Patents

Literature

246results about How to "Realize the purpose of energy saving and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic backlight control method

InactiveCN101777310AOvercoming the problem of light leakage in dark grayscaleImprove dynamic contrastStatic indicating devicesLiquid-crystal displayDynamic contrast

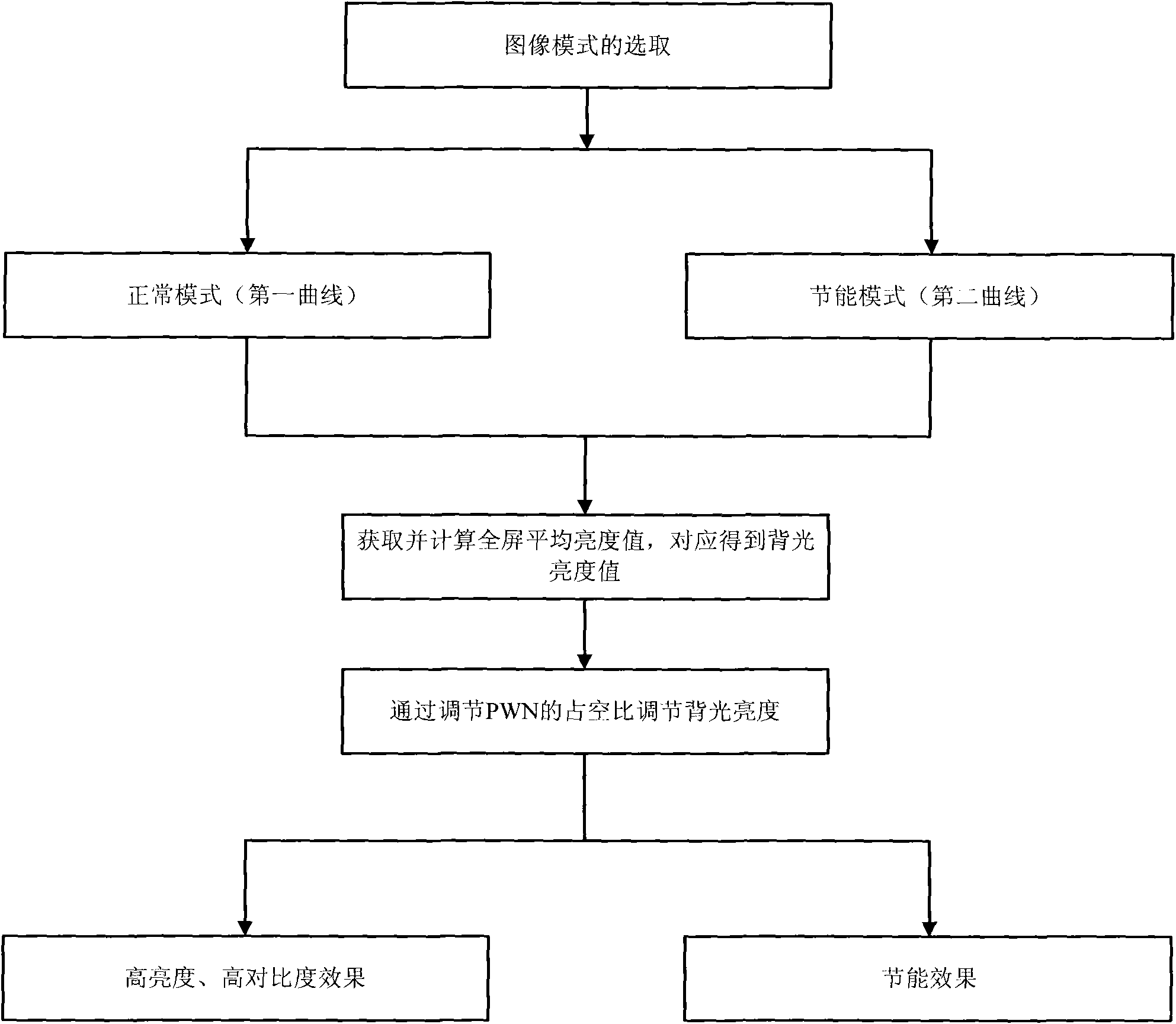

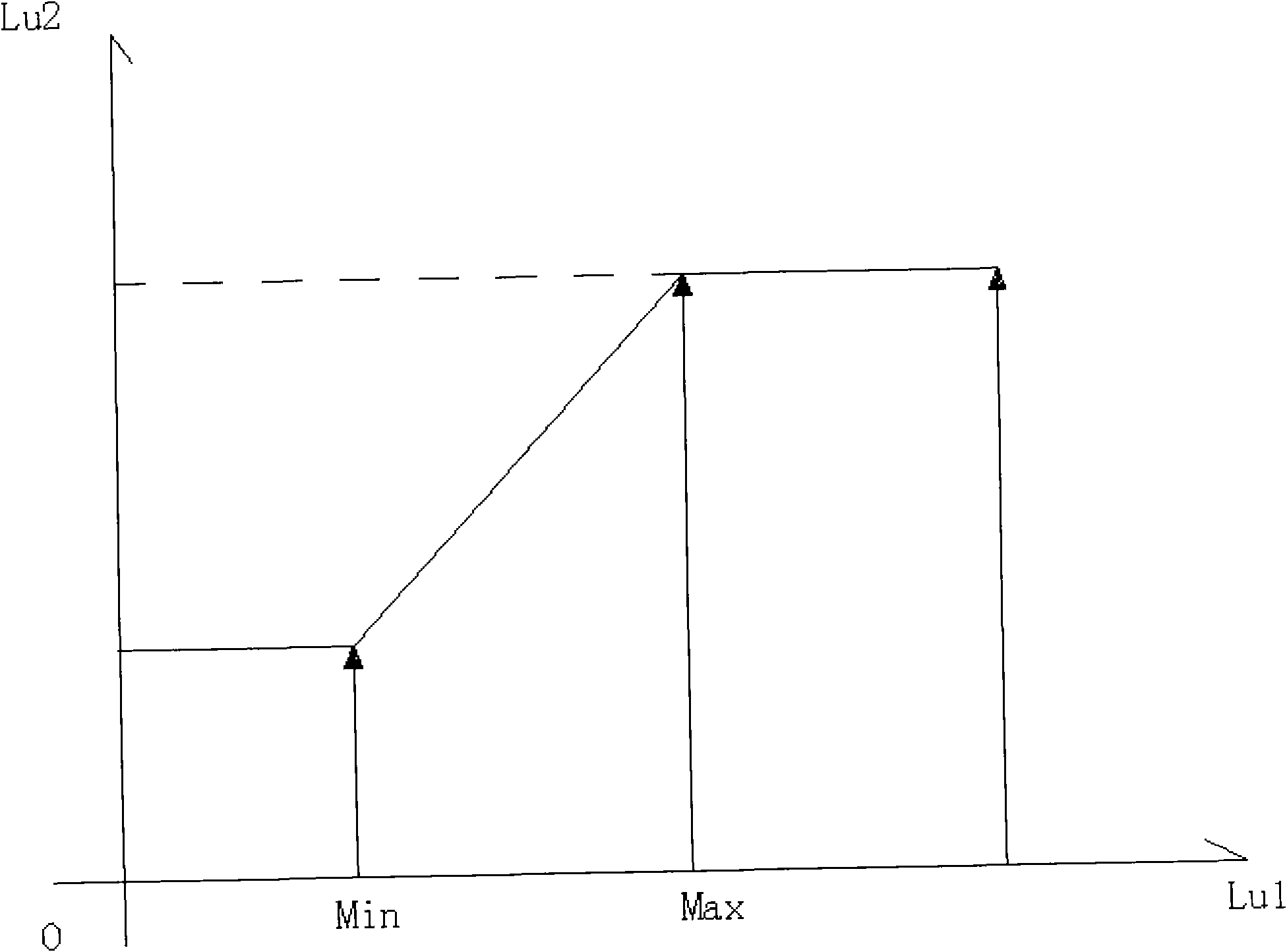

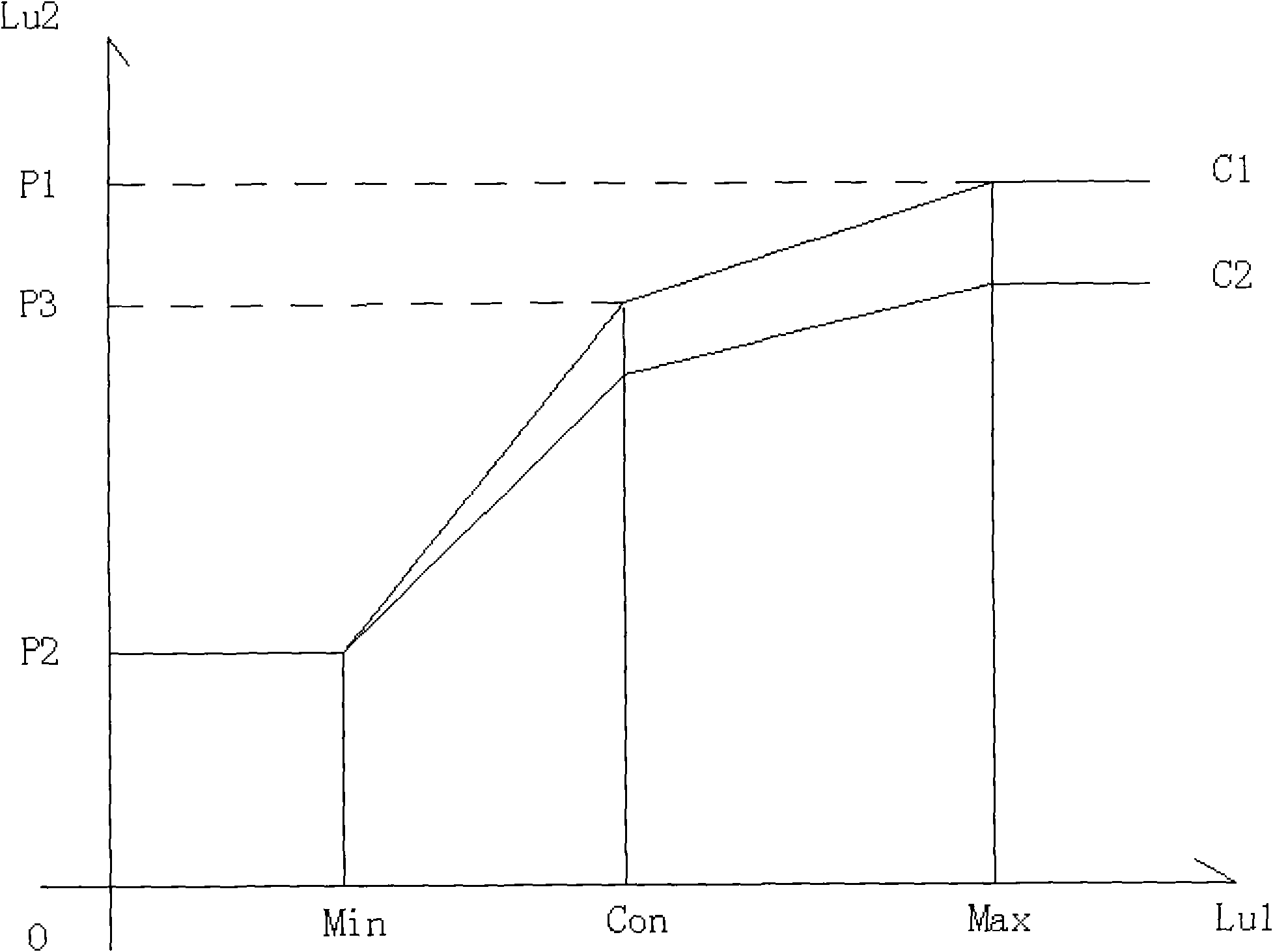

The invention relates to a light-emitting control method for adopting and controlling liquid crystals to emit light from independent light sources for displaying characters, in particular to a dynamic backlight control method for an LED display panel. The control method comprises the following steps: setting at least one control point between two preset fixed threshold values of the average brightness of the full screen, and forming a regulation curve corresponding to backlight brightness between the control point and each of the two fixed threshold values to be used as a reference for backlight regulation; computing the weighted average of the previously computed average brightness value and the subsequently computed average brightness value to acquire the average brightness value of the full screen of the current frame image; and correspondingly regulating the backlight brightness according to the backlight brightness value corresponding to the average brightness value on the regulation curve used as the reference for backlight regulation. Thus, the invention provides a method for dynamically regulating backlight brightness, which overcomes the defect of light leakage of the inherent dark gray scale in liquid crystal display and structure coordination, increases the dynamic contrast, improves the image quality, and realizes the purposes of energy saving and environmental protection.

