Patents

Literature

30results about How to "Emission clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulphurization and dust removal integrating flue gas purification device and method

InactiveCN104984633AReduce dust concentrationReduce dissolved salt concentrationUsing liquid separation agentPurification methodsFlue gas

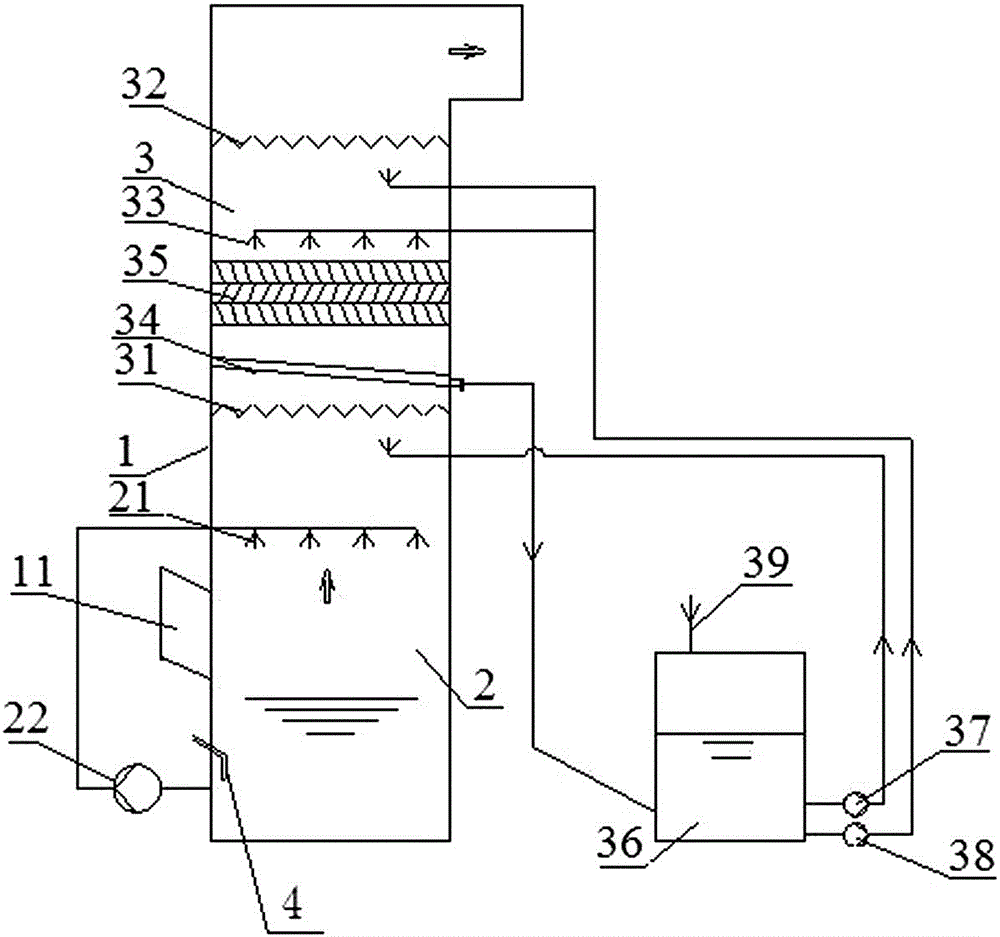

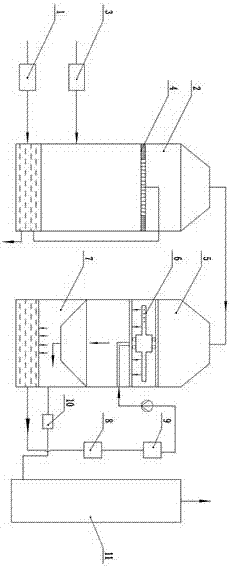

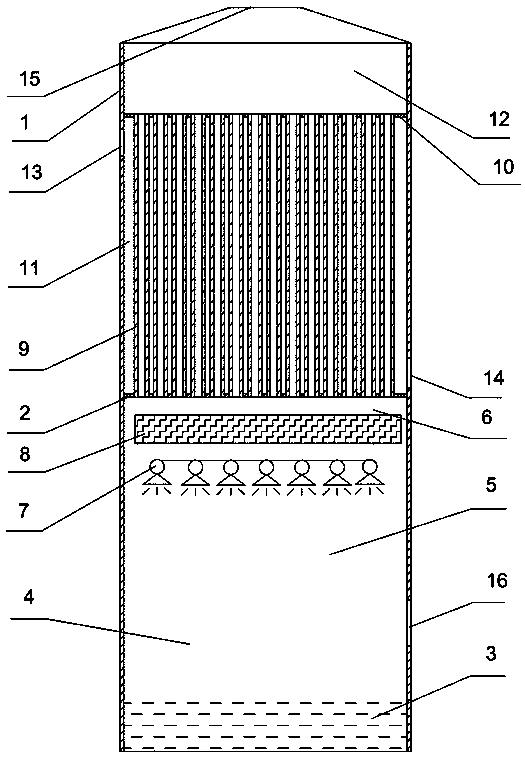

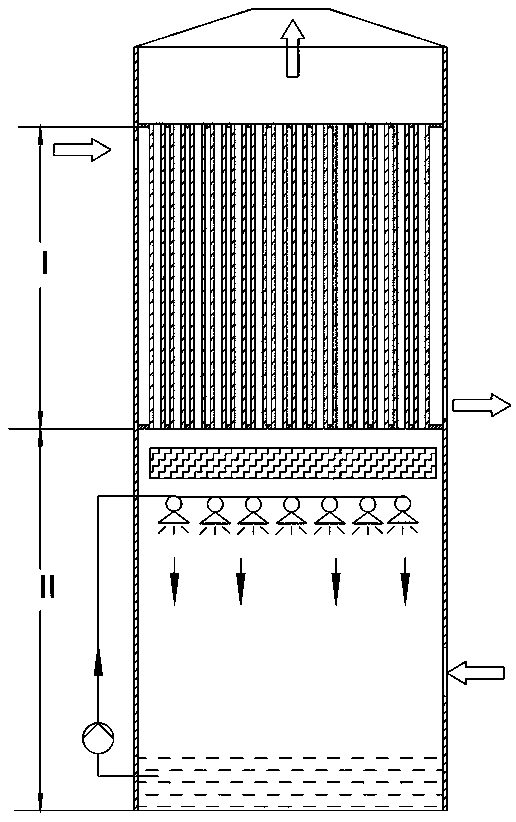

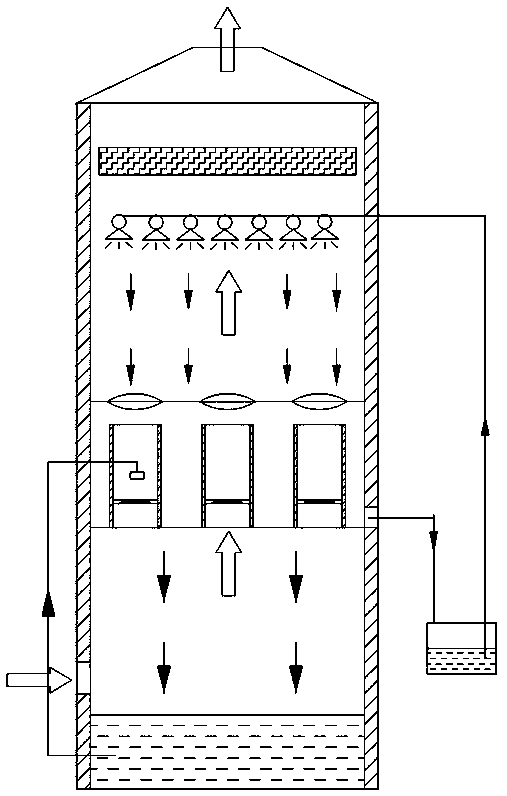

The invention relates to a desulphurization and dust removal integrating flue gas purification device and a desulphurization and dust removal integrating flue gas purification method. The device comprises an absorption tower, wherein a wet desulphurization system and a water-washing deep dedusting system are sequentially arranged in the flue gas flowing direction in the absorption tower. The glue gas enters the absorption tower; after being desulphurized by the wet desulphurization system, the flue gas enters the water-washing deep dedusting system to be deeply cleaned and washed, so that dust concentration in the flue gas and the concentration of dissolving salt in outlet fog drops are reduced, and SO2 and SO3 are also removed to certain degree; finally, the flue gas enters a chimney, cleaning emission is realized, desulphurization and dust removal are integrated, and the flue gas is exhausted without causing pollution.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

