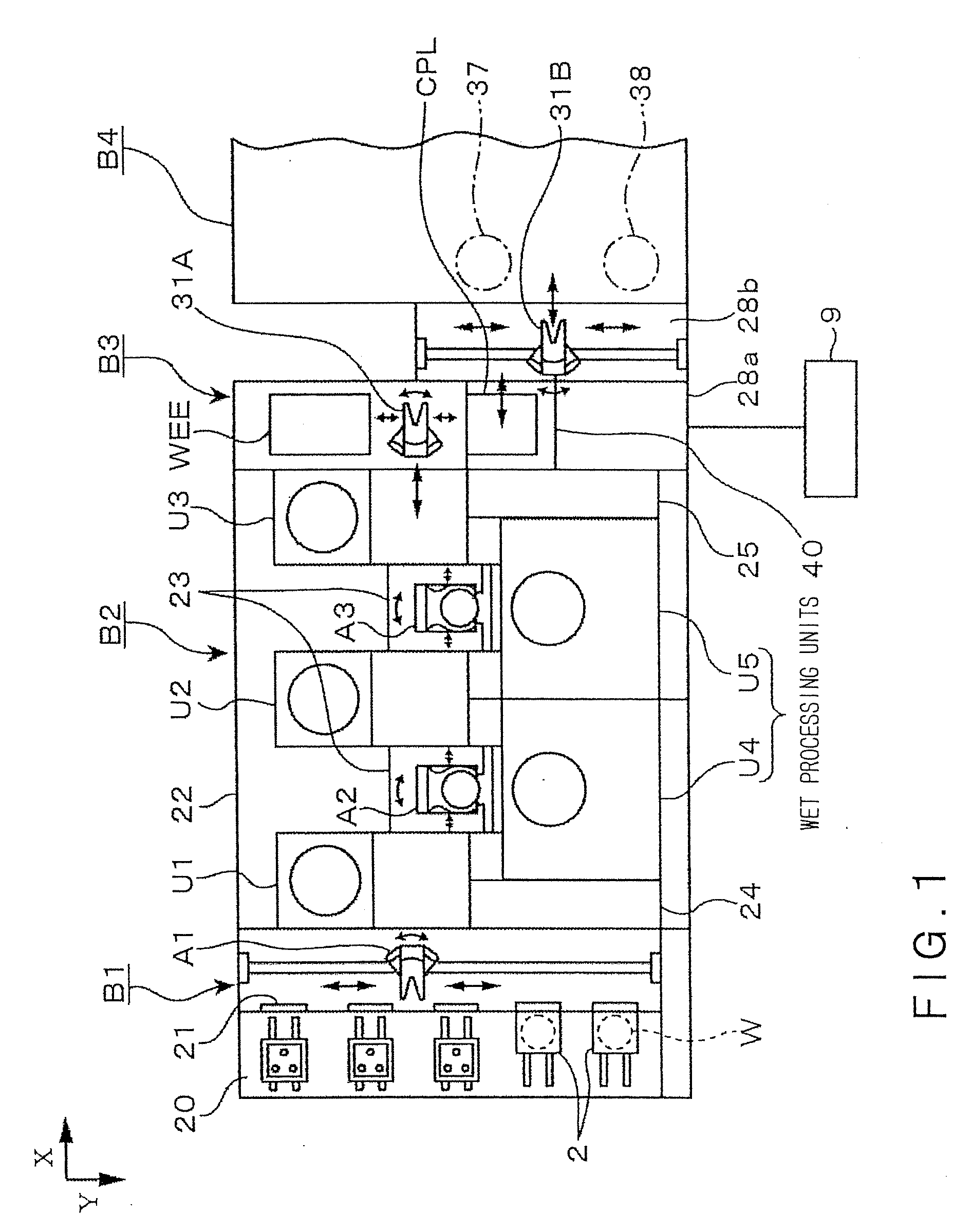

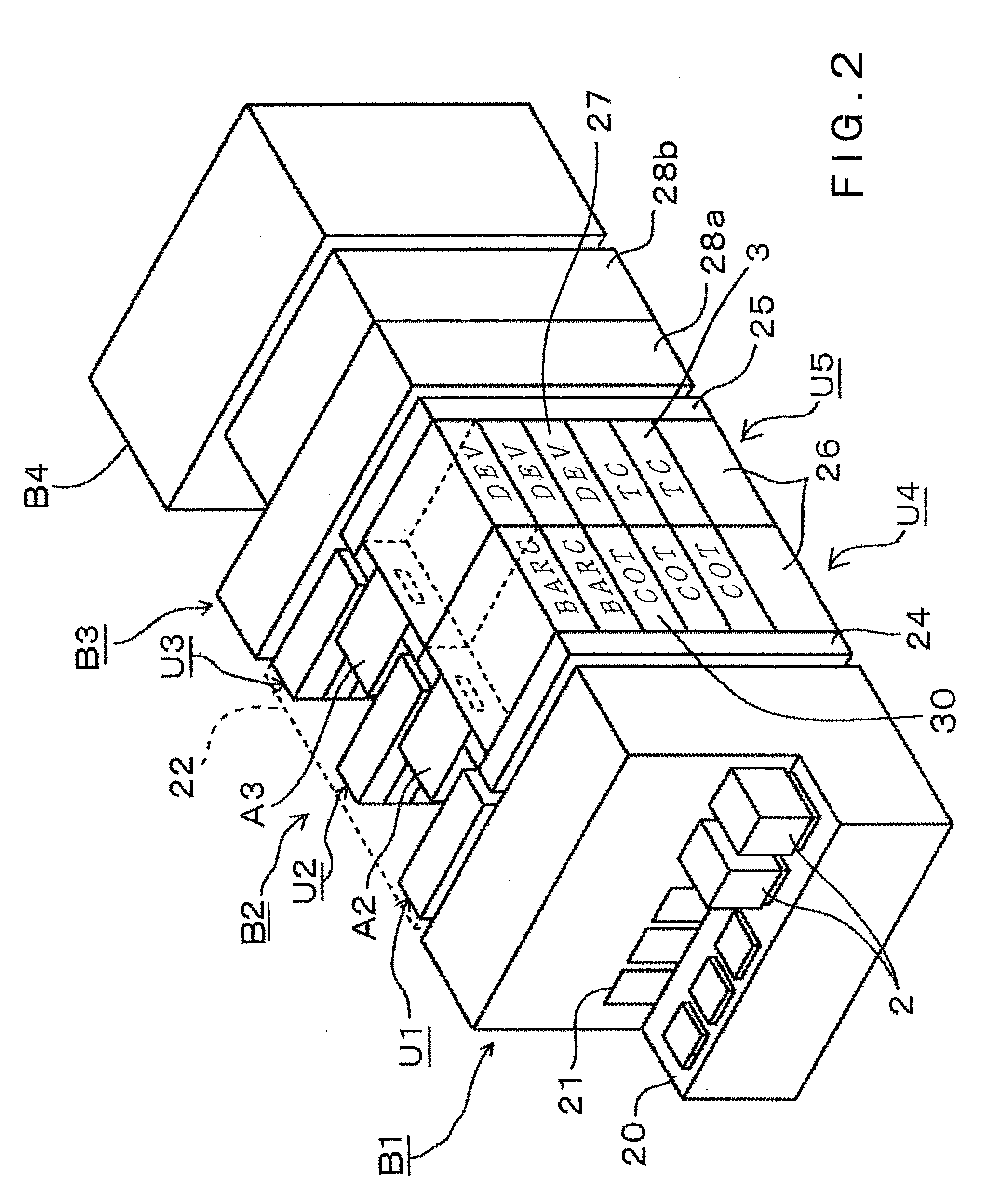

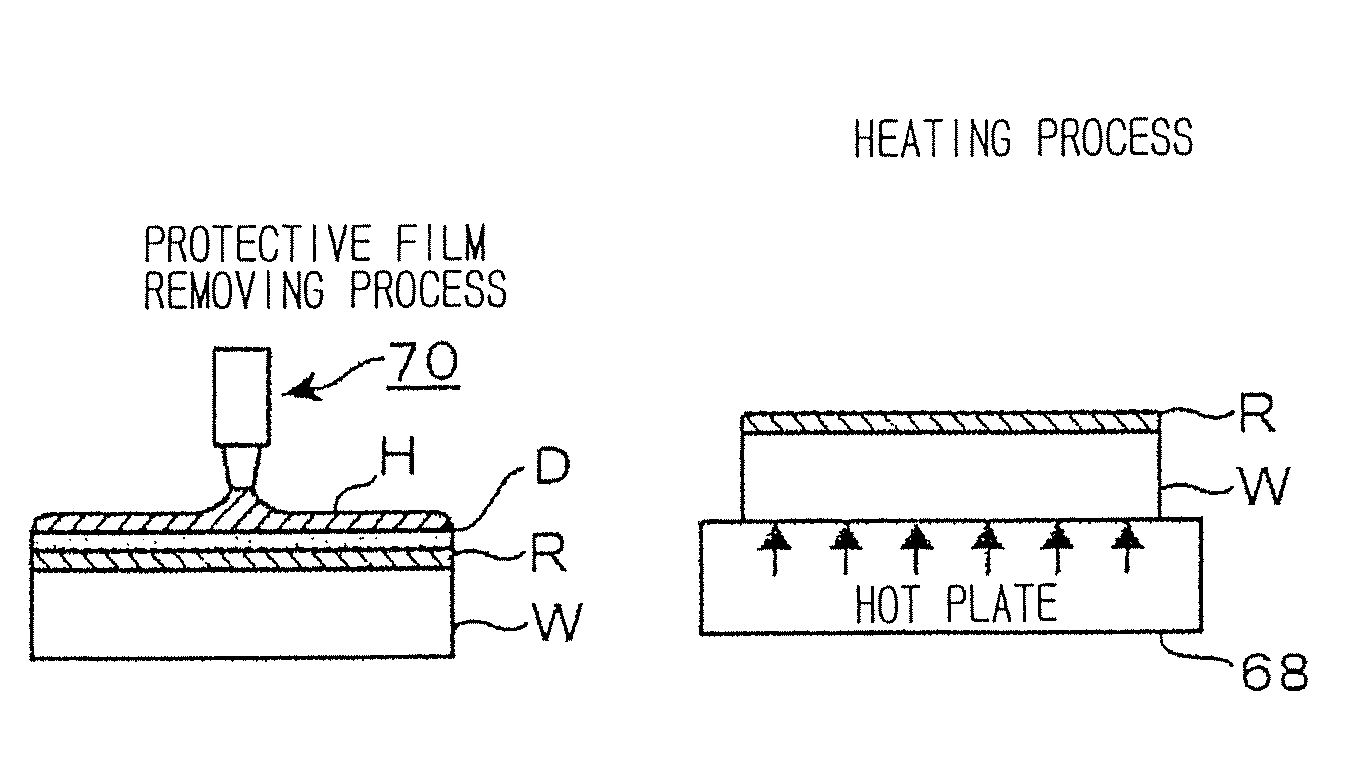

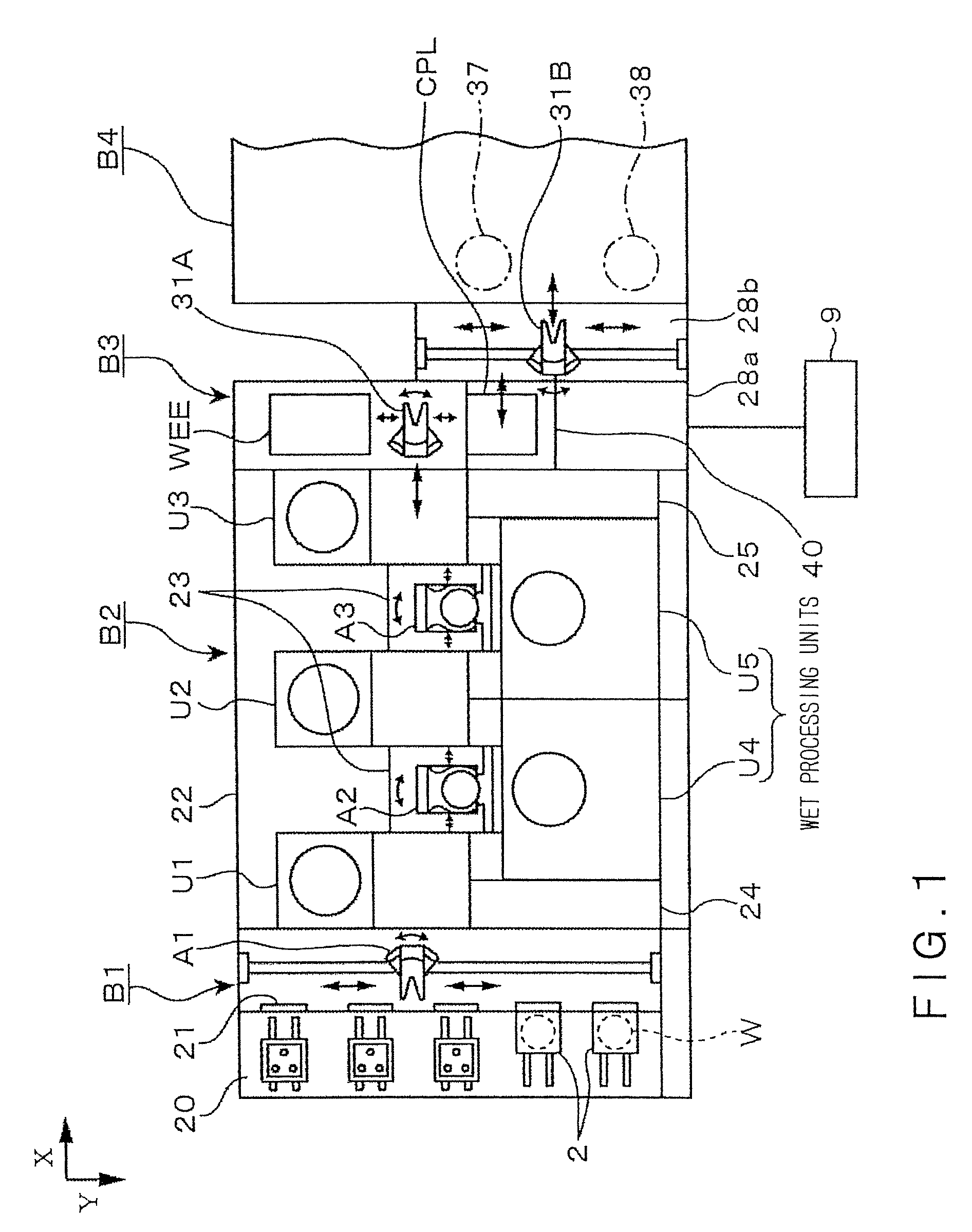

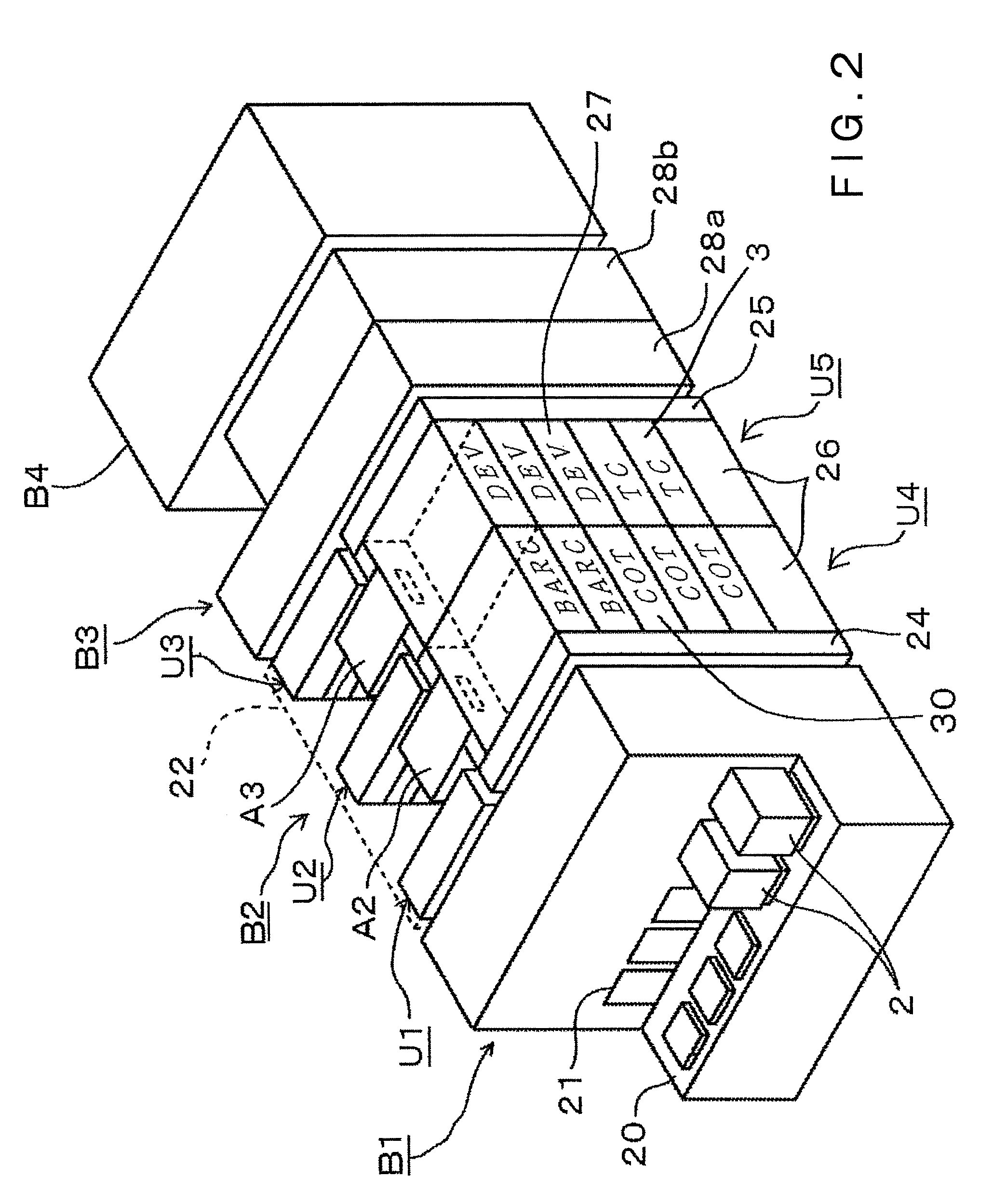

Coating and developing method, coating and developing system and storage medium

InactiveUS20070184392A1Reduce defectsImprove controllabilityLiquid processingSemiconductor/solid-state device manufacturingTectorial membraneResist

A resist film formed on a substrate is coated with a water-repellent protective film and the substrate is subjected to a developing process after the substrate has been processed by an immersion exposure process. The protective film is removed from the substrate after the resist film has been processed by the immersion exposure process, the substrate is processed by a heating process, and then the substrate is subjected to a developing process. The surface of the substrate is cleaned with a cleaning liquid before the protective film is removed and after the substrate has been processed by the immersion exposure process or the surface of the substrate is cleaned with a cleaning liquid after removing the protective film and before the substrate is subjected to the heating process.