Owner:HISENSE VISUAL TECH CO LTD

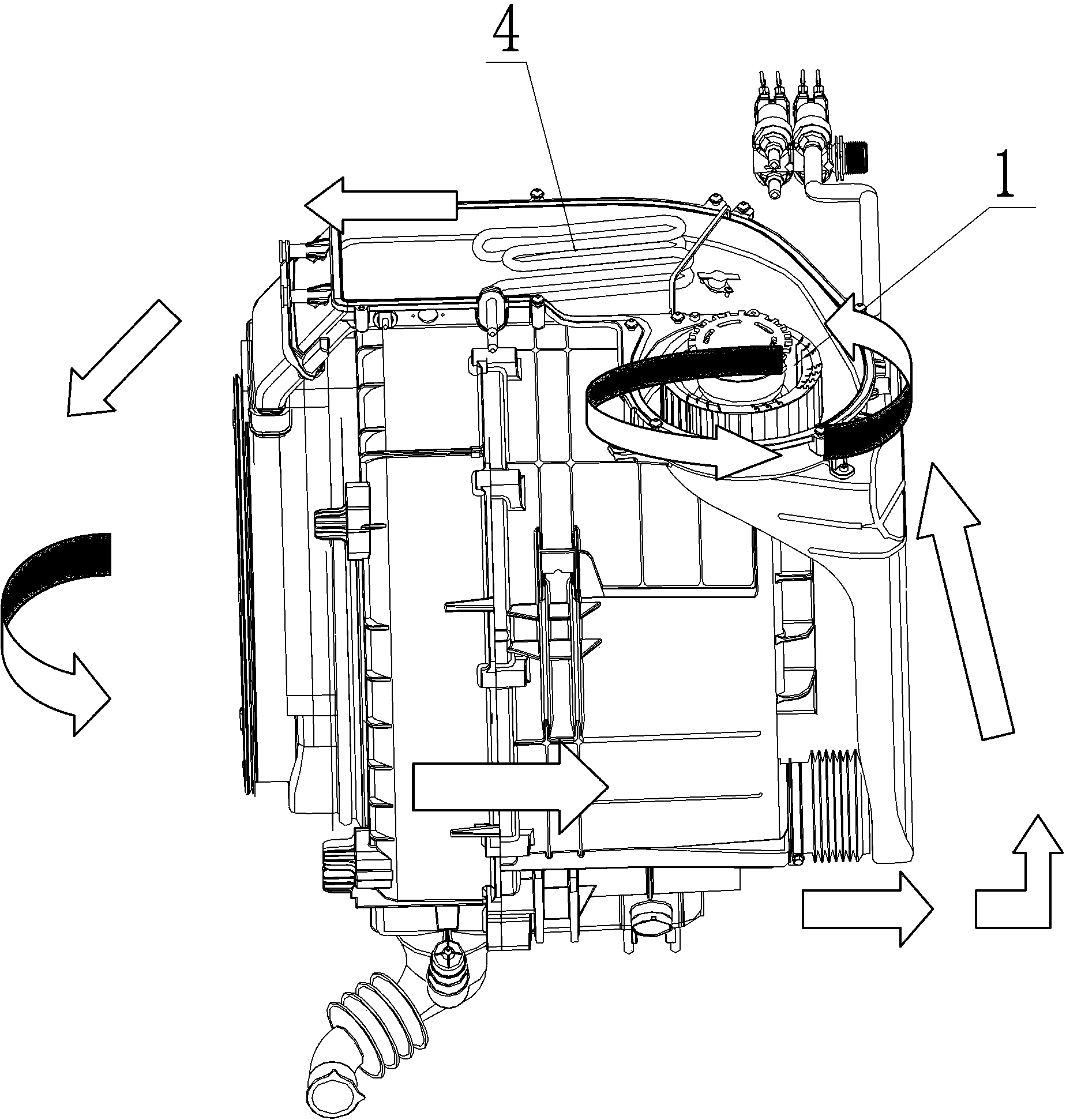

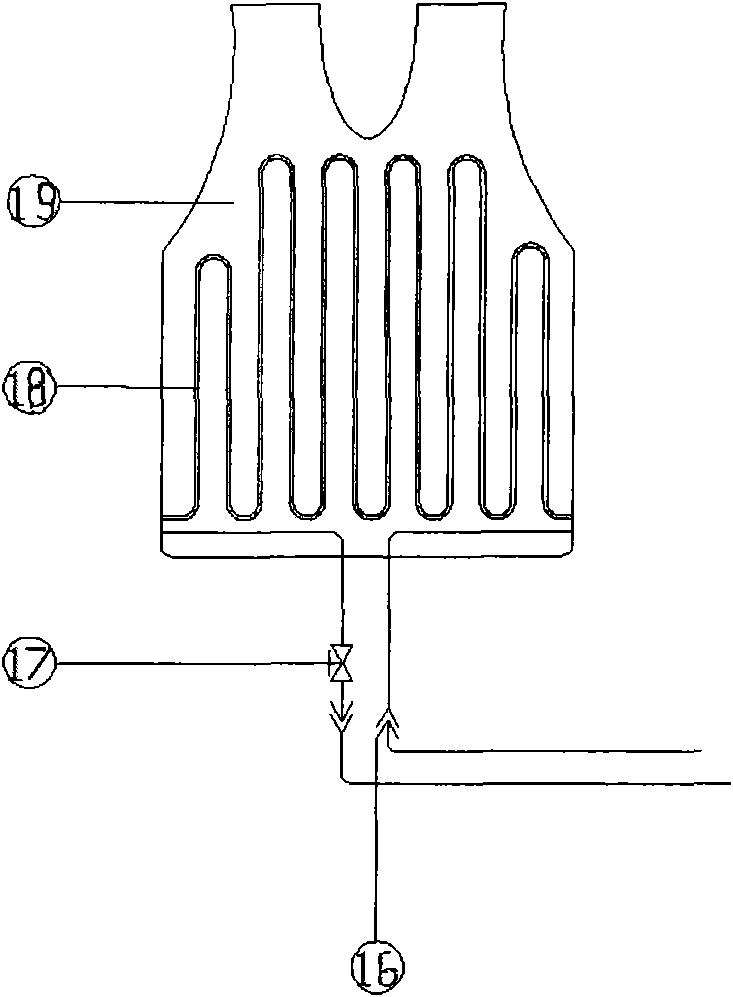

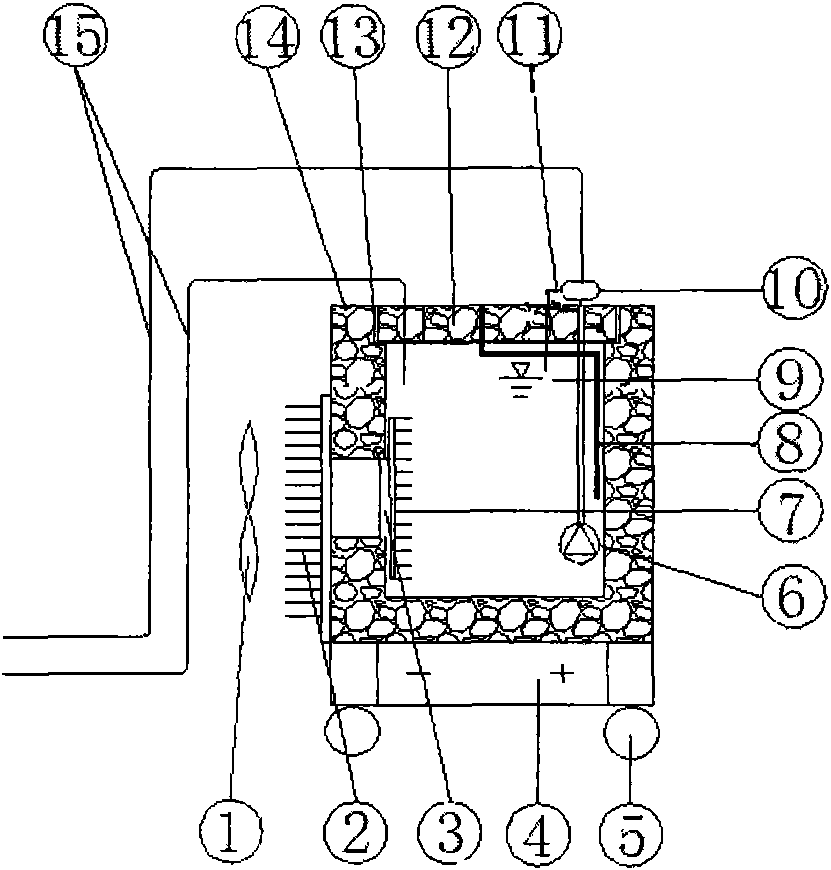

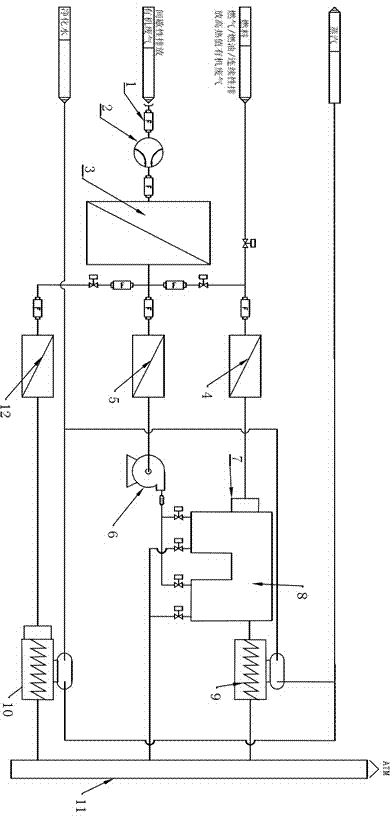

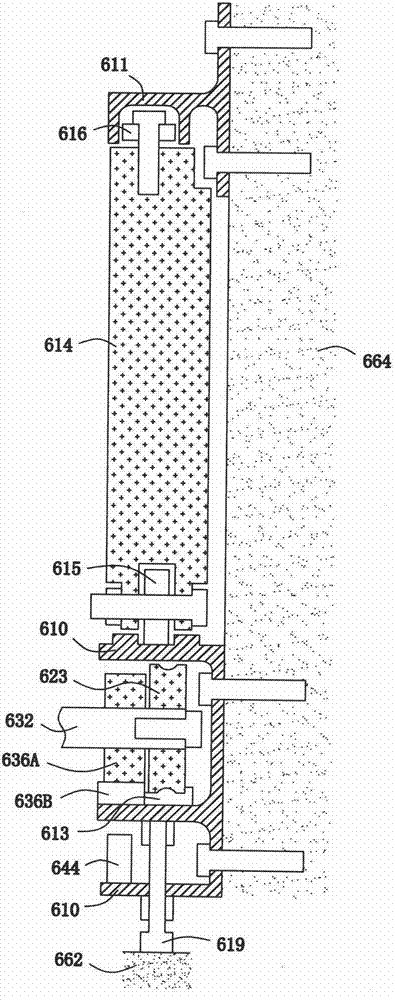

Composite rainwater power generation device based on mini water bucket and PVDF film piezoelectric technology

ActiveCN103343725AImprove flexibility and universalityEasy to makePiezoelectric/electrostriction/magnetostriction machinesHydro energy generationAutomatic controlMagnet

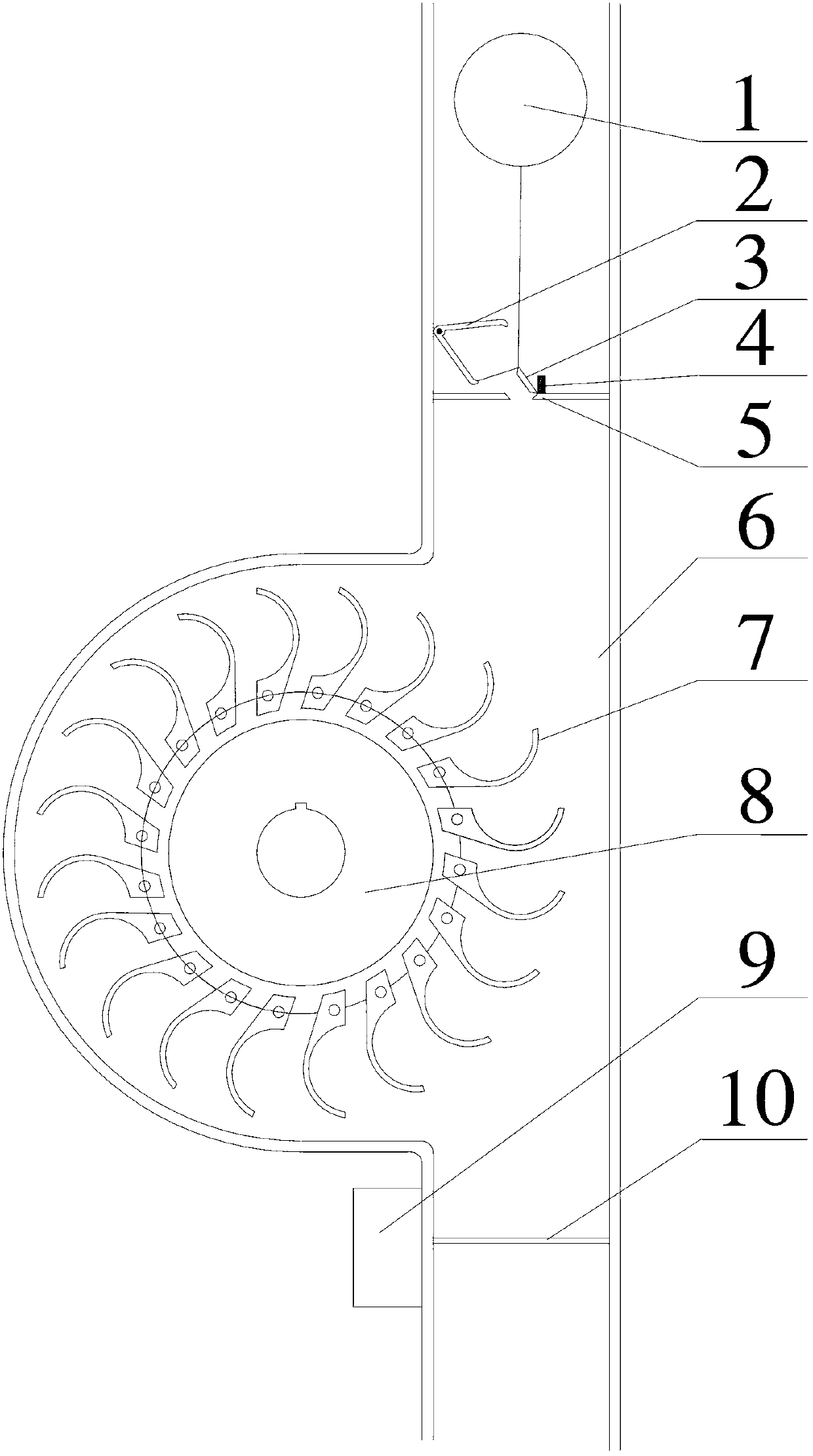

The invention provides a composite rainwater power generation device based on a mini water bucket and a PVDF film piezoelectric technology, and belongs to the field of hydroelectric generation. The device solves the problems that an existing rainwater power generation device is high in cost and complex in installation and debugging. The device comprises a water level automatic control unit arranged on a water inlet of a rain drainage pipeline, a mini water buckle power generation unit arranged under the water level automatic control unit, and a PVDF piezoelectric module power generation unit arranged on a water outlet of the rain drainage pipeline. The water level automatic control unit comprises a floating ball, a V-type connecting rod, a partition board with a through hole, a valve and a magnet, wherein the V-type connecting rod is fixed to the inner side wall of the rain drainage pipeline, the lower portion of the V-type connecting rod is provided with the partition board with the through hole, and the valve is matched with the through hole in the partition board to control flowing and stopping of rainwater. The mini water bucket power generation unit comprises a mini water bucket hub, m mini water bucket vanes, a driving wheel, a driven wheel, a belt and a water bucket power generation circuit. The PVDF piezoelectric module power generation unit comprises a PVDF piezoelectric film and a PVDF power generation circuit.

Owner:HARBIN INST OF TECH

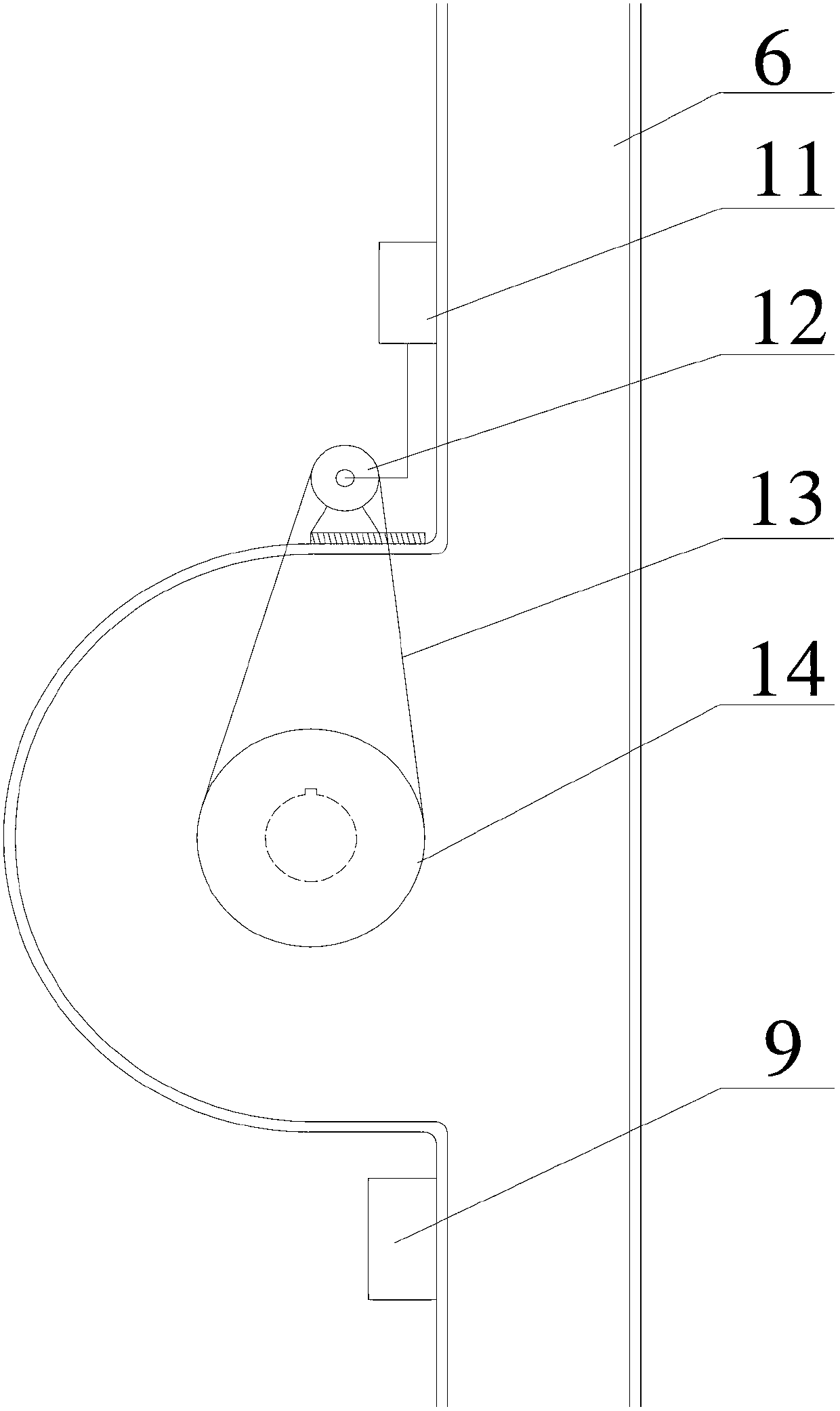

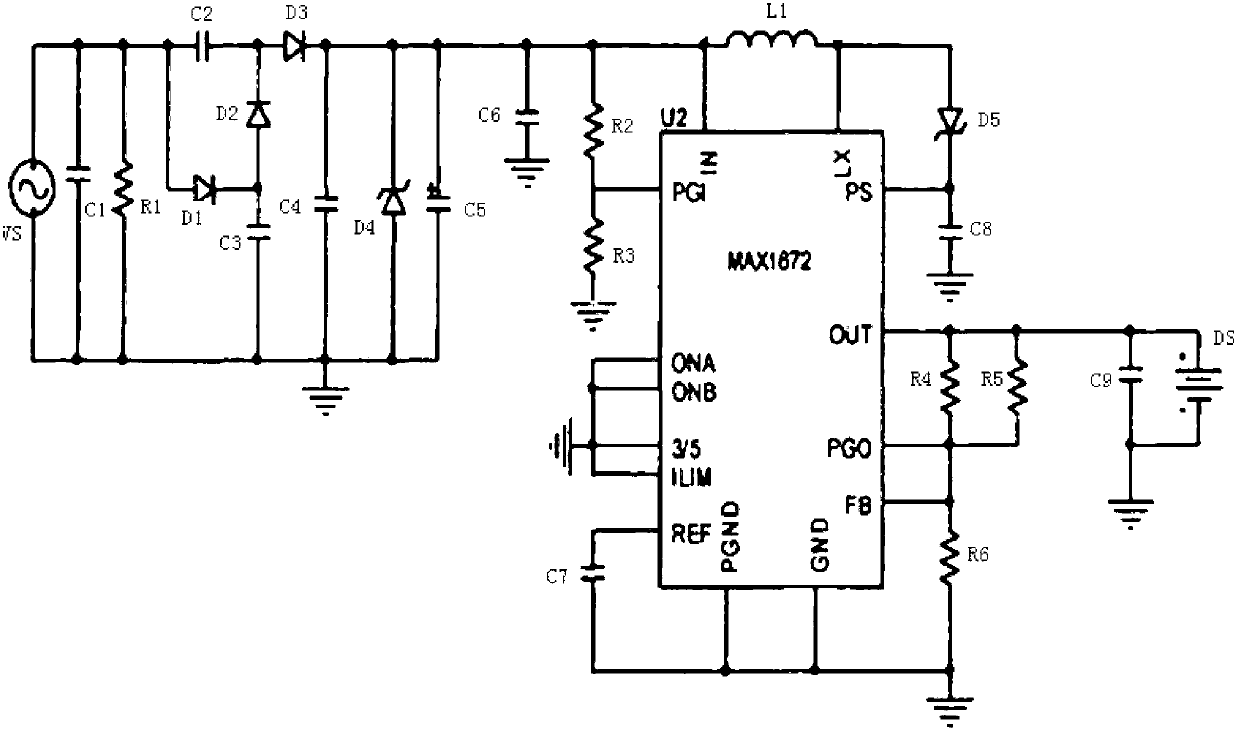

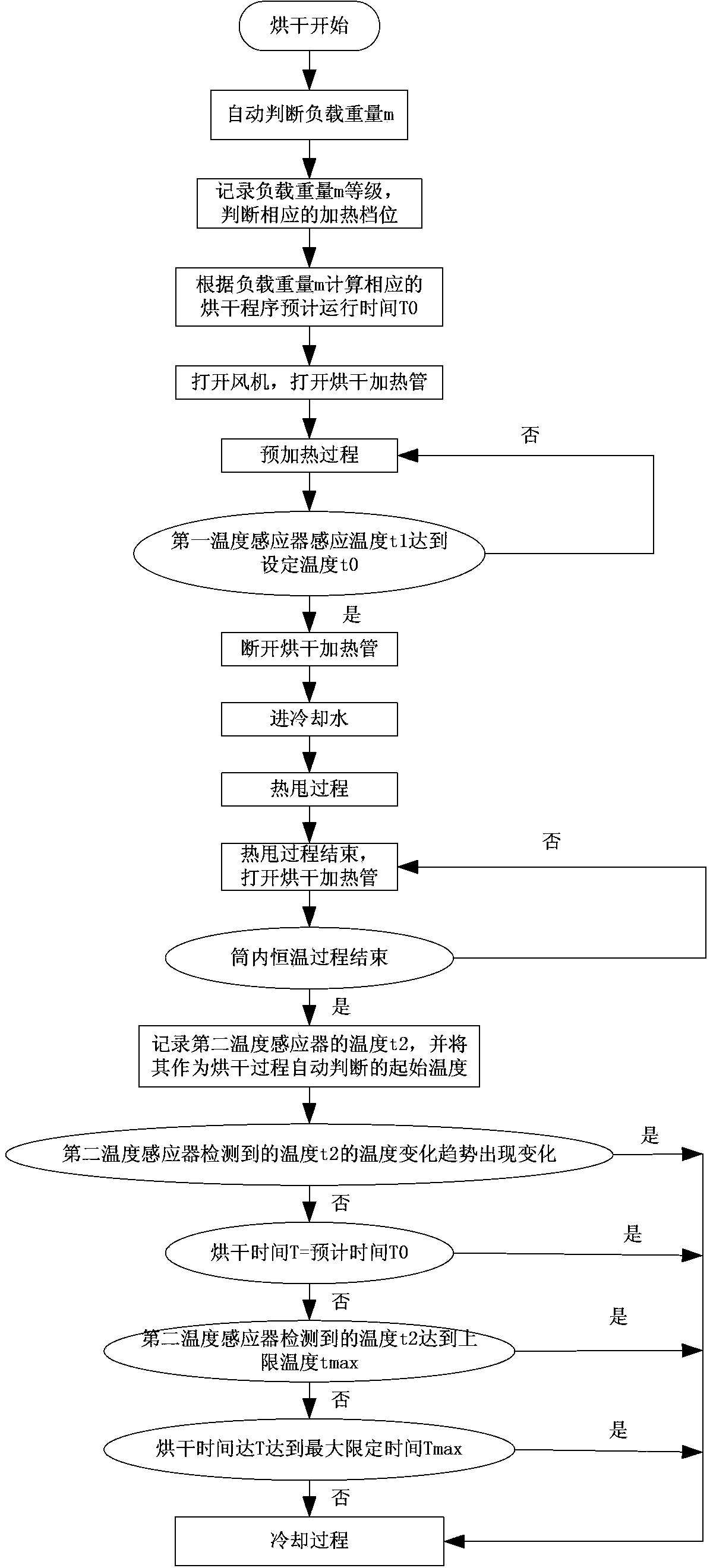

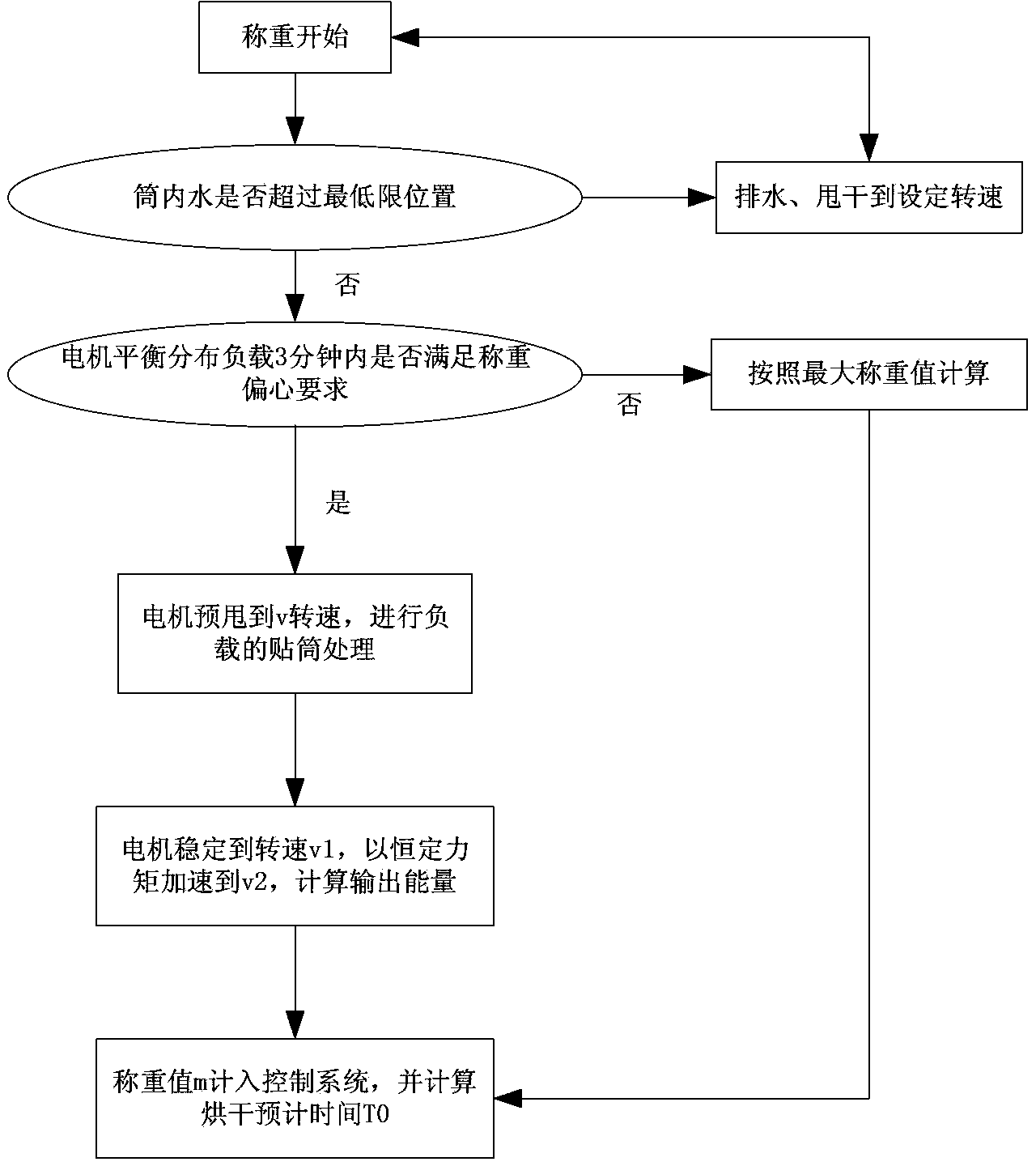

Washing and drying all-in-one machine and dry judging method thereof

ActiveCN103835111AReduce power consumptionRealize the purpose of energy saving and environmental protectionWashing machine with receptaclesTextiles and paperStopped workProcess engineering