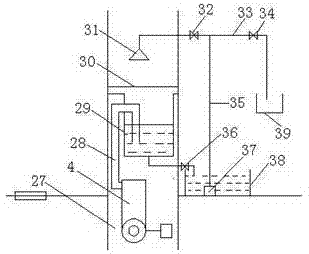

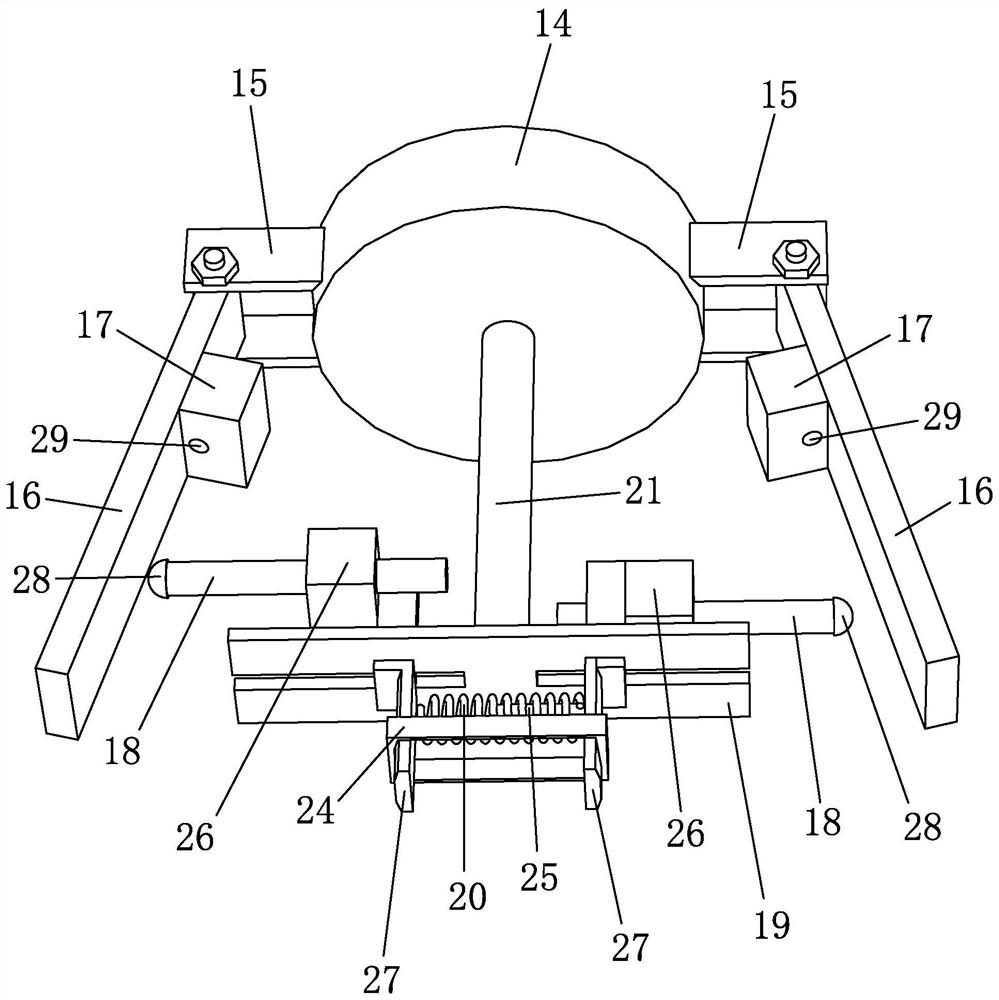

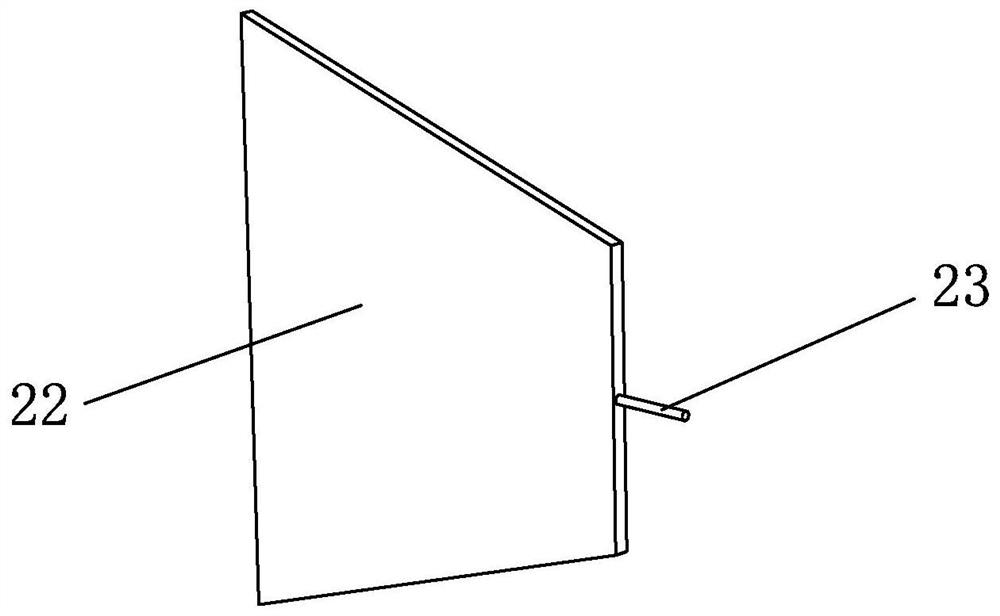

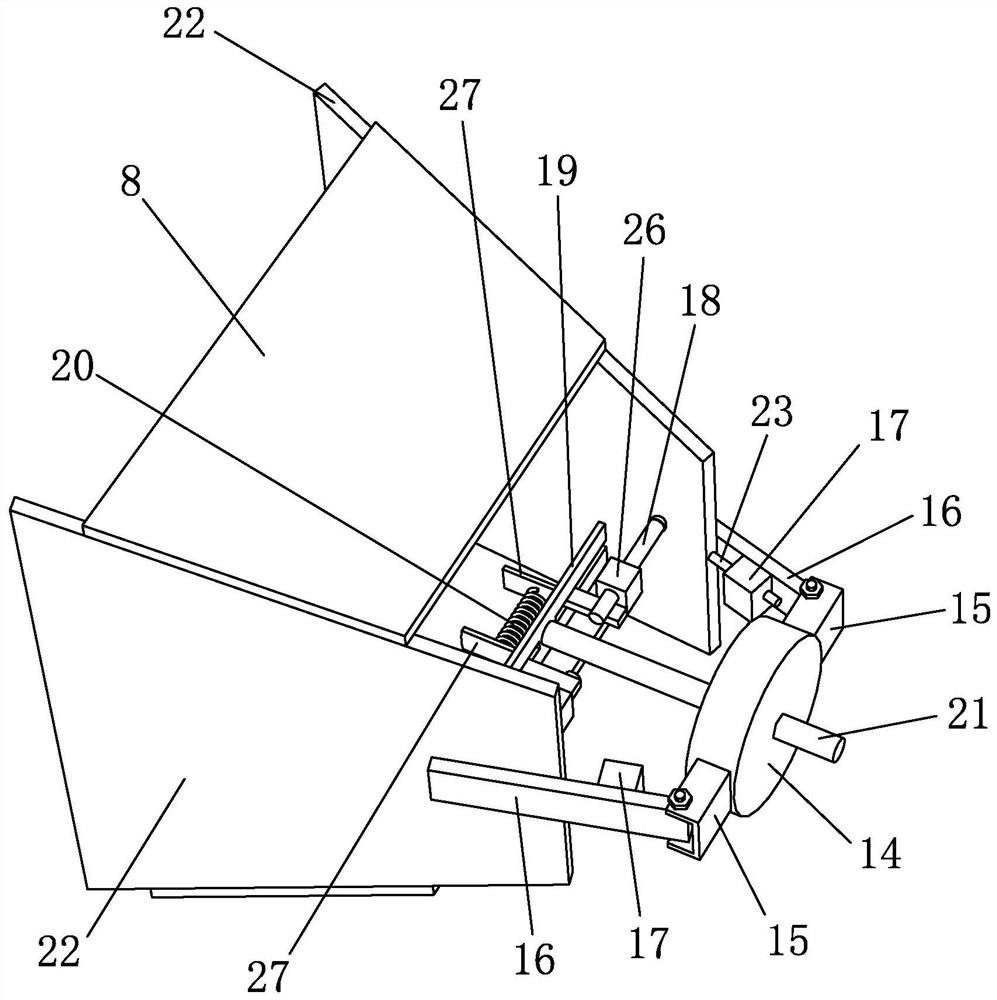

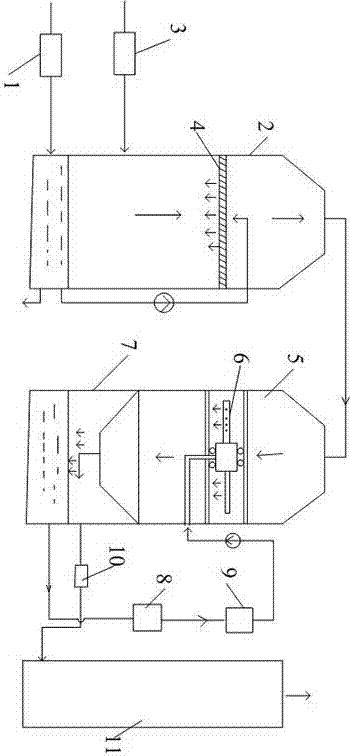

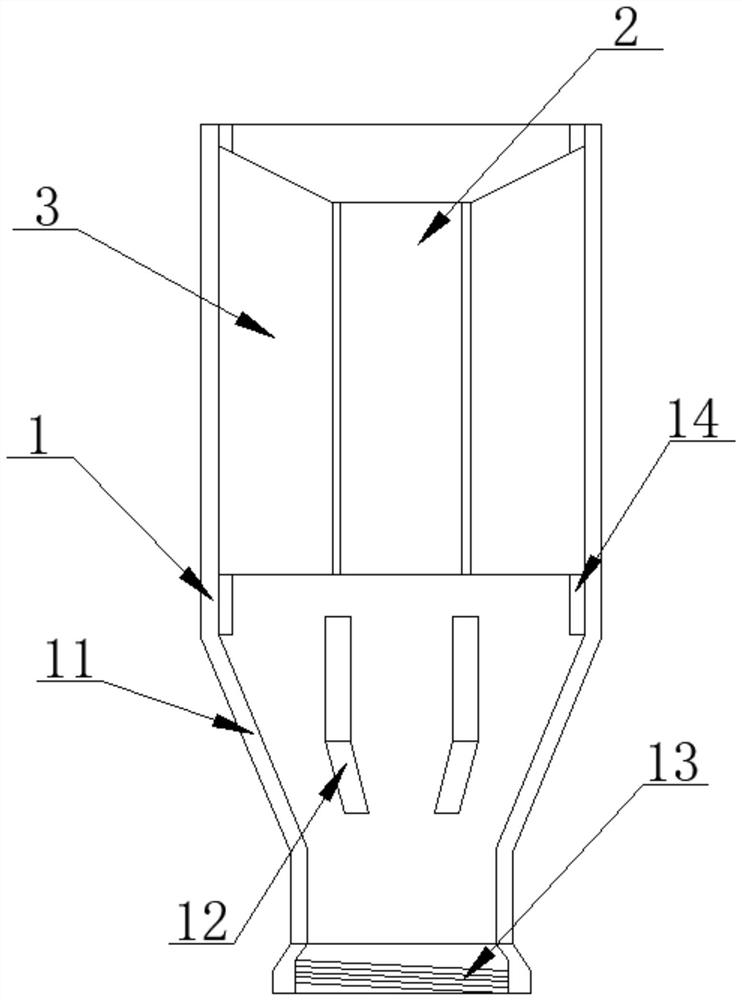

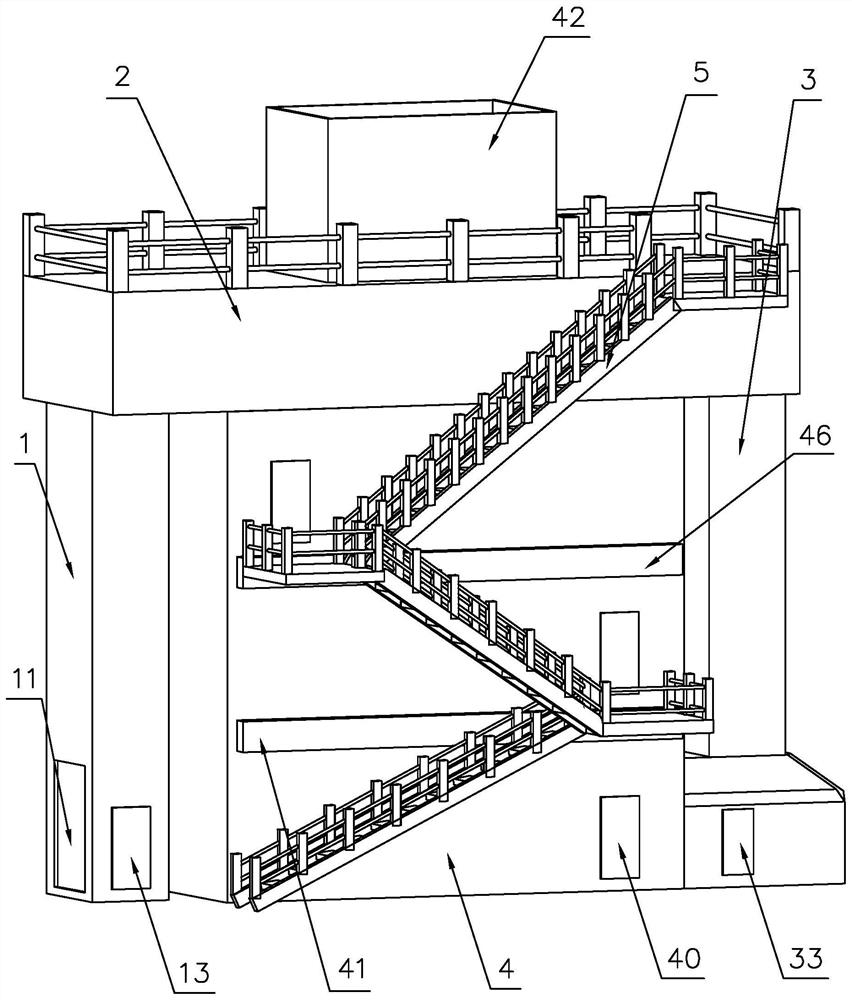

Waste gas treatment emission device for factories

InactiveCN107213751AAbsorb moreAbsorb thoroughlyCombination devicesIncinerator apparatusParticulatesActivated carbon

The invention discloses a waste gas treatment emission device for factories. The device comprises an inhaling and conveying rack, a settling tank, a spray plate, a dust storage bin, an electrostatic adsorption plate, an adsorption table, an activated carbon rotary table, a roasting plate, an emission pipe, a suction plate, a motor, a fan, a slide supporting column, a suck-filtration hole, a slide groove, telescopic spray racks, a rotary rail, a transmission volution, an activated carbon suction nozzle and burning frames. The device has the beneficial effects that the suction plate is used for sucking and filtering factory waste gas in a sliding manner on the slide supporting column, so that the waste gas can be absorbed comprehensively and completely; dust in the waste gas can be settled by spraying of the settling tank; a plurality of telescopic spray racks are used for constantly spraying the waste gas, so that the dust settling efficiency is quick and complete; and particles in the waste gas are electrostatically adsorbed, so that the waste gas can be comprehensively adsorbed and purified; and the waste is combusted and filtered through a plurality of burning frames, the waste can be cleanly emitted, and the environmental friendliness of emission can be guaranteed. The device is convenient to operate, and the components are connected flexibly.

Owner:柳州源联科技有限公司

Desulphurization dust removal process of smoke clean emission

InactiveCN107952312AImprove desulfurization effectReduce or even eliminate the generation ofGas treatmentUsing liquid separation agentPollutionFlue

The invention discloses a desulphurization dust removal process of smoke clean emission. The desulphurization dust removal process comprises the following steps: enabling smoke to enter an absorptiontower by virtue of a flue, performing the desulphurization, dust removal and cooling for the smoke on a plate grid tower tray of the absorption tower, then washing the smoke in a cooling and washing tower, and finally discharging the smoke via a chimney. The desulphurization dust removal process has good desulphurization dust removal effect; and moreover, the 'white smoke' problem caused by the smoke can be eliminated, the secondary pollution problem in the desulphurization process can also be solved, and assistance can be provided for reducing and eliminating the smog.

Owner:涉县亿玮坤节能科技有限公司

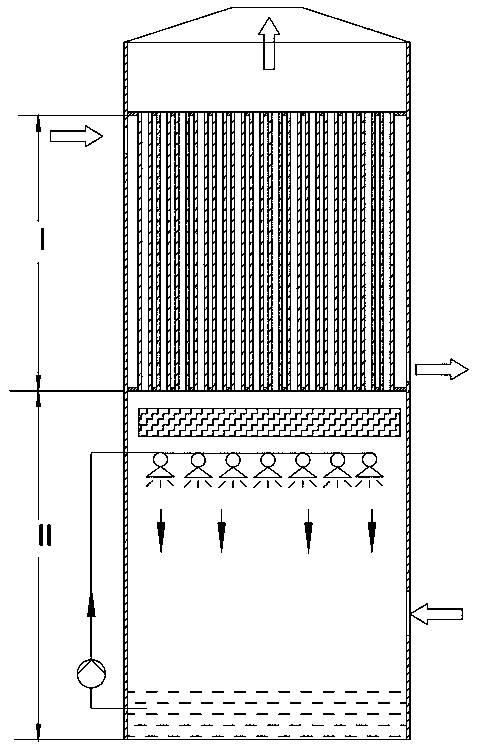

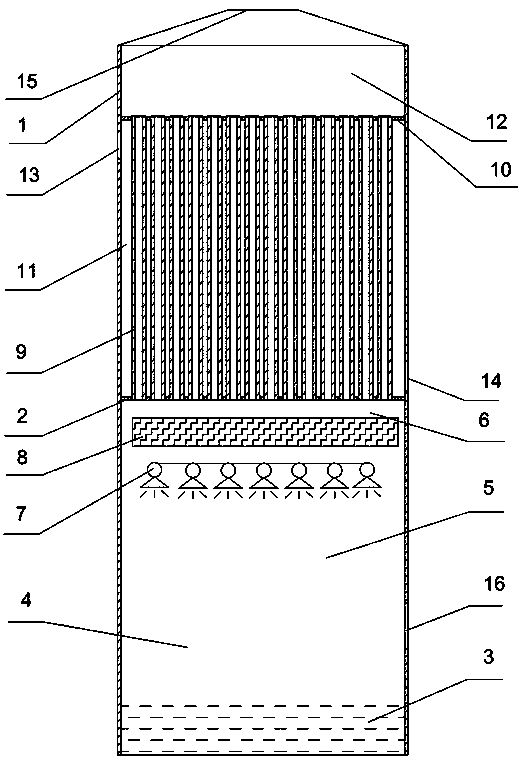

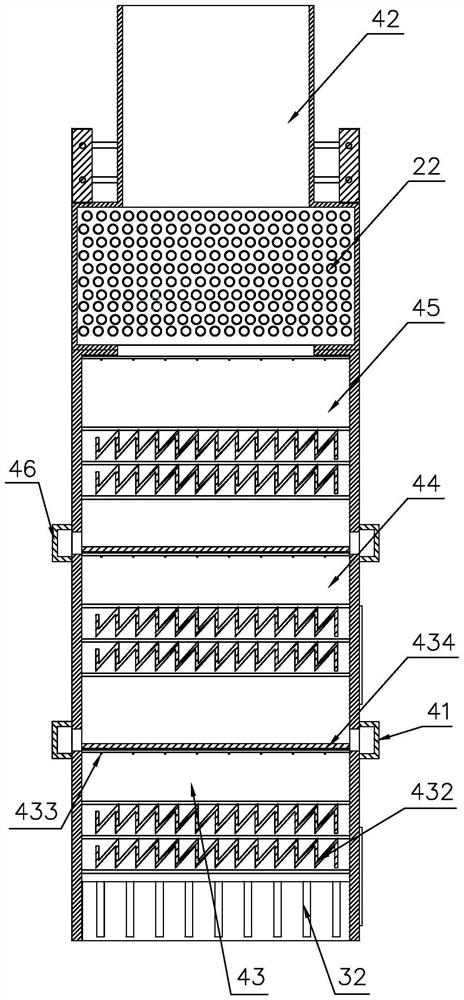

Haze reducing and white smoke eliminating tower for flue gas

The invention discloses a haze reducing and white smoke eliminating tower for flue gas. The haze reducing and white smoke eliminating tower comprises tower shell and an internal assembly, wherein thetower body is divided into a haze reducing part on the lower portion and a heating part on the upper portion, the heating part and the haze reducing part use the position of a separation plate a as adividing line, a water storage zone, a desulfurization flue gas inlet zone, a washing zone and a defogging zone are sequentially arranged from bottom to top in the inner cavity of the tower shell, a heating zone is arranged above the separation plate a, a heat exchange pipe is arranged in the heating zone, the heating zone and a purified flue gas outlet zone are separated by a separation plate b,and the defogging zone and the purified flue gas outlet zone are communicated by the heat exchange pipe cavity. According to the present invention, desulfurized flue gas sequentially subjected to hazeremoving and white smoke eliminating so as to achieve clean emission.