Owner:TOKYO ELECTRON LTD

Coating and developing method, coating and developing system and storage medium

InactiveUS7742146B2Improve controllabilityReduce defectsLiquid processingSemiconductor/solid-state device manufacturingResistEngineering

A resist film formed on a substrate is coated with a water-repellent protective film and the substrate is subjected to a developing process after the substrate has been processed by an immersion exposure process. The protective film is removed from the substrate after the resist film has been processed by the immersion exposure process, the substrate is processed by a heating process, and then the substrate is subjected to a developing process. The surface of the substrate is cleaned with a cleaning liquid before the protective film is removed and after the substrate has been processed by the immersion exposure process or the surface of the substrate is cleaned with a cleaning liquid after removing the protective film and before the substrate is subjected to the heating process.

Owner:TOKYO ELECTRON LTD

Nitride semiconductor optical element and manufacturing method thereof

ActiveUS8124432B2Composition variation regions in both interfaces of the well layer are reducedSimple interfaceOptical wave guidanceLaser detailsIndiumHydrogen

In an InGaN-based nitride semiconductor optical device having a long wavelength (440 nm or more) equal to or more than that of blue, the increase of a wavelength is realized while suppressing In (Indium) segregation and deterioration of crystallinity. In the manufacture of an InGaN-based nitride semiconductor optical device having an InGaN-based quantum well active layer including an InGaN well layer and an InGaN barrier layer, a step of growing the InGaN barrier layer includes: a first step of adding hydrogen at 1% or more to a gas atmosphere composed of nitrogen and ammonia and growing a GaN layer in the gas atmosphere; and a second step of growing the InGaN barrier layer in a gas atmosphere composed of nitrogen and ammonia.

