A method of bottom blowing oxygen-lime powder to improve the reduction of chromium ore

A technology of lime powder and chrome ore, which is applied in the manufacture of converters, etc., can solve the problems of hindering the melting of chrome ore, insufficient stirring of molten pool, high FeO, etc., and achieve the effects of improving utilization rate, shortening smelting cycle and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

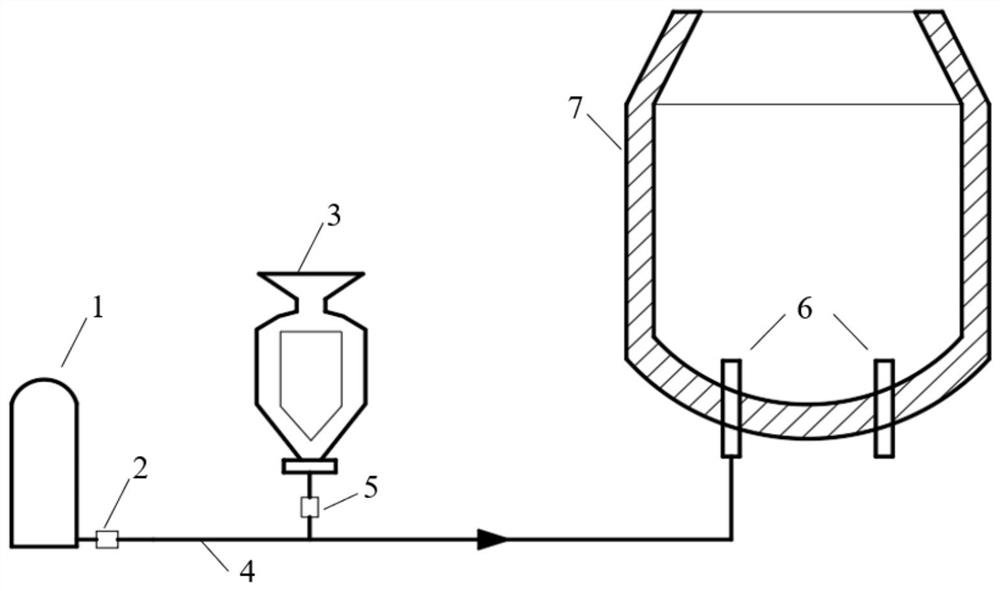

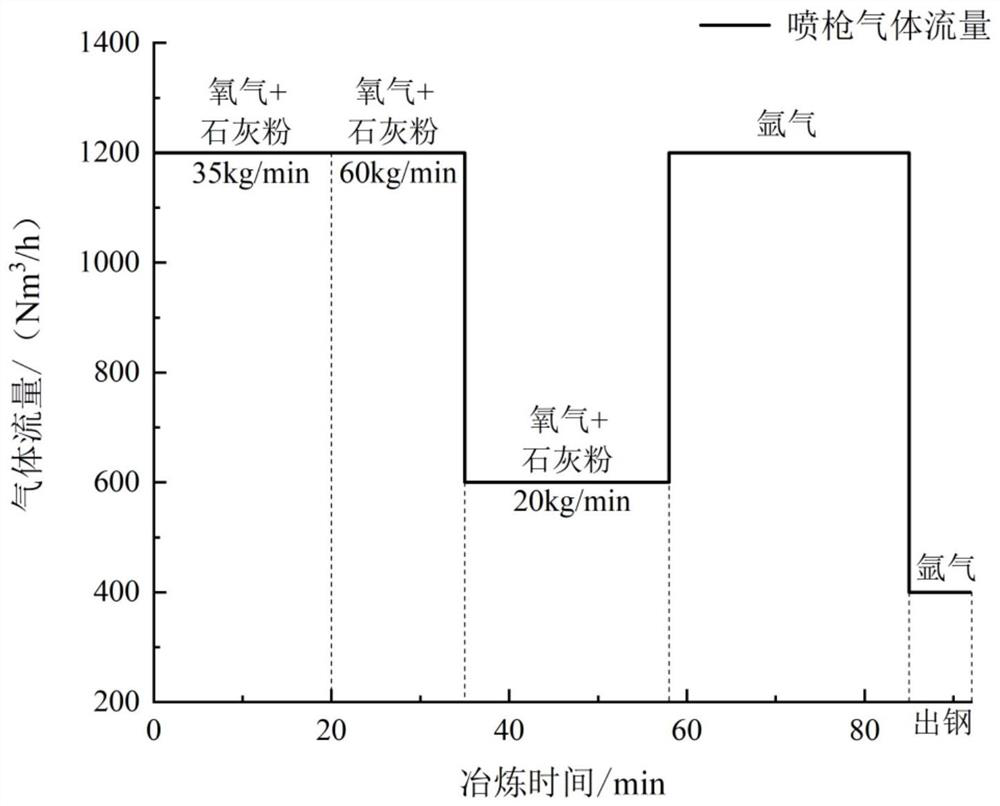

[0026] The invention is applied to smelting stainless steel in a 70t TSR furnace, and the smelting raw materials are molten iron, chrome ore and ferrochrome. Install 2 bottom blowing spray guns, which are symmetrically distributed on the center line of the trunnion of the furnace bottom. The carrier gas of the spray guns conveying lime powder is oxygen, and the flow rate of a single gun is 600-1200Nm 3 / h, argon gas is injected in the later stage of smelting, and the flow rate of a single gun is 400-1200Nm 3 / h, the single-gun injection rate of lime powder is 20-60kg / min, and the particle size of lime powder is 200 mesh. The injection parameters of the spray gun are as follows: figure 2 .

[0027] The specific smelting process is:

