Consumable stirrer added device and method for producing large homogeneous electro-slag re-melting steel ingots

A technology of electroslag remelting steel and agitator, which is applied in the solidification process of large electroslag remelting steel ingots in the metallurgical industry. It can solve the problems of slow progress in segregation control measures, shorten the solidification time, strengthen the compactness of the structure, and eliminate porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

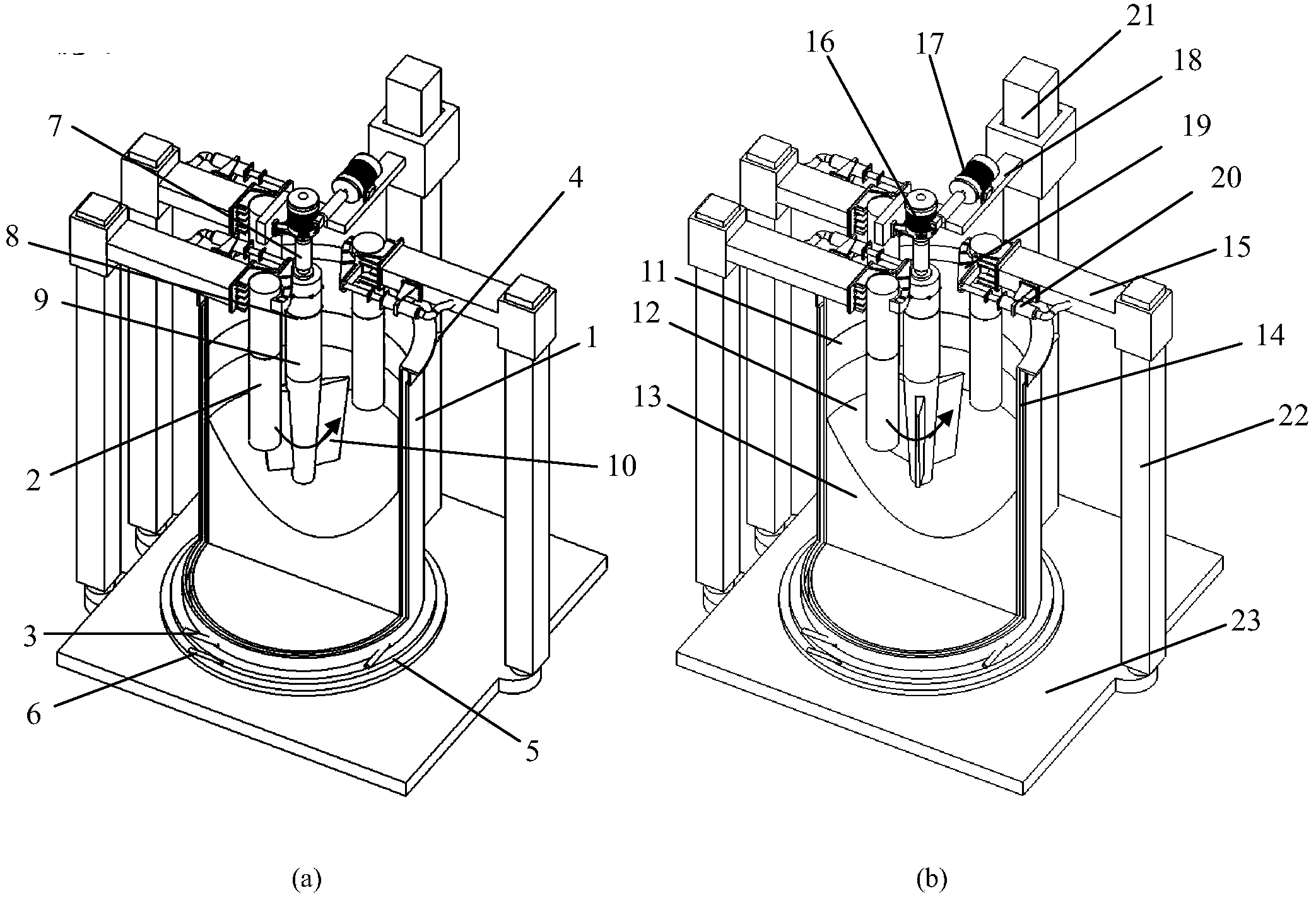

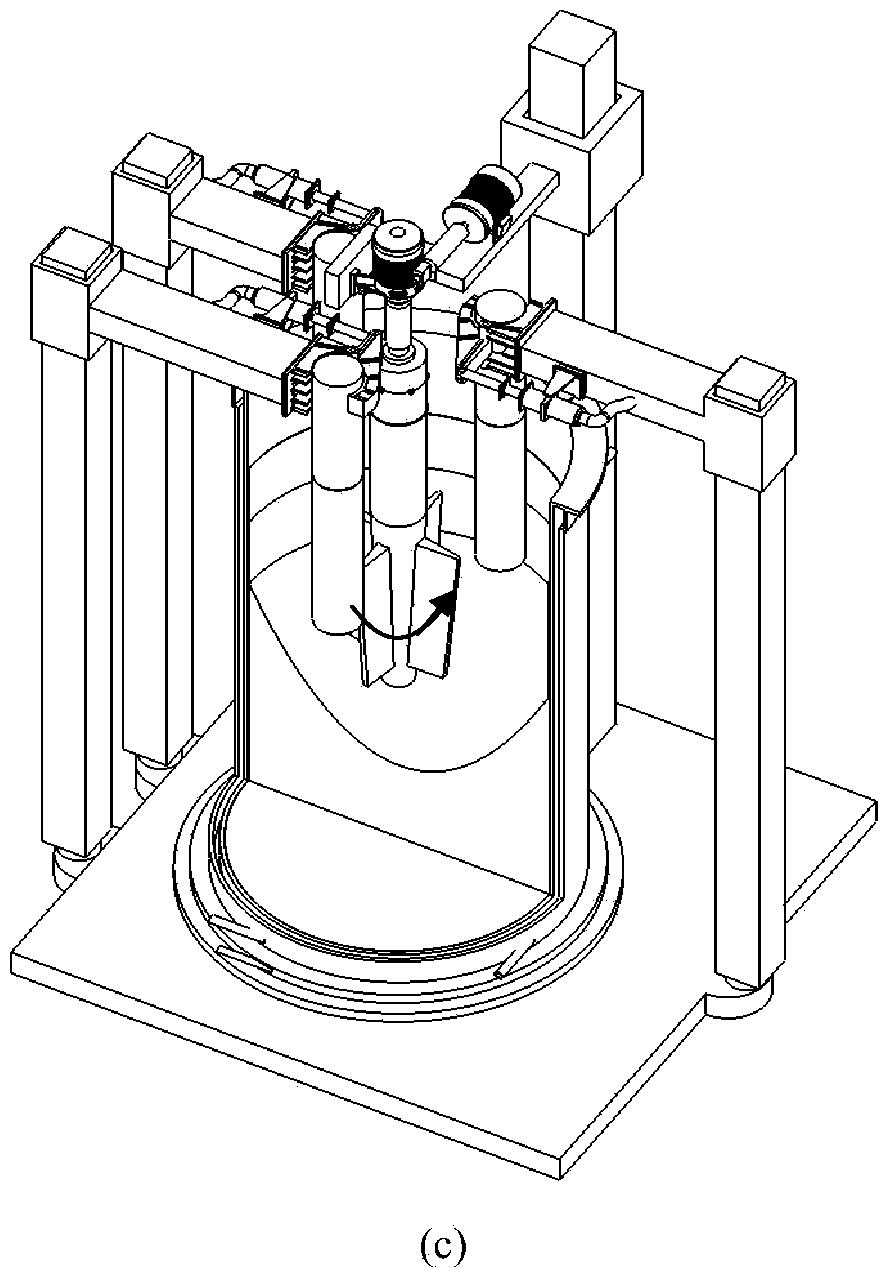

[0032] The device for preparing large-scale homogeneous electroslag remelting steel ingots with the additional consumable stirrer of this embodiment, such as figure 2 As shown in (a)~(c), it includes crystallizer 1, consumable electrode 2, cooling water circulation system, lifting arm 18 and electric control device, consumable electrode control device and consumable stirrer.

[0033] The slag pool 11 inside the crystallizer 1 contains electrode slag or pre-melted slag, and the state of the molten metal pool 12 is liquid. During the electroslag remelting process, molten steel droplets from the consumable electrode 2 pass through the slag pool 11 Falling to the bottom of the crystallizer 1 , the molten steel gradually accumulated at the bottom of the crystallizer 1 forms a molten metal pool 12 , and then is cooled by the water wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com