Owner:USHIO OPTO SEMICON

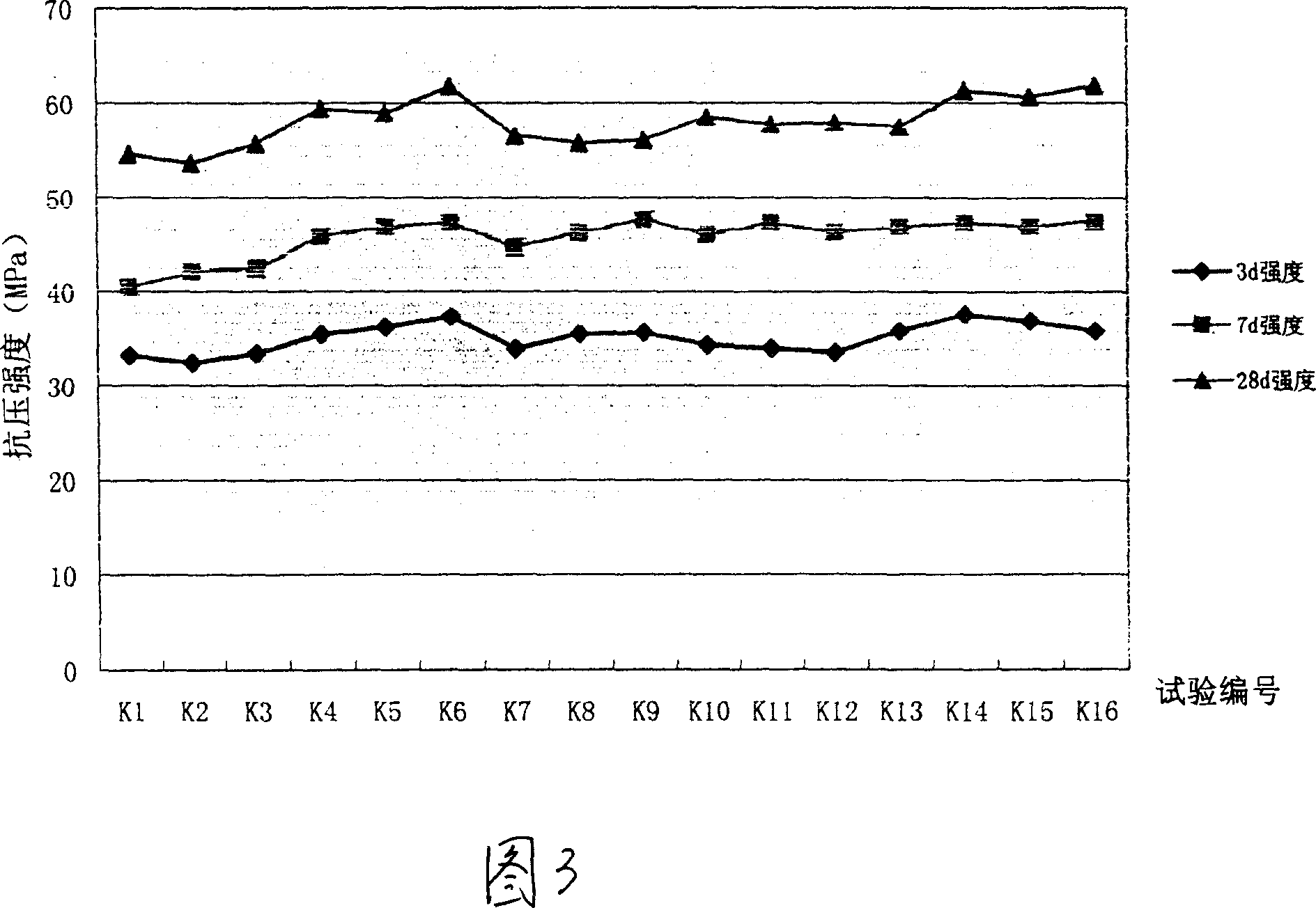

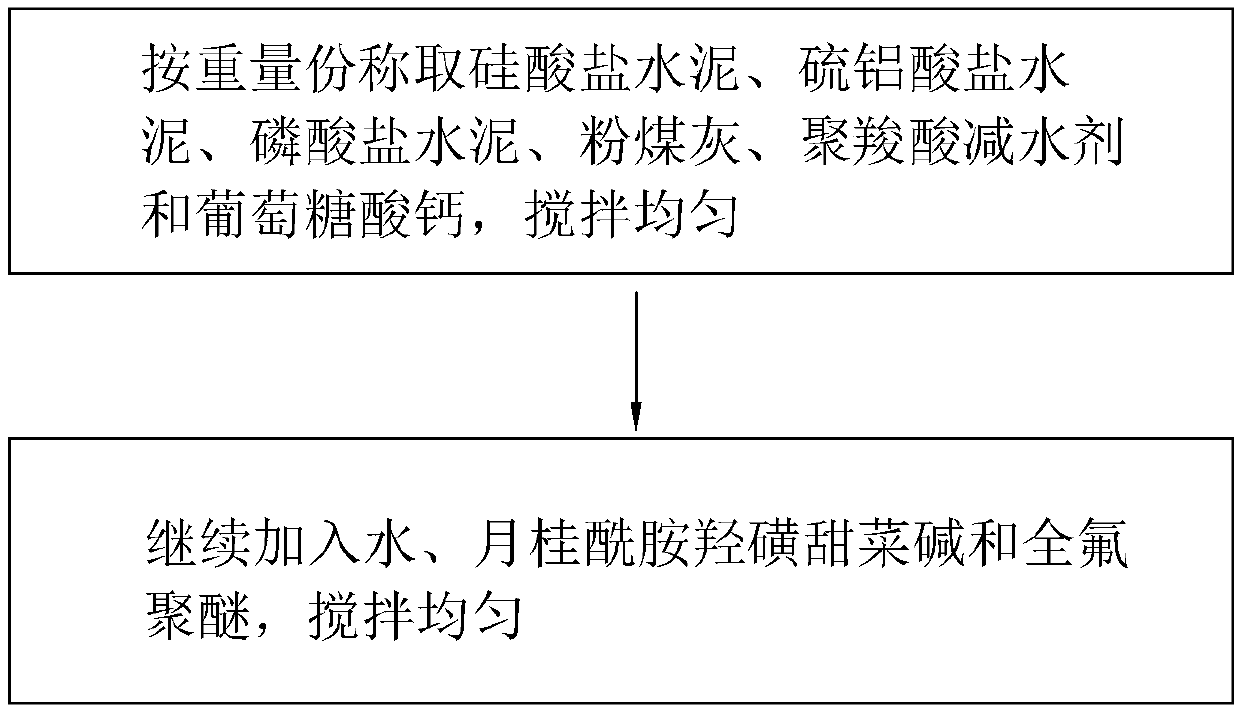

Formula and preparation method for concrete used for bridge construction

The invention discloses a formula and a preparation method for concrete used for bridge construction, and relates to the field of civil engineering. The concrete has the formula which comprises the following raw materials by weight: 320 to 350 parts of cement, 60 to 65 parts of fly ash, 15 to 16 parts of a water reducing agent, 0.1 to 0.3 part of a retarder and 150 to 160 parts of water. The concrete provided by the invention has the following advantages: the fly ash contains a large number of glass spheres, exerts the effects of a ball bearing and significantly reduces the yield shear stressof a mixed material; thus, through addition of the fly ash into the concrete, the continuity of a concrete mixture slurry can be improved, and the fluidity of the concrete mixture slurry is improved.The water reducing agent is a concrete admixture which can reduce the usage amount of water for mixing under the condition that the slump of the concrete is maintained to be substantially unchanged, has a dispersing effect on cement particles, can improve the workability of the cement particles, and improves the fluidity of the concrete.

Owner:温州嘉豪建设有限公司

Mixed powder for powder metallurgy and manufacturing method thereof

InactiveUS20130180359A1Less scatteringImprove liquidityTransportation and packagingMetal-working apparatusGraphiteFullerene

This mixed powder for powder metallurgy, the powder having excellent fluidity and minimal graphite powder scattering, can be obtained relatively conveniently by mixing fine graphite having an average grain diameter of 4 μm or less with an iron based powder. The process is performed without the addition of a binder and while shearing force is applied. It is preferable that the fine graphite have an average grain diameter of 2.4 μm or less and be wet-milled. A portion of the fine graphite is preferably added in place of at least one constituent selected from the group consisting of carbon black, fullerene, carbon compounds carbonized by baking, and graphite having an average grain diameter of 5 μm or more.

