Device and method for preparing large-size homogeneous steel ingot by stirring with self-consuming stirrer

An agitator and self-consumption technology, which is applied in the field of devices for preparing large-scale homogeneous steel ingots by agitating a self-consumption agitator, can solve the problems of limited effect and slow progress of segregation control measures, and achieves elimination of porosity, shortening of solidification time, and strengthening of microstructure. The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

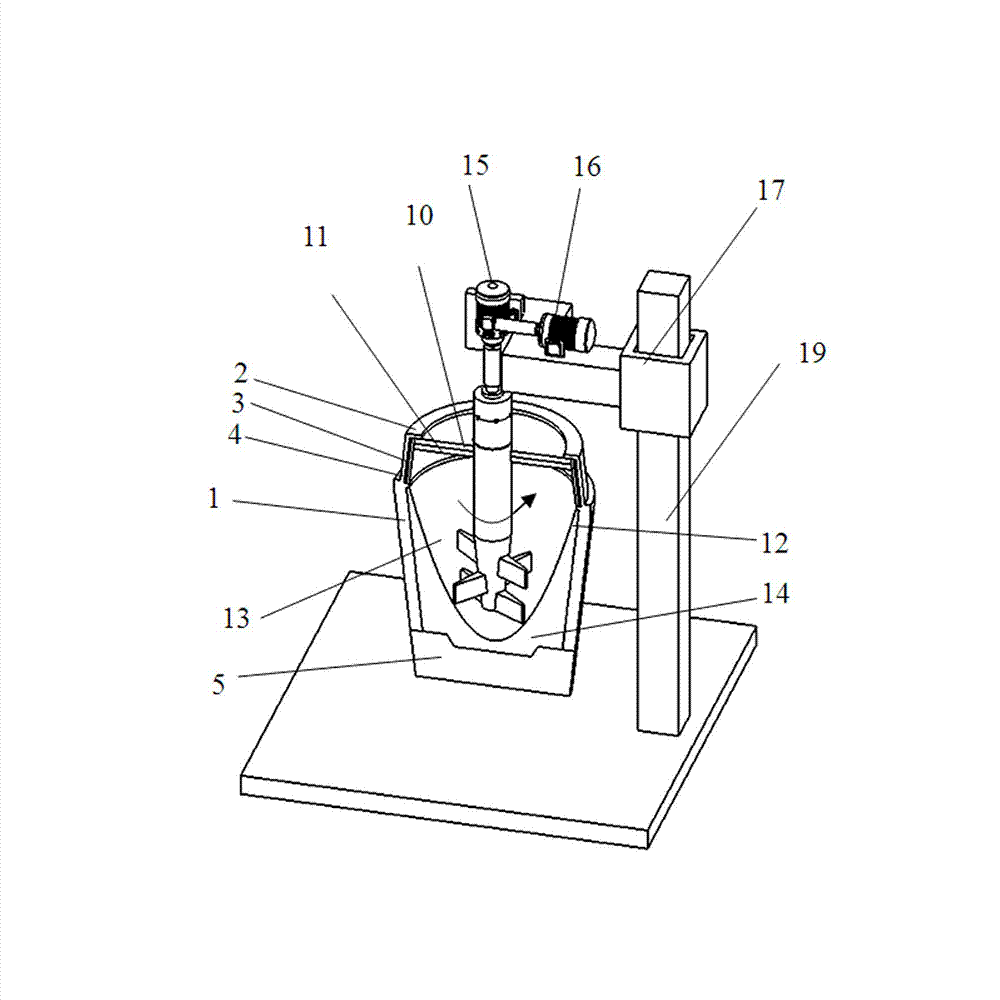

[0042] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

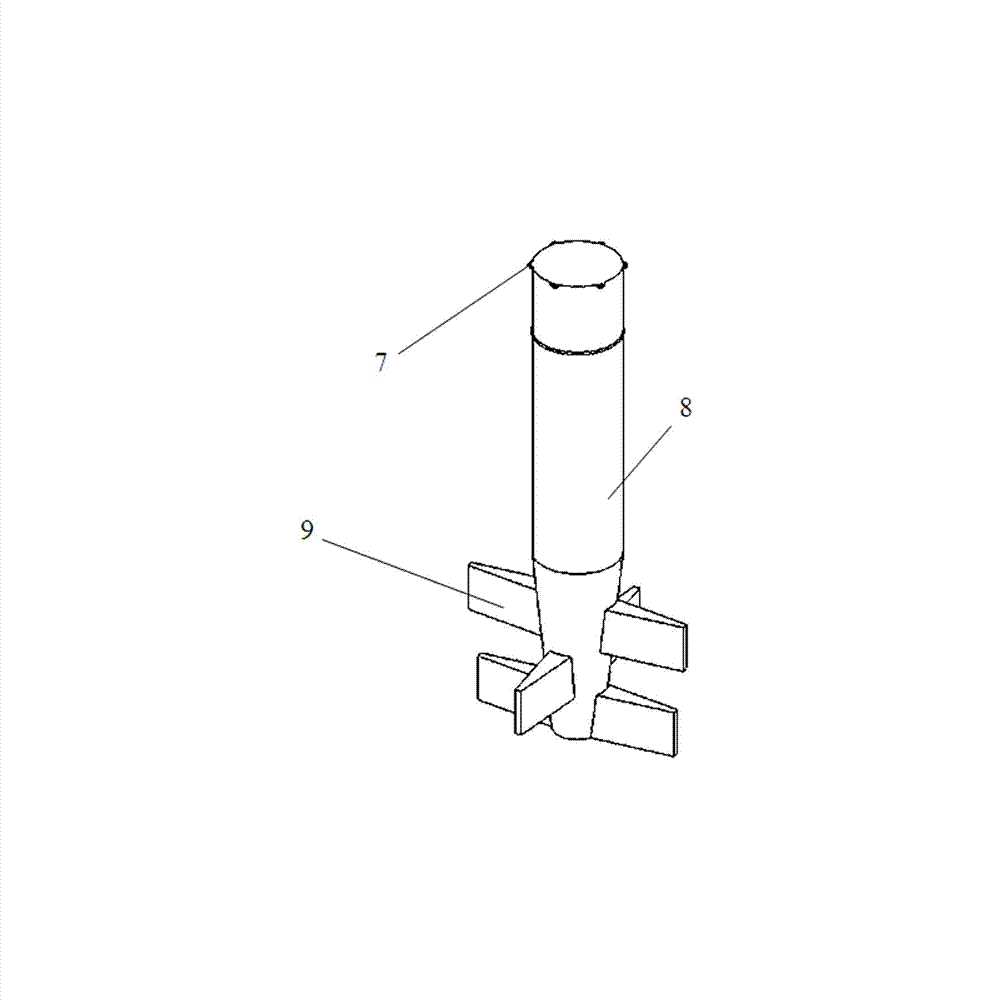

[0043] The device for preparing a large homogeneous steel ingot by stirring with a consumable stirrer in this embodiment is shown in Fig. Mouth 2, thermal insulation board 4, chassis 5.