Owner:SHANDONG NORMAL UNIV

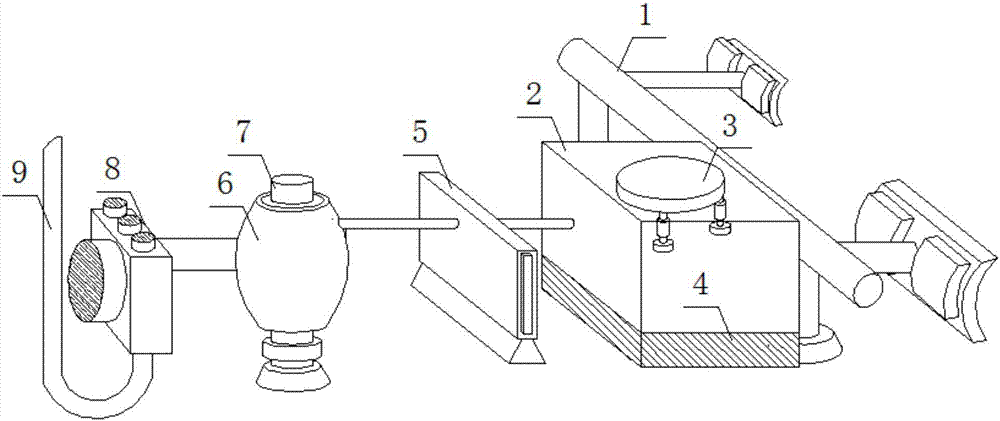

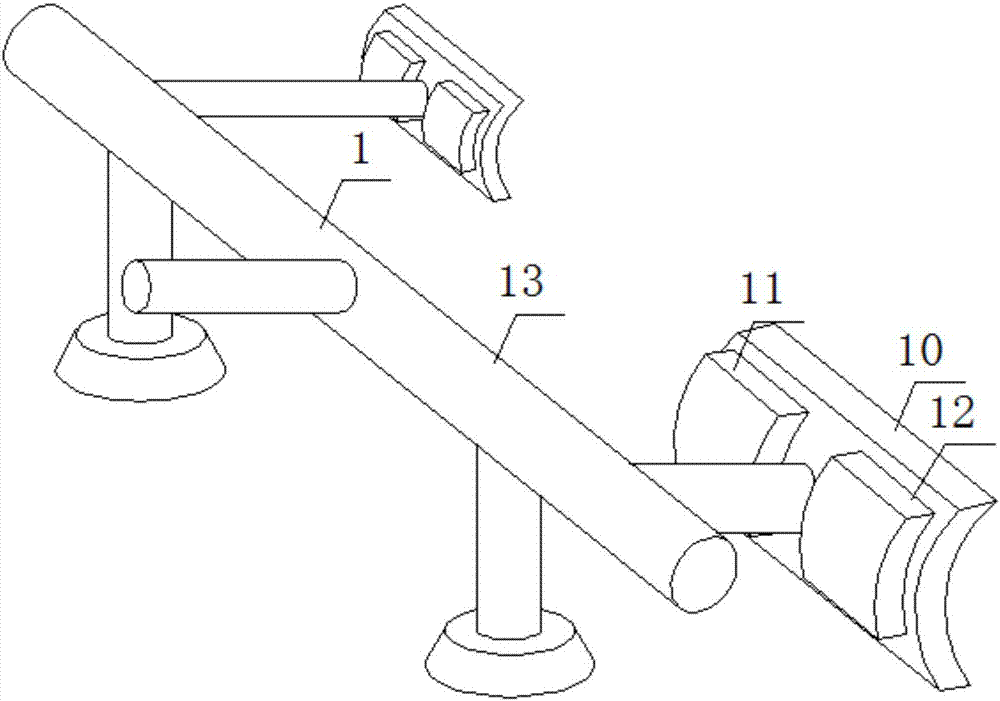

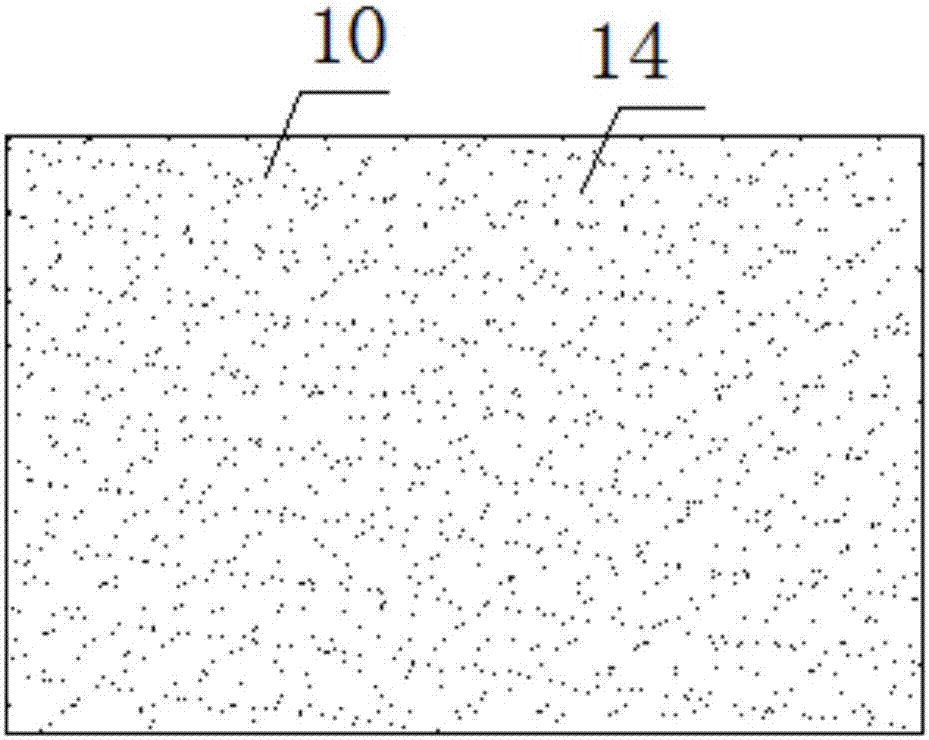

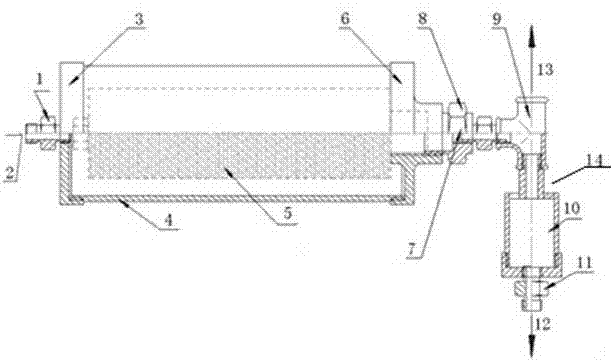

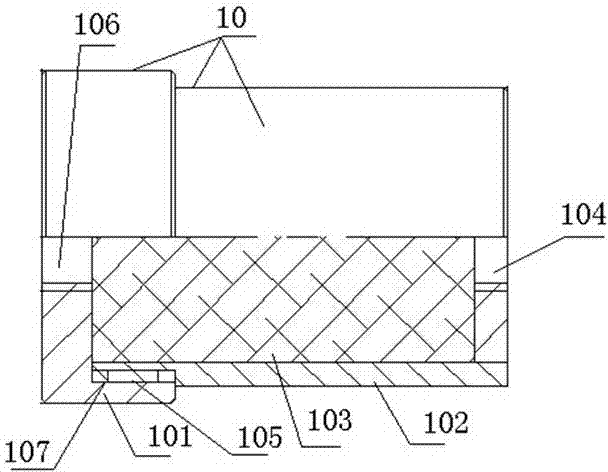

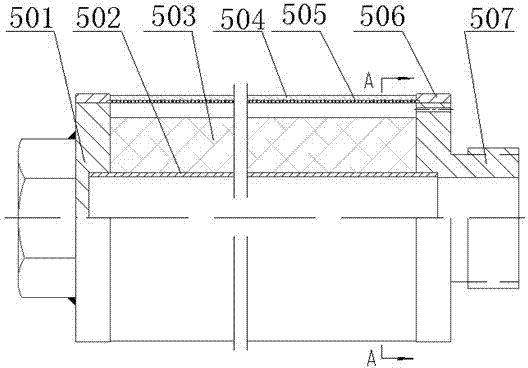

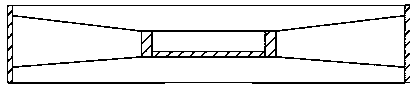

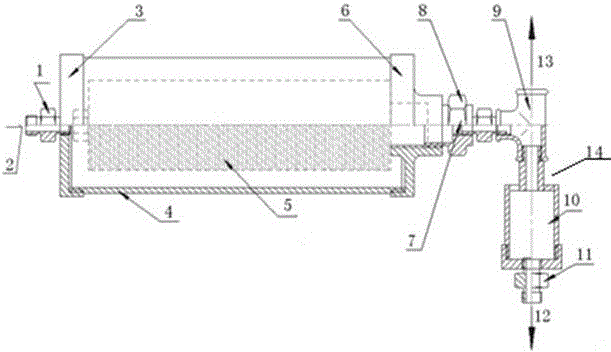

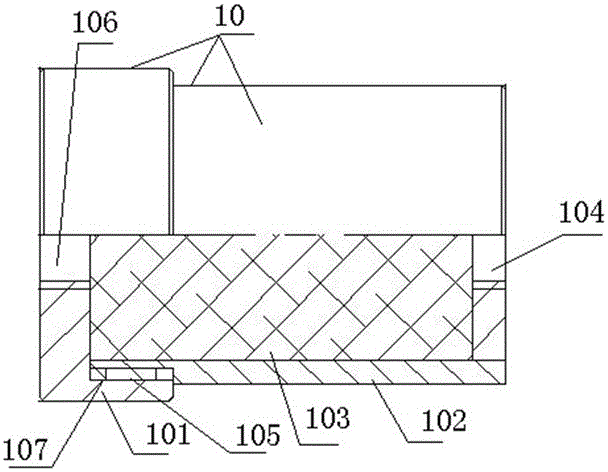

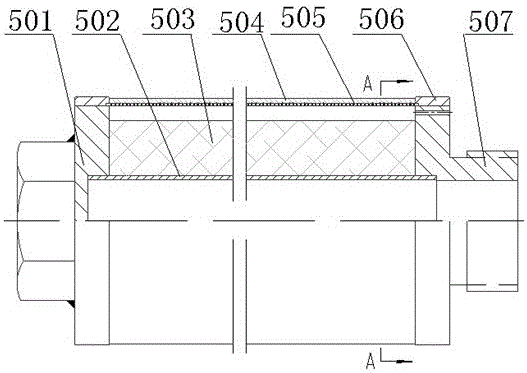

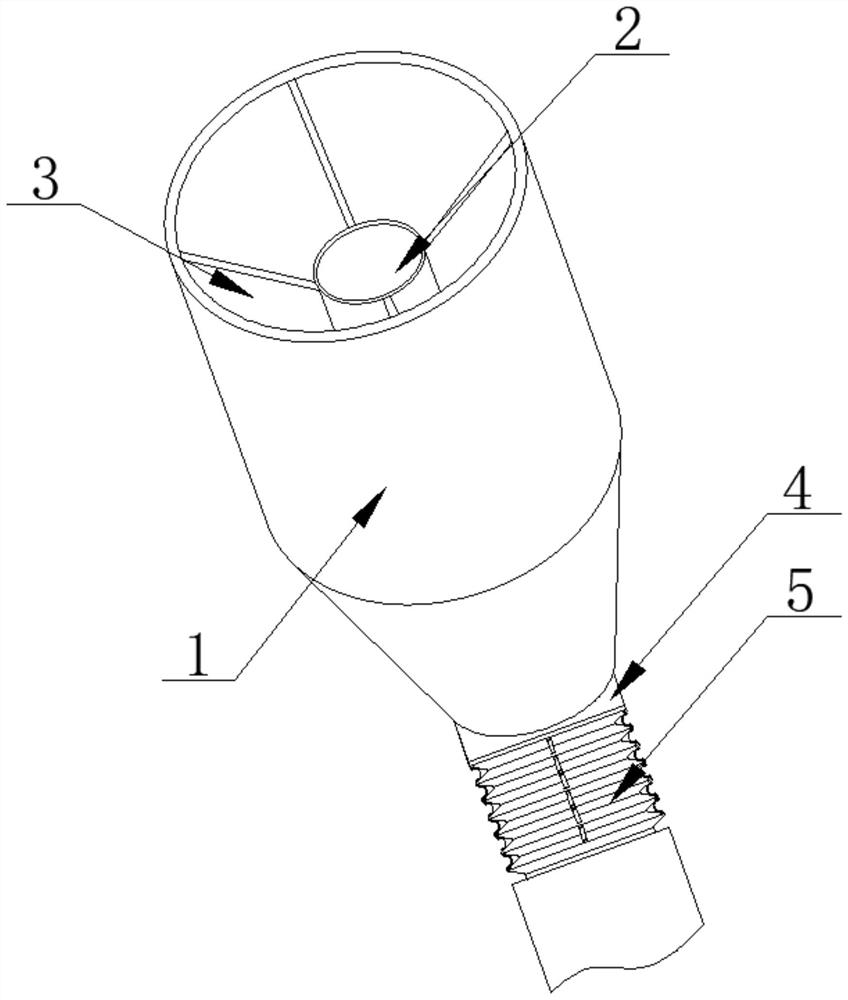

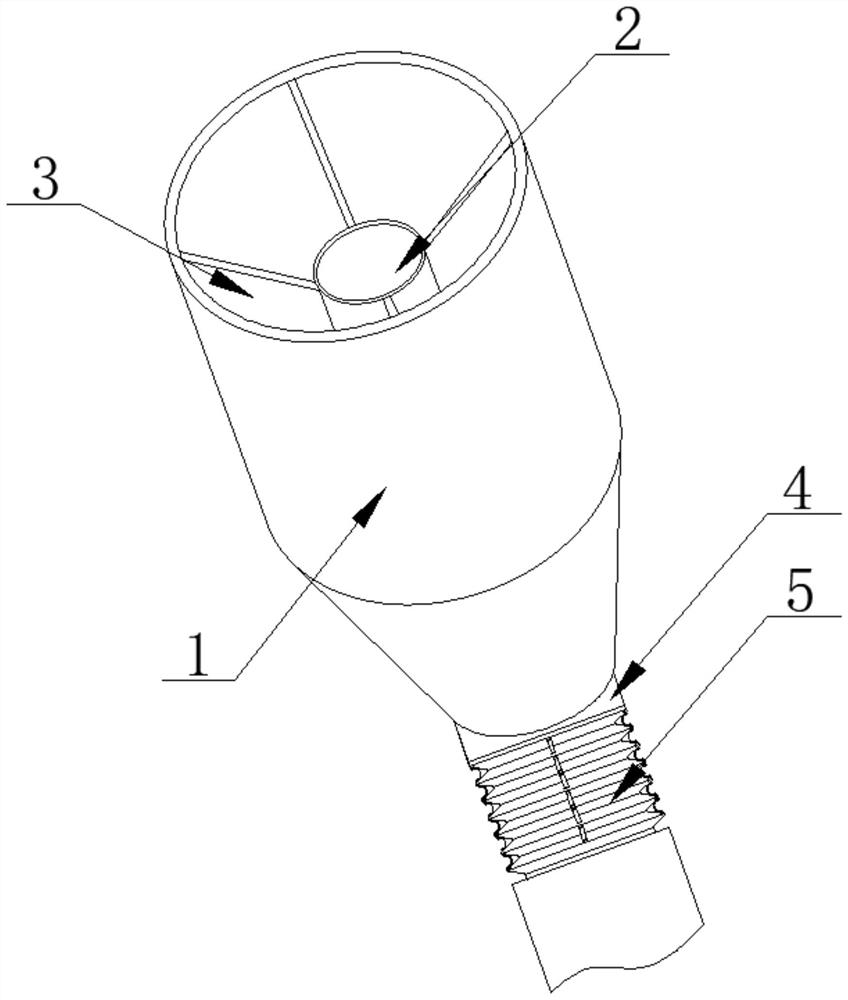

Single gun oil-gas recovery separator

The present invention relates to a single gun oil-gas recovery separator, which is characterized by at least comprising a filter cylinder, a gas inlet joint and a connection joint, wherein an accumulation filtration unit is fixed inside the filter cylinder, the accumulation filtration unit is packaged in the filter cylinder through the upper cover and the lower cover by both ends of the filter cylinder, the upper cover is connected with the gas inlet joint, the lower cover is connected with the connection joint, the gas inlet joint and the connection joint are arranged on both ends of the filter cylinder, the gas inlet joint, the filter cylinder, the accumulation filtration unit and the connection joint form a first filtration body, and the separated gas-liquid enters from the gas inlet of the gas inlet joint and is discharged from the connection joint. The single gun oil-gas recovery separator has characteristics of low cost, simple structure and good process, wherein the existing recycling equipment is completely utilized so as to reduce the engineering cost.

Owner:西安集良石油技术开发有限公司

Central air purification dust removal system

The invention discloses a central air purification dust removal system. The central air purification dust removal system comprises a desulfuration dust removal tower. A smoke inlet is formed in the lower portion of the desulfuration dust removal tower, and a smoke outlet is formed in the upper portion of the desulfuration dust removal tower. The central air purification dust removal system further comprises a lime water tank and a settling tank. A sprayer is arranged on the upper portion in the desulfuration dust removal tower, filler layers distributed at intervals in a staggered mode are arranged at the position, located below the sprayer, in the desulfuration dust removal tower, the lime water tank and the sprayer are connected through a lime water pipeline, an exhaust pipeline communicated with the interior of the settling tank is arranged at the bottom of the desulfuration dust removal tower, and a supernatant recovery pipeline communicated with the interior of the lime water tank is arranged on the upper portion of the settling tank. The central air purification dust removal system is very suitable for being used under the working conditions that the smoke exhaust amount of industrial waste gas is large and the smoke flow speed is high, dust and sulfur dioxide in smoke can be efficiently removed, the smoke can be exhausted cleanly, installation and use are convenient, and cost can be reduced.

Owner:NANJING DEQING ENVIRONMENT ENG CO LTD

Desulfurization and denitration synergistic action system

PendingCN108246085AImprove removal efficiencyEmission cleanDispersed particle separationFlue gasEngineering

The invention provides a desulfurization and denitration synergistic action system which can be used for spraying a synergist into a previous flue gas pollution removal device. The flue gas pollutionremoval device is internally provided with a plurality of pollution removal agent spraying layers which are arranged in sequence from top to bottom, wherein the system comprises an atomizing layer, asynergist storage tank and a synergist conveying pipeline which is connected with the atomizing layer and the synergist storage tank; the synergist conveying pipeline is provided with a synergist conveying pump; the atomizing layer can be arranged between the pollution removal agent spraying layers; a plurality of atomizing heads are arranged on the atomizing layer. The synergist is selected fromone or more of NaClO, HO, a .OH free radical (a hydroxyl free radical). According to the desulfurization and denitration synergistic action system, provided by the invention, the desulfurization and denitration efficiency is remarkably improved; meanwhile, the engineering investment and the operation cost are remarkably reduced.

Owner:新疆乾坤环能投资有限公司 +1

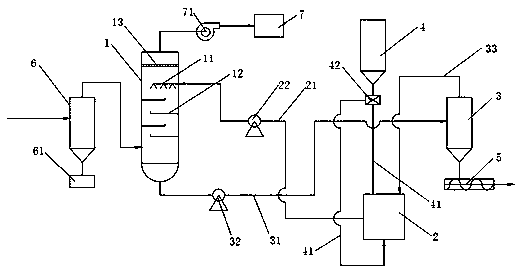

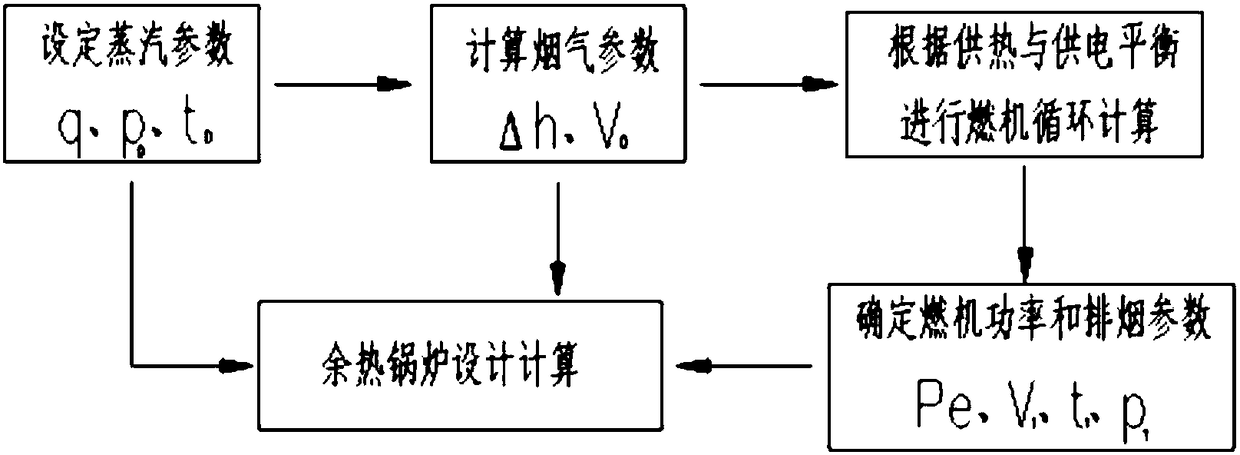

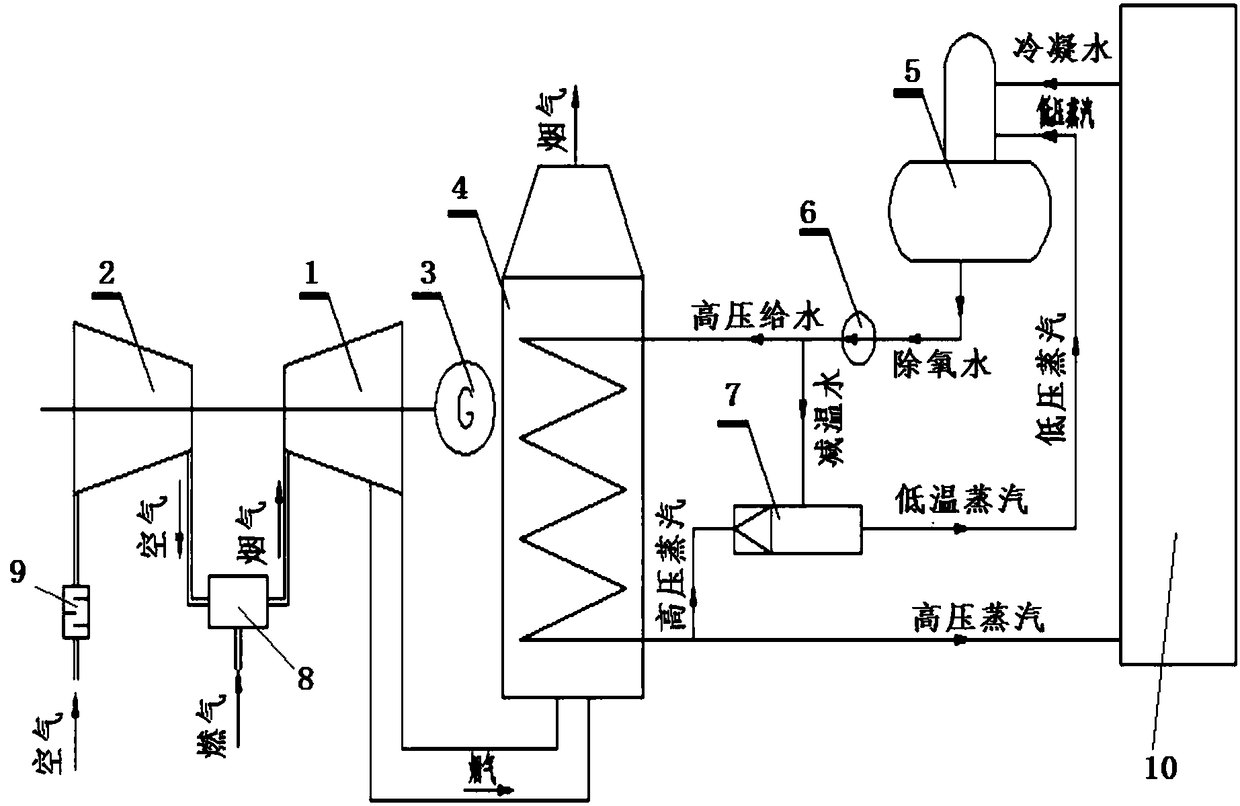

Method for combined heating and power of aluminum oxide plant

InactiveCN108869040AEmission cleanSmall footprintGas turbine plantsSteam engine plantsProcess engineeringAluminium oxides

The invention discloses a method for combined heating and power of an aluminum oxide plant. On the basis of a traditional gas turbine combined cycle combined heating and power system, appropriate craft adjustment is carried out, and the power and the fume exhaust parameters of a gas turbine are determined according to the requirements of a high-pressure digestion system. The method for combined heating and power of the aluminum oxide plant has the advantages that for an aluminum oxide high-pressure digestion system, it can be achieved that heating and power are both given consideration to andare balanced, and isolated network operation can be achieved; and meanwhile, on the aspects of energy saving and environmental protection, compared with the situation that a traditional aluminum oxideplant owns a thermal power plant for fire coal, the gas turbine combined cycle combined heating and power system has the advantages of being higher in comprehensive thermal efficiency, cleaner in exhausted fume, smaller in occupied area and the like.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