The invention discloses a washing and drying all-in-one machine and a dry judging method thereof. The washing and drying all-in-one machine and the dry judging method thereof are characterized in that the load capacity in a drying barrel is detected in advance to calculate the operation estimated time T0 of a drying process under the corresponding load capacity. Heat drying is conducted on loads in the drying barrel, the drying time is shortened, and drying energy consumption is lowered. Heating wires stop working after meeting any following conditions that the temperature value in the drying barrel is obviously changed; the temperature value in the drying barrel exceeds an upper limit; the time T of the entire drying process reaches the operation estimated time T0 of the drying process. Moreover, when the three conditions all lose efficacy, the heating wires are controlled to stop working through the following condition that the entire drying time T is larger than the maximum operation time Tmax of the drying process. Through the washing and drying all-in-one machine and the dry judging method thereof, the purpose of accurately judging the work time of a drying machine is achieved, and the effect of lowering the power consumption of the washing and drying all-in-one machine is achieved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Portable human body air conditioner

Owner:谢逢华

Intermittently discharged organic waste gas gathering and processing method

InactiveCN104501187AIncrease motivationAchieve energy saving effectIncinerator apparatusAir quality improvementFlame arresterDirect combustion

The invention discloses an intermittently discharged organic waste gas gathering and processing method. After the intermittently discharged organic waste gas passes through a flame arrester, a booster pump and a waste gas gathering cabinet, if the organic waste gas is very high in concentration, the organic waste gas can be burnt directly or directly burnt in a combustion device / a boiler after passing through a purification / decontamination device B, and the heat generated by burning directly generates steam. If the organic waste gas is low in purity, the organic waste gas is thinned to the concentration lower than an explosion limit through a thinning device, the thinned organic waste gas is conveyed to heat storage oxidization / heat storage catalysis / catalytic oxidation devices to oxidize and decontaminate, one part of the gas is switched between the heat storage oxidization / heat storage catalysis / catalytic oxidation devices, one part of the heat generated by oxidization heats the waste gas to arrive at a combustible temperature, and most of the heat generates steam through a waste heat boiler. The intermittently discharged organic waste gas gathering and processing method is capable of realizing energy conservation and environment protection, a pollutant discharge enterprise even can gain profit when treating pollutant, and accordingly the pollutant treatment enthusiasm of the enterprise is greatly increased.

Owner:德州奥深节能环保技术有限公司

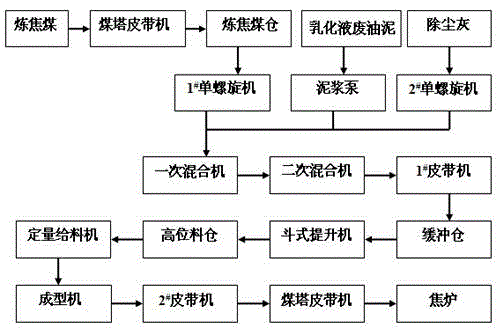

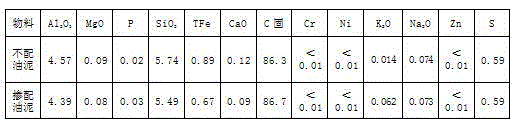

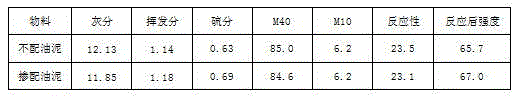

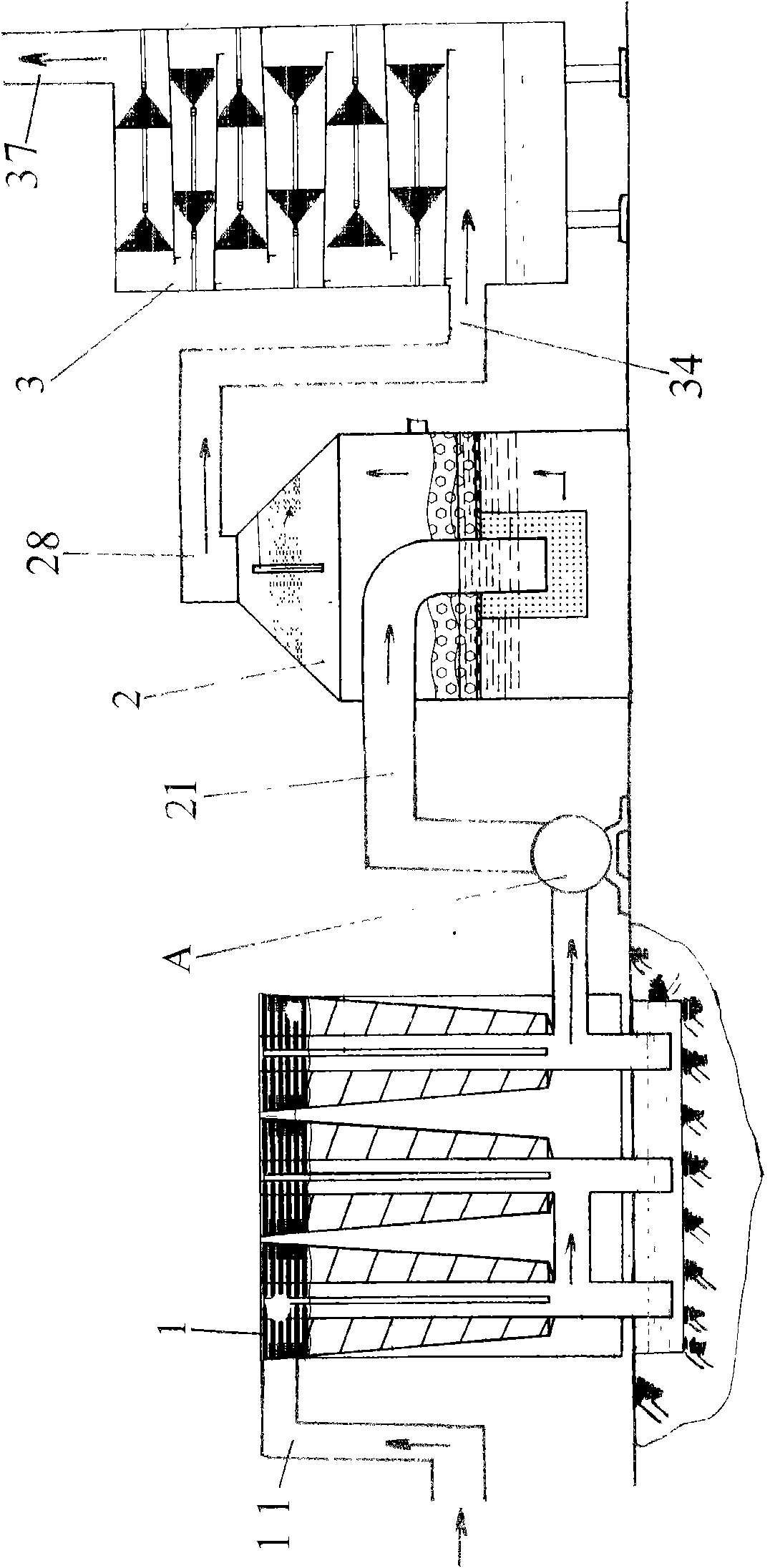

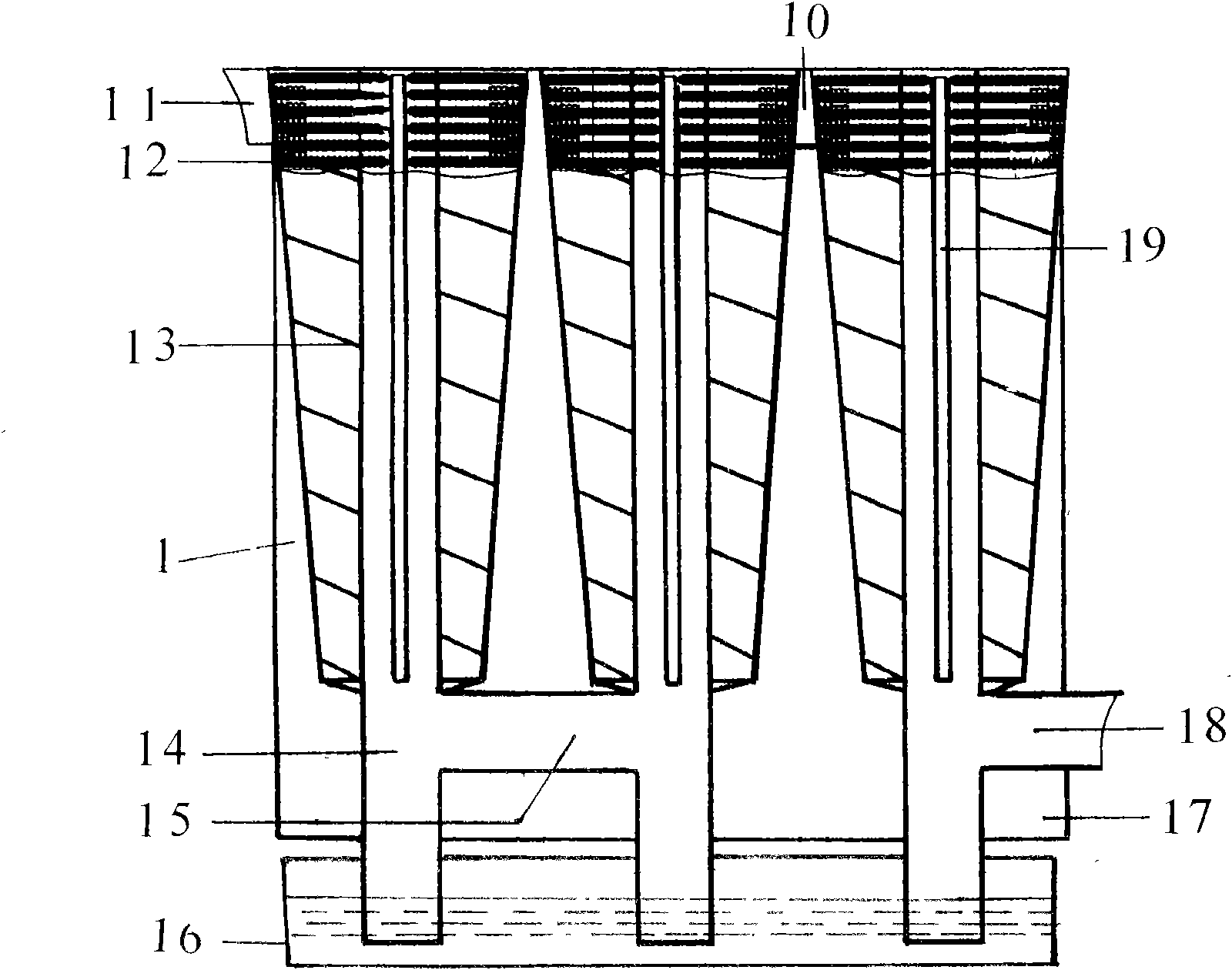

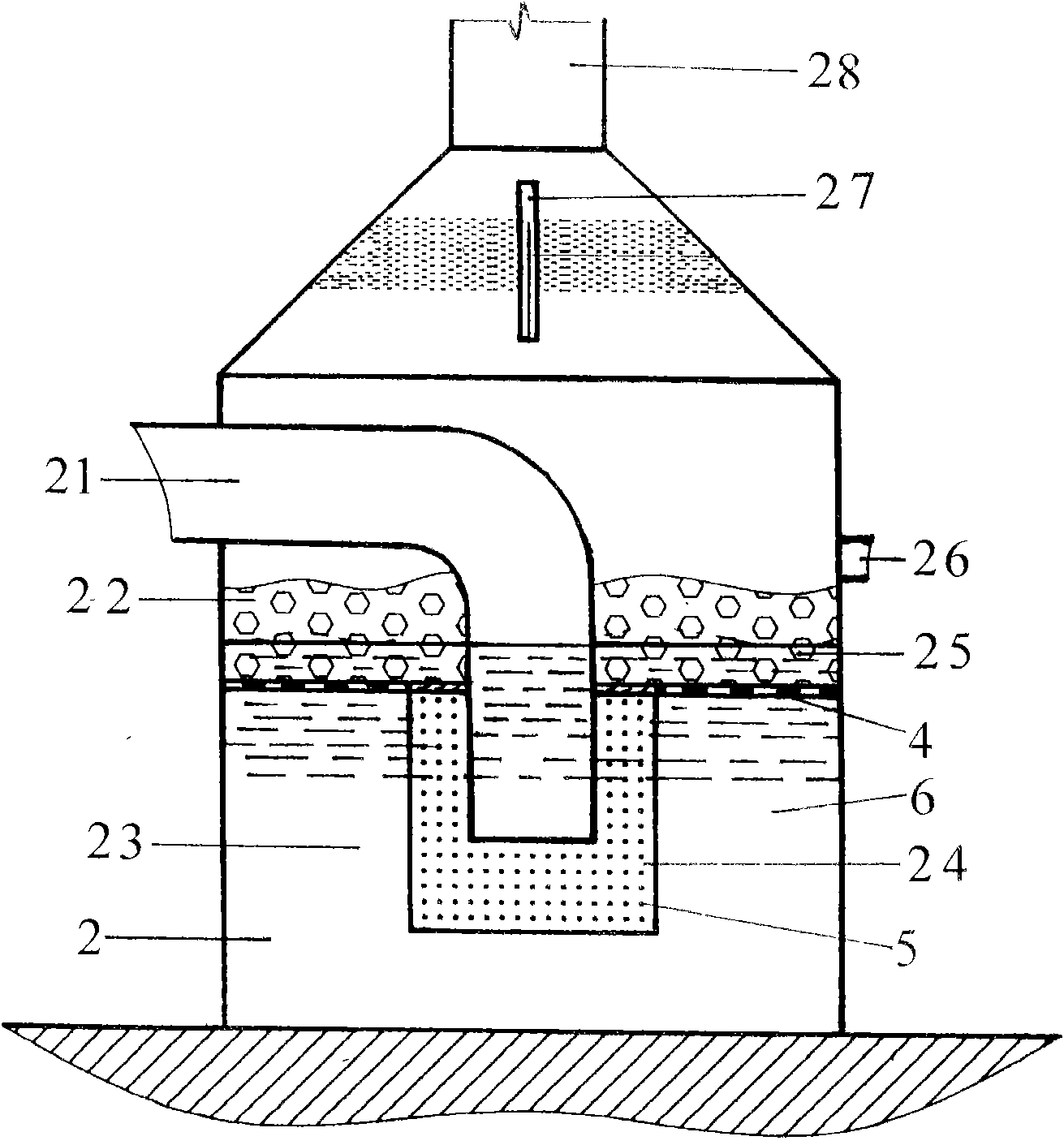

Emulsion waste oil sludge and coking system dust-removal ash briquette coal production process

The invention relates to an emulsion waste oil sludge and coking system dust-removal ash briquette coal production process. The production process comprises the following steps: intercepting coking coal from a belt conveyor sent to a coke oven coal tower, sending 14 to 17 percent by weight of emulsion waste sludge, 16 to 20 percent of coking system dust-removal ash and 65 to 68 percent of coking coal into a primary mixing machine, then stirring, then sending the stirred material into a secondary mixing machine, sending the secondarily-stirred material into a buffer cabin by virtue of the belt conveyor, sending the material discharged from the buffer cabin into an overhead bunker through a hopper type lifter, feeding the material discharged from the overhead bunker into a quantitative feeding machine, quantitatively sending the material into a forming machine by virtue of the quantitative feeding machine, sending the formed briquette coal onto the coal tower belt conveyor by virtue of the belt conveyor, and then sending the formed briquette coal into the coal tower coke oven together with the coking coal. The production process has the advantages that the produced briquette coal is high in strength, the briquette coal can be coked normally in the coke oven, and the produced coke can be used for the production of a blast furnace; the expense for treating the waste oil sludge in an iron and steel factory can be saved, the dust-removal ash produced in a coking factory can be recycled, and an energy-saving environmental-protection purpose can be realized.