[0028] (1) 0-20 minutes after the end of feeding, during the chromium ore melting period, control the oxygen flow rate to 1200Nm 3 / h, the lime powder injection rate is 35kg / min;

[0029] (2) 20 to 35 minutes, the initial reduction period, co...

Embodiment 2

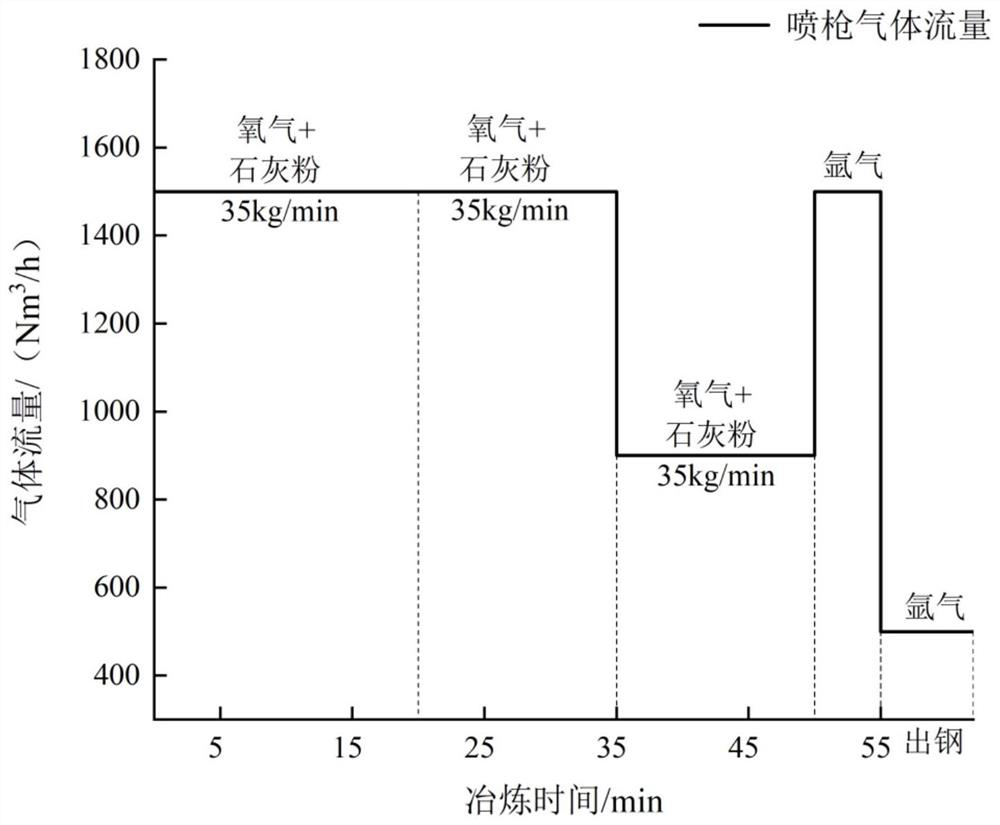

[0035] The invention is applied to smelting stainless steel mother liquid in a 150t top-bottom combined blowing converter, and the smelting raw materials are molten iron and chromium ore. Install 2 bottom blowing spray guns, which are symmetrically distributed on the center line of the trunnion of the furnace bottom. The carrier gas of the spray guns transporting lime powder is oxygen, and the flow rate of a single gun is 900-1500Nm 3 / h, argon gas is injected in the later stage of smelting, and the flow rate of a single gun is 500~1500Nm 3 / h, the single-gun injection rate of lime powder is 60-110kg / min, and the particle size of lime powder is 200 mesh. The injection parameters of the spray gun are as follows: image 3 .

[0036] The specific smelting process is:

[0037] (1) 0-20 minutes after the end of feeding, during the chrome ore melting period, control the oxygen flow rate to 1500Nm 3 / h, the lime powder injection rate is 60kg / min;

[0038] (2) 20 to 35 minutes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com