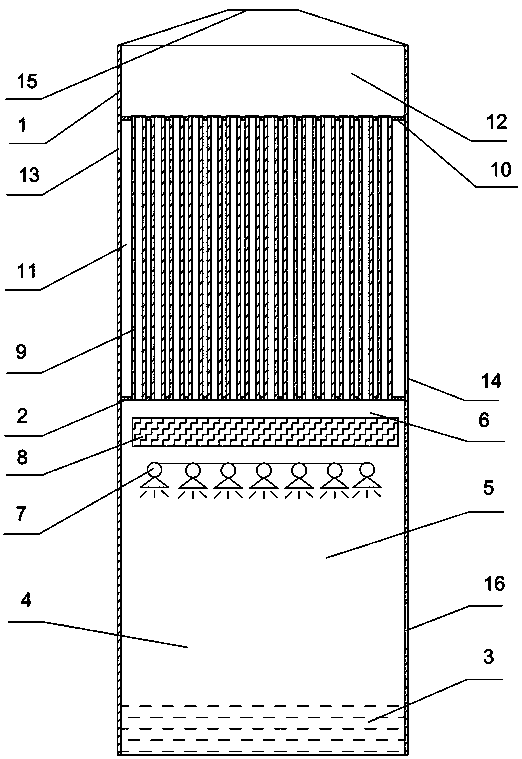

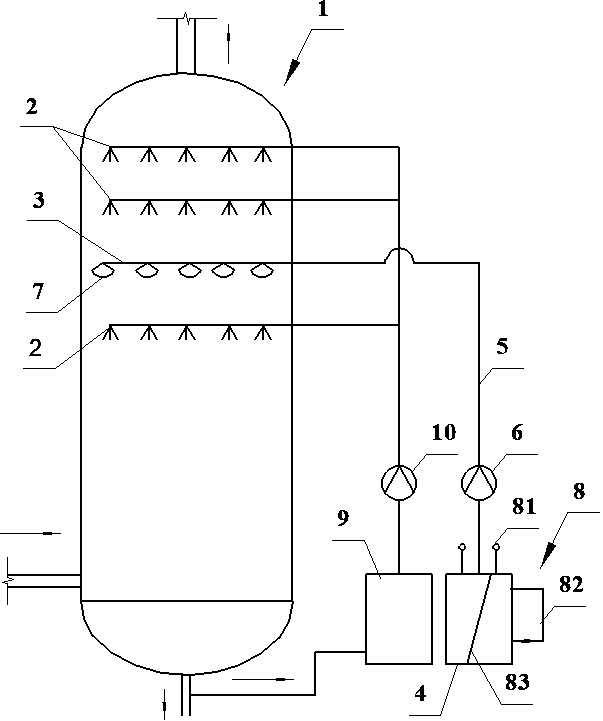

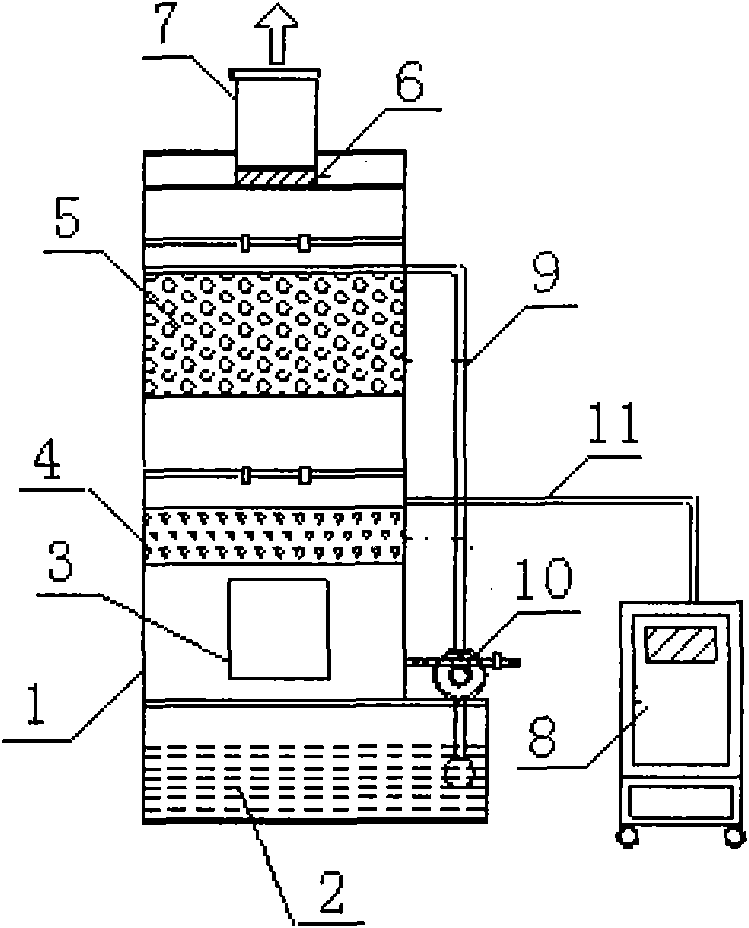

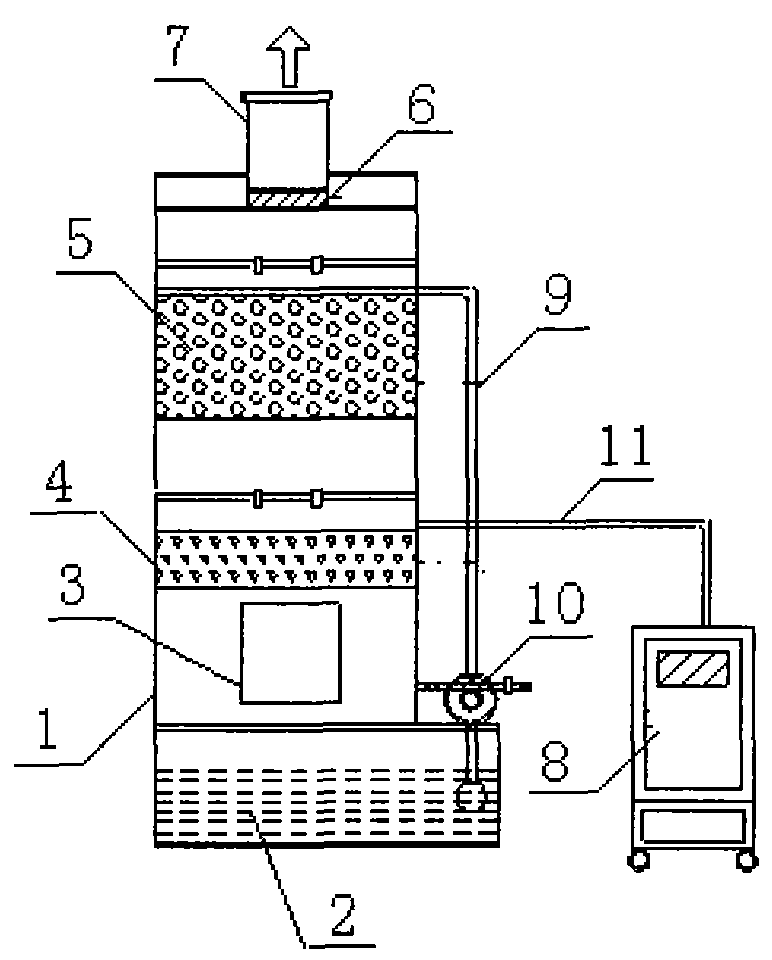

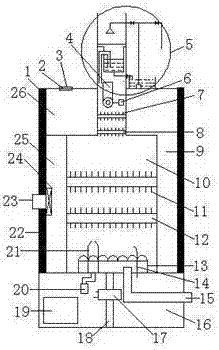

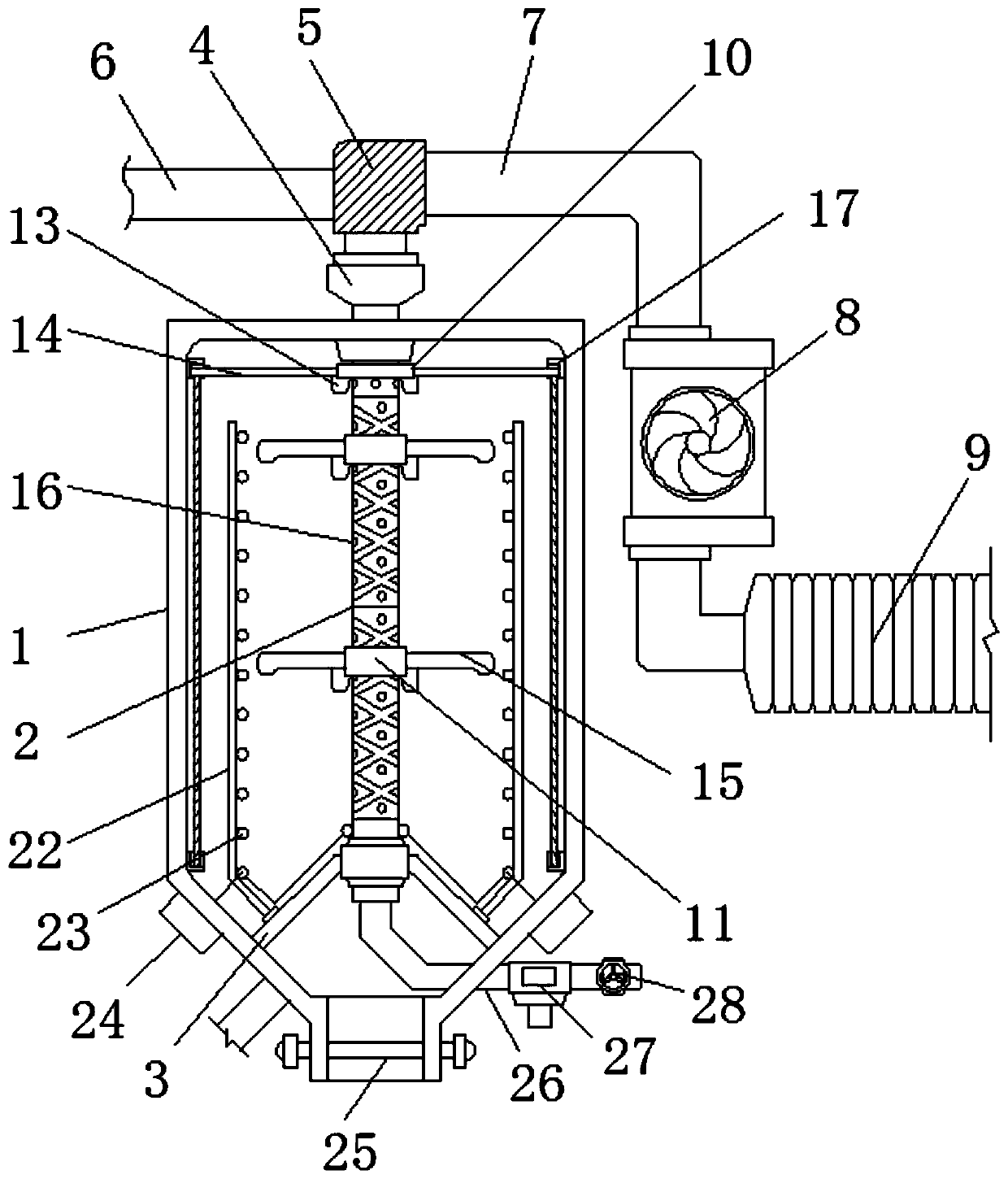

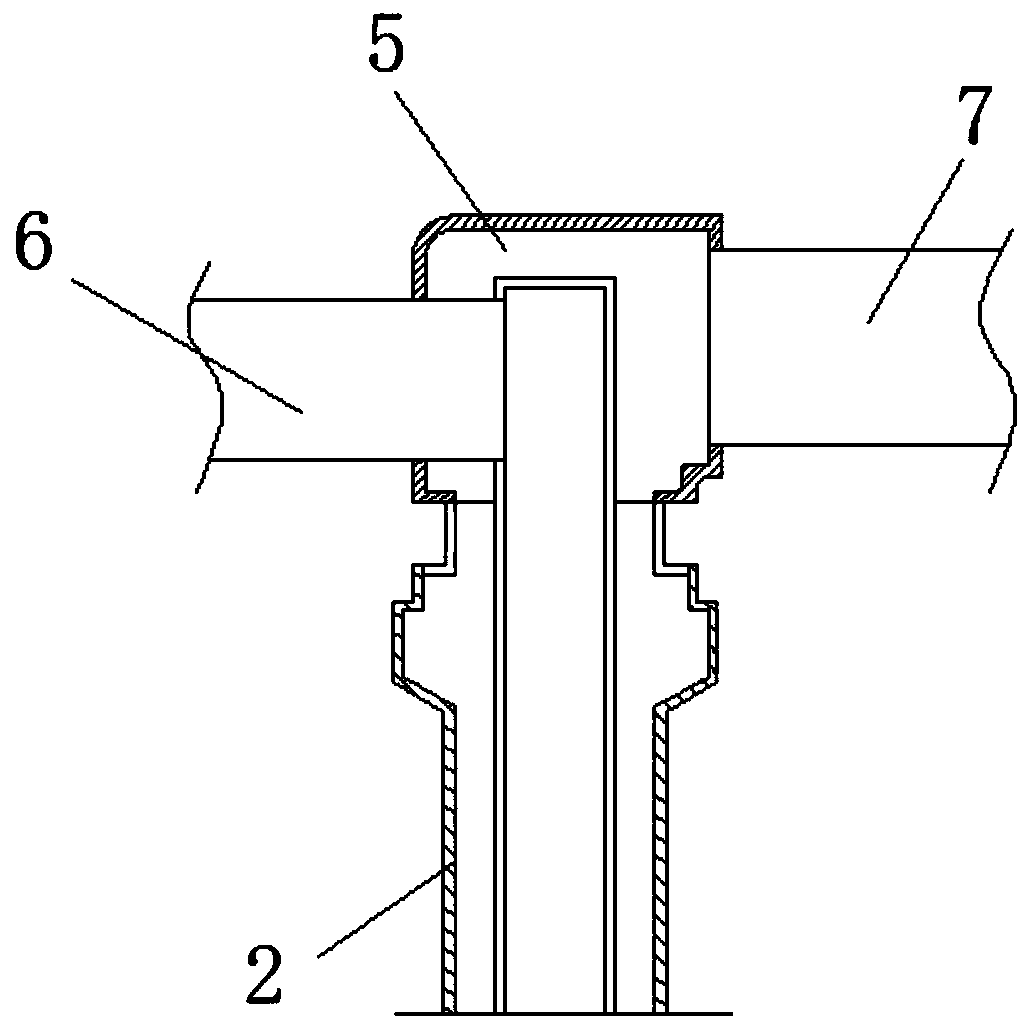

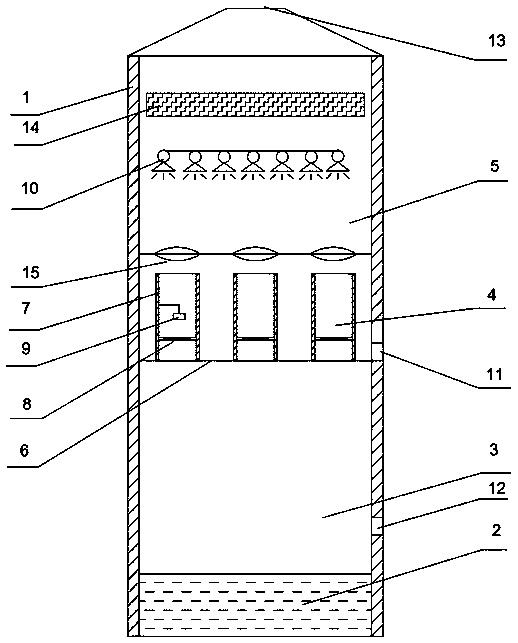

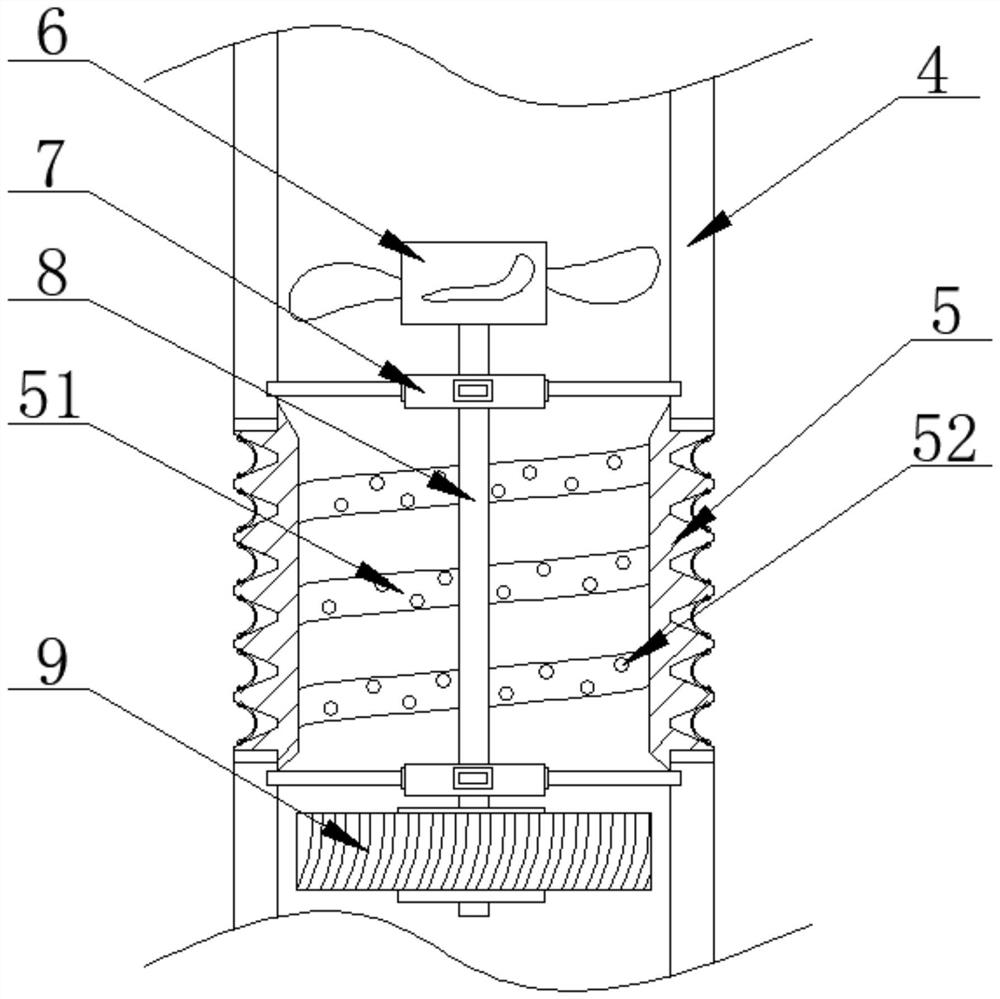

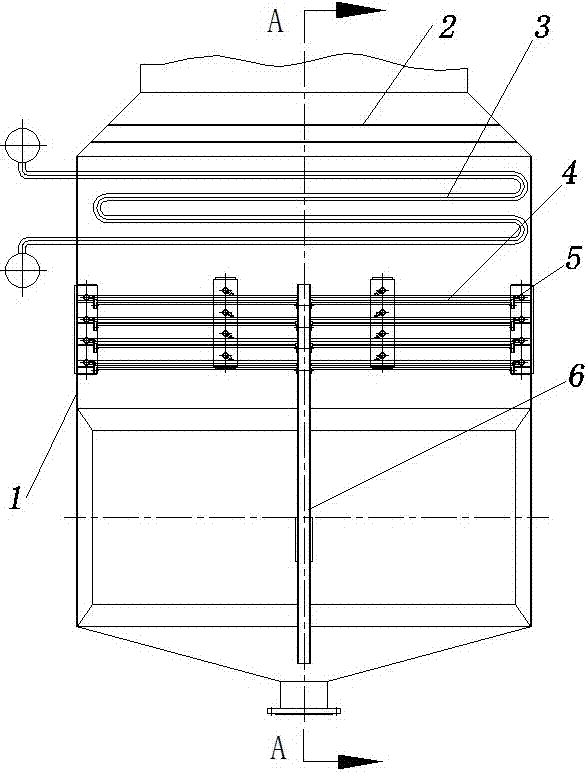

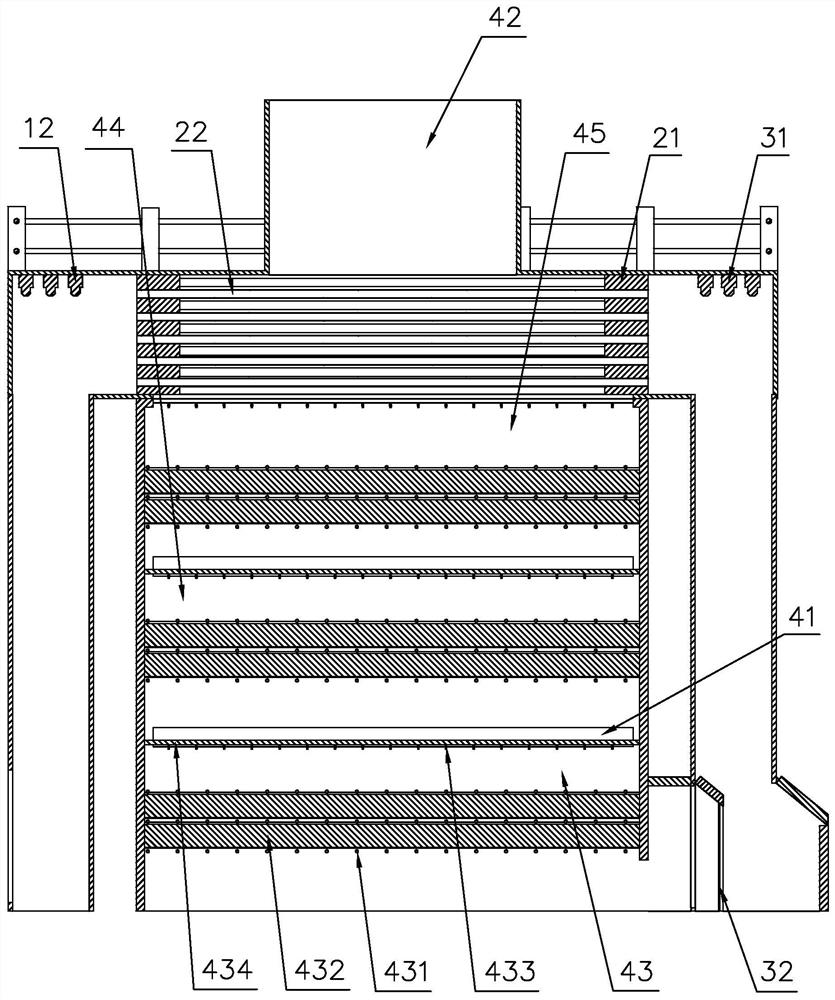

High-activity biological waste gas purification tower

InactiveCN102371119AGood atomization effectImprove purification effectDispersed particle separationAir quality improvementBiological wasteExhaust gas