Owner:太原钢城企业集团化工有限公司

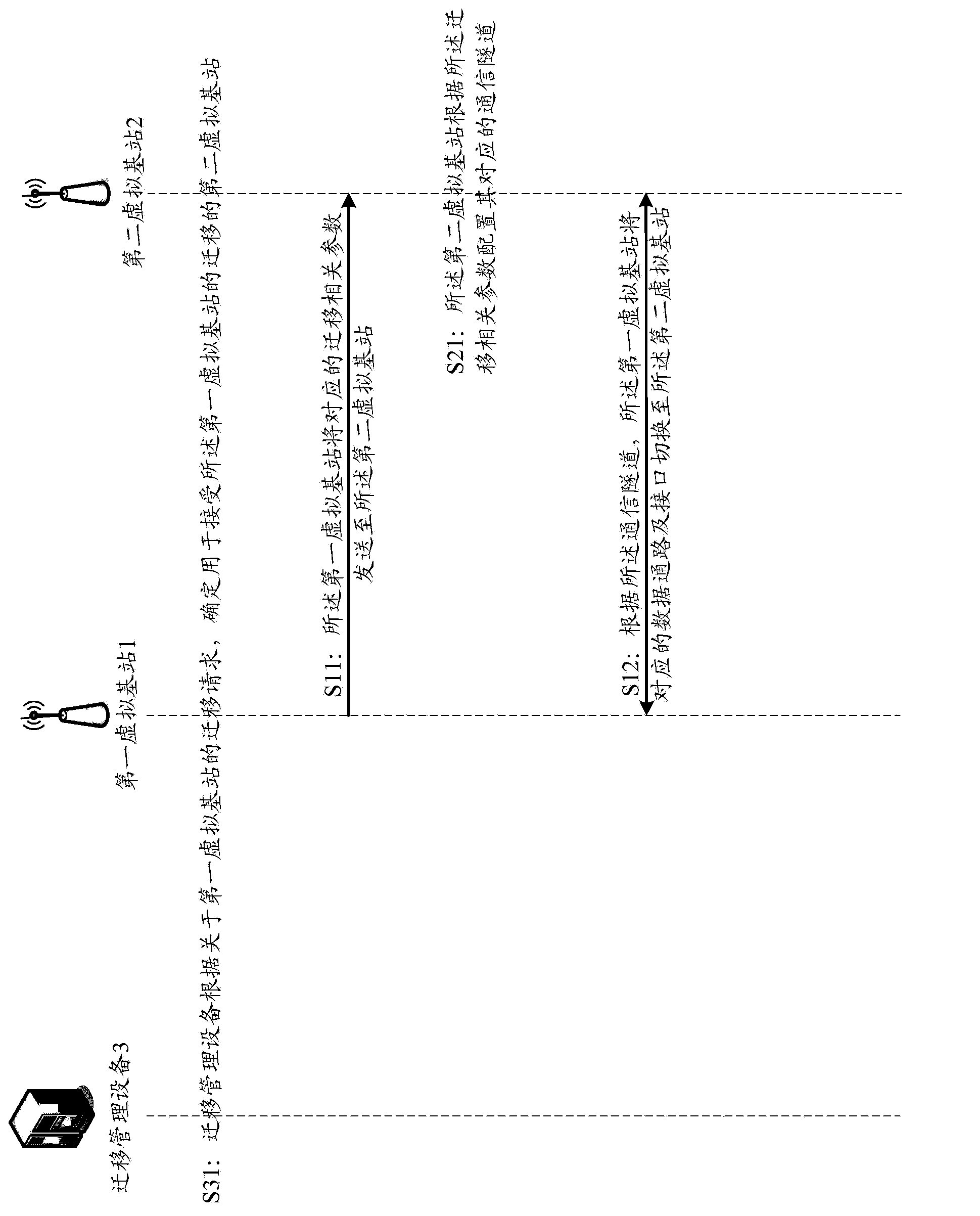

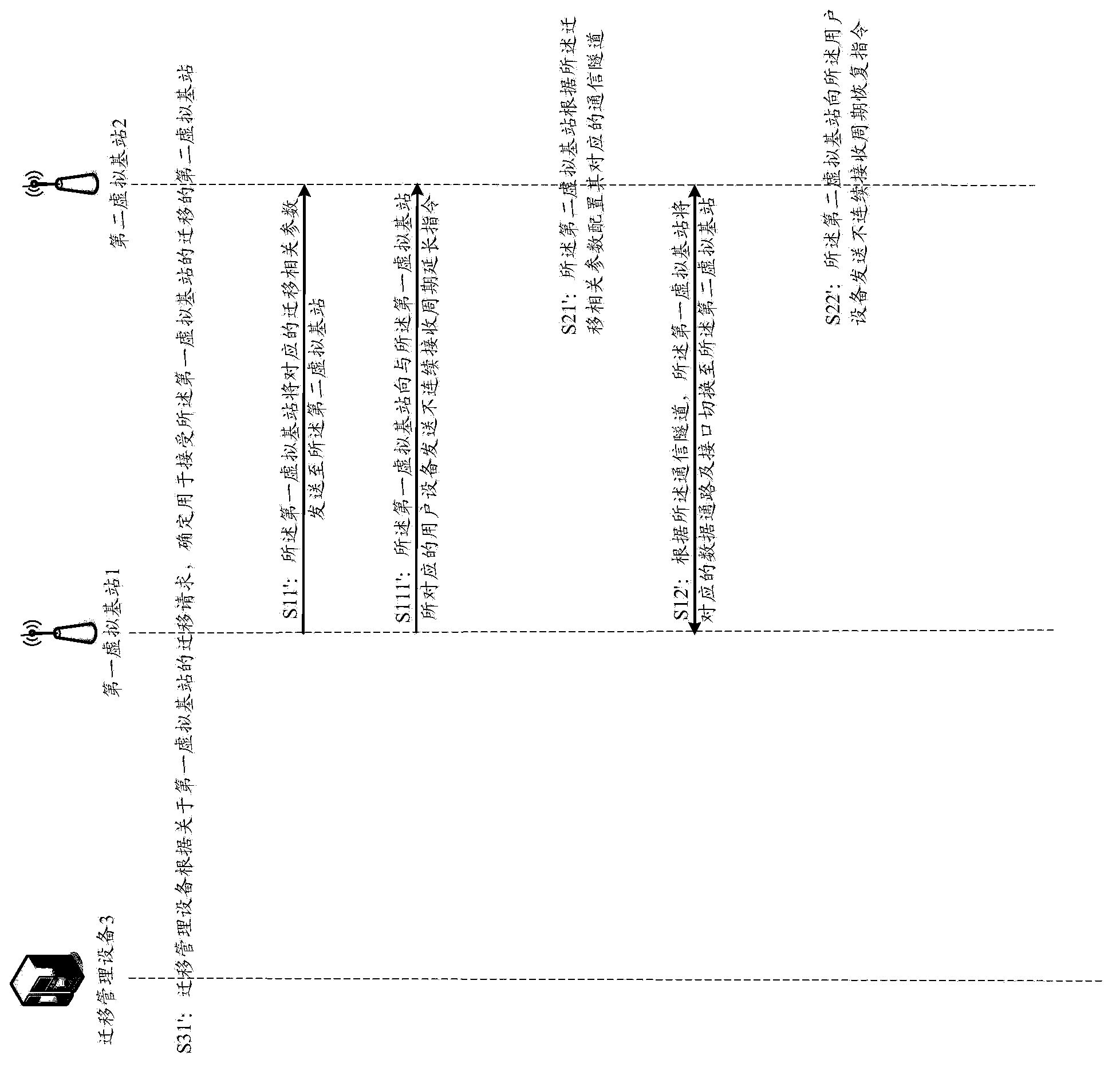

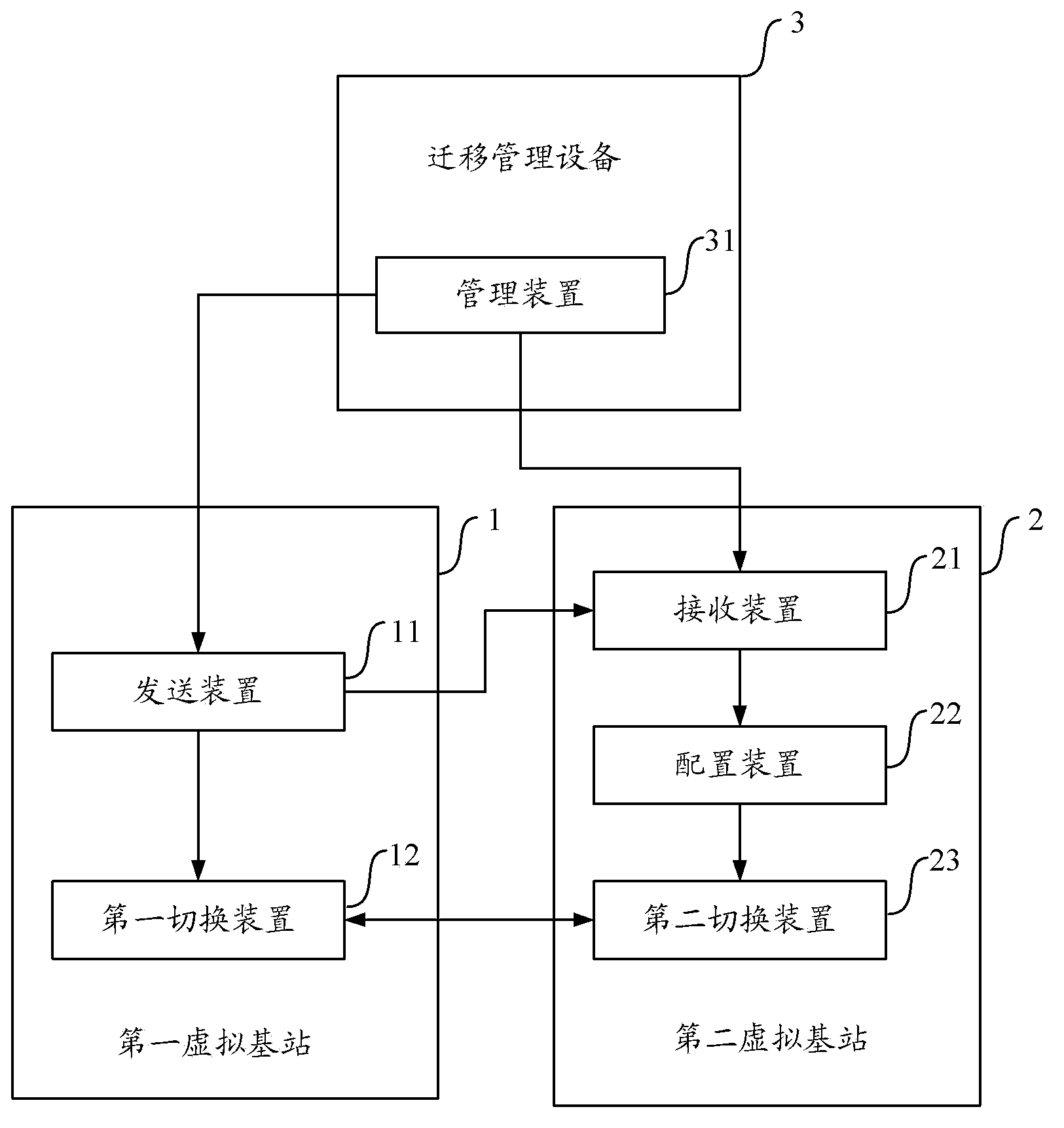

Method and device for achieving dynamic migration of virtual base stations in BBU pool

ActiveCN104080136AAchieve migrationLossless migrationWireless communicationNon destructiveQuality of service

The invention aims at providing a method, a device and a system for achieving dynamic migration of virtual base stations in a BBU pool. A second virtual base station for accepting migration of a first virtual base station is determined by utilizing a migration management device according to a migration request of the first virtual base station; the first virtual base station sends a corresponding migration relevant parameter to the second virtual base station; the second virtual base station configures a corresponding communication tunnel according to the migration relevant parameter; the first virtual base station switches a corresponding data path and an interface to the second virtual base station according to the communication tunnel. Compared with the prior art, the method, the device and the system achieve non-destructive virtual base station migration, millisecond-magnitude-order service interruption time and packet loss freeing, ensure the service quality and enable users not to feel the migration process.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

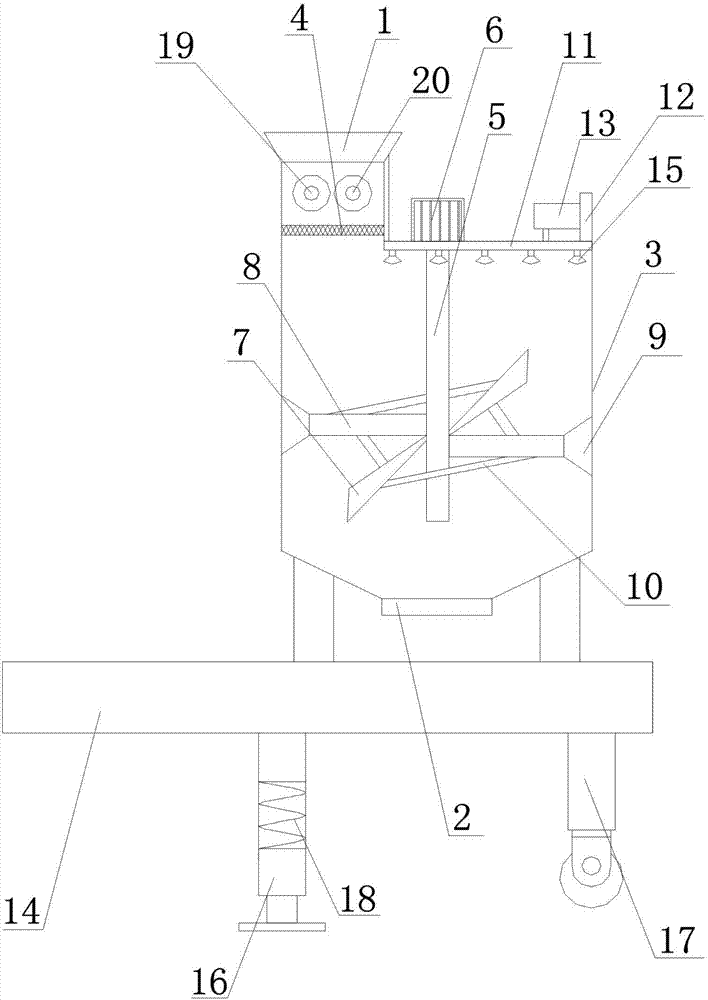

Energy-saving stirrer for building

InactiveCN107160560AQuality improvementSimple structureCement productionCement mixing apparatusEngineeringHigh pressure water

The invention discloses an energy-saving stirrer for a building. The problems that in the prior art, energy is wasted, cement on the inner wall of a stirrer is difficult to clear away, and the stirring efficiency is low are solved. The energy-saving stirrer for the building comprises a cylindrical stirrer body with a feeding port in the top and a discharging funnel port in the bottom, a smashing device, a filter screen, a stirring shaft, an energy-saving motor, stirring blades, a connecting shaft rod, an automatic cleaning knife, a protecting rod, a water spraying pipe, a water conveying pipe, a high-pressure water pump arranged on the water conveying pipe, and a supporting frame body fixed to the bottom of the stirrer body; more than five downward water spraying heads are arranged on the water spraying pipe in a staggered manner; hydraulic supporting legs and universal wheel supporting legs are arranged at the bottom of the supporting frame body; and shock absorbing springs are arranged on the hydraulic supporting legs. The energy-saving stirrer for the building is low in production cost, high in stirring efficiency and long in service life, the cement is good in quality after being stirred, energy conservation and environment protection are achieved, and the energy-saving stirrer for the building is suitable for being popularized and applied energetically in the technical field and the technical fields approaching to the technical field.

Owner:CHENGDU JUHUICAI TECH

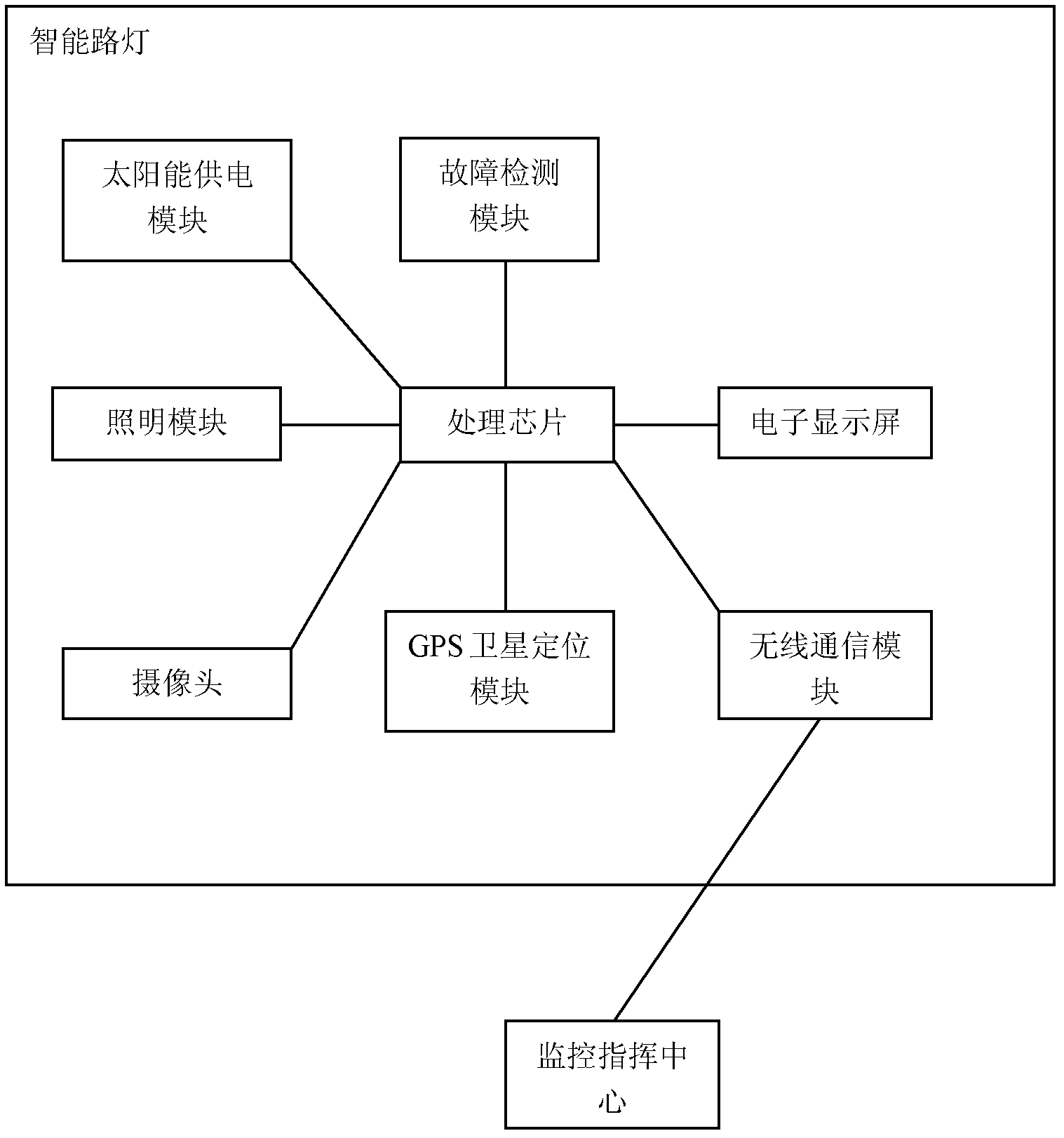

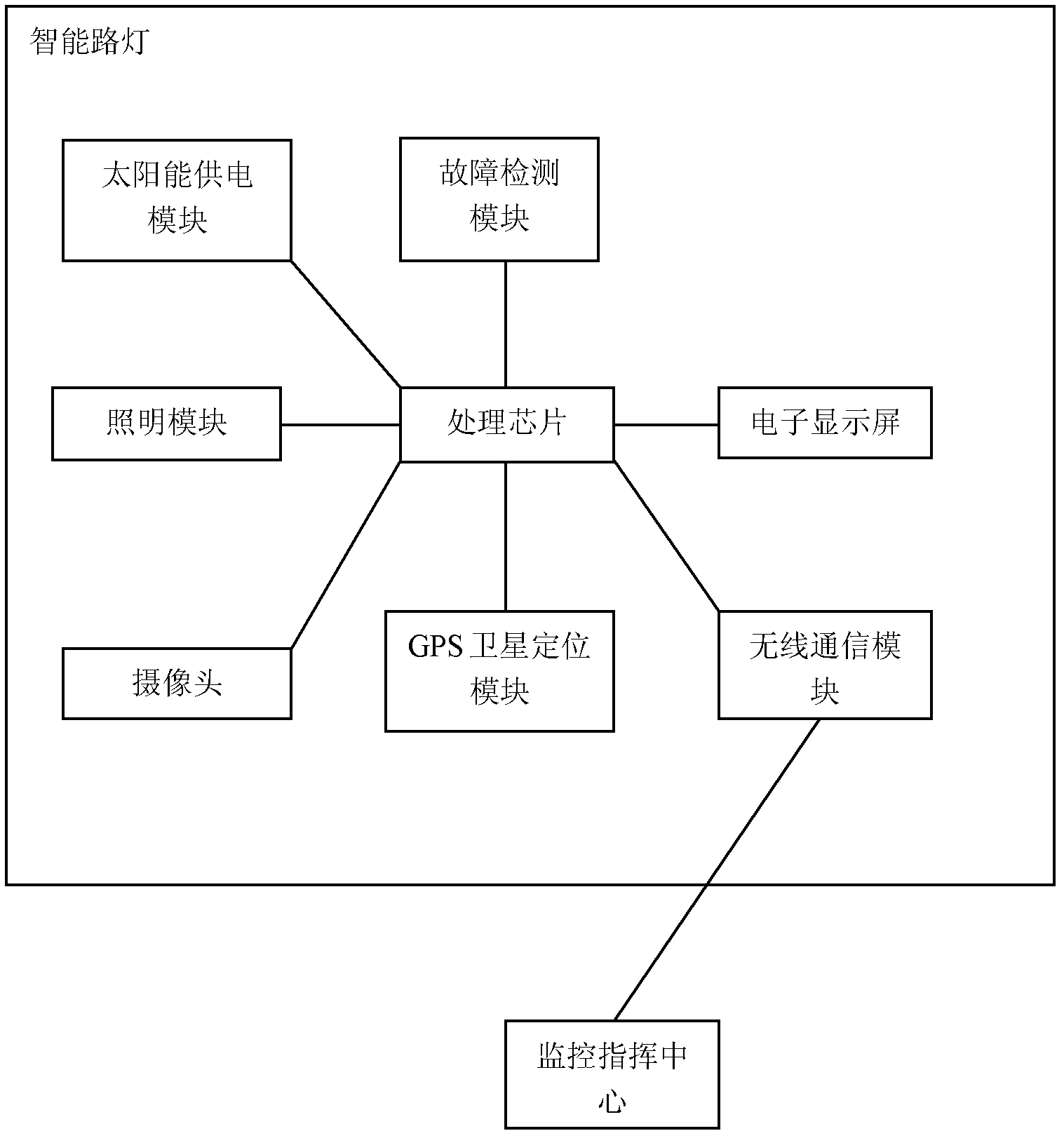

Multifunctional social management system based on cloud computing

InactiveCN102495600ASolve the problem of low resource utilizationRealize the purpose of energy saving and environmental protectionProgramme total factory controlResource utilizationSolar power

The invention relates to a multifunctional social management system based on cloud computing. The multifunctional social management system comprises a plurality of intelligent street lamps and a monitoring command center. Each intelligent street lamp comprises a solar power supply module, an illumination module, a lamp post, a processing chip, a wireless communication module, a fault detection module, a camera, a GPS (Global Position System) satellite positioning module and an electronic display screen. A plurality of the intelligent street lamps are respectively mounted on different city roads. Compared with the traditional street lamp, the multifunctional social management system disclosed by the invention exerts the advantages of positions of the street lamps by additionally arranging various modules. Therefore, the problem of low use ratio of city resources can be effectively solved and the purposes of energy conservation and environmental friendless are achieved. The multifunctional social management system disclosed by the invention further has an integrated function of traffic management, society security management, emergency management and city propaganda.