Owner:KOBE STEEL LTD

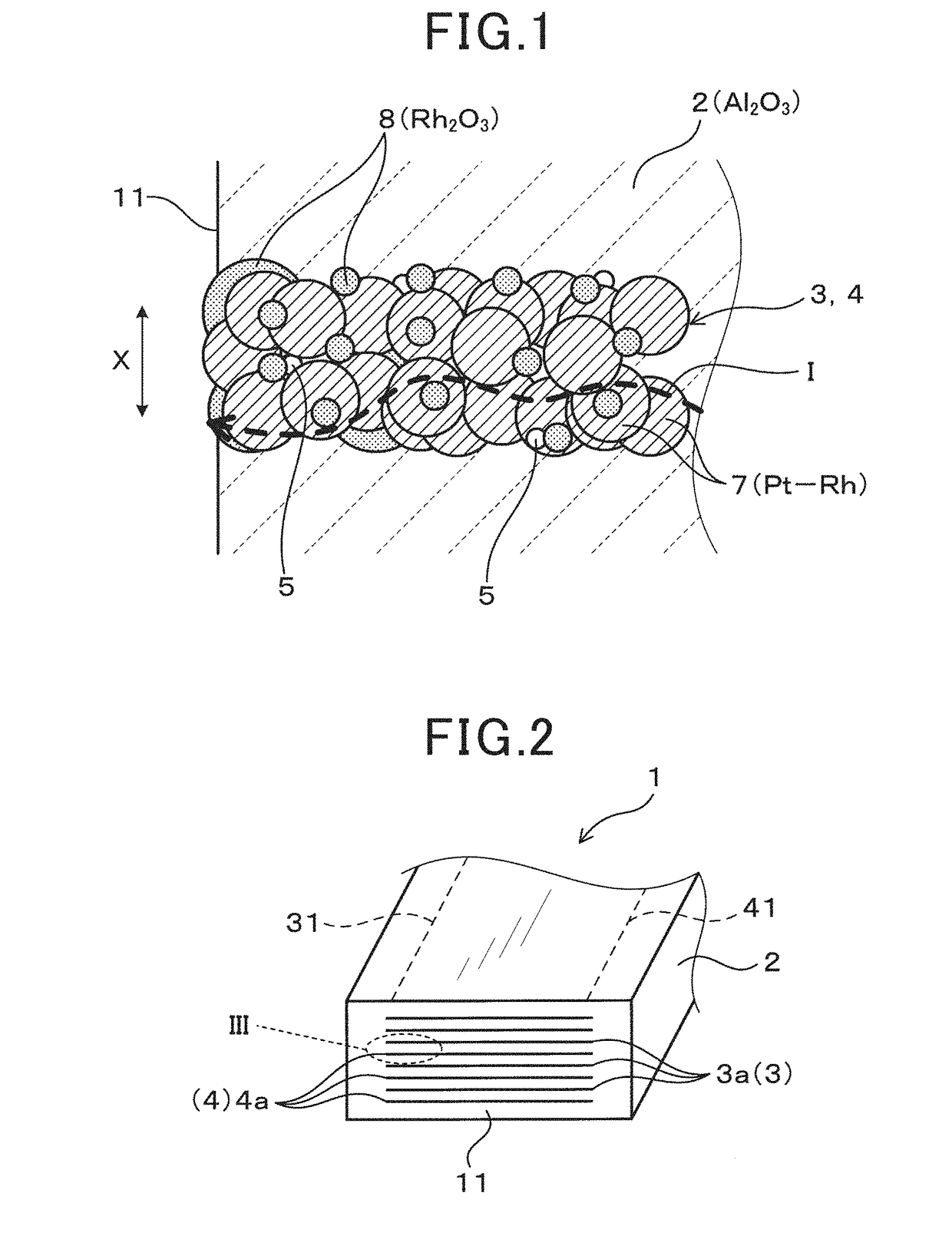

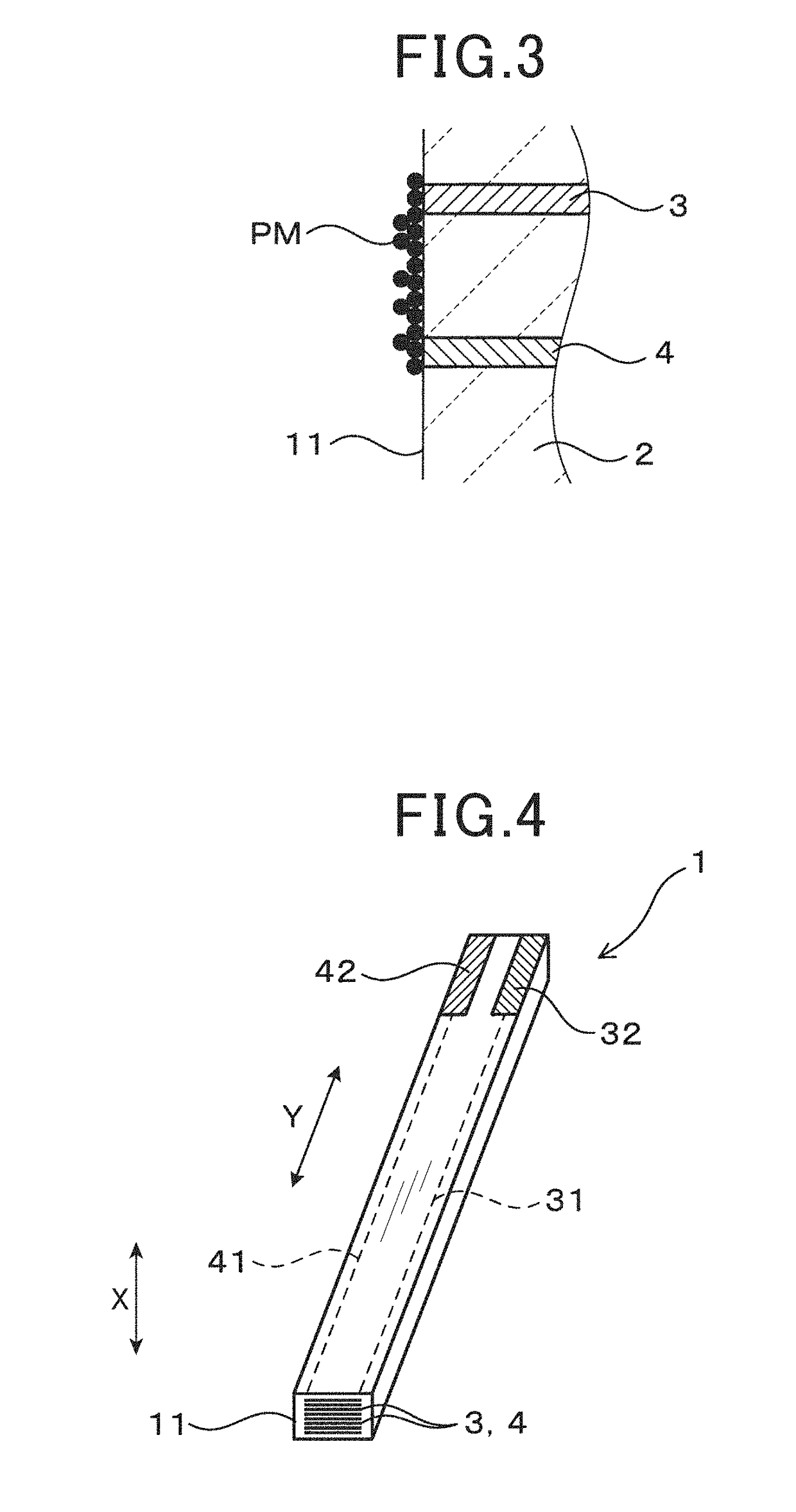

Sensor element

ActiveUS20190003997A1Prevent evaporationReduce increase ratioEngine testingMachines/enginesAlloyMetal

An electrode for a sensor element 1 that detects a specific substance in a gas to be measured, wherein the electrode is embedded in an insulating substrate having a detection face to which the specific substance adheres, the electrode being embedded in such a manner that a part of the electrode is exposed at the detection face, the electrode comprises an alloy of Pt and at least one metal selected from the group consisting of Rh, Ru, Ir, Os, and Pd, and granular voids dispersed among the alloy, and the content of the metal in the alloy is 40 mass % or less, and the number of the granular voids per unit volume of the electrode for a sensor element is 3 / 100 μm3 to 50 / 100 μm3.

Owner:DENSO CORP

Method for manufacturing semiconductor device, semiconductor device, and laser irradiation apparatus

InactiveUS7160762B2Variation can be suppressedAvoid mixingPolycrystalline material growthFrom solid stateNoble gasLaser light

It is an object of the present invention to provide a laser irradiation apparatus being able to crystallize the semiconductor film homogeneously while suppressing the variation of the crystallinity in the semiconductor film and the unevenness of the state of the surface thereof. It is another object of the present invention to provide a method for manufacturing a semiconductor device using the laser irradiation apparatus which can suppress the variation of on-current, mobility, and threshold of TFT, and to further provide a semiconductor device manufactured with the manufacturing method.A method for manufacturing a semiconductor device comprising the steps of adding the first noble gas to the semiconductor film formed over the insulating surface with the ion doping method and irradiating the semiconductor film with the first noble gas added therein with the laser light in an atmosphere of second noble gas, wherein the magnetic field is applied to the semiconductor film with the first noble gas added when the laser light is irradiated.