The invention discloses a high-activity biological waste gas purification tower, comprising a tower body, wherein, the top of the tower body is provided with a clean air outlet; the bottom of the tower body is provided with a water tank and an exhaust gas inlet; a main control system is arranged at the side part of the water tank; the interior of the tower body is divided into an upper layer, a middle layer, and a lower layer, the upper layer is an aerosol separating layer, the middle layer is a bioactive exhaust gas washing layer, the lower layer is an ultramicro atomization purifying layer, and the position orders of the bioactive exhaust gas washing layer and the ultramicro atomization purifying layer can be adjusted; the ultramicro atomization purifying layer is provided with atomization catalysts and communicated with the exhaust gas inlet; the aerosol separating layer uses metal polyhedron balls as the filler and is communicated with the clean air outlet; the ultramicro atomization purifying layer is connected with the water tank through a transfer line, and the transfer line is provided with a control valve. According to the invention, exhaust gas is processed by using the combination of ultramicro atomization and washing, and multitime purification and aerosol separation, thus the advantages of good purification effect and low energy consumption of the system are achieved.

Owner:SHANGHAI ZHENZIQIN ENVIRONMENTAL TECH

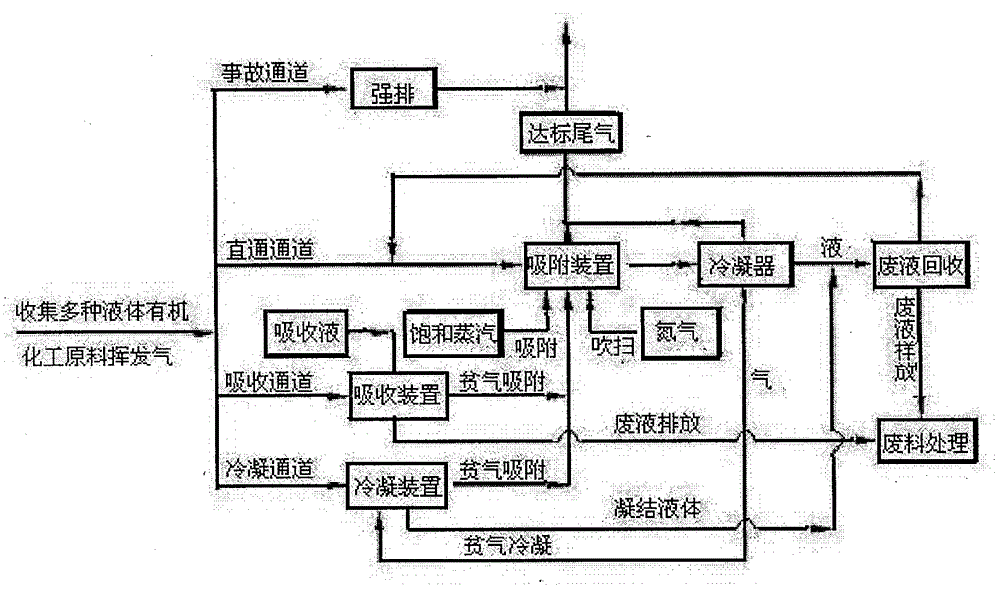

Centralized collection and treatment method of a plurality of liquid organic chemical raw material volatile gases

ActiveCN103272400BThe best treatment process planEnergy efficient recycling processDispersed particle separationVapor condensationLiquid wasteEnvironmental resistance

The invention belongs to the air pollution emission control of the environmental protection field. The invention relates to a centralized collection and treatment method of a plurality of liquid organic chemical raw material volatile gases for collecting a plurality of liquid organic chemical raw material volatile gases in the petrochemical industry. According to characteristic classification, gases with low solidifying points enter into a straight-through channel; water-soluble gases and organic acid gases enter into a water phase absorption channel; gases with high condensation points which are insoluble or slightly soluble in water enter into a condensation channel; volatile gases pass through the three channels and enter into an adsorption apparatus for adsorption treatment, after desorption, the gas liquid mixture enter into a condenser for coagulation and recovery at the cooling temperature 35-40 DEG C., and after gas-liquid separation, the liquid separated from the gas-liquid separation process is sent to a waste liquid recovery pot for temporary storage; the separated gas which meets the environmental protection requirement can be emitted directly. The method solves the air pollution caused by volatilization of a plurality of liquid organic chemical raw material volatile gas, thereby the emitted volatile gas can reach the environmental protection air pollution emission control standard.

Owner:大连德丰尚捷环保科技有限公司

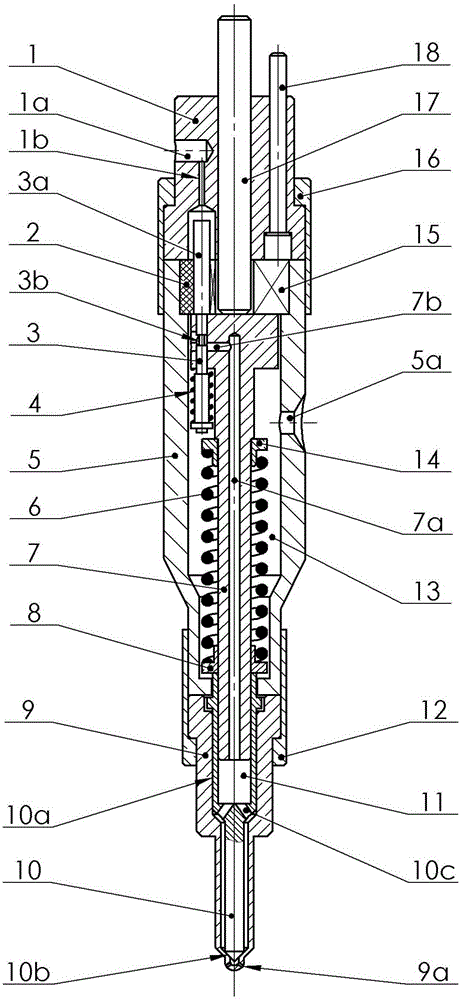

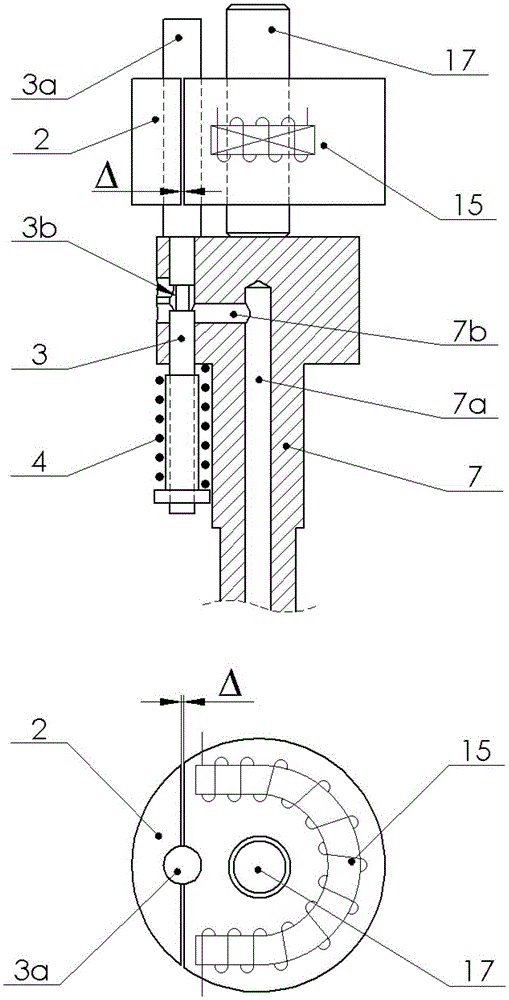

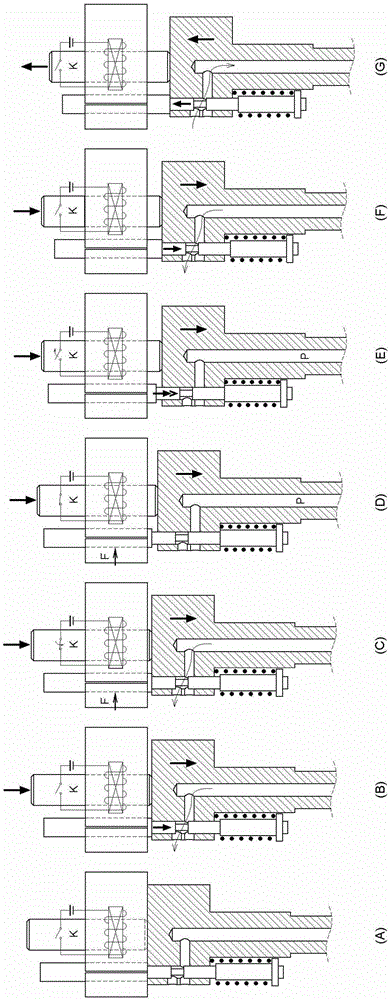

fuel injector

InactiveCN102748179BEmission cleanReduce consumptionFuel injection apparatusMachines/enginesSolenoid valveEngineering

Provided is a fuel injector for a diesel engine. A plunger is arranged in the fuel injector, and the plunger and a fuel nozzle needle valve are combined into a pair of matching parts. The matching parts can be in a mode that the fuel nozzle needle valve is installed in an inner hole of the plunger or in a mode that the plunger is installed in an inner hole of the fuel nozzle needle valve. Fuel injection and fuel feeding of a high-pressure cavity can be controlled through an electric control method or a mechanical method. The plunger can be pushed through a mechanical method or a hydraulic method, wherein pressurizing injection can be further achieved by means of the hydraulic method. The fuel injector reduces volume of the high-pressure cavity and a leakage link furthest. Therefore, the fuel injector is quick in pressure building up, less in leakage amount, high in injection pressure, clean in discharged tail gas and low in fuel consumption. An electric control valve is not driven by an armature directly, and clearance between a solenoid valve and the armature can be smallest, so that miniaturization of the solenoid valve is facilitated.

Owner:袁辉

Energy-saving and environment-protecting wall-mounted furnace and application method thereof

InactiveCN107062604AHeating up fastImprove thermal efficiencyAir heatersCombustion chamberProcess engineering

The invention relates to an energy-saving and environment-friendly wall-hung furnace and a method for using the same. An air buffer bin and a hot air collection bin are provided, at least one set of heat exchangers are fixed in the combustion chamber, and the combustion chamber communicates with the air heat absorption bins and The hot air collection chamber is connected; the waste gas heat exchanger is fixed at one end of the exhaust gas discharge channel close to the combustion chamber, and the air heat absorption chamber communicates with the air buffer chamber through the heat absorption passage II on the waste gas heat exchanger ; The end of the exhaust gas discharge passage away from the combustion chamber is connected with an exhaust gas purification device. The invention uses indoor air as a heat transfer medium, has high thermal efficiency and small heat loss, and the exhaust gas after combustion can be absorbed by the exhaust gas purification device and can be discharged in an environmentally friendly and clean manner to reduce air pollution.

Owner:董广文

Negative pressure waste gas discharge disinfection sterilizer and manufacturing method thereof

ActiveCN111421302BEmission cleanPrevent leakageGas treatmentDispersed particle separationAir volumeExhaust gas emissions

The invention discloses a negative pressure waste gas discharge disinfection and sterilizer and a manufacturing method thereof, which comprises a housing, a gas pipeline, a junction box and a heating element. Both ends of the housing are provided with protective covers, and the size of the opening of the protective cover is along the The center of the shell gradually decreases toward the end, and the inner cavity of the protective cover communicates with the gas pipeline. The method includes: a, installing a protective cover welding device; b, welding to obtain a protective cover with an initial shape; c, welding an inner cavity in the protective cover with an initial shape; d, cutting to obtain a formed protective cover; The sealing plate is welded and fixed; f, the protective cover is painted; g, the protective cover is respectively welded on both ends of the shell; h, the bottom of the junction box is sealed on the shell. The invention can avoid the phenomenon of gas leakage, reduce the temperature of the exhaust at the same time, improve the safety, and increase the processing air volume; and solve the technical problem that the inside of the truss-shaped protective cover is not easy to weld, and increase the vertical pressure bearing of the protective cover Capability, can be welded in batches to get the protective cover.

Owner:ZHEJIANG QIANGSHENG MEDICAL ENG

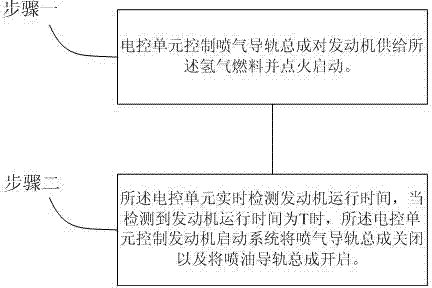

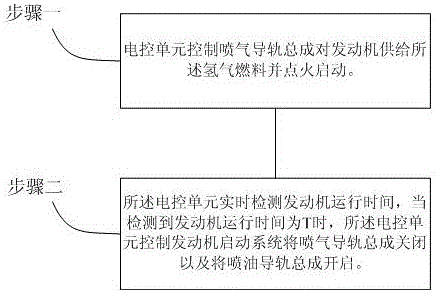

Control method for engine starting system

ActiveCN104514662ASolve the difficulty of startingEmission reductionElectrical controlElectric motor startersHydrogen fuelElectric control

The invention provides a control method for an engine starting system. The control method includes the steps that: 1, when an engine starts, an electronic control unit controls an air jet guide rail assembly to supply hydrogen fuel to the engine and ignite to start up; 2, after then engine starts, the electronic control unit detects the operating time of the engine in real time, when it is detected that the operating time of the engine is time T, the electronic control unit control the air jet guide rail assembly to close and control an oil jet guide rail assembly to open, wherein the time T is the operating time of the engine when a three-way catalyst reaches an initiation temperature. According to the control method for the engine starting system, the hydrogen is adopted as the fuel of the starting system of the engine, so that the problem that the engine is difficult to start under the low temperature environment is solved, and meanwhile the ECU (Electronic Control Unit) switches a fuel supply system according to the operating time of the engine when the three-way catalyst reaches the initiation temperature, thus further reducing discharge of pollutant when the engine starts.

