Novel energy-saving environment-friendly trolley furnace

An energy-saving, environmentally friendly, trolley furnace technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of large temperature difference, high scrap rate, high cost, achieve uniform temperature, reduce energy consumption, and accurately control temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

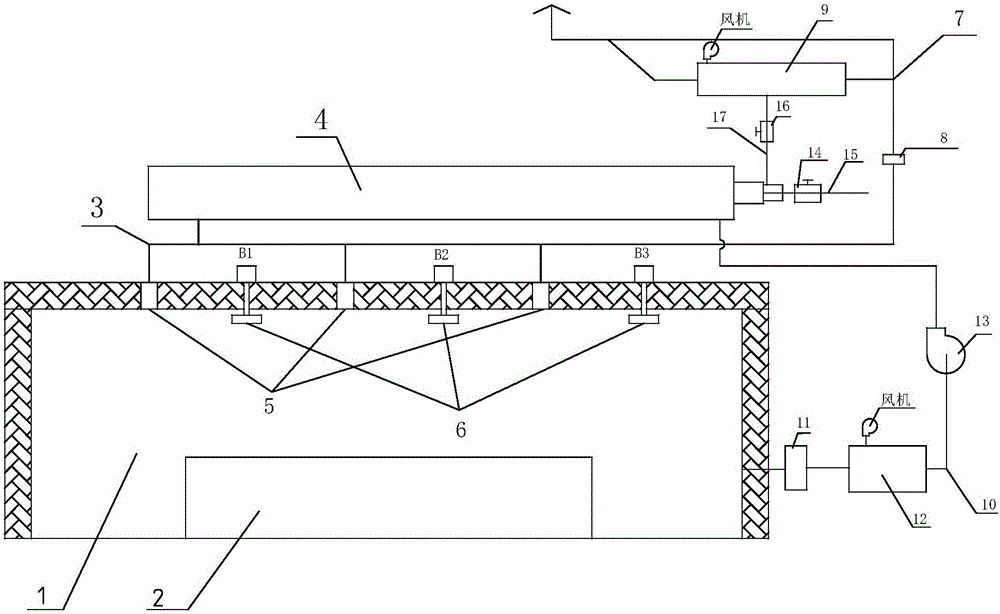

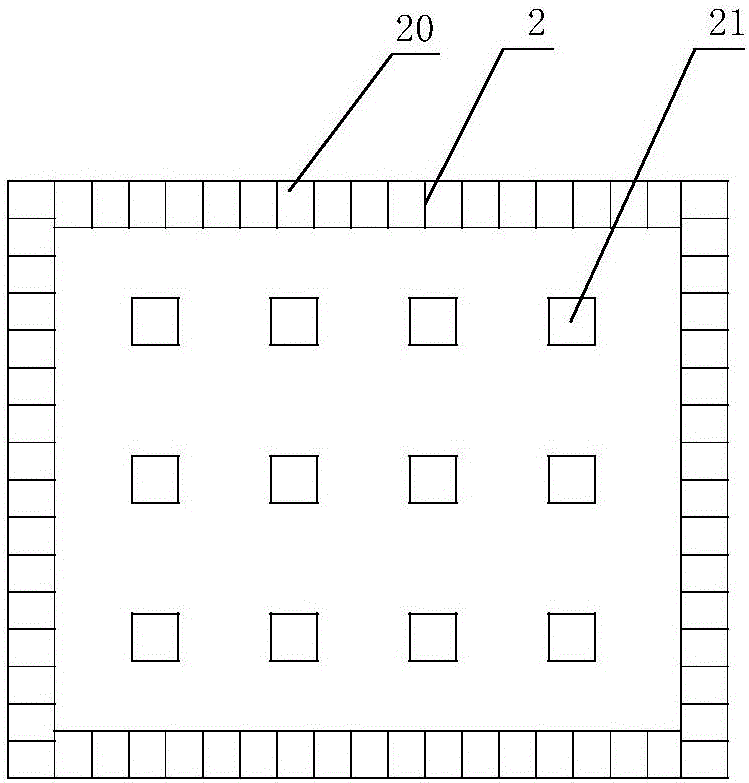

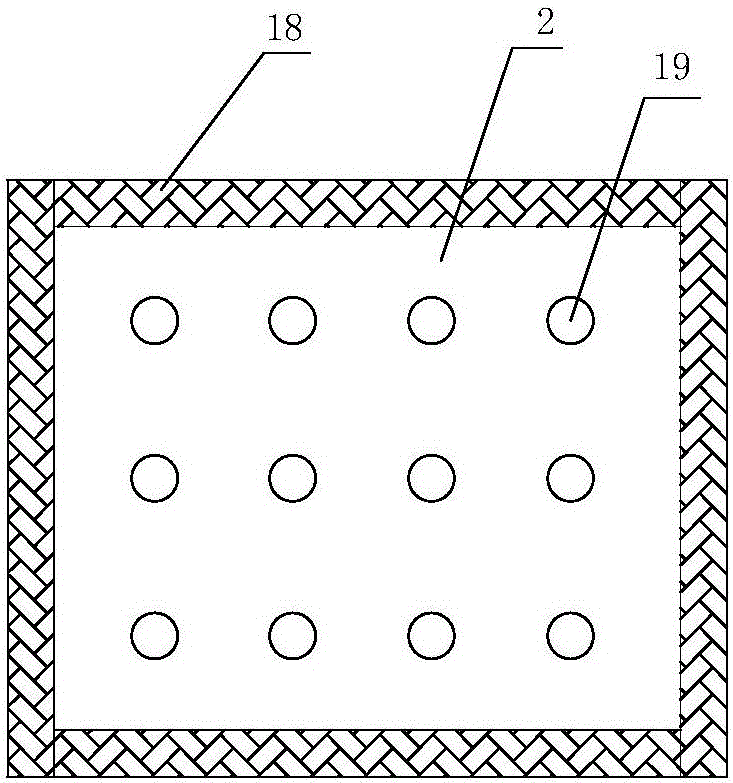

[0028] The following is attached with the manual Figure 1-7 The present invention is further described in detail.

[0029] A new energy-saving and environment-friendly trolley furnace, characterized in that:

[0030] work process:

[0031] 1) Put the special ultra-fine structure isotropic graphite green body into the steel drum, put the steel drum on the trolley, and put the trolley in the roasting furnace;

[0032] 2) Send the gas and hot air into the combustion chamber, and the fully combusted hot gas is connected to the furnace through the pipeline, and the hot gas in the furnace is stirred evenly by the stirring fan to make the temperature in the furnace uniform, and ensure that the difference between the maximum temperature and the minimum temperature in the furnace does not exceed 12 ℃;

[0033] 3) The hot gas in the furnace and the volatile matter discharged from the product are sent back to the combustion chamber through the induced draft fan through the pipeline, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com