Owner:肇庆全商联盟信息科技有限公司

Fluorine-containing heterocyclic compound and preparation method thereof

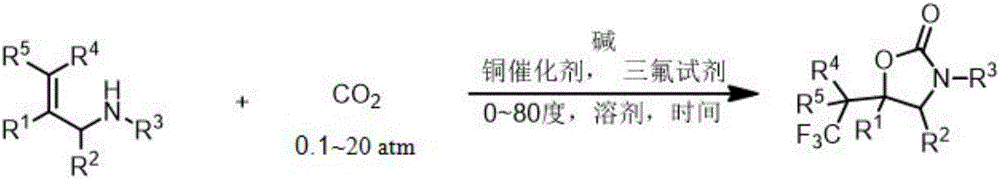

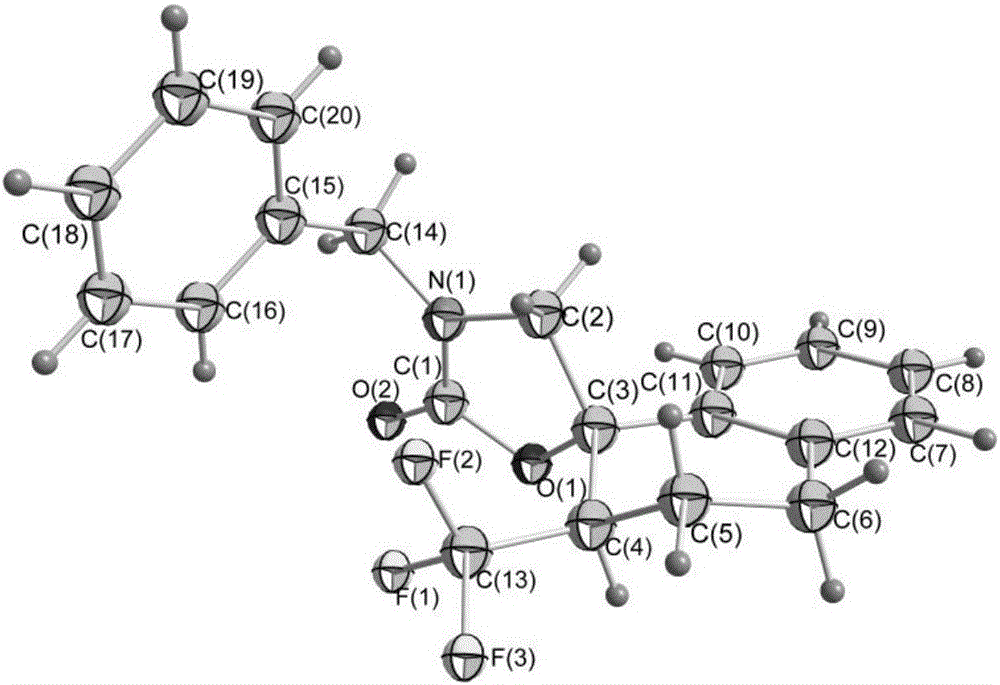

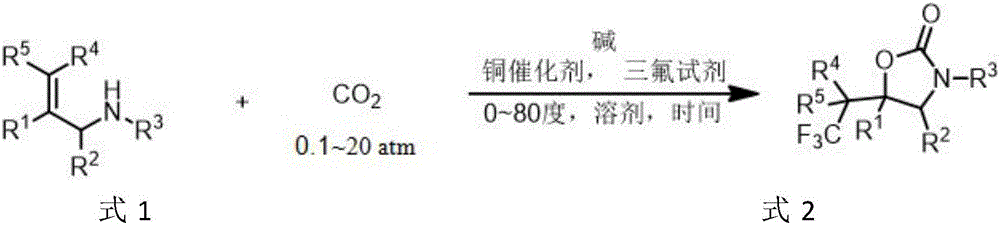

ActiveCN106220581AEasy to synthesizeReduce usageOrganic compound preparationCarboxylic acid amides preparationTrifluoromethylationAryl

The invention relates to a method for preparing a 2-oxazolinone compound containing a trifluoromethyl group from an allyl amine compound in virtue of carbon dioxide. Specifically, the allyl amine compound as shown in a formula 1 which is described in the specification reacts with CO2 in a solvent in the presence of a copper catalyst, alkali and a trifluoromethylation reagent so as to prepare the 2-oxazolinone compound as shown in a formula 2 which is described in the specification. In the formula 2, R<1>, R<2>, R<4> and R<5> are independently selected from a group consisting of H, halogen, a cyano group, an alkyl group, a carbonyl group, an ester group, an aryl group, a heteroaryl group and the like, R4 or R5 can optionally form a ring with R1, and the alkyl group, the carbonyl group, the ester group, the aryl group and the heteroaryl group can be optionally substituted by halogen, the alkyl group or the like; and R3 is H, halogen, an alkyl group, an aryl group, or the like.

Owner:SICHUAN UNIV

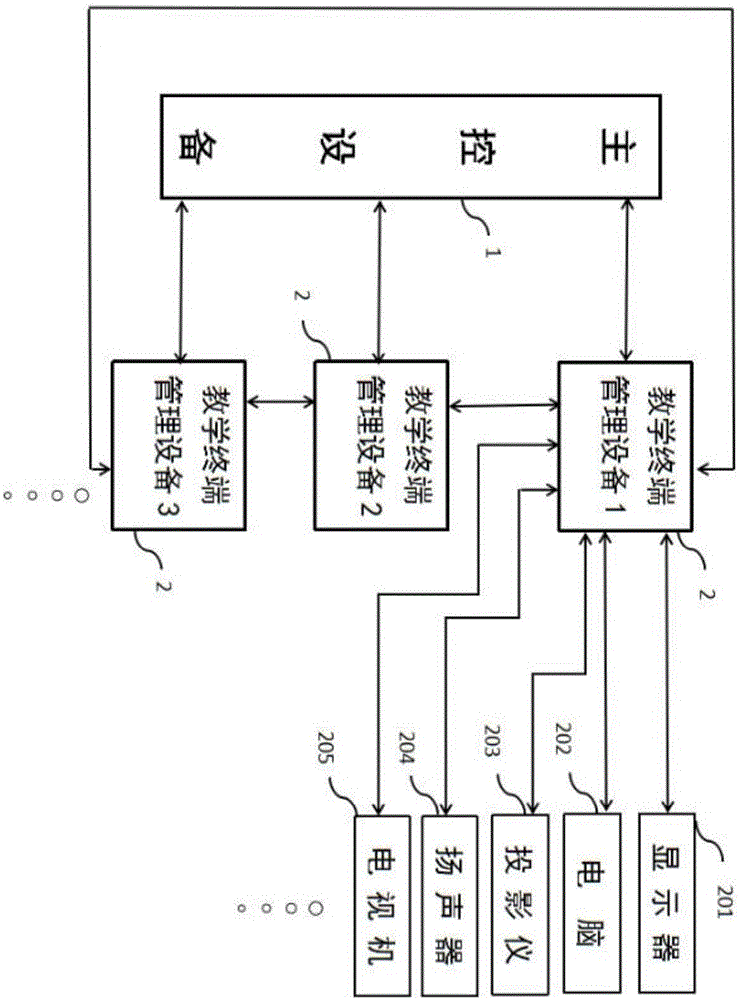

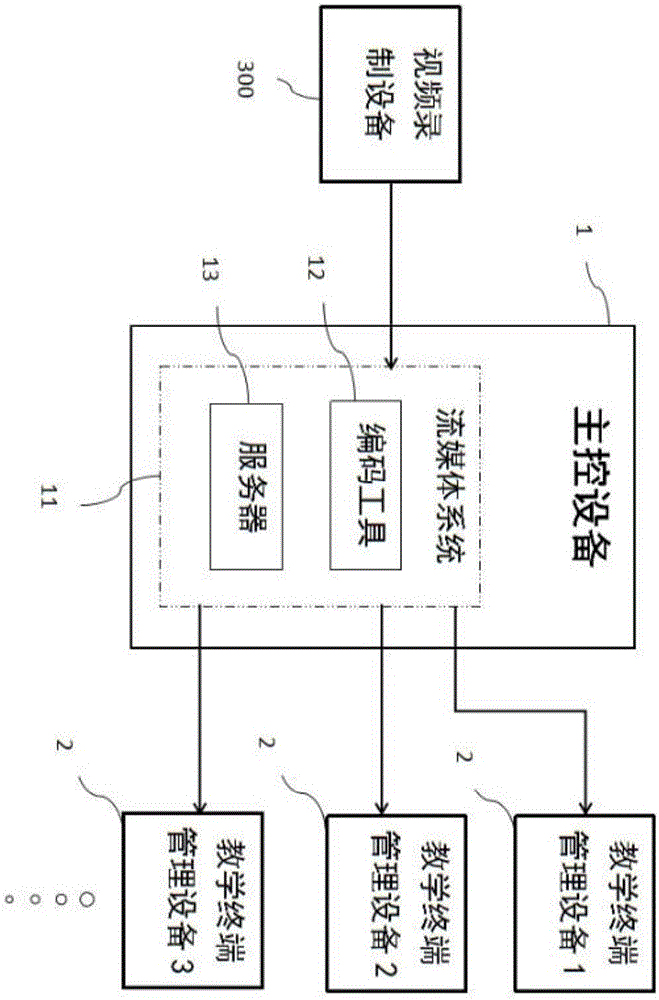

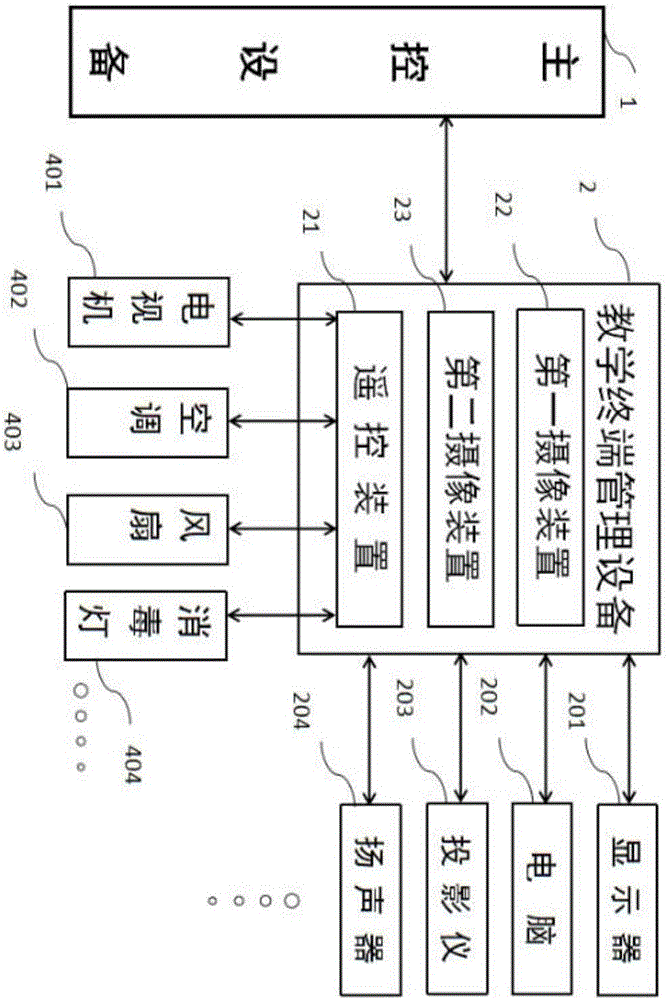

Teaching management system

InactiveCN106023689AAchieve interactionRealize unified managementData processing applicationsElectrical appliancesInformation transmissionComputer terminal

The invention provides a teaching management system which can provide various forms of video data, and can carries out uniform management on electrical appliances in a classroom. The teaching management system provided by the invention comprises a master control device and a number of teaching terminal management devices. A number of teaching terminal management devices are provided with management operation interfaces suitable for controlling and managing various external connected teaching devices, and interactive interfaces suitable for interacting with the master control device. The master control device is provided with a management operation interface suitable for remotely controlling and managing a number of teaching terminal management devices, and an interactive interface suitable for interacting with a number of teaching terminal management devices. The master control device and a number of teaching terminal management devices interact with each other, including text, image, audio and / or video information transmission. The master control device can control and manage the external teaching devices which are connected with a number of teaching terminal management devices.

Owner:深圳市科佳达科技有限公司

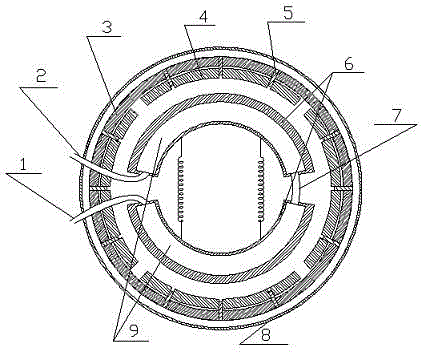

Truck braking radiating system

The invention provides a truck braking radiating system which comprises a braking drum, braking shoes and a braking piece, wherein a pair of arc-shaped braking shoes are arranged inside the braking drum. The truck braking radiating system is characterized in that a plurality of braking drum rivet holes are formed in the inner wall of the braking drum, braking piece rivet holes corresponding to the braking drum rivet holes are formed in the braking piece, and the braking piece is fixed on the inner wall of the braking drum through a rivet; the inner cavity of each braking shoe is emptied, the opposite ends of the braking shoes are connected through a guiding pipe, the other end of one braking shoe is provided with a braking shoe water inlet pipe, and the other end of the other braking shoe is provided with a braking shoe water outlet pipe; a water tank circulating radiating device or a mechanical circulating radiating device provided with a water pump and a radiator is arranged between the braking shoe water inlet pipe and the braking shoe water outlet pipe. A truck does not need to fill the water in a large water tank anytime to spray the braking drum to radiate, the oil consumption quantity of the truck is reduced, the trouble that a driver needs to add the water in the midway is omitted, and the time and the money are reduced.