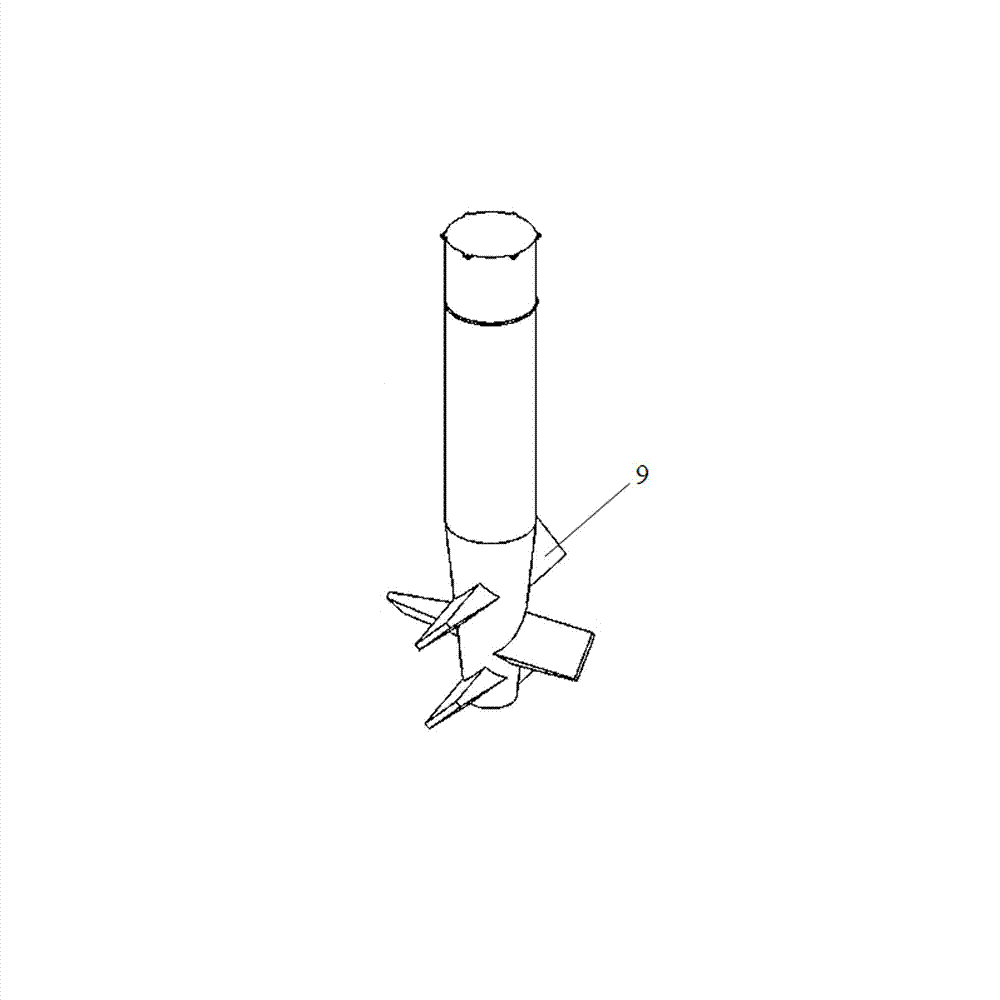

[0044] As shown in Figure 1, the consumable agitator includes a stirring shaft 8 and a stirring blade 9. The material of the consumable agitator is the same as that of the finished large homogeneous steel ingot that is finally prepared, and the composition meets the requirements. The consumable mixer itself is constantly being consumed.

[0045] In order to ensure that the consumable agitator is not blown during the working process, the agitating shaft 8 is conical from top to bottom, and the agitating blade 9 is a sheet-like structure that gradually thickens from the top of the blade to the root of the blade. The inclination angle of the agitating blade 9 is 20 ° ~ 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com