Owner:BYD CO LTD

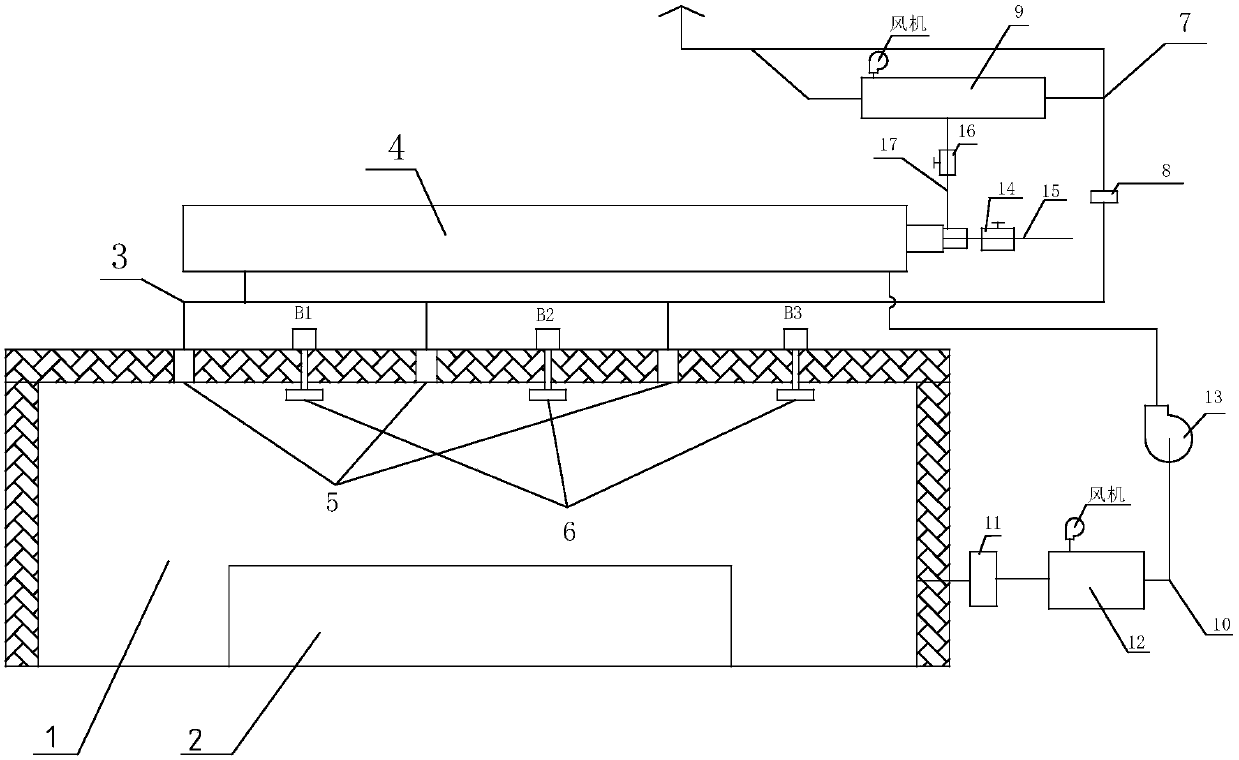

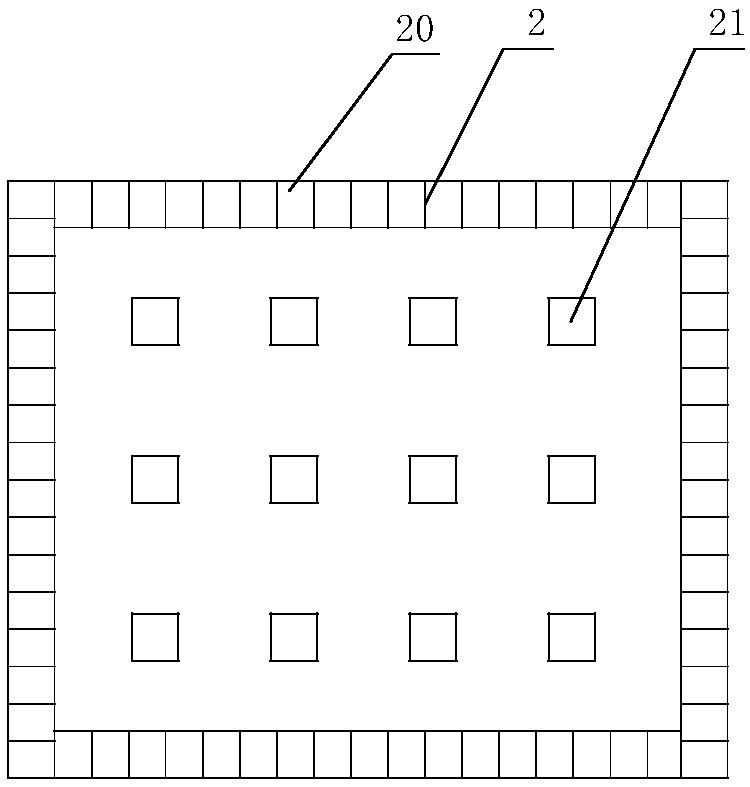

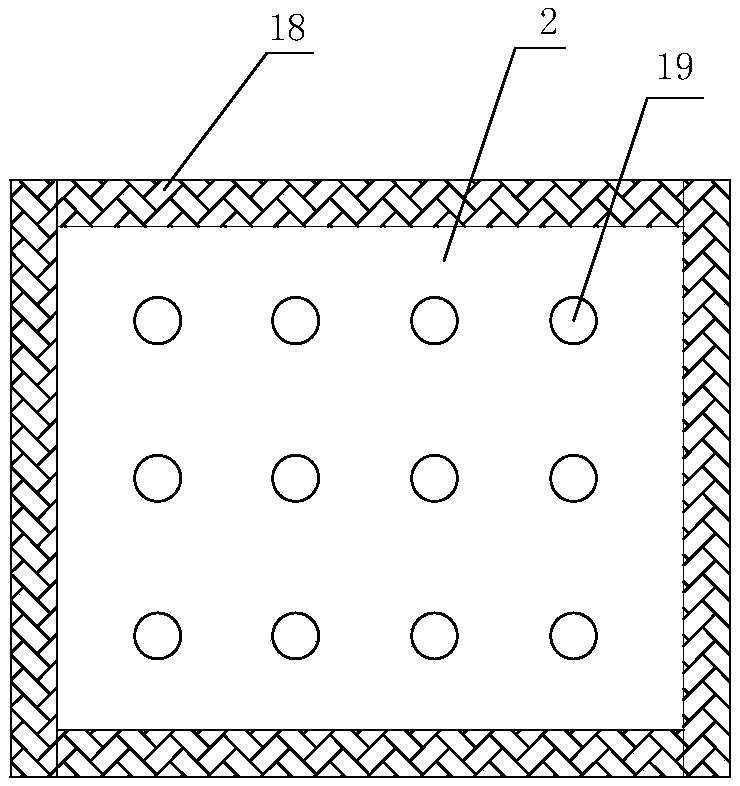

Desulfurization and dedusting system capable of realizing emission of clean flue gas

PendingCN107961656AGood desulfurization effectImprove dust removal rateCombination devicesGas treatmentSpray towerFlue

The invention discloses a desulfurization and dust removal system for clean emission of flue gas, which comprises a flue gas washing system and a discharge system of the desulfurization system. The desulfurization system is composed of an absorption tower, a desulfurizer preparation and a circulation system; The water supply system is composed of the cooling washing tower as a water spray tower, and the flue gas is dedusted and cooled twice in the spray tower; the flue gas discharge system includes an exhaust flue and a chimney, and the cleaned flue gas is finally discharged through the chimney. The invention has good desulfurization and dust removal effects, and can eliminate the problem of "white smoke" caused by flue gas. The invention also solves the problem of secondary pollution in the desulfurization process, and provides help for reducing and eliminating smog.

Owner:北京亿玮坤节能科技有限公司

A control method of an engine starting system

ActiveCN104514662BSolve the difficulty of startingEmission reductionElectrical controlMachines/enginesHydrogen fuelElectric control

Owner:BYD CO LTD

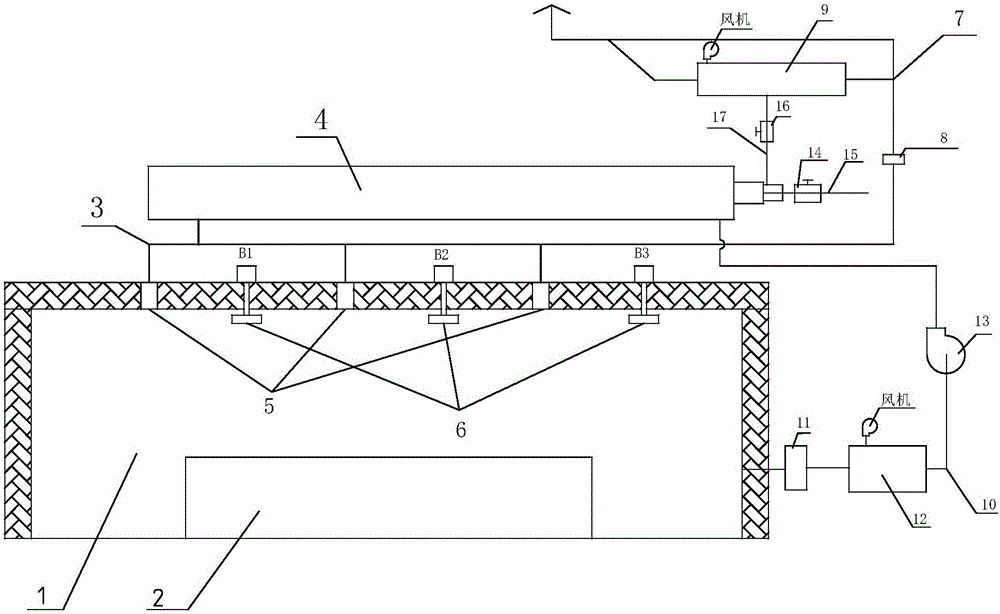

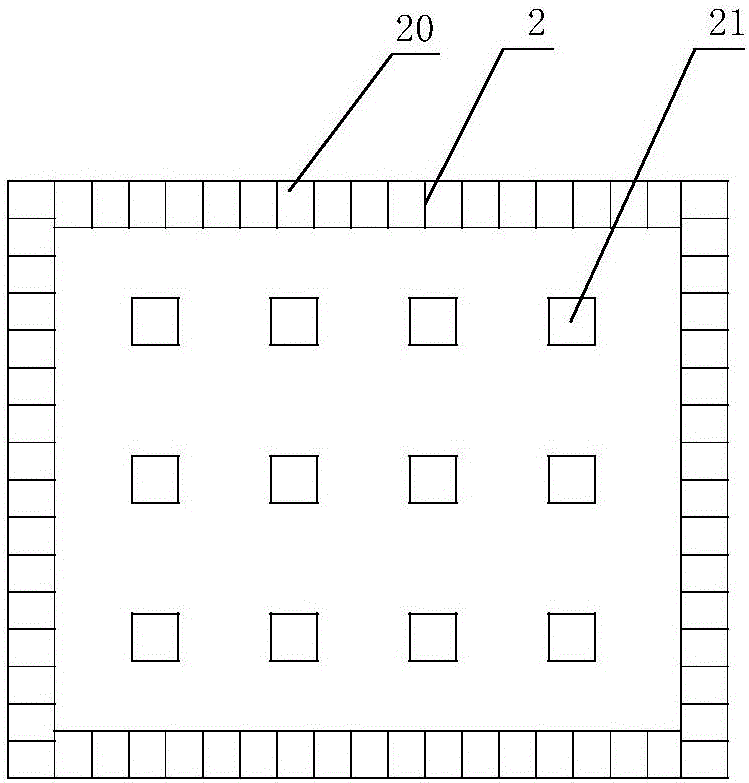

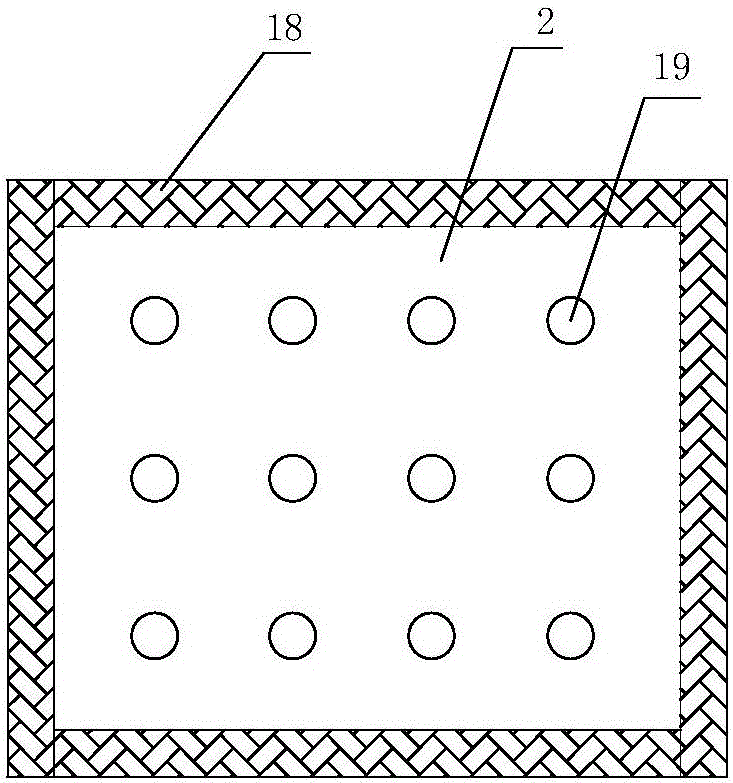

Novel energy-saving environment-friendly trolley furnace

ActiveCN106643137ASatisfy RoastingImplement automated controlFurnace typesTemperature controlCombustion chamber

The invention relates to a novel energy-saving environment-friendly trolley furnace. Aworkflow is as follows: 1) putting a special superfine structural isostatic pressing isotropic graphite green ware into a steel barrel, putting the steel barrel onto a trolley and putting the trolley into a roasting furnace; 2) feeding fuel gas and hot air into a combustor, introducing the fully combusted hot air into the furnace through a pipeline and uniformly stirring the hot air in the furnace by a stirring fan; 3) returning the hot air in the furnace and the volatile components discharged from the product to the combustor through a draught fan, recycling the hot air, fully combusting the volatile components discharged from the product in the combustor and reusing the generated heat; 4) when the hot air pressure in a kiln exceeds the standard, exchanging heat through a waste heat air pipeline and then discharging clean air, and preheating air entering into the combustor by a heat exchanger; and 5) taking out the trolley and completing the electrode manufacturing. According to the invention, the temperature in the furnace is uniform; the maximum temperature difference does not exceed 12 DEG C; the accurate temperature control can be realized; the instant temperaturedifference does not exceed 0.5 DEG C; andthe roasting of the special superfine structural isostatic pressing isotropic graphite can be realized.

Owner:辽宁丹炭科技集团有限公司

Haze reducing and white smoke eliminating tower for flue gas

The invention discloses a haze reducing and white smoke eliminating tower for flue gas. The haze reducing and white smoke eliminating tower comprises tower shell and an internal assembly, wherein a water storage zone, a desulfurization flue gas inlet zone, a washing zone, a defogging zone and a heat exchange zone are sequentially arranged from bottom to top in the inner cavity of the tower shell,and are communicated, a washing device is arranged in the washing zone, a defogging device is arranged in the defogging zone, and a heat exchange pipe bundle is arranged in the heat exchange zone. According to the present invention, raw flue gas is heated, washed and purified by the heat exchange pipe bundle to obtain desulfurized flue gas, and finally the desulfurized flue gas is subjected to haze removing and white smoke eliminating so as to achieve clean emission.

Owner:SHANDONG NORMAL UNIV

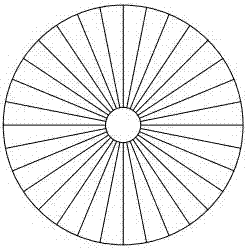

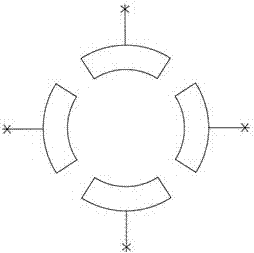

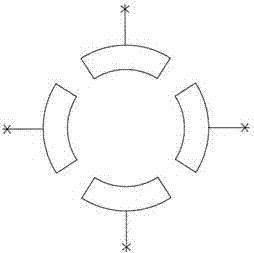

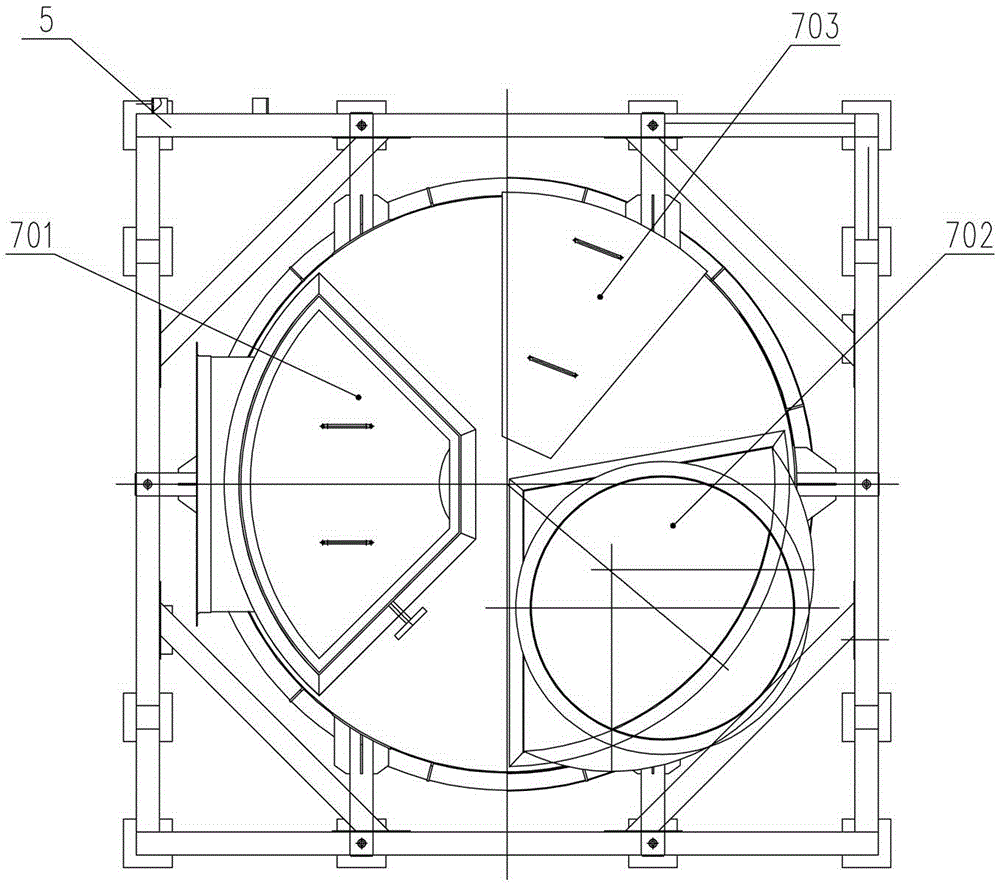

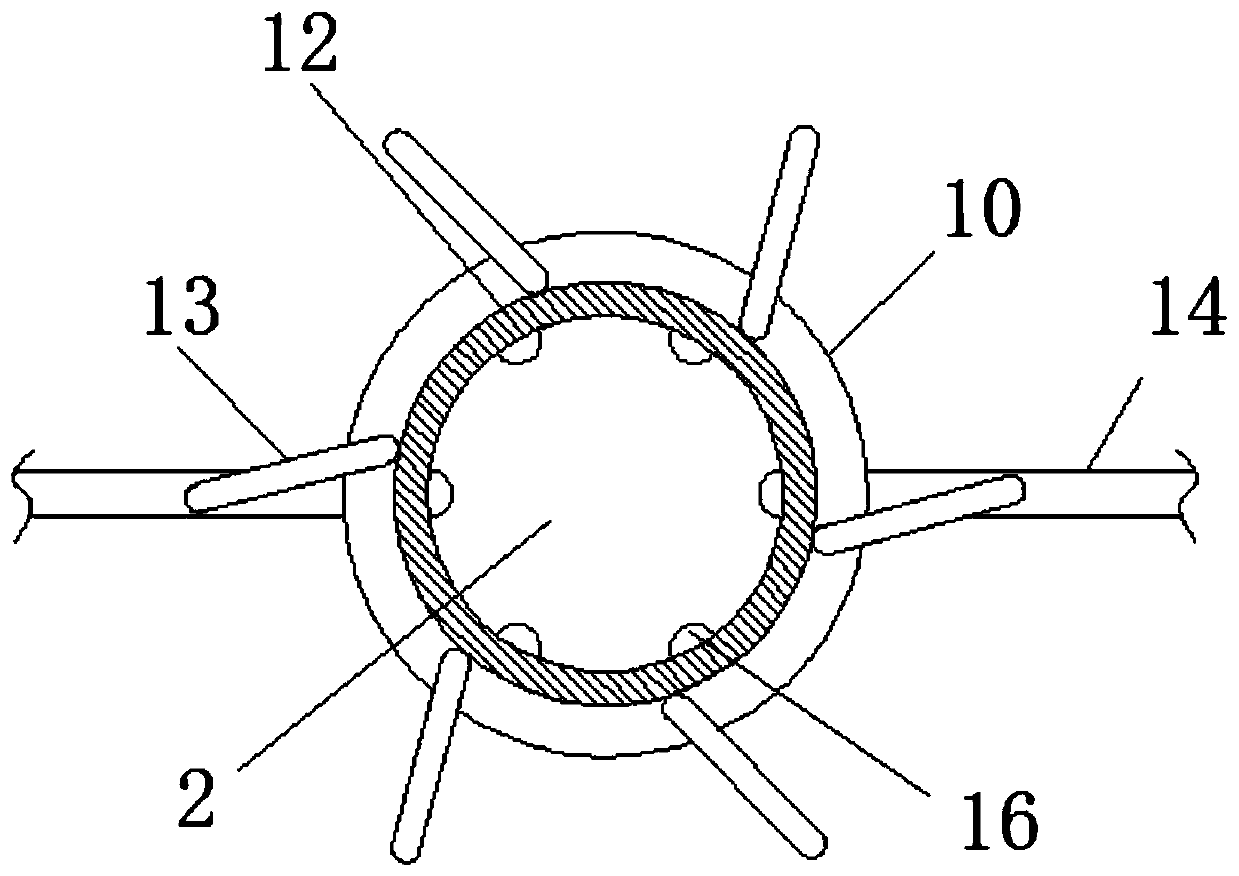

A rotary regenerative air preheater

ActiveCN104061584BHigh thermal efficiencyReduce pollutionCombustion processIndirect carbon-dioxide mitigationAir preheaterSulfide

The invention relates to a heat accumulating type slewing air preheater which comprises an upper air chamber, a lower air chamber and a middle slewing heat accumulating device. The slewing heat accumulating device comprises a slewing bearing, a speed reducer and a slewing body, wherein the slewing bearing is arranged at the top of the lower air chamber, the speed reducer is arranged on one side of the slewing bearing and drives the slewing bearing to rotate, and the slewing body is arranged on the slewing bearing and rotates along with the slewing bearing. A liquor condensate collection and neutralization system is arranged at the bottom of a cold smoke chamber of the lower air chamber and comprises a mixed precipitation chamber and a heavy metal processing chamber, wherein limestone alkaline particles are arranged in the mixed precipitation chamber, the heavy metal processing chamber is connected with a discharging pipe, and processed liquor condensate is discharged out through the discharging pipe. The slewing bearing drives the slewing body and a heat accumulating body to rotate to complete heat exchange between high-temperature smoke and cold air, pollutants such as acid liquid containing nitration and sulfide and produced by condensation of low-temperature smoke can be collected and neutralized through the liquor condensate collection and neutralization system, and therefore, air pollution caused by smoke discharged out of a heating furnace is reduced.