Owner:范伟俊

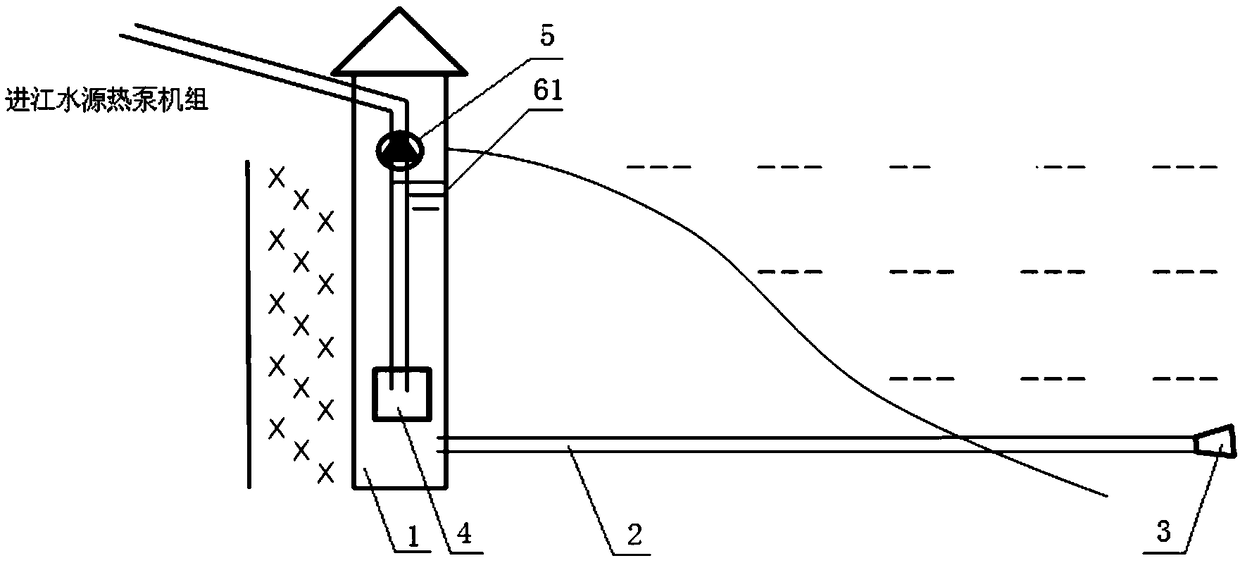

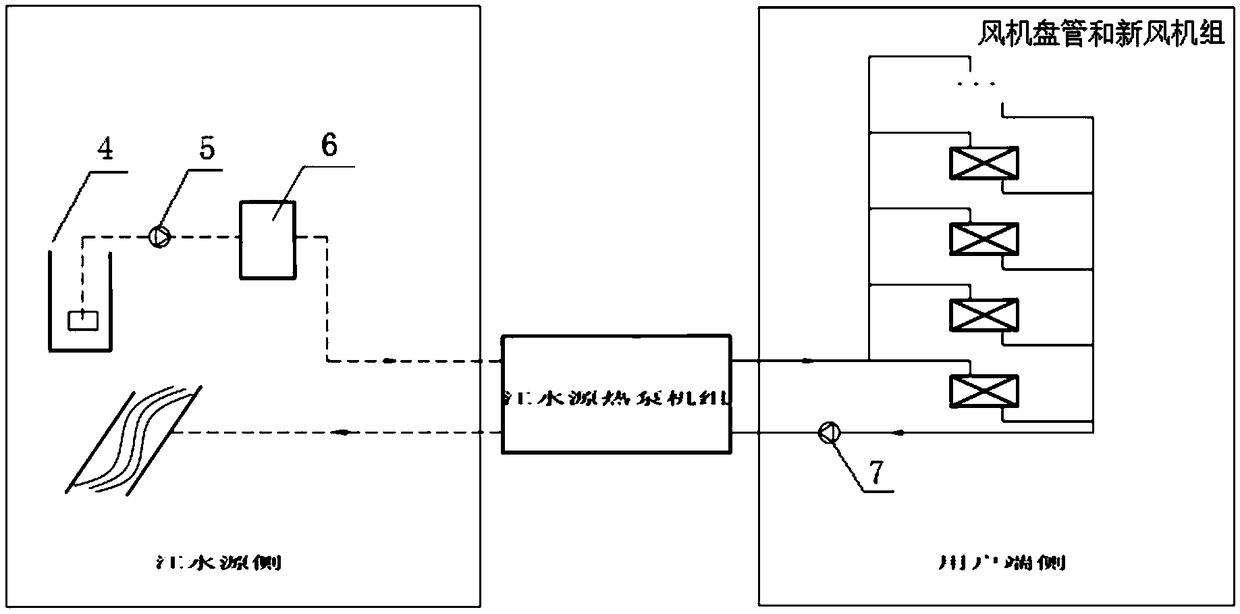

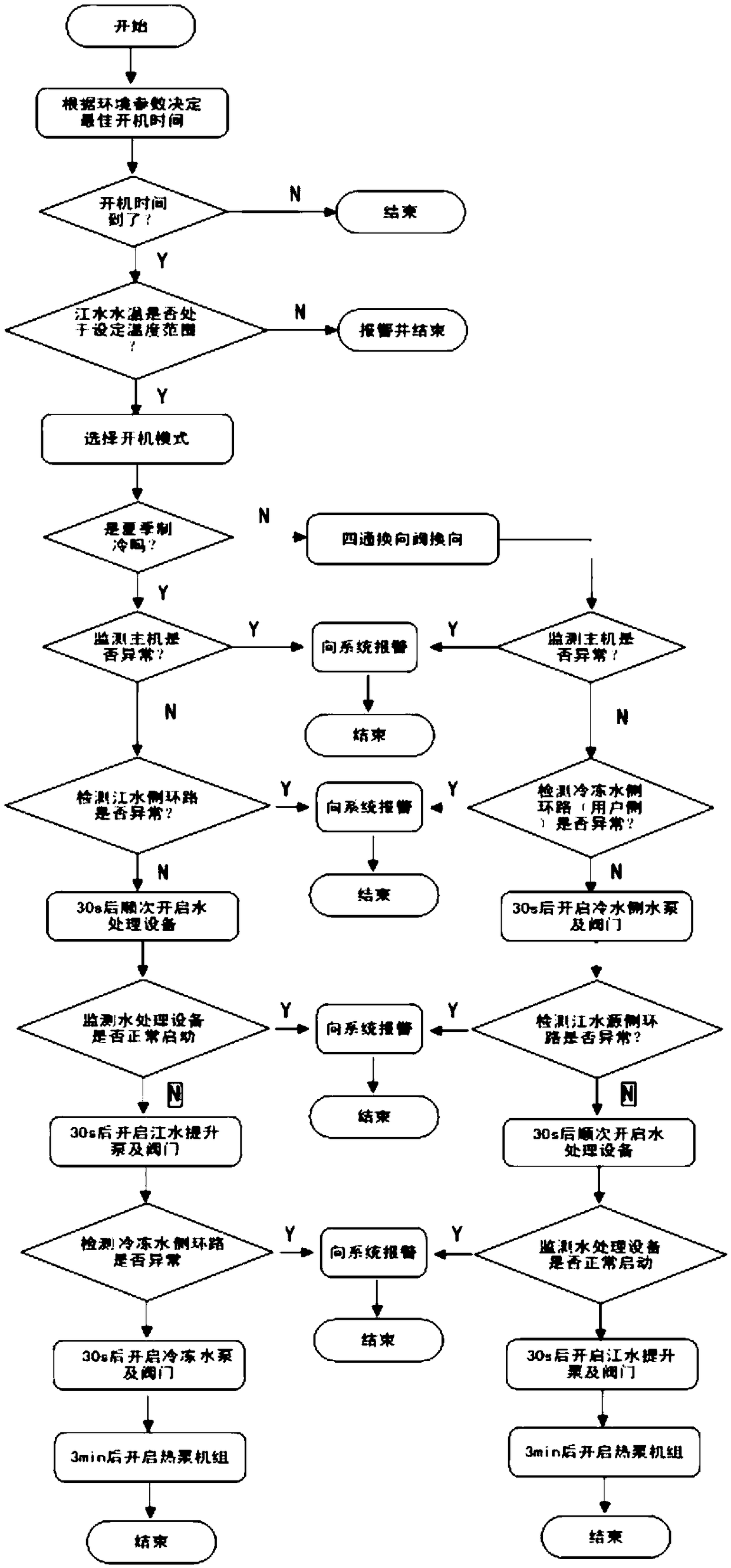

Energy-saving control method and system for river water source heat pump system

InactiveCN108931030AWith self-learning functionOvercome control and regulation difficultiesMechanical apparatusSpace heating and ventilation safety systemsHysteresisWater source

Provided are an energy-saving control method and system for a river water source heat pump system. The method comprises the following steps that S1, building standard cold and heat energy consumptionlarge data are built; S2, according to the building function, energy using time and load distribution difference, by combination with the building standard cold and heat energy consumption large data,building refinement partitioning is conducted, a cold and heat energy requirement dynamic curve of all subzones of a building is generated, and the dynamic curve is updated once at fixed intervals; and S3, according to the cold and heat energy requirement dynamic curve of the building, the large hysteresis quality and nonlinearity of an air conditioner system are considered, the river water source heat pump system is divided into an equipment starting stage, a steady-state operation stage and an equipment halt stage, and staged control is conducted; and the temperature changes of river waterare monitored in real time, and when the temperature difference of inlet and outlet water of a river water source heat pump unit exceeds the set value, corresponding water pumps are controlled in a variable-frequency mode, and the water flow is adjusted. The invention further discloses the energy-saving control system for the river water source heat pump system. The energy-saving control method and system for the river water source heat pump system have the advantages of being high in efficiency, stable, free of pollution, small in energy consumption, remarkable in energy-saving effect and thelike.

Owner:湖南湖大瑞格能源科技有限公司

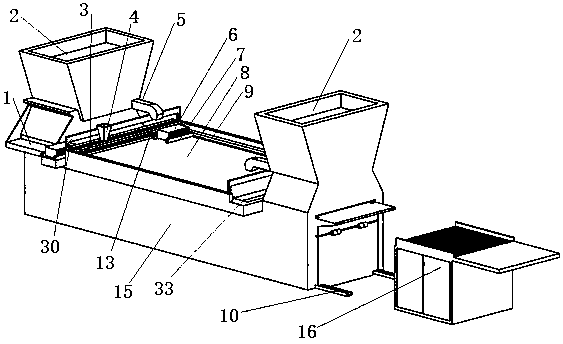

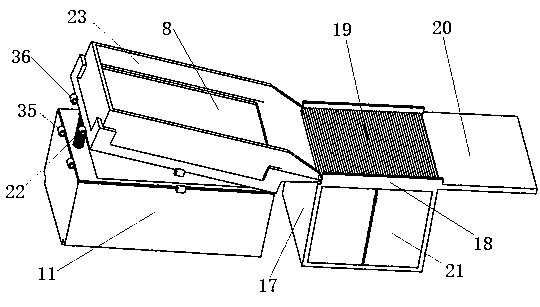

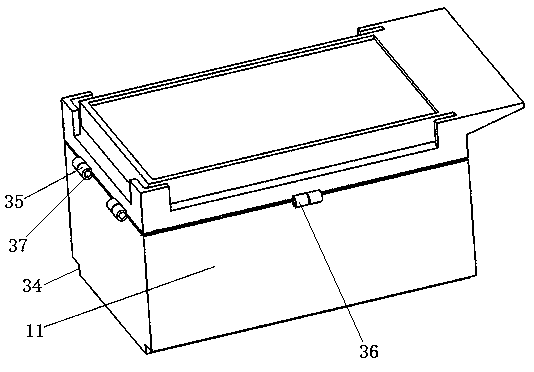

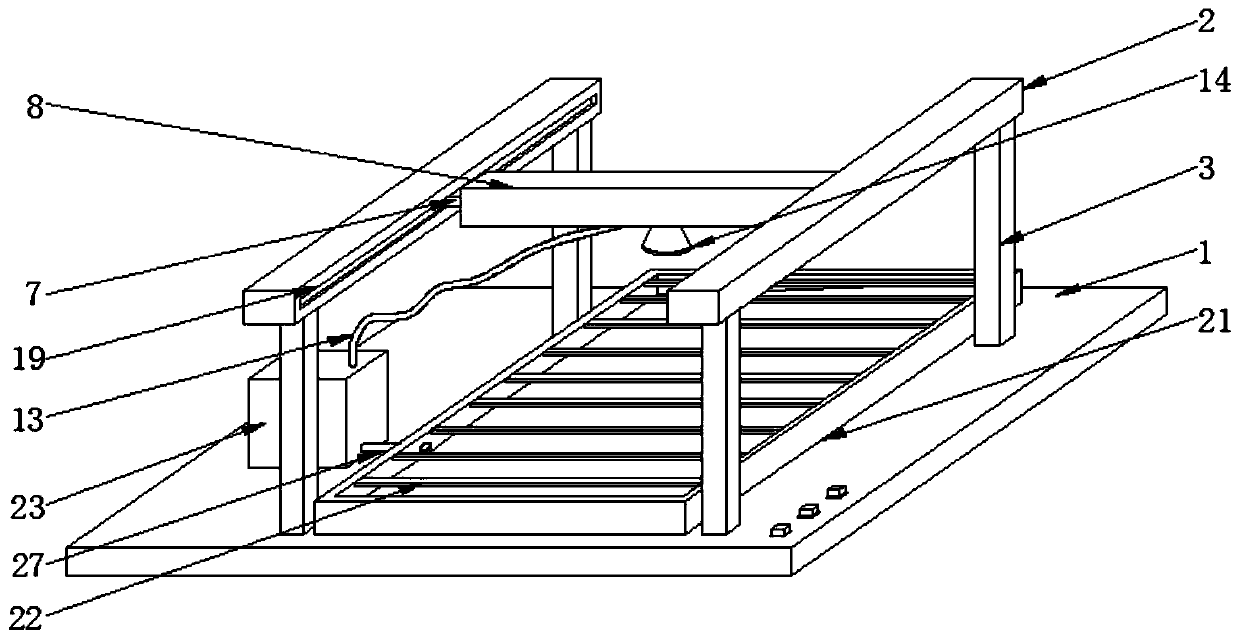

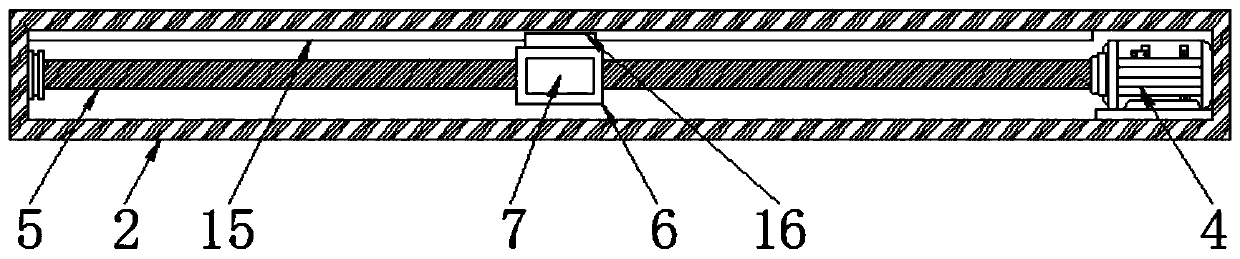

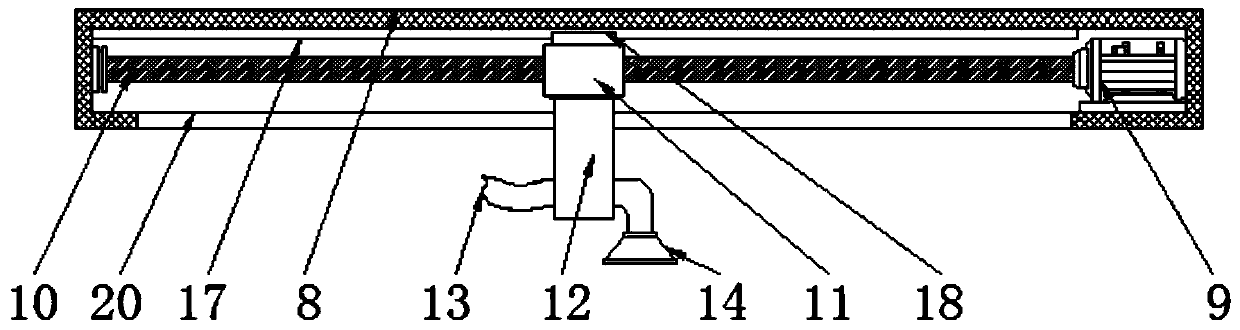

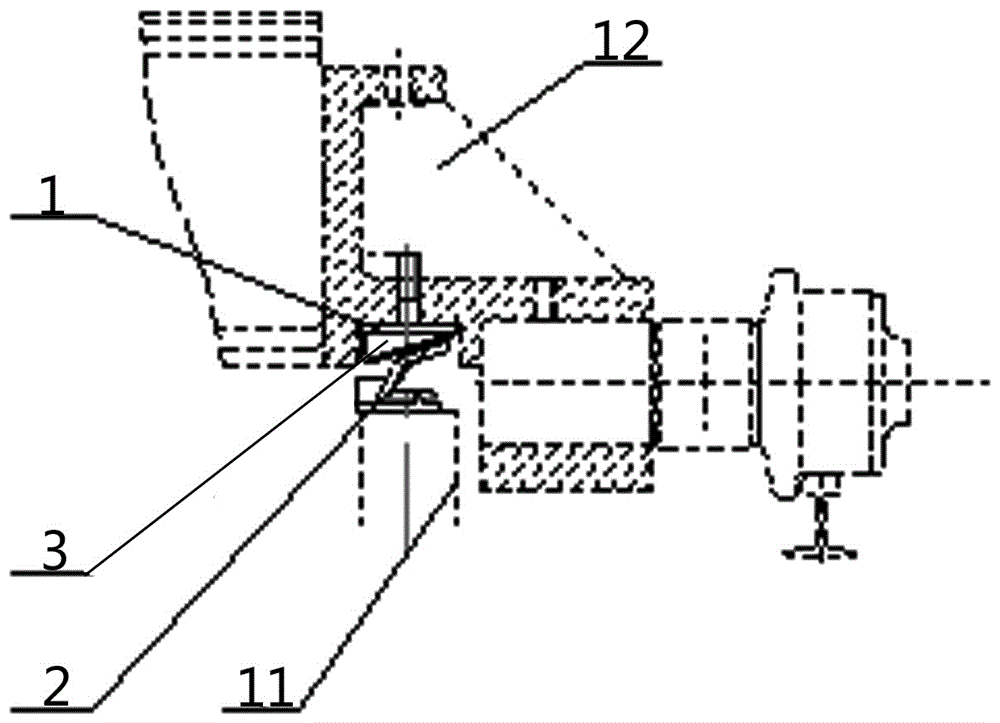

Rapid dual-way material paving full-color 3D printing machine

PendingCN109176824AShort pauseShorten the timeAdditive manufacturing apparatusCeramic shaping apparatus3d printerFull color

The invention discloses a rapid dual-way material paving full-color 3D printing machine. The rapid dual-way material paving full-color 3D printing machine comprises a shell, a control platform and a material paving mechanism; printing assemblies are arranged on the two sides of the material paving mechanism, and adopt photocuring full-color inkjet print heads, UV photocuring lamp tubes are arranged on the two sides of the bottoms of the photocuring full-color inkjet print heads, material boxes are arranged on the two ends of the shell, quantitative discharging devices are arranged at the lowerends of the material boxes, a forming cylinder body is arranged in the shell, the forming cylinder body can slide along guide rails on the two sides of the bottom in the shell, a forming cylinder upper rend powder bed is arranged on the top of the forming cylinder body, a discharging opening is formed in one end of the shell, and a sand removal device is arranged on the outer side of the discharging opening. Dual-way material paving of a material paving mechanism is achieved, in the back and forth process of the material paving mechanism, the dwell time is short, the work efficiency is greatly improved, sand removal and material taking are integrated, the automation degree is high, manpower and time are greatly saved, the sand removal efficiency is improved, the raw material use rate is high, and cost is greatly saved.

Owner:甘肃顺域新材料科技有限公司 +2

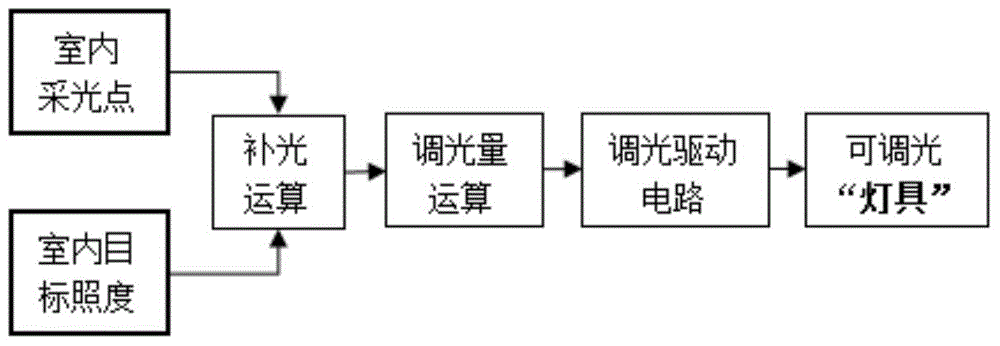

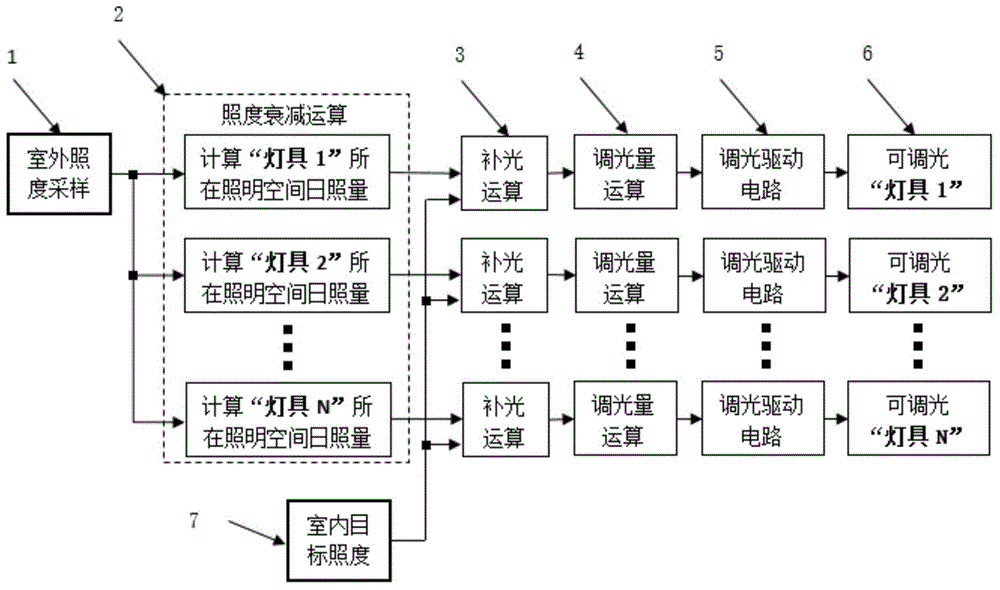

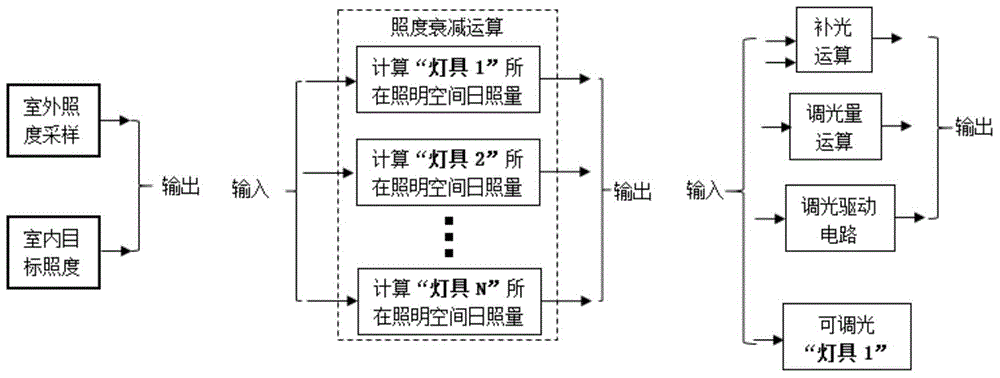

Indoor illumination control system and method based on outdoor illumination sampling

InactiveCN106488623AAvoid wastingRealize the purpose of energy saving and environmental protectionElectric light circuit arrangementUltrasound attenuationIlluminance

The invention discloses an indoor illumination control system and method based on outdoor illumination sampling. The indoor illumination control system comprises an outdoor illumination sampling module, an illumination attenuation calculating module, a supplementary lighting calculating module, a dimming quantity calculating module and a dimming drive circuit, wherein the outdoor illumination sampling module is used for collecting outdoor sunlight information; the illumination attenuation calculating module is used for calculating the actual sunshine amount of an illumination space in which each indoor lamp is so as to calculate the supplementary lighting amount of the lamps for supplementary lighting illumination; the supplementary lighting calculating module is used for calculating the supplementary lighting amount required for each lamp according to the actual sunshine amount of the illumination space in which each indoor lamp is which is calculated and obtained by an illumination attenuation model and according to required indoor target illumination; the dimming quantity calculating module is used for calculating output dimming quantity of each lamp required for supplementary lighting illumination according to the supplementary lighting amount of each lamp required in the illumination space calculated and obtained by the supplementary lighting calculating module; the dimming drive circuit is used for carrying out illumination power drive output for each lamp respectively according to the output dimming quantity of each lamp required for supplementary lighting illumination calculated and obtained by the supplementary lighting calculating module.