Owner:SEMICON ENERGY LAB CO LTD

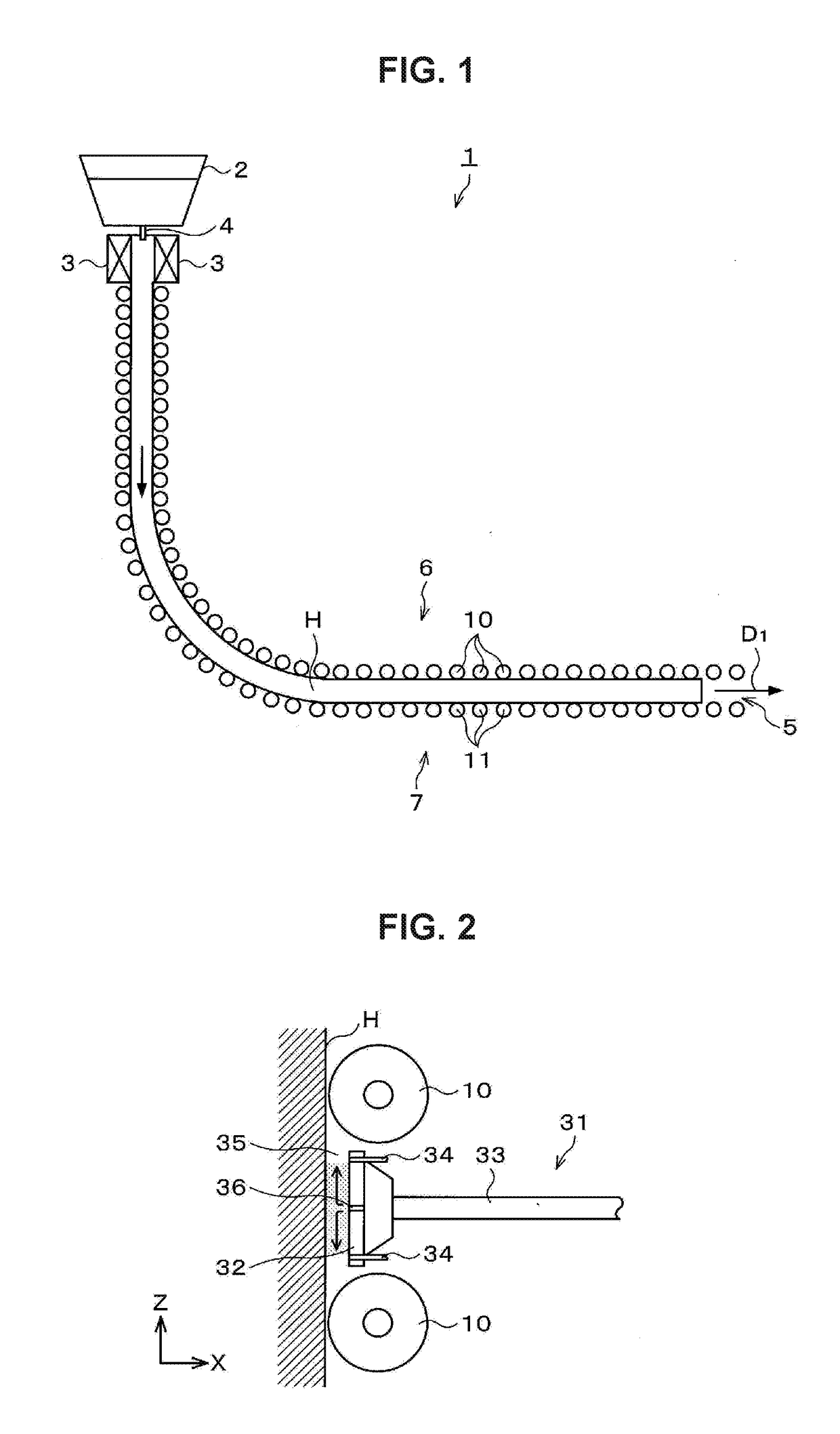

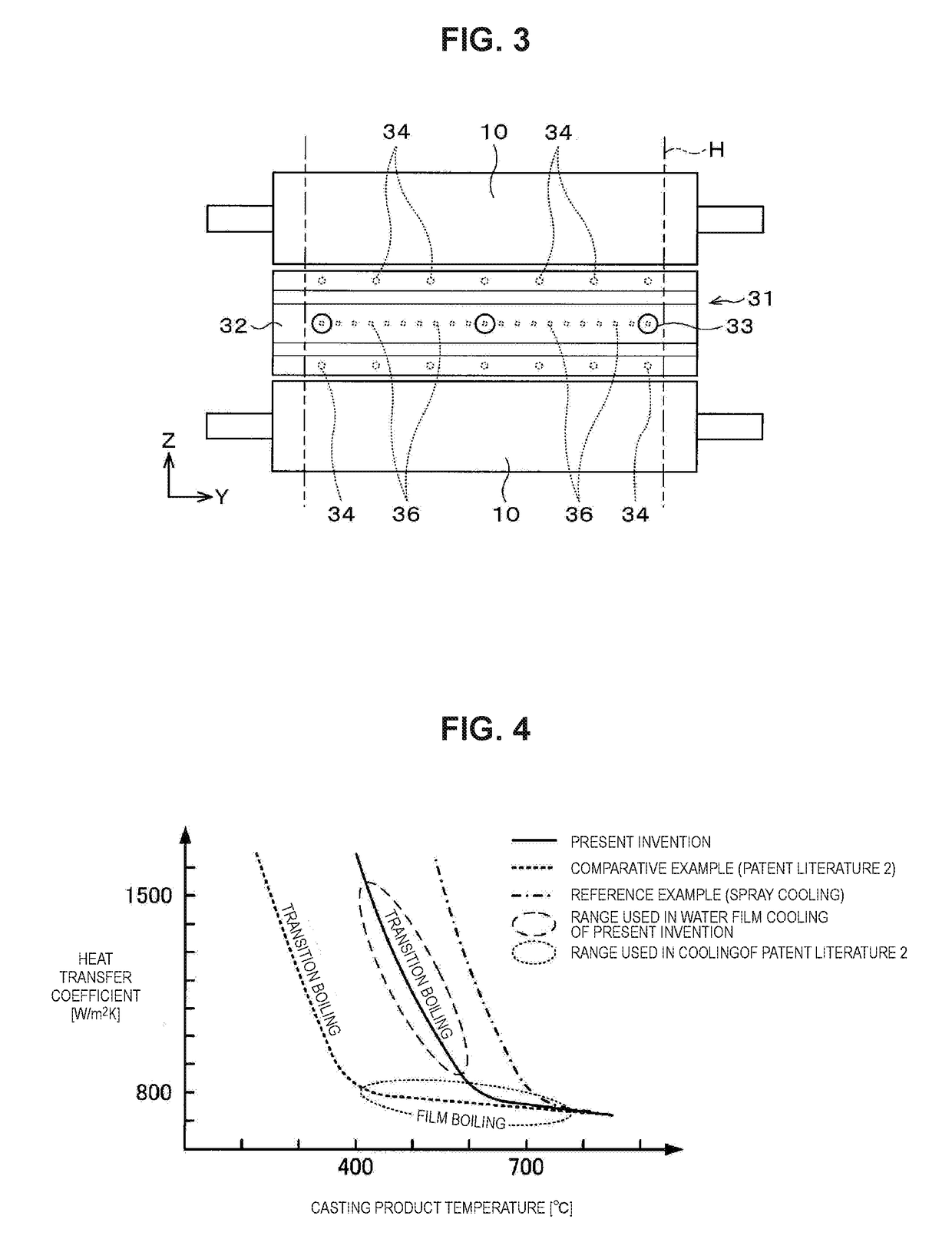

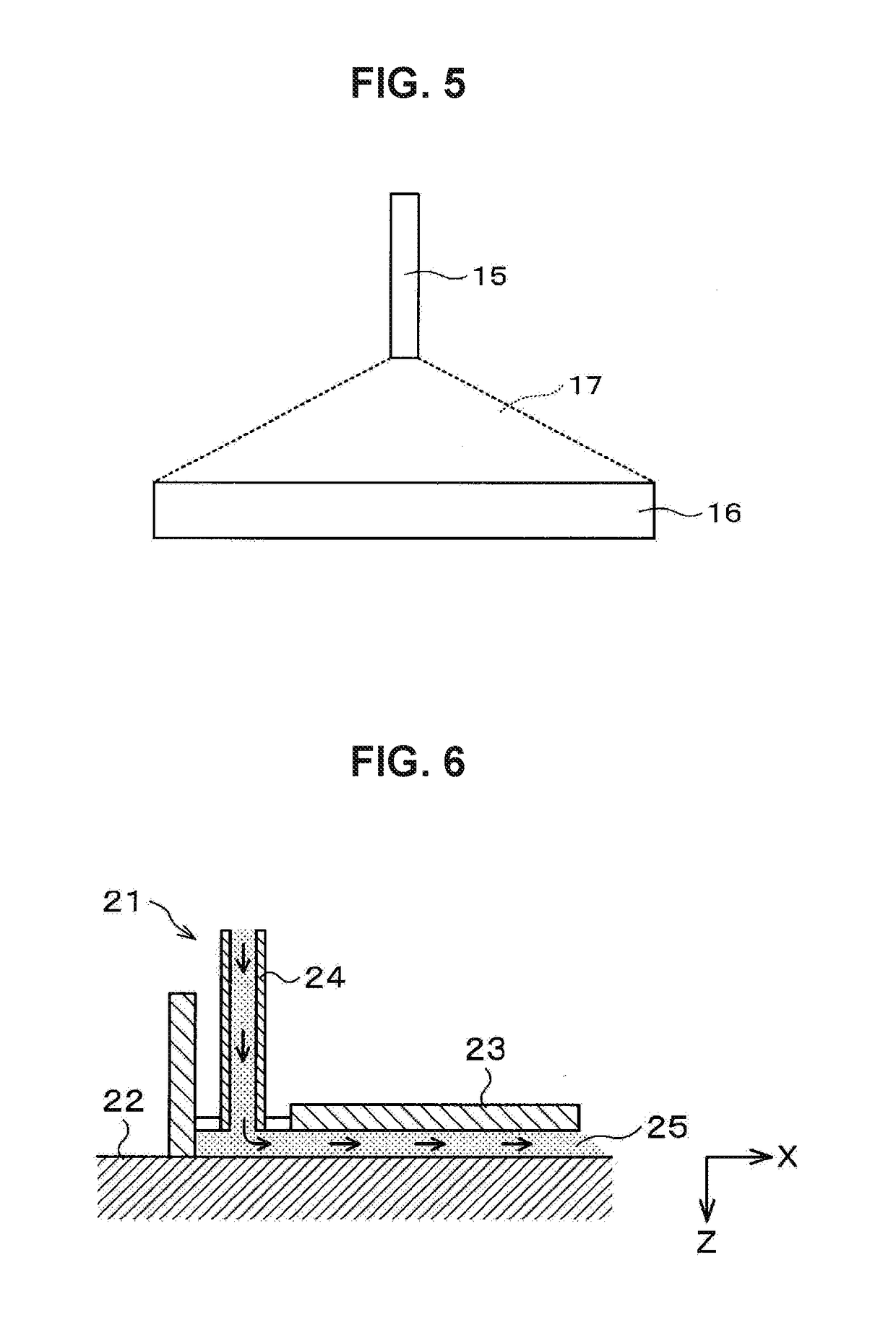

Secondary cooling method and secondary cooling device for casting product in continuous casting

The present invention is a secondary cooling method and a secondary cooling device for a casting product casted in a continuous casting machine, the continuous casting machine including, in a secondary cooling zone below a mold, a plurality of pairs of support rolls that support the casting product from both sides of the casting product in a thickness direction, a cooling device being disposed between support rolls adjacent to each other along a casting direction of the continuous casting machine, the cooling device including a coolant pipe that supplies a coolant, and a coolant guide plate with a flat plate shape for spreading the coolant on the casting product, the coolant guide plate being disposed parallel to and spaced in a perpendicular direction from a surface of the casting product. The coolant is supplied from a coolant supply port provided in the coolant guide plate to a gap between the casting product surface and the coolant guide plate, and the casting product is cooled using the coolant mainly in a transition boiling region.