Owner:YUEYANG ZHONGDING THERMAL ELECTROMAGNETIC TECH CO LTD +1

Oil-water mixed combustion device of internal combustion engine

PendingCN108661825APromotes secondary combustionStable combustionInternal combustion piston enginesNon-fuel substance addition to fuelHigh energyEngineering

The invention relates to an oil-water mixed combustion device of an internal combustion engine. The oil-water mixed combustion device is characterized in that a circulating heating pipe which is connected with a radiator of the internal combustion engine in series is arranged in a preheating water tank; the preheating water tank is connected with a steam generator by virtue of a suction pipe, anda metering pump and an electromagnetic valve are installed on the suction pipe; the steam generator is a sealing member and is welded to the front section of an exhaust pipe of the internal combustionengine, a water level sensor and a temperature sensor are installed on the steam generator, an air inlet of the steam generator is accessed to the front end of a Venturi pipe by virtue of a connecting pipe and an air pressure balancing valve, and the back end of the Venturi pipe is connected with an air outlet of the steam generator by virtue of a steam pipe; and a front end opening of the Venturi pipe is installed in an air inlet pipe of the internal combustion engine, and a back end opening of the Venturi pipe is connected with a front end opening of an air inlet manifold of the internal combustion engine. According to the oil-water mixed combustion device, long-term experiments prove that when a certain proportion of water steam is added to air in an air inlet process of the internal combustion engine, the internal combustion engine can be promoted to generate secondary combustion, so that the combustion process of the internal combustion engine is stable, and the oil-water mixed combustion device has the advantages of high energy efficiency and cleanness in discharge.

Owner:胡清萍

White smoke removing apparatus used for non-ferrous metal processing and convenient for flue gas recovery

The invention discloses a white smoke removing apparatus used for non-ferrous metal processing and convenient for flue gas recovery. The white smoke removing apparatus comprises a white smoke removingkettle, a pressure pump, a positioning ring and a high-pressure electrostatic device, wherein a positioning vertical pipe is fixedly mounted at the vertical central position of the white smoke removing kettle; return pipes are connected to a flow diversion pipe and the outer wall of the bottom of the white smoke removing kettle; a rotating ring and a sliding sleeve are sequentially arranged on the outer wall of the positioning vertical pipe from top to bottom; a bearing is fixed between the positioning vertical pipe and the rotating ring; a connecting rod is vertically fixed to the outer wallof the positioning vertical pipe; the positioning ring is fixedly installed on the inner wall of the white smoke removing kettle; a wire support is fixed to the top of a vertical pipe support; an ashdischarging valve is installed at an outlet in the bottom of the white smoke removing kettle; and a filter screen is arranged in a demister. The white smoke removing apparatus used for non-ferrous metal processing and convenient for flue gas recovery can perform quick white smoke removal operation on soot, fog drops and the like in flue gas, is simple and efficient in structure, reduced in working energy consumption, and avoids effective substance emission caused by low flue gas reaction during white smoke removal of metal.

Owner:山东保蓝环保有限公司

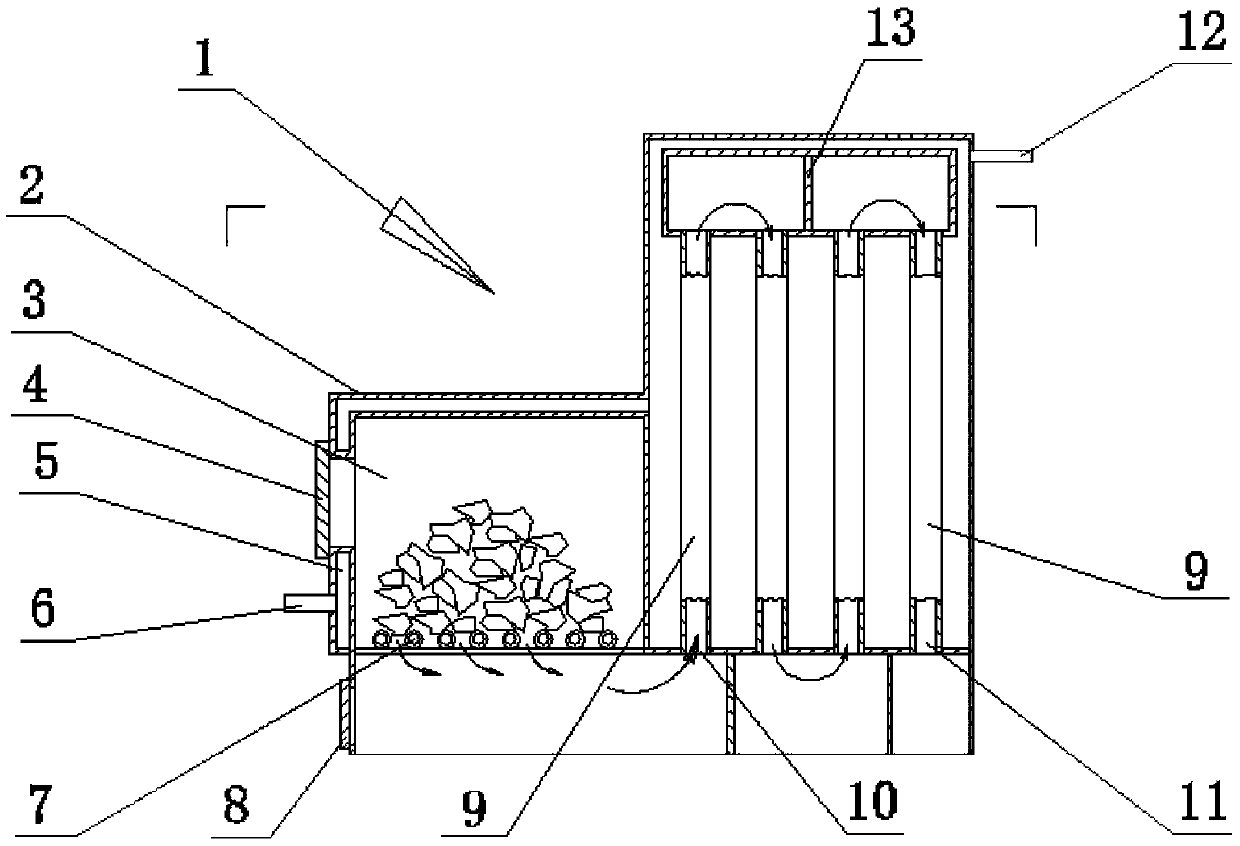

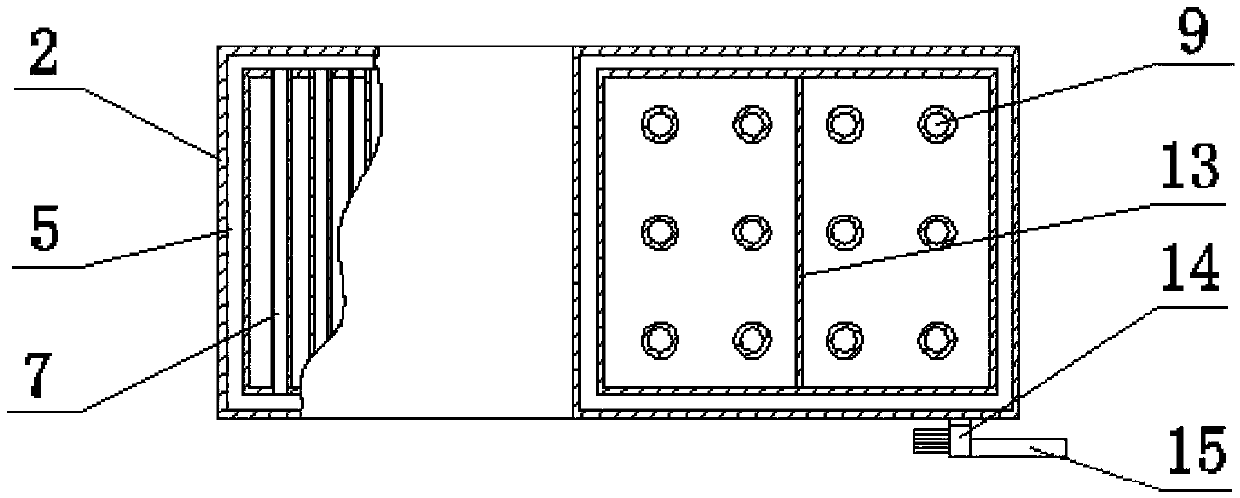

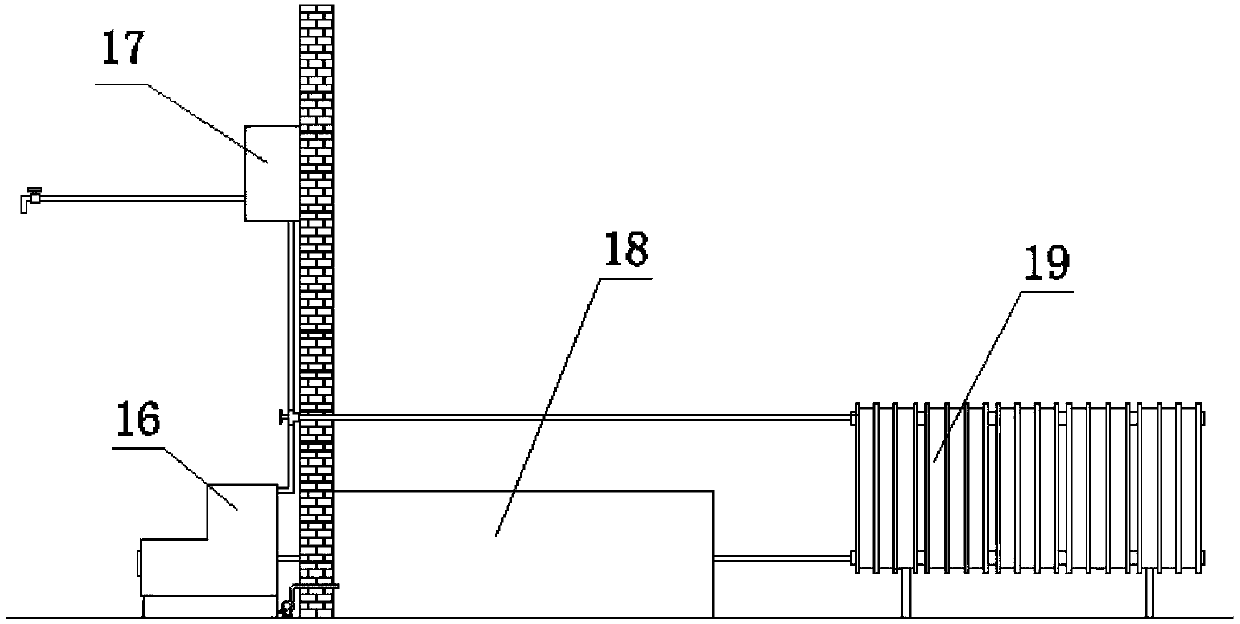

Negative pressure reverse burning energy-saving furnace

The invention relates to an energy-saving stove, namely a negative-pressure reversal combustion energy-saving stove suitable for heating of a room. The negative-pressure reversal combustion energy-saving stove comprises a shell (2), a water jacket (5), a hearth (3), a fire grate (7) and a smoke tube (9); and a hot water tube (12) and a return water tube (6) of the water jacket (5) are connected with circulating tubes at two ends of a heater (19). The negative-pressure reversal combustion energy-saving stove is characterized in that the hearth is provided with a stove door capable of being closed in a sealed manner, the smoke tube is repeatedly bent and coiled in closed space communicating with the water jacket, and the tail end of the smoke tube is connected with an inlet of an induced draft fan. The negative-pressure reversal combustion energy-saving stove has the beneficial effects that heat can be supplied for the heater and a heated brick bed simultaneously under the driving effect of the induced draft fan, banked fire is maintained for a long time and open fire can be started at any time, manual frequent operation is not required, heat efficiency is improved remarkably, emission is clean and little, and the stove is excellent in environmental protective performance. In addition, the negative-pressure reversal combustion energy-saving stove has the advantages of simple structure, low cost, stable work, safety, reliability and the like, and is expected to become a necessary utensil for families and small units.

Owner:王海龙

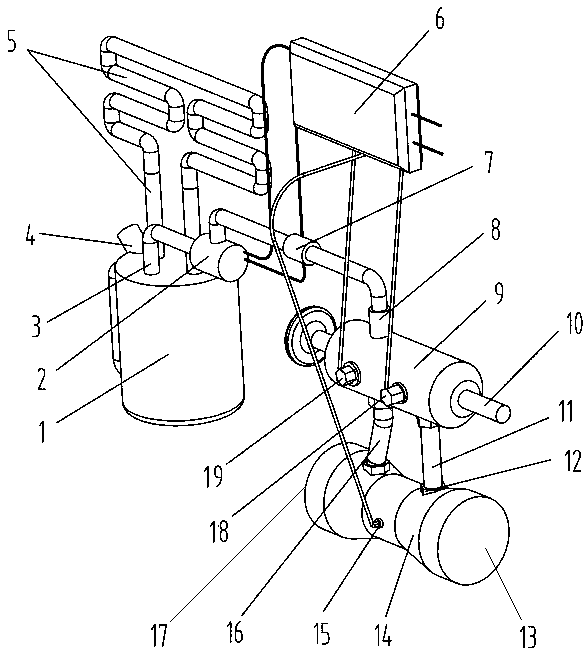

A single gun oil gas recovery separator

InactiveCN104324579BLow costSimple structureDispersed particle filtrationFiltrationPetroleum engineering

The present invention relates to a single gun oil-gas recovery separator, which is characterized by at least comprising a filter cylinder, a gas inlet joint and a connection joint, wherein an accumulation filtration unit is fixed inside the filter cylinder, the accumulation filtration unit is packaged in the filter cylinder through the upper cover and the lower cover by both ends of the filter cylinder, the upper cover is connected with the gas inlet joint, the lower cover is connected with the connection joint, the gas inlet joint and the connection joint are arranged on both ends of the filter cylinder, the gas inlet joint, the filter cylinder, the accumulation filtration unit and the connection joint form a first filtration body, and the separated gas-liquid enters from the gas inlet of the gas inlet joint and is discharged from the connection joint. The single gun oil-gas recovery separator has characteristics of low cost, simple structure and good process, wherein the existing recycling equipment is completely utilized so as to reduce the engineering cost.

Owner:西安集良石油技术开发有限公司

Flue gas desulfurization and haze reducing tower

The invention discloses a flue gas desulfurization and haze reducing tower, which comprises a tower shell and an internal assembly, wherein a slurry zone, a gas inlet zone, a desulfurization zone anda washing zone are sequentially arranged from bottom to top in the inner cavity of the tower shell, the slurry zone and the gas inlet zone are communicated, a separation plate is arranged between thegas inlet zone and the washing zone, and separates the gas inlet zone and the washing zone, the gas inlet zone and the washing zone are communicated through the inner cavity of the desulfurization cylinder on the separation plate, and the inner cavity of the desulfurization cylinder is a desulfurization zone. According to the present invention, flue gas can be subjected to desulfurization and dustremoving purification in the flue gas desulfurization and haze reducing tower so as to achieve the purposes of desulfurization and haze reducing and complete clean emission.