Owner:苏州市星创宇智能科技有限公司

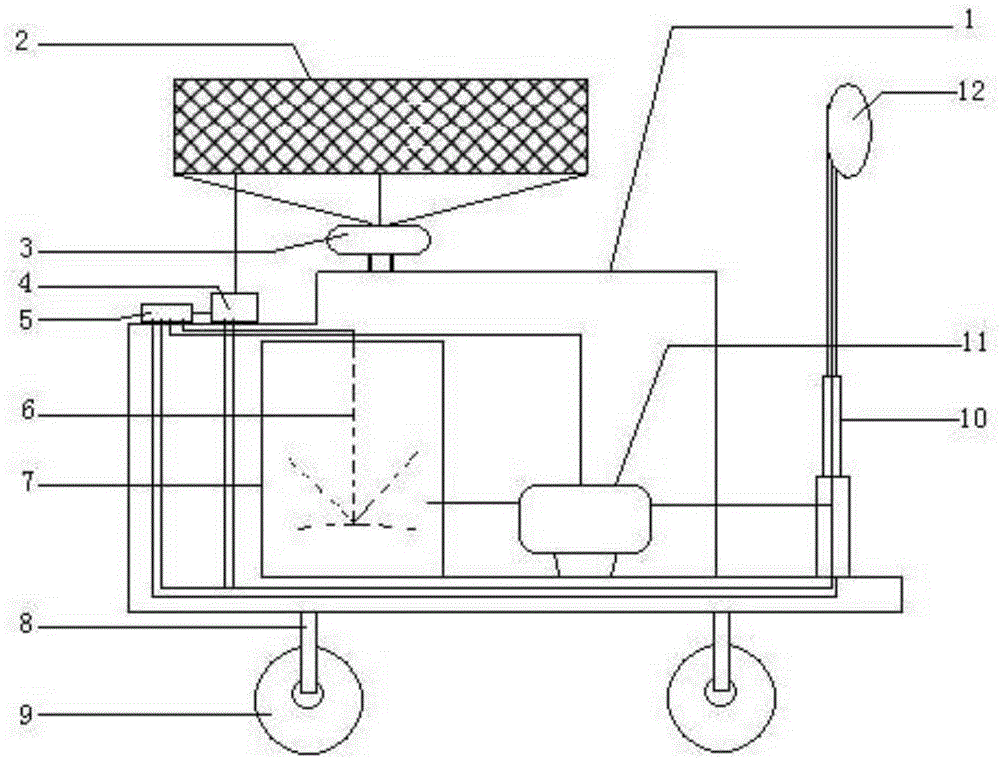

Multifunctional pesticide spraying cart

InactiveCN104145924AReasonable structural designFlexible and convenient to moveInsect catchers and killersSolar energy storageEngineering

The invention discloses a multifunctional pesticide spraying cart which comprises a cart body, a solar sensitive plate, a solar energy storage cell, a controller, a pesticide box, a pressure pump, an electric lifting rod and wheels. The solar sensitive plate is arranged at the top of the cart body and connected with the cart body through a rotary support, the solar energy storage cell is arranged on the left side of the top of the cart body, electrically connected with the controller and connected with the solar sensitive plate, the pesticide box is arranged in the cart body, and a stirring device is arranged in the pesticide box. The controller is respectively connected with the stirring device, the pressure pump and the electric lifting rod electrically, the pressure pump is arranged in the cart body and connected with liquid pipes in the pesticide box and the electric lifting rod respectively through liquid pipes, a nozzle is arranged at the upper end of the electric lifting rod, and the wheels are connected with the cart body through connection rods. The multifunctional pesticide spraying cart is high in spraying efficiency, and capable of moving conveniently, saving energy, protecting the environment and effectively spraying pesticide to crops different in plant heights.

Owner:苏州多贝机械科技有限公司

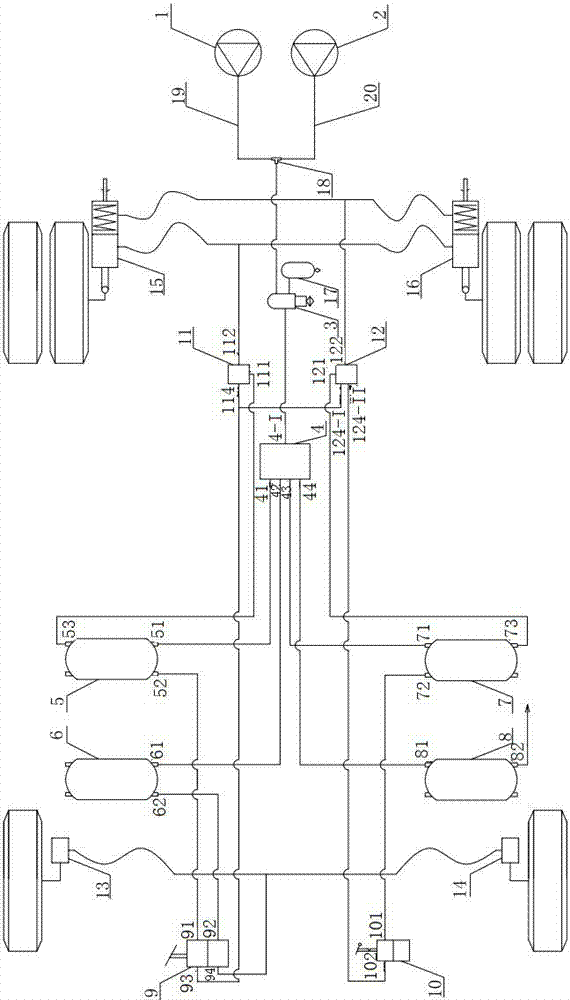

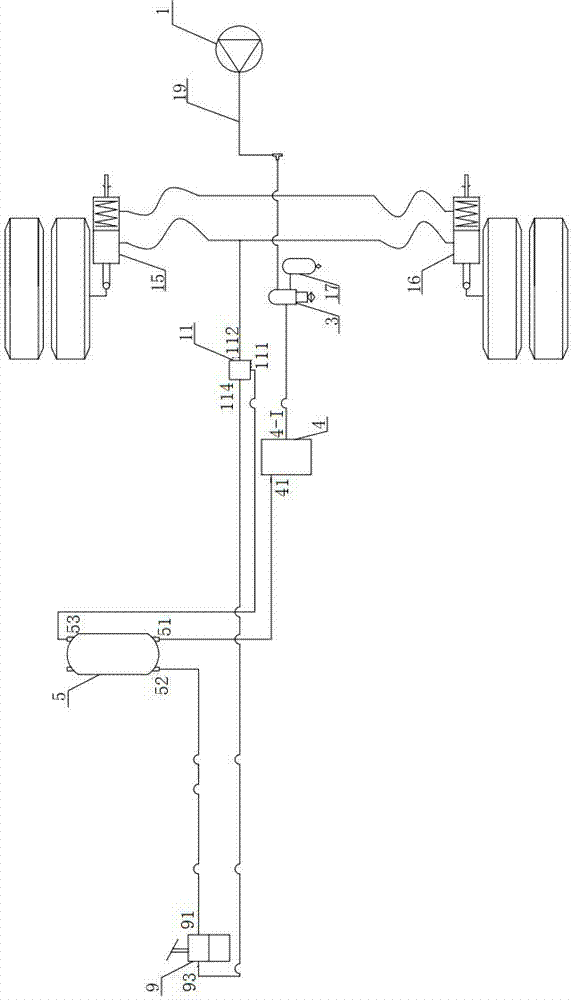

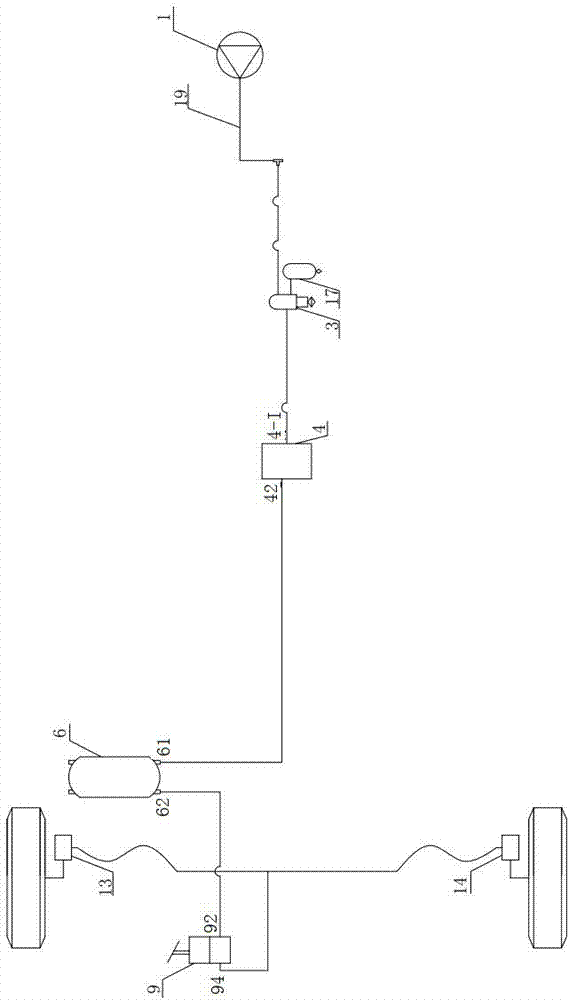

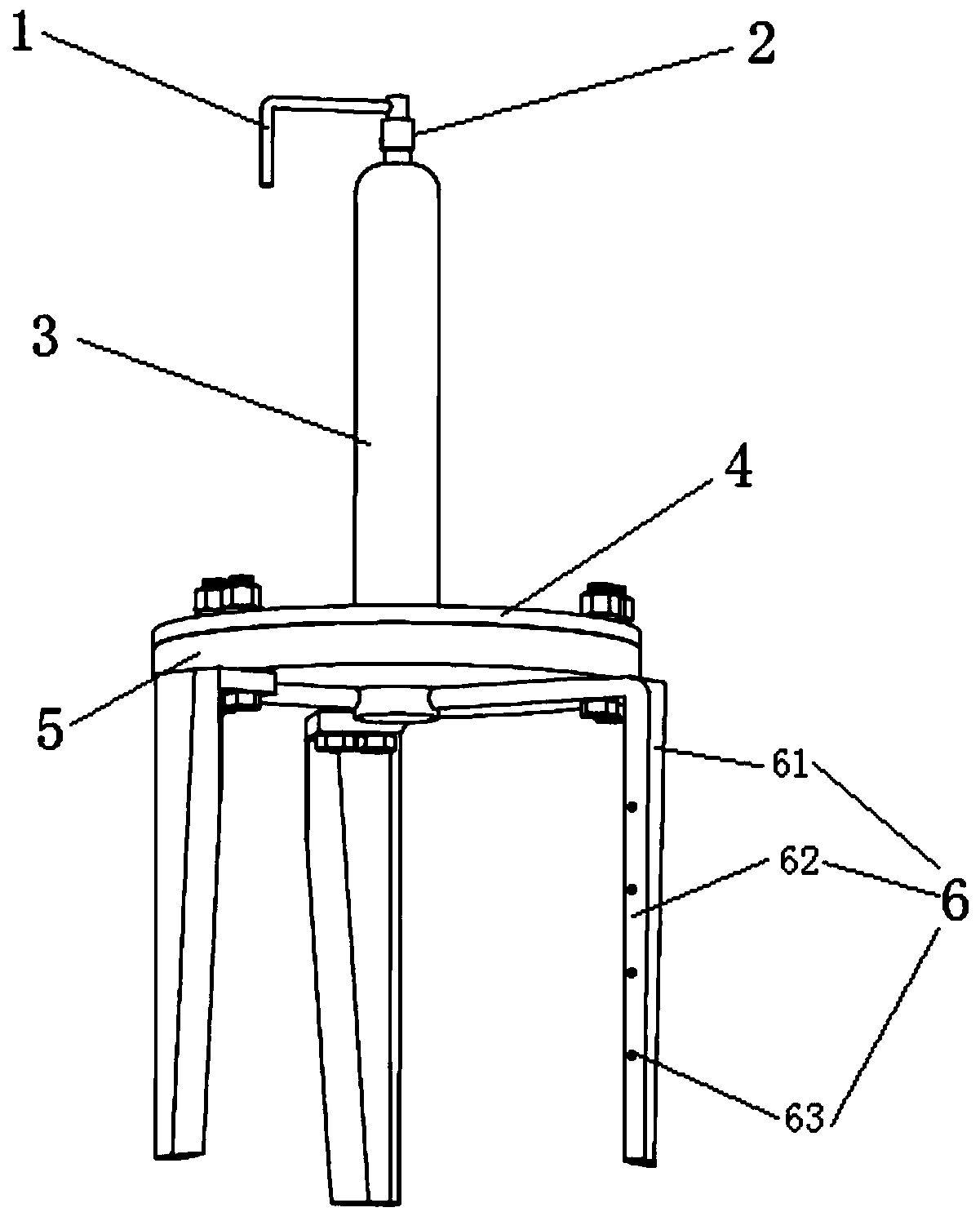

Hybrid power bus braking system

InactiveCN104842986AGuaranteed stabilityEnsure the safety of people and vehiclesBraking action transmissionApplication and release valvesCircuit protectionRelay valve

The invention relates to a hybrid power bus braking system. The hybrid power bus braking system comprises an engine inflating pump, an electric inflating pump, a bi-pass one-way valve, a four-circuit protection valve, a relay valve, a differential relay valve, a left front-axle air chamber, a right front-axle air chamber, a left rear-axle air chamber, a right rear-axle air chamber, a main foot braking valve, a hand braking valve, a front braking air reservoir, a rear braking air reservoir, a hand braking air reservoir, an auxiliary air reservoir, a regenerative air reservoir and a dryer. According to the technical scheme, the hybrid power bus braking system has the advantages that since two kinds of braking air sources provided by the conventional inflating pump and the electric inflating pump are designed in a full vehicle, stable full-vehicle baking performance can be guaranteed, and the requirements on energy conservation and environment protection can be met.