Owner:NIPPON STEEL CORP

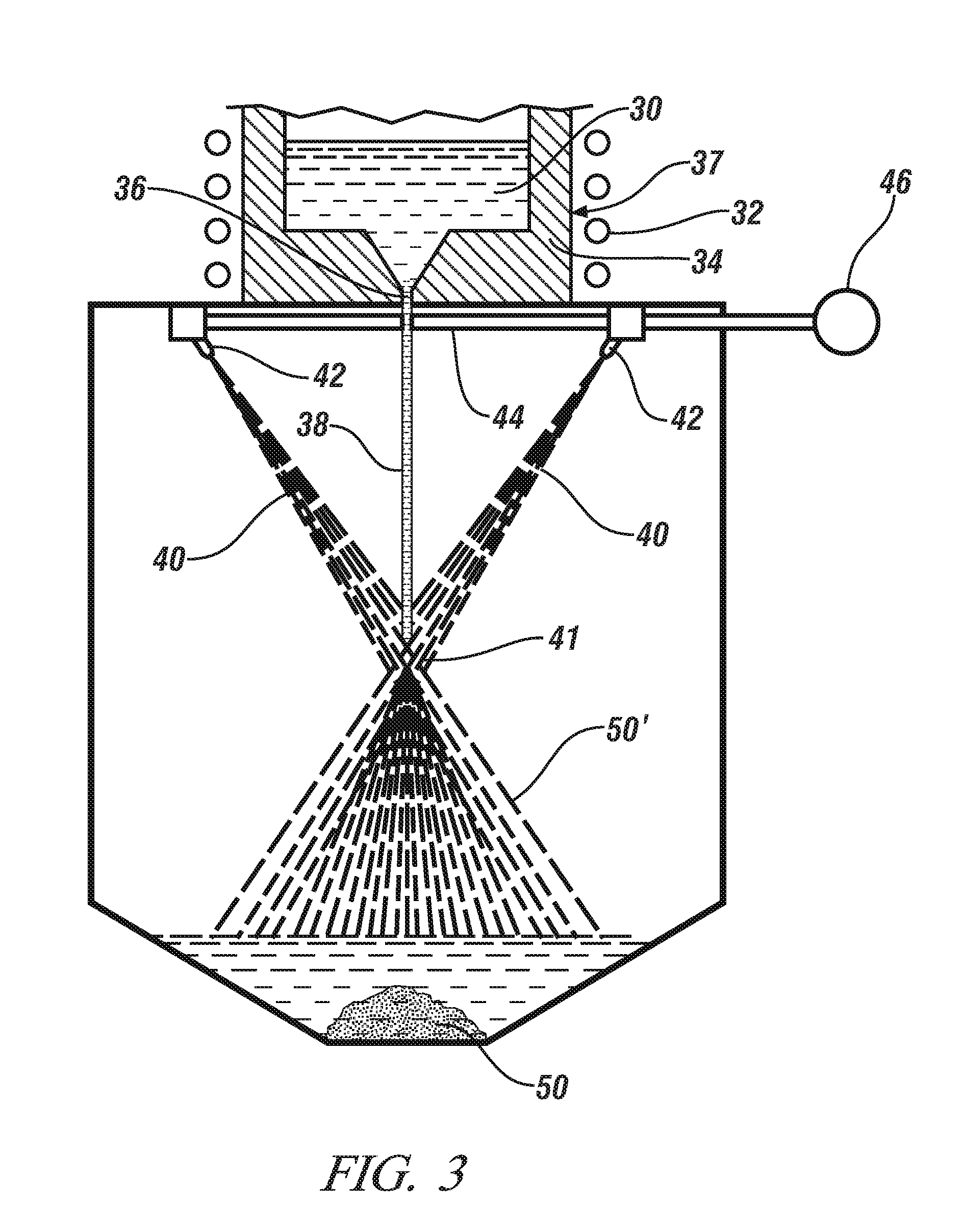

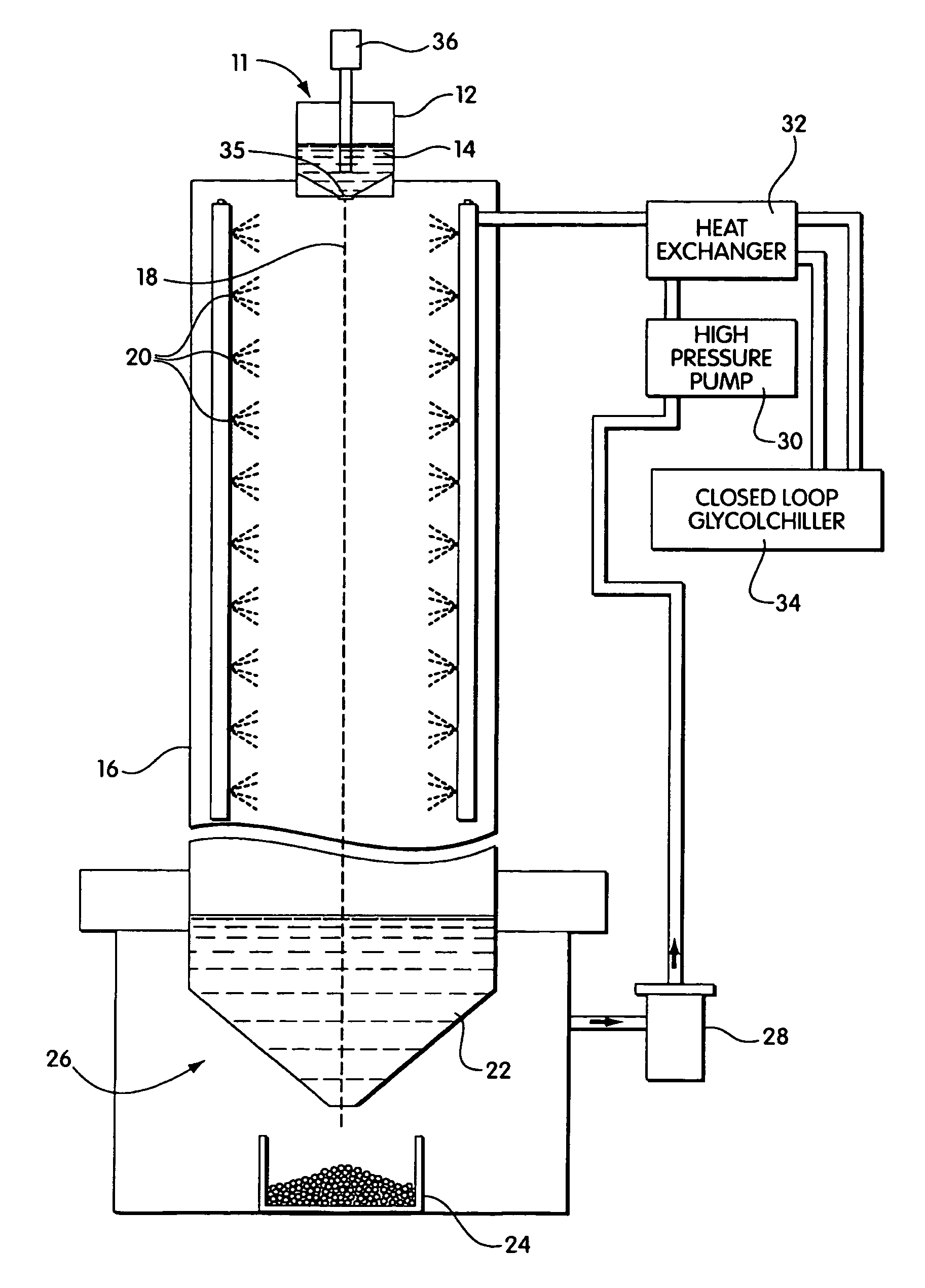

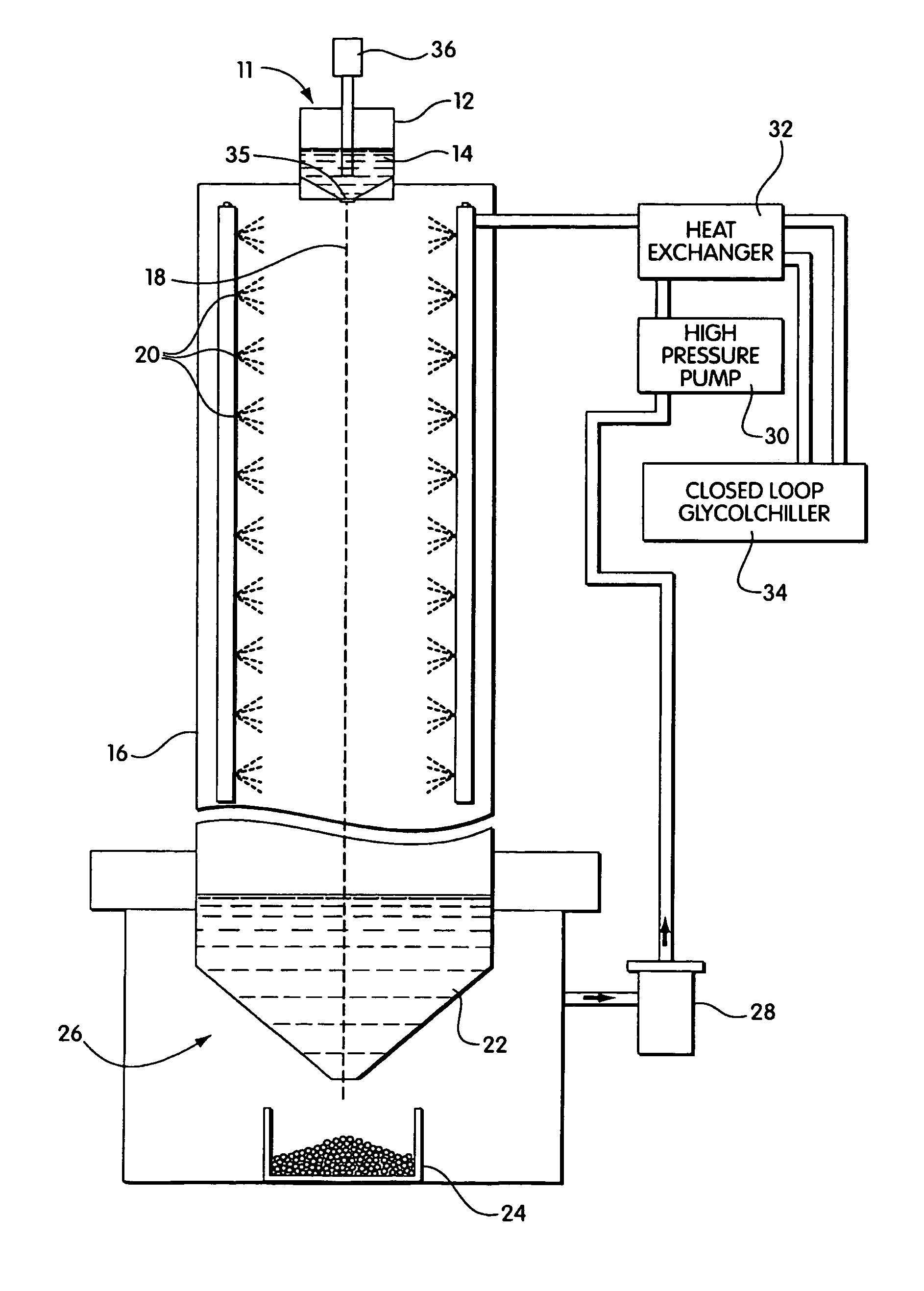

Rapid surface cooling of solder droplets by flash evaporation

InactiveUS7097806B2Fast waySuppress formationWelding/cutting media/materialsSoldering mediaSurface coolingMetallurgy

A mist of liquid coolant is introduced into the path of atomized, molten, solder droplets. The mist and other conditions within the chamber are engineered to enable the liquid coolant droplets in the mist to contract the surfaces of molten solder droplets and be flash vaporized upon contact, thereby rapidly extracting heat from the molten solder droplets and accelerating cooling and solidification to produce an enhanced solder ball as a product of this process.

Owner:FRY S METALS INC

Wear-resistant and heat-resistant aluminum alloy material for mobile phone shell and preparation method thereof

InactiveCN108425045AImprove corrosion resistanceImprove thermal conductivityWear resistantHeat resistance

The invention discloses a wear-resistant and heat-resistant aluminum alloy material for a mobile phone shell and a preparation method thereof. The ear-resistant and heat-resistant aluminum alloy material comprises the following components in percent by mass: 0.65-0.9% of Li, 1.2-2% of Mg, 0.04-0.1% of B, 0.15-0.32% of Zn, 0.25-0.4% of Mn, 2.5-3.2% of Si, 0.1-0.2% of Ti, 0.1-0.2% of Fe, 0.8-1.8% ofCu, 0.08-0.15% of Nb, 0.08-0.14% of Mo, 0.01-0.03% of Re, 0.05-0.1% of Ce and the balance of Al and unavoidable impurities. According to the wear-resistant and heat-resistant aluminum alloy materialfor the mobile phone shell and the preparation method thereof, provided by the invention, the wear-resistant and heat-resistant aluminum alloy material has good wear resistance, corrosion resistance,heat resistance, heat conductivity and mechanical properties, and has good falling resistance and plasticity and long service life.

Owner:安徽酷米智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com