Owner:SHANDONG NORMAL UNIV

Intake propulsion unit of vector car

ActiveCN112628036BLarge feedWell mixedInternal combustion piston enginesAir intakes for fuelAir filterDrive shaft

Owner:诸暨市恒兴混凝土有限公司

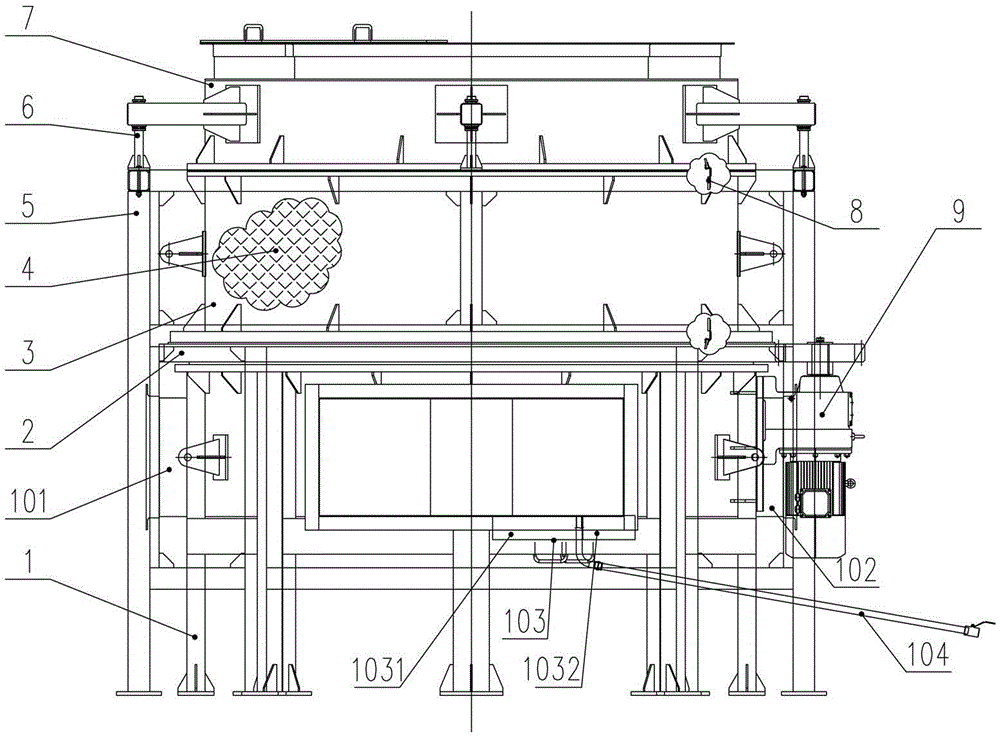

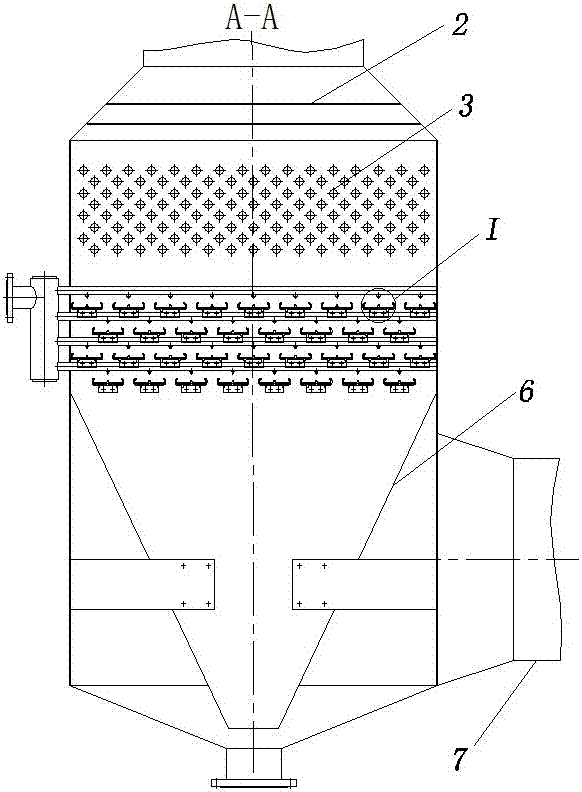

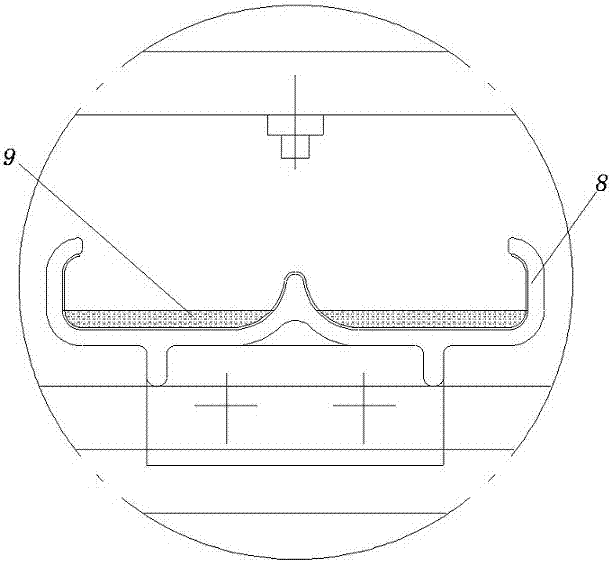

Efficient condensing horizontal film wet dust removal system

ActiveCN105664619BPrevent scalingEffective absorptionAuxillary pretreatmentUsing liquid separation agentPower stationTower

The invention discloses an efficient condensation transverse film wet type dust collection system which comprises a shell with an upper part connected with an outlet flue of a desulfurizing tower, a smoke flow averaging device mounted at the upper part in the shell, a smoke condenser which is positioned below the smoke flow averaging device and is mounted in the shell, a plurality of layers of transverse film plate fog and dust removers which are positioned below the smoke condenser and are mounted in the shell, a plurality of flushing devices mounted on each layer of transverse film plate fog and dust remover, a liquid collection guide pipe mounted in the center of each transverse film plate fog and dust remover, and a smoke exhaust pipeline mounted on the lower side face of the shell. The efficient condensation transverse film wet type dust collection system disclosed by the invention is high in dust collection efficiency, low in investment and operation cost and saved in energy, and can purify smoke and discharge clean smoke. The efficient condensation transverse film wet type dust collection system can be widely applied to purification of smoke of coal-fired boilers in power stations.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

Circulating washing and purifying treatment device for kiln waste gas

The invention discloses a circulating washing and purifying treatment device for kiln waste gas. The device comprises a waste gas channel I, a waste gas channel II, a waste gas channel III and a washing and purifying chamber, the waste gas channel II is arranged on one side of the waste gas channel I, the waste gas channel III is arranged on one side of the waste gas channel II, and the washing and purifying chamber is arranged on one side of the waste gas channel III; the waste gas of the kiln is fully purified through layer-by-layer circulating spraying, filtering and purifying, and is discharged in a water vapor state, so that the discharge standard is completely met; and the purified water vapor is heated by utilizing a large amount of heat carried by the kiln waste gas, so that the water vapor is discharged in a cleaner state.

Owner:上官修强

Air intake propulsion device of vector automobile

ActiveCN112628036ALarge feedWell mixedInternal combustion piston enginesAir intakes for fuelAir filterDrive shaft

The invention discloses an air intake propulsion device of a vector automobile, and particularly relates to the field of automobile manufacturing. The air intake propulsion device comprises an outer air intake guide cylinder and a flow guide through pipe, sliding guide rails are fixedly mounted on the inner side of the outer air intake guide cylinder, flow guide plates are slidably mounted on the inner sides of the sliding guide rails, the other sides of the flow guide plates are fixedly connected with a flow guide shaft cylinder in the outer air intake guide cylinder, bearing frames are fixedly installed on the inner side of the flow guide through pipe, a transmission shaft rod penetrates through the inner sides of the bearing frames, and the upper end and the lower end of the transmission shaft rod are fixedly connected with an air intake driving fan blade and an air blower turbofan correspondingly. According to the scheme, the air intake propulsion device of the vector automobile is additionally arranged in an air intake channel between an air filter and a throttle valve so as to increase the air feeding amount, various vortexes are formed after air pumped in through the air blower turbofan and air entering through siphon air intake holes are fused, air and fuel oil are stirred more sufficiently, combustion is more complete, carbon accumulation is avoided, and therefore the combustion efficiency is further improved.

Owner:诸暨市恒兴混凝土有限公司

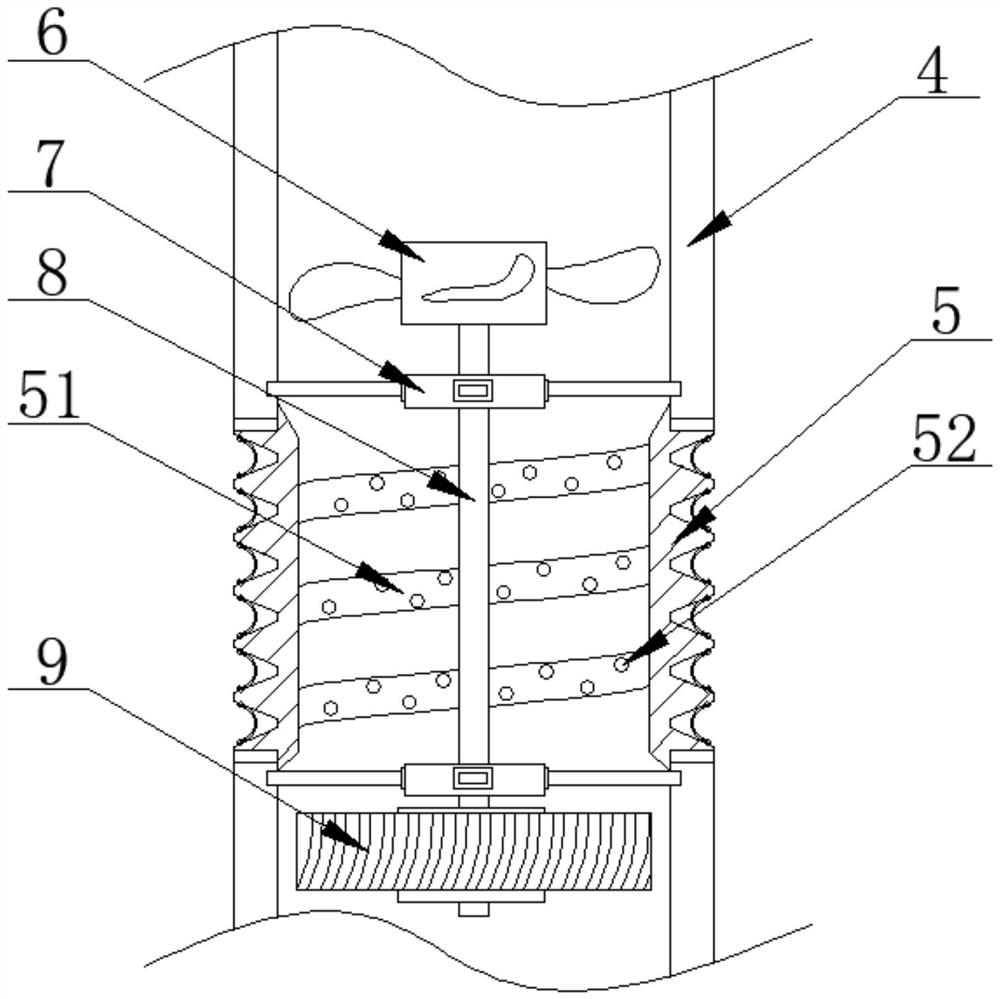

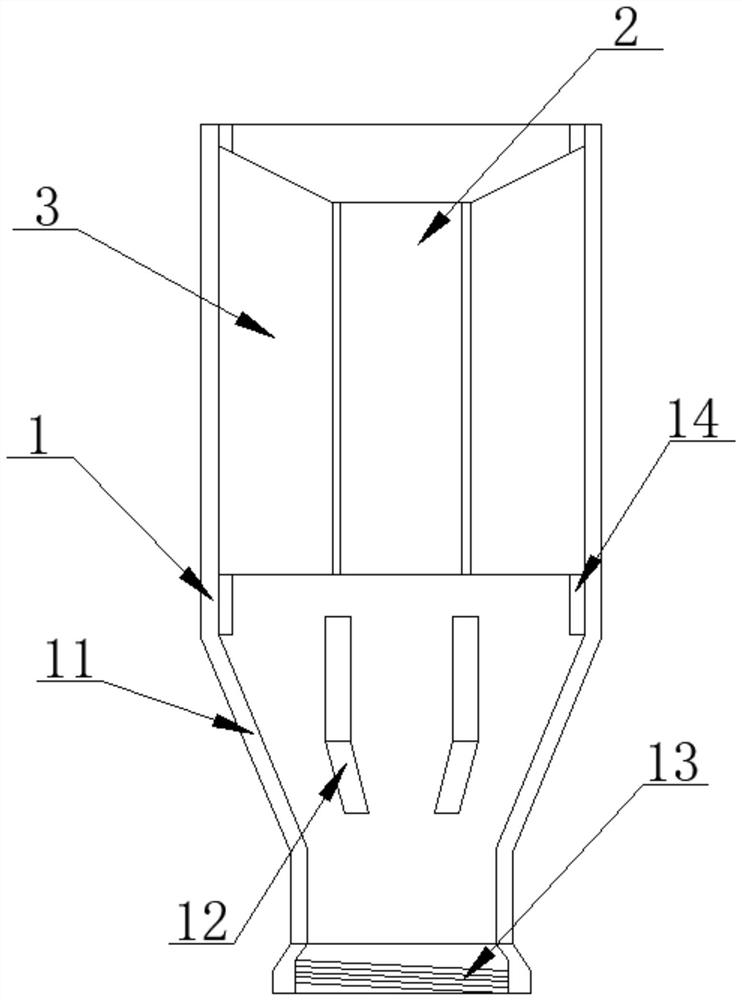

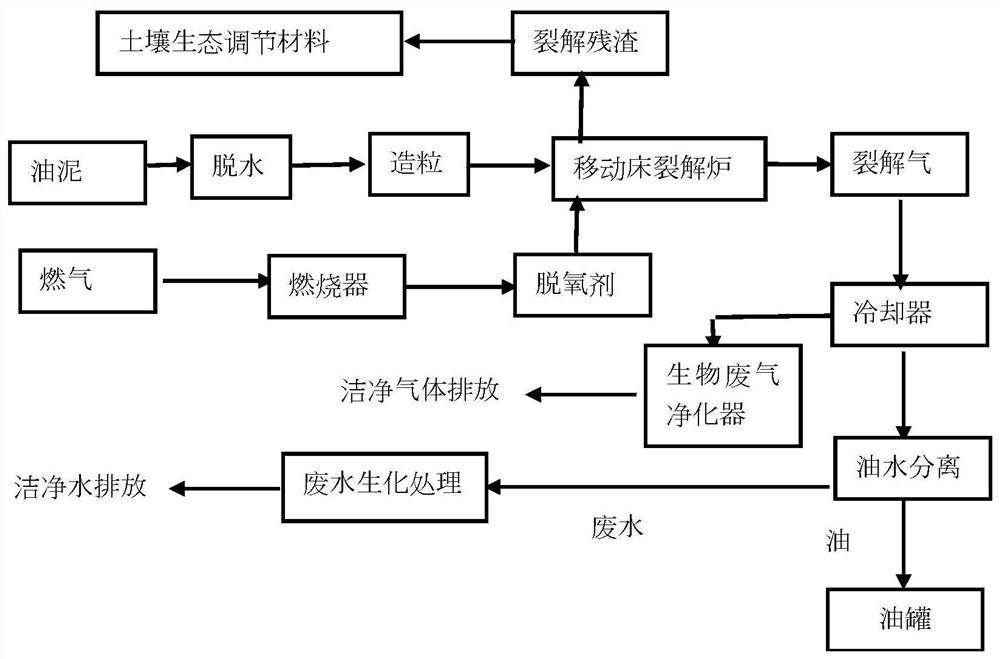

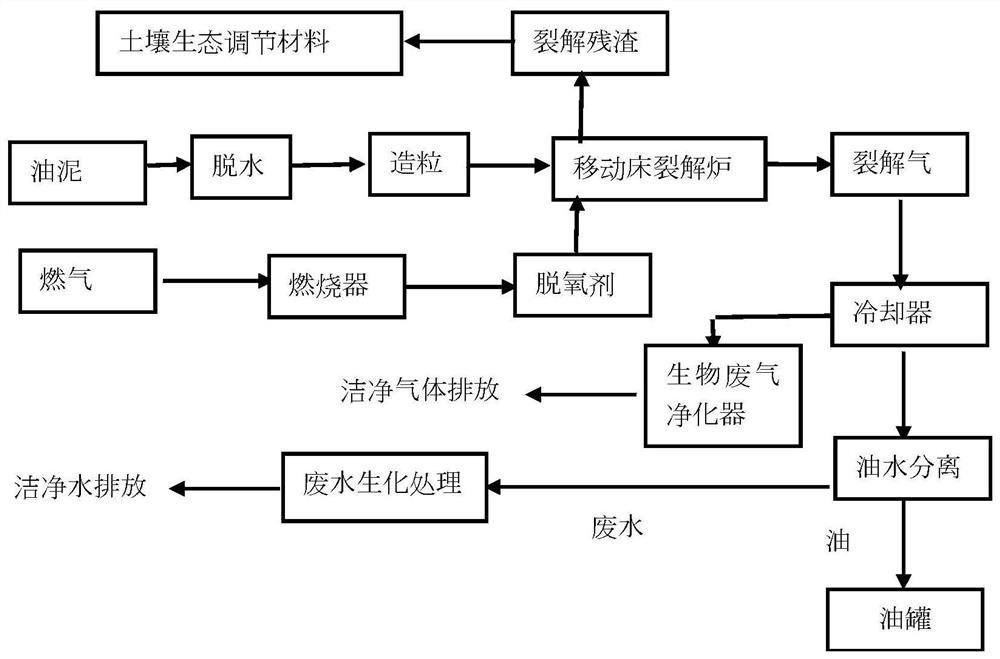

Oil-containing resourceful treatment method

PendingCN113955908AHigh recovery rateReduce the content of harmful substancesSludge treatment by de-watering/drying/thickeningWater treatment parameter controlWastewaterExhaust fumes

The invention relates to an oil-containing resourceful treatment method. The method comprises the following steps: dehydrating and granulating are performed on oil sludge to obtain oil sludge particles; the oil sludge is conveyed into a rotary moving bed; fuel gas is combusted to generate hot air flow, deoxidized with a deoxidizing agent, and fed into the rotary moving bed; oil sludge particles and e hot air flow are in contact in the rotary moving bed, and oil in the oil sludge volatilizes at a certain temperature and is carried out of the rotary moving bed by the air flow; mixing residues obtained after the oil sludge is deoiled with a failure material discharged from the biological waste purifier and residual sludge in the sewage biochemical treatment device, and processing the mixture into a soil ecological conditioning agent; and the hot airflow carrying oil gas is cooled by a cooler and then separated into gas and liquid phases, the liquid is separated into oil and wastewater by an oil-water separator, the oil enters an oil tank for storage, and the wastewater enters a sewage biochemical treatment device for treatment and then is discharged. The method provided by the invention can be used for treating the oil sludge on a large scale to obtain the soil ecological regulation material and oil, so that waste water and waste gas are realized, and resourceful treatment of the oil sludge is realized.

Owner:肖进彬

A new energy-saving and environment-friendly trolley furnace

ActiveCN106643137BEmission cleanRealize the purpose of energy saving and environmental protectionFurnace typesTemperature controlCombustion chamber

The invention relates to a novel energy-saving environment-friendly trolley furnace. Aworkflow is as follows: 1) putting a special superfine structural isostatic pressing isotropic graphite green ware into a steel barrel, putting the steel barrel onto a trolley and putting the trolley into a roasting furnace; 2) feeding fuel gas and hot air into a combustor, introducing the fully combusted hot air into the furnace through a pipeline and uniformly stirring the hot air in the furnace by a stirring fan; 3) returning the hot air in the furnace and the volatile components discharged from the product to the combustor through a draught fan, recycling the hot air, fully combusting the volatile components discharged from the product in the combustor and reusing the generated heat; 4) when the hot air pressure in a kiln exceeds the standard, exchanging heat through a waste heat air pipeline and then discharging clean air, and preheating air entering into the combustor by a heat exchanger; and 5) taking out the trolley and completing the electrode manufacturing. According to the invention, the temperature in the furnace is uniform; the maximum temperature difference does not exceed 12 DEG C; the accurate temperature control can be realized; the instant temperaturedifference does not exceed 0.5 DEG C; andthe roasting of the special superfine structural isostatic pressing isotropic graphite can be realized.

Owner:辽宁丹炭科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com