Device and method for preparing electroslag remelted steel ingot with tubular electrode attached to consumable stirrer

A technology of electroslag remelting steel and agitator, which is applied in the solidification process of large electroslag remelting steel ingots in the metallurgical industry. It can solve the problems of unclean removal of impurities and harmful substances, slow progress of segregation control measures, and influence on electrode melting efficiency. Achieve uniform distribution of droplet locations, shorten solidification time, and speed up cooling and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

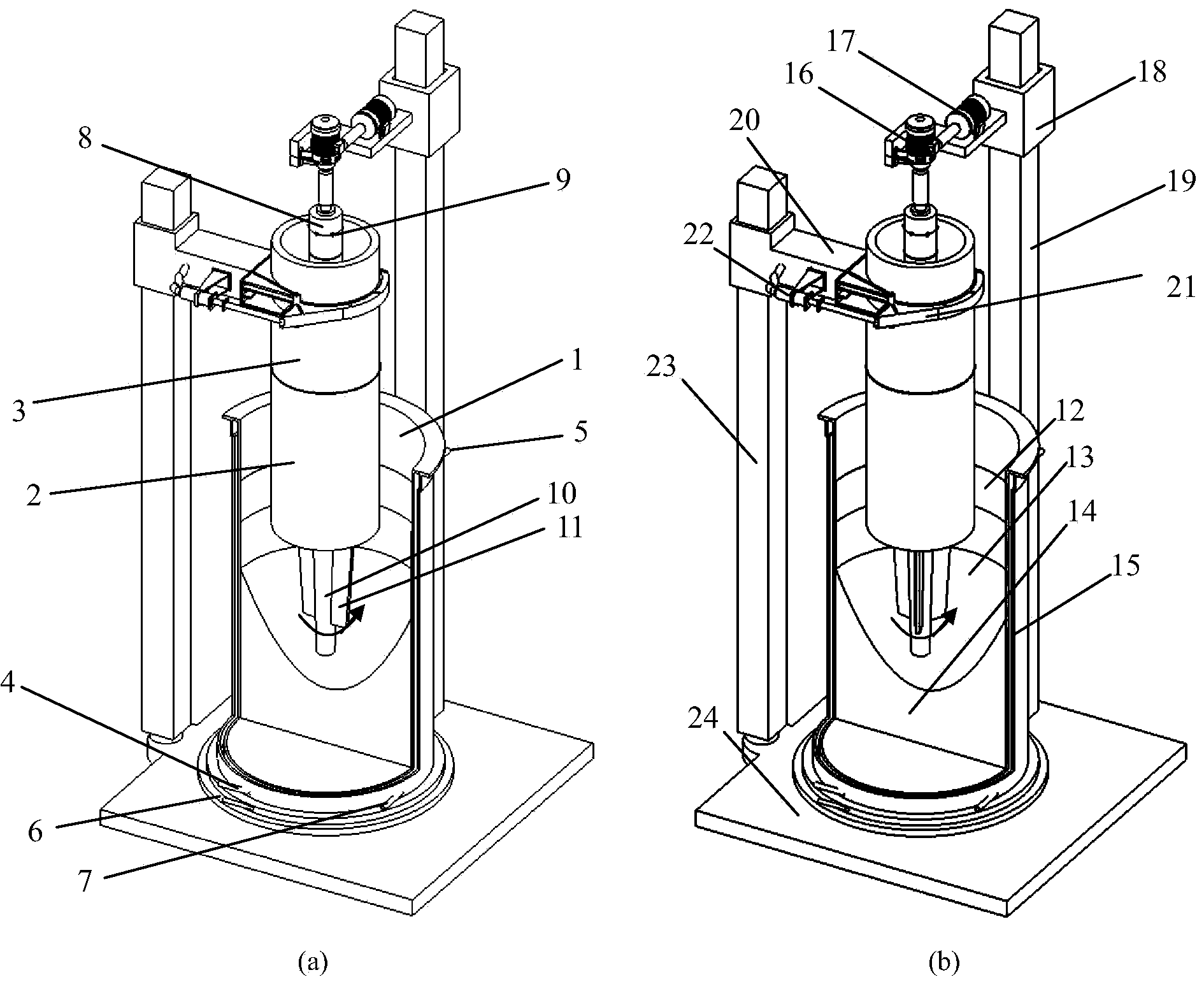

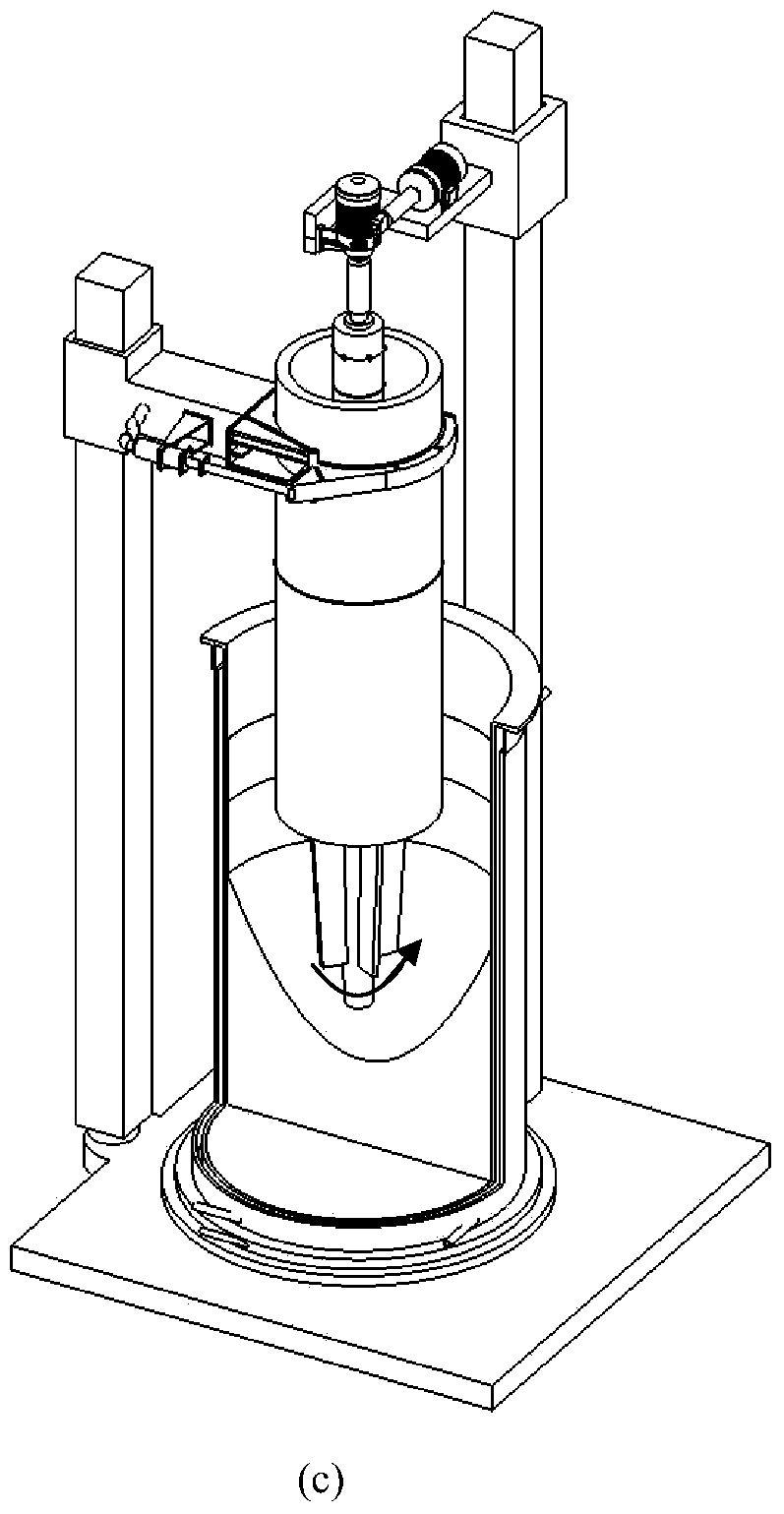

[0031] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In this embodiment, the device for preparing electroslag remelted steel ingots with a tubular electrode attached to a consumable stirrer is as follows: figure 2 As shown, it includes the crystallizer body 1 of the electroslag remelting system, the conductive cross arm 20 , the lifting cross arm 18 , the electric control device for the consumable stirrer, the electrode control device and the bottom water tank 6 .

[0033] The bottom water tank 6 is fixed on the operating platform 24, the crystallizer body 1 is placed on the bottom water tank 6, the main pole 19 on one side of the operating platform 24 is connected to the lifting cross arm 18, and the electric control device of the consumable agitator is fixed on the lifting horizontal arm 18. arm 18.

[0034] The electric control device of the self-consumption agitator includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com