Owner:ANHUI ANKAI AUTOMOBILE

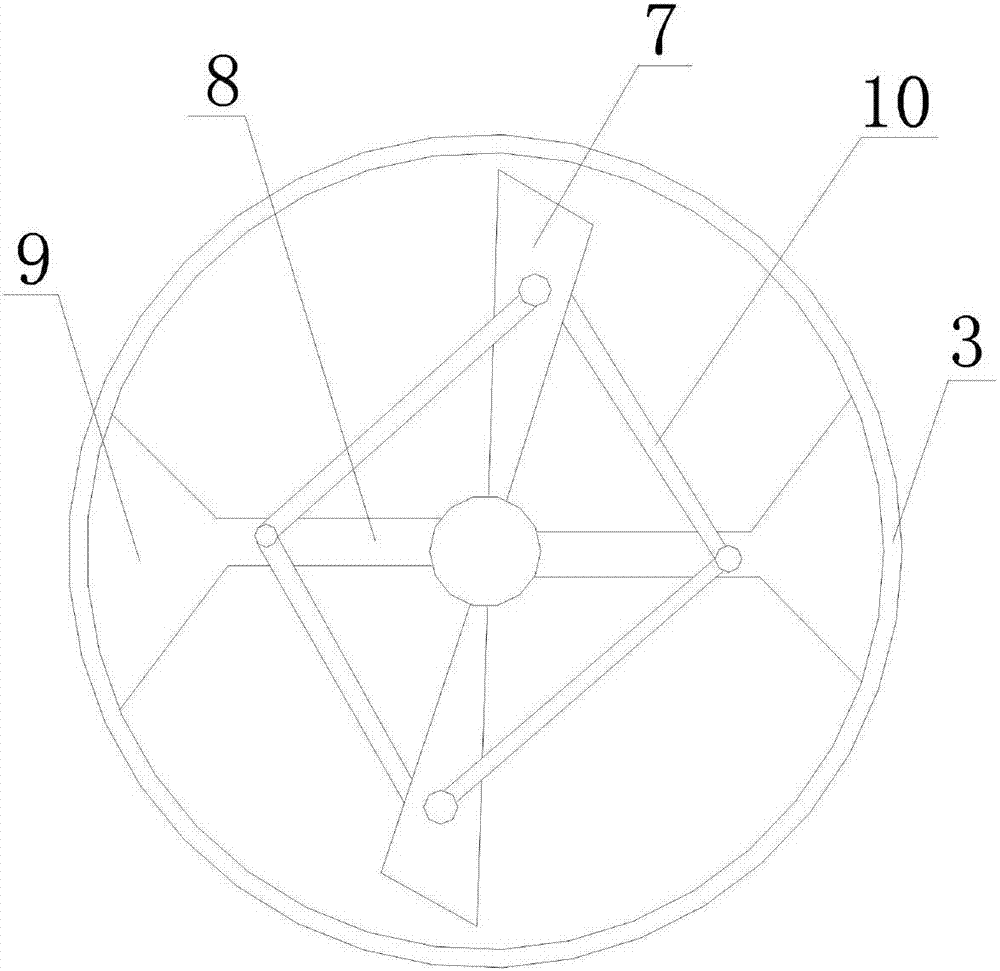

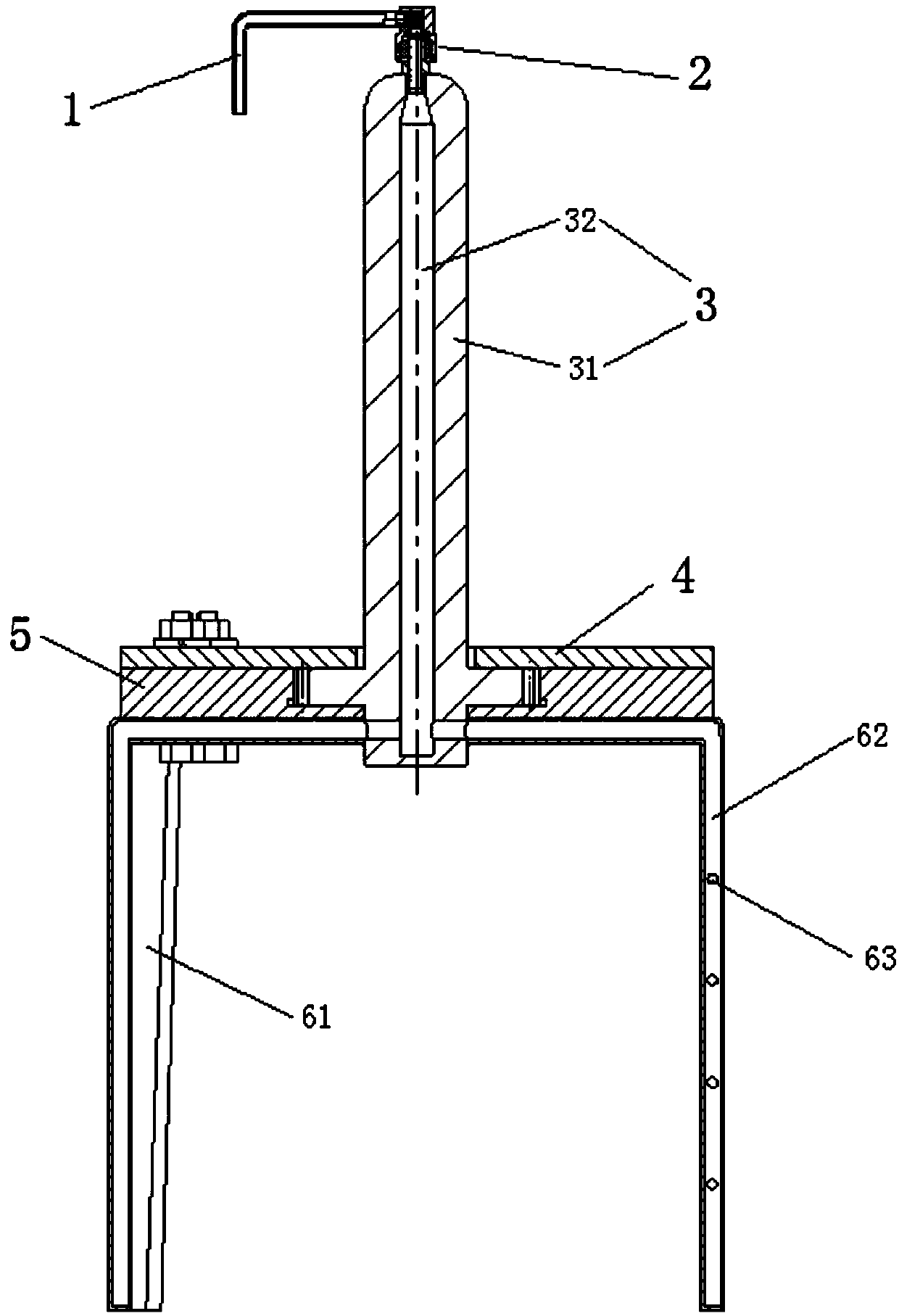

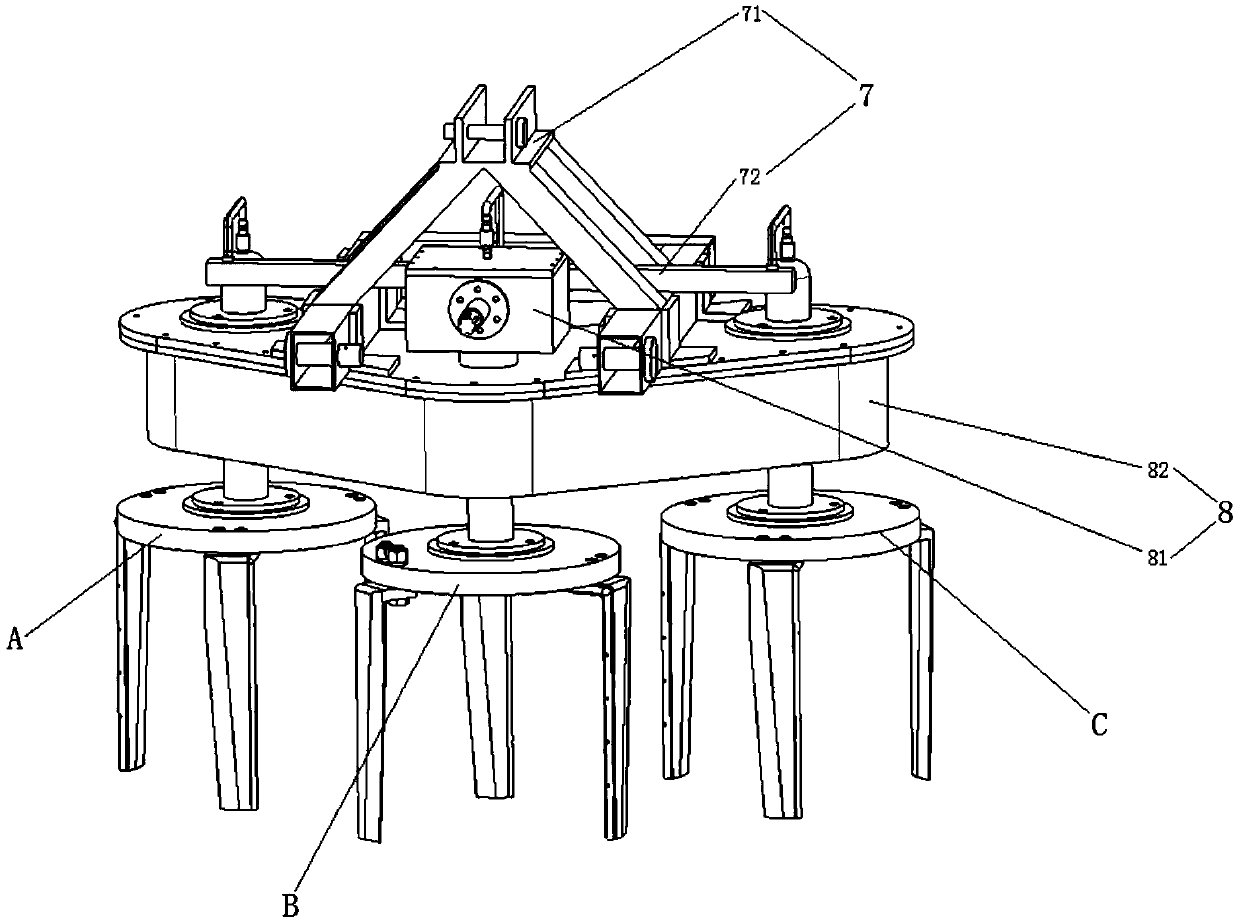

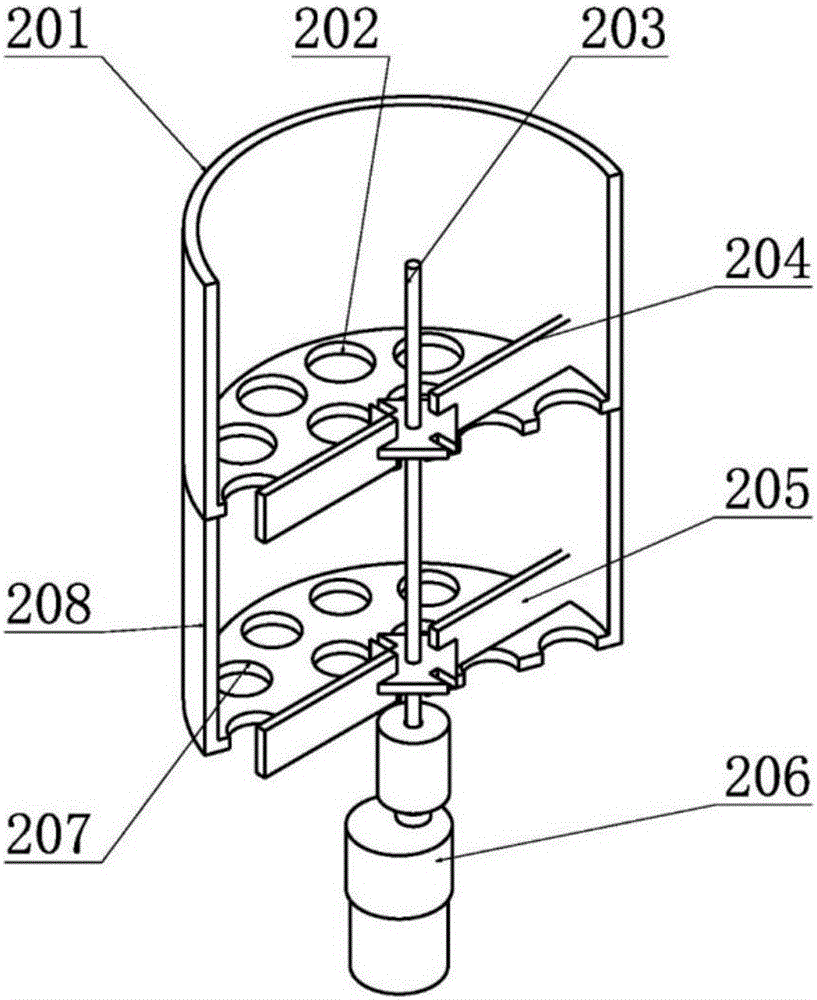

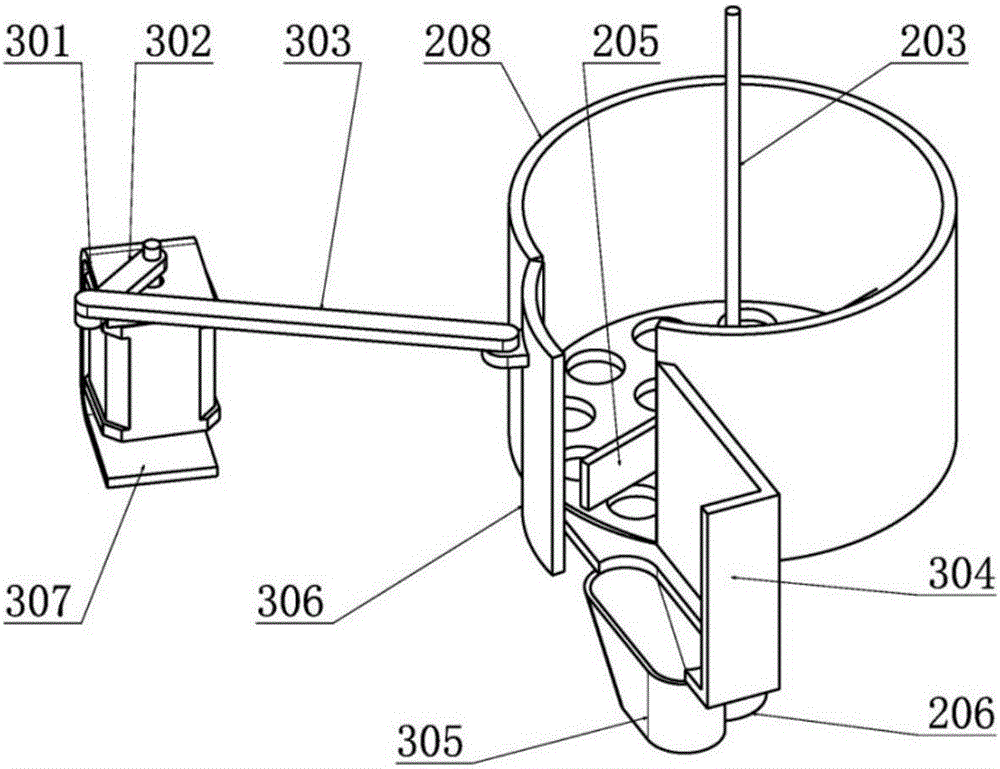

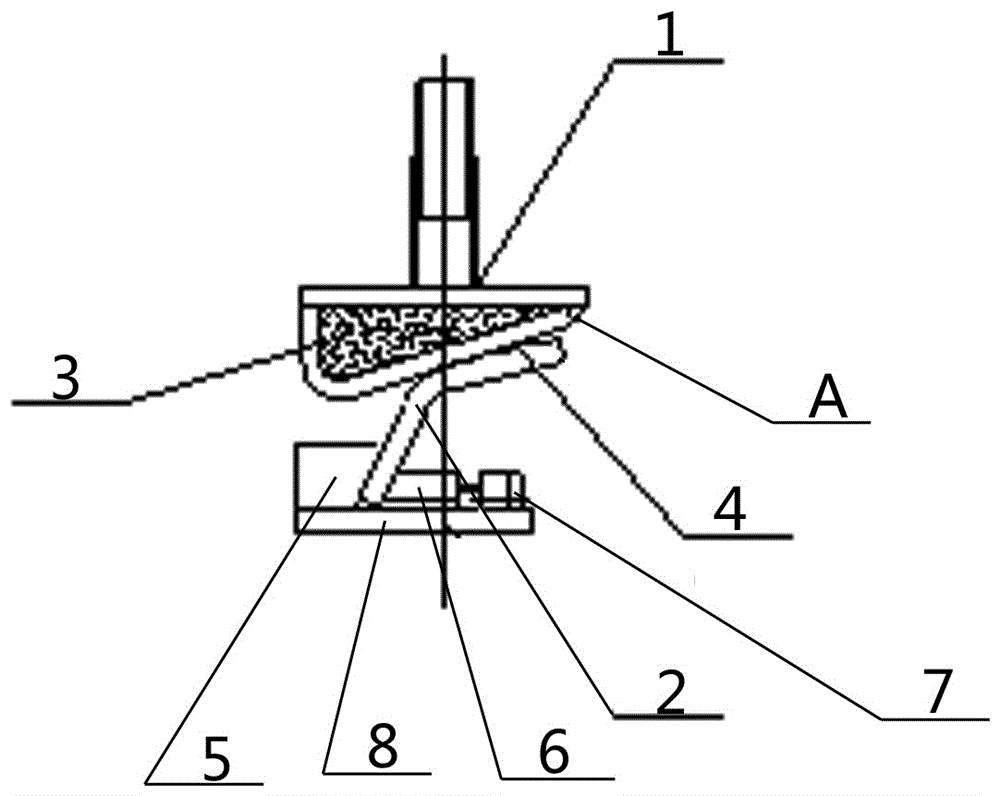

Steam sterilizing rotary blade component and vertical spindle type steam sterilizing processor

InactiveCN109618574AHeating evenlyGuarantee the quality of insecticide and sterilizationSpadesSteam soil sterilisationDiseaseAgricultural engineering

The invention discloses a steam sterilizing rotary blade component and a vertical spindle type steam sterilizing processor. The steam sterilizing rotary blade component comprises a ventilating rotaryshaft, a tool disc is fixedly arranged on the ventilating rotary shaft, and at least one tool bit is arranged on the tool disc. A steam guide-in part is arranged at the position, away from a blade, ofthe tool bit, and a ventilating channel is arranged in the ventilating rotary shaft. The steam guide-in part is communicated with the ventilating channel. External high-temperature steam passes through a steam main pipe and a steel wire hole to be exhausted by the steam guide-in part and soil is heated. The steam sterilizing rotary blade component is a mechanical innovation of soil sterilization,steam sterilization is completed while rotary tillage and soil smashing are achieved, the soil can be evenly heated by the processor, the killing efficiency on soil diseases, insect pests and weeds is improved, and energy saving and environmental protection are achieved.

Owner:NORTHWEST A & F UNIV

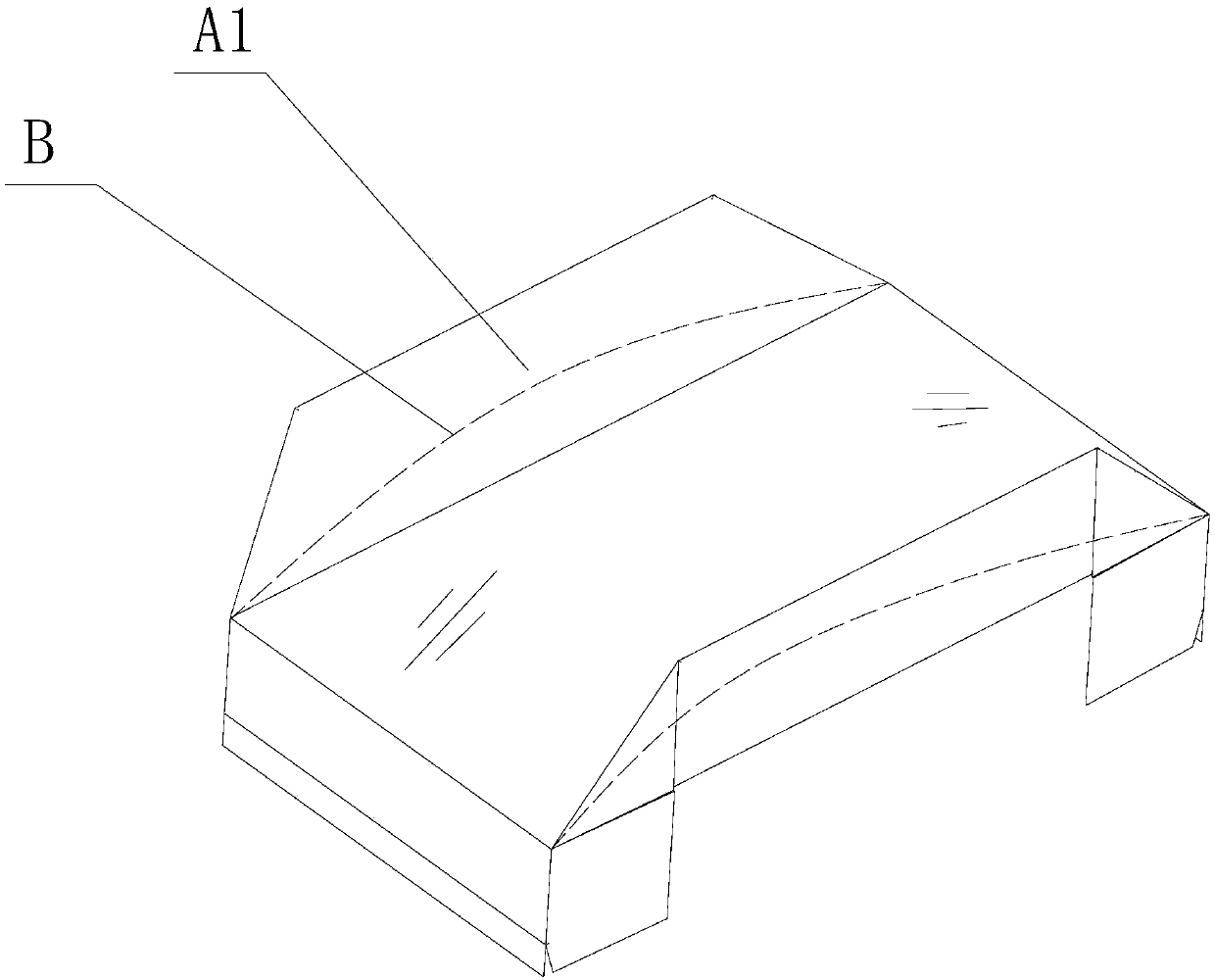

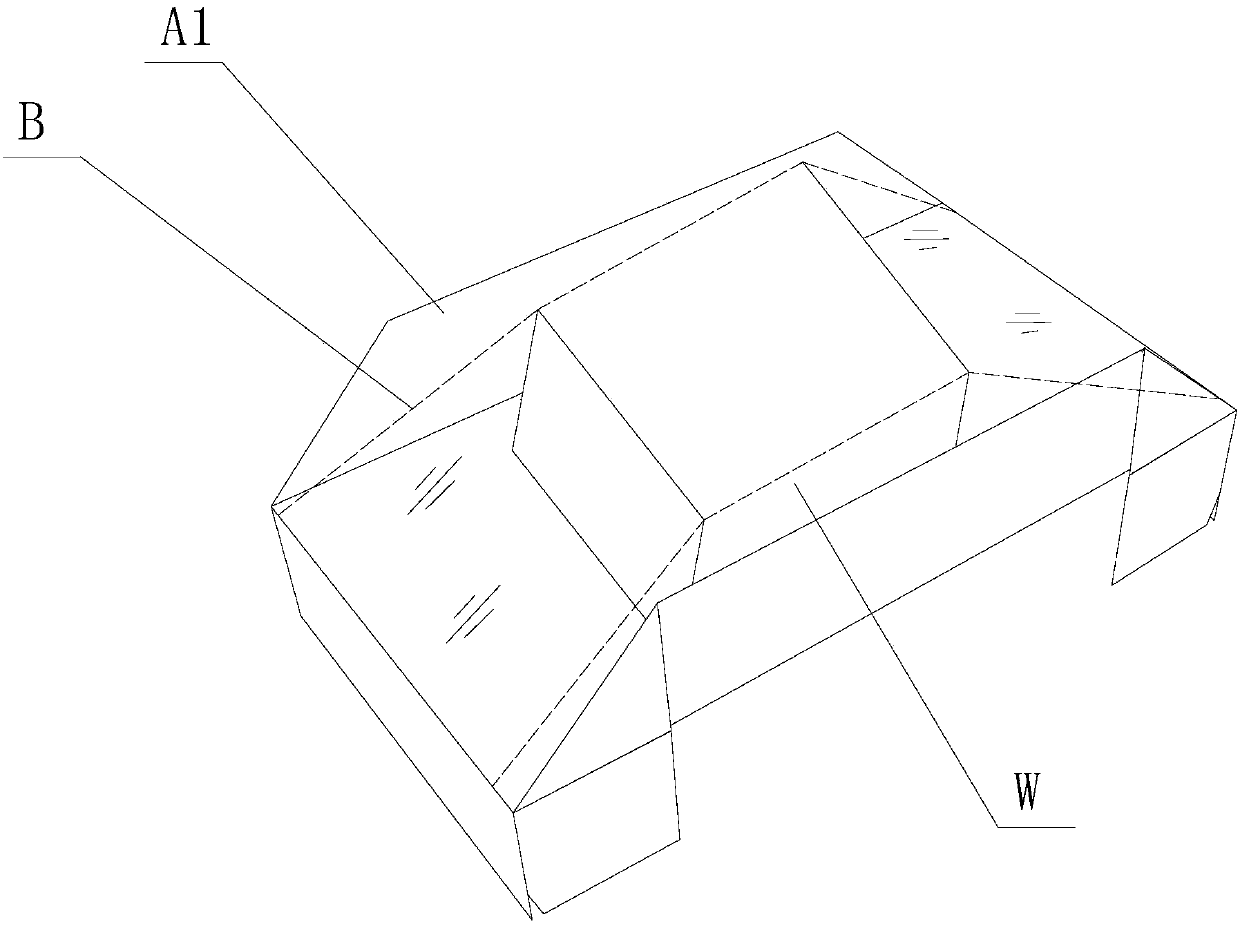

