Low-carbon steel for deep drawing and smelting method thereof

A smelting method and low-carbon steel technology, applied in the direction of manufacturing converters, etc., can solve the problems of long smelting cycle and high smelting cost, and achieve the effects of shortening smelting cycle, reducing smelting cost, and widening the control window of converter end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

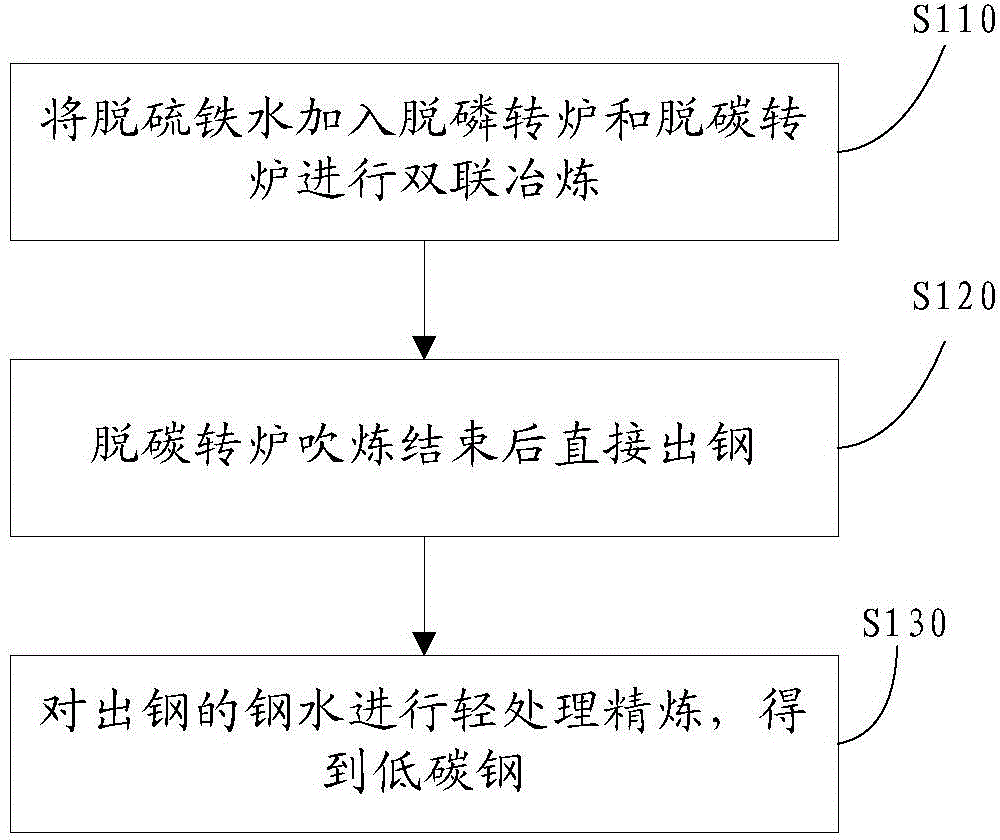

Method used

Image

Examples

Embodiment 3

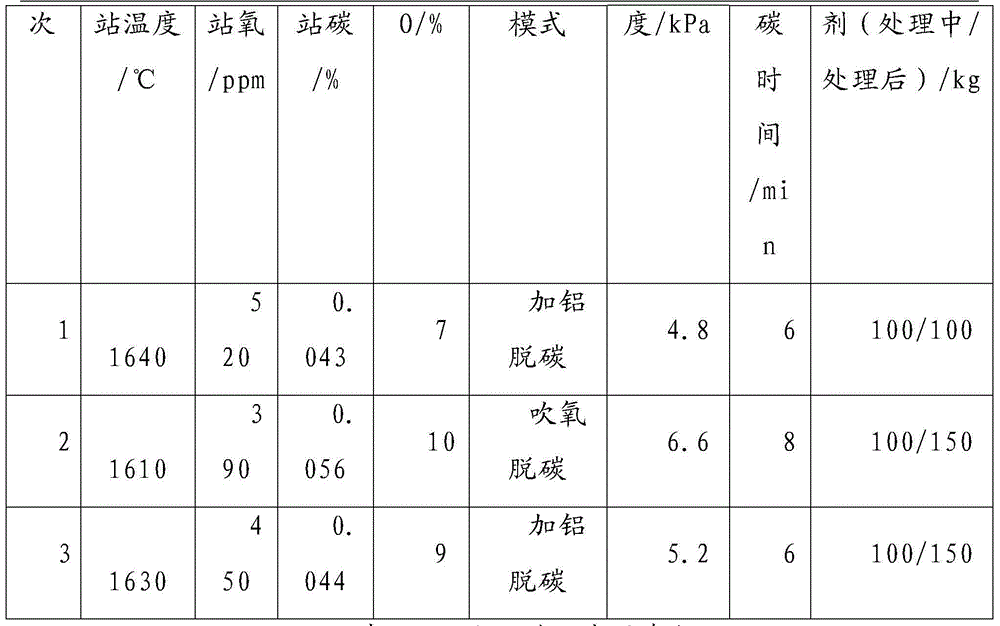

[0067] The embodiment of the present invention takes 3 furnaces as an example, specifically comprising the following steps:

[0068] Step 1, molten iron KR desulfurization treatment, adding desulfurized molten iron into the dephosphorization converter and decarburization converter for double smelting, the composition and temperature of the converter end point are shown in Table 1.

[0069] Stoves

[C] / %

[O] / ppm

temperature / ℃

1

0.044

550

1686

2

0.058

440

1670

3

0.048

480

1679

[0070] Table 1 Composition and temperature at end point of converter

[0071] In step 2, the molten steel is directly tapped without deoxidation, the slag is added to modify the slag during the tapping process, and the slag is used to tap the steel during the tapping process. The slag material and ladle slag thickness added in the tapping process are shown in Table 2.

[0072] Stoves

Small grains of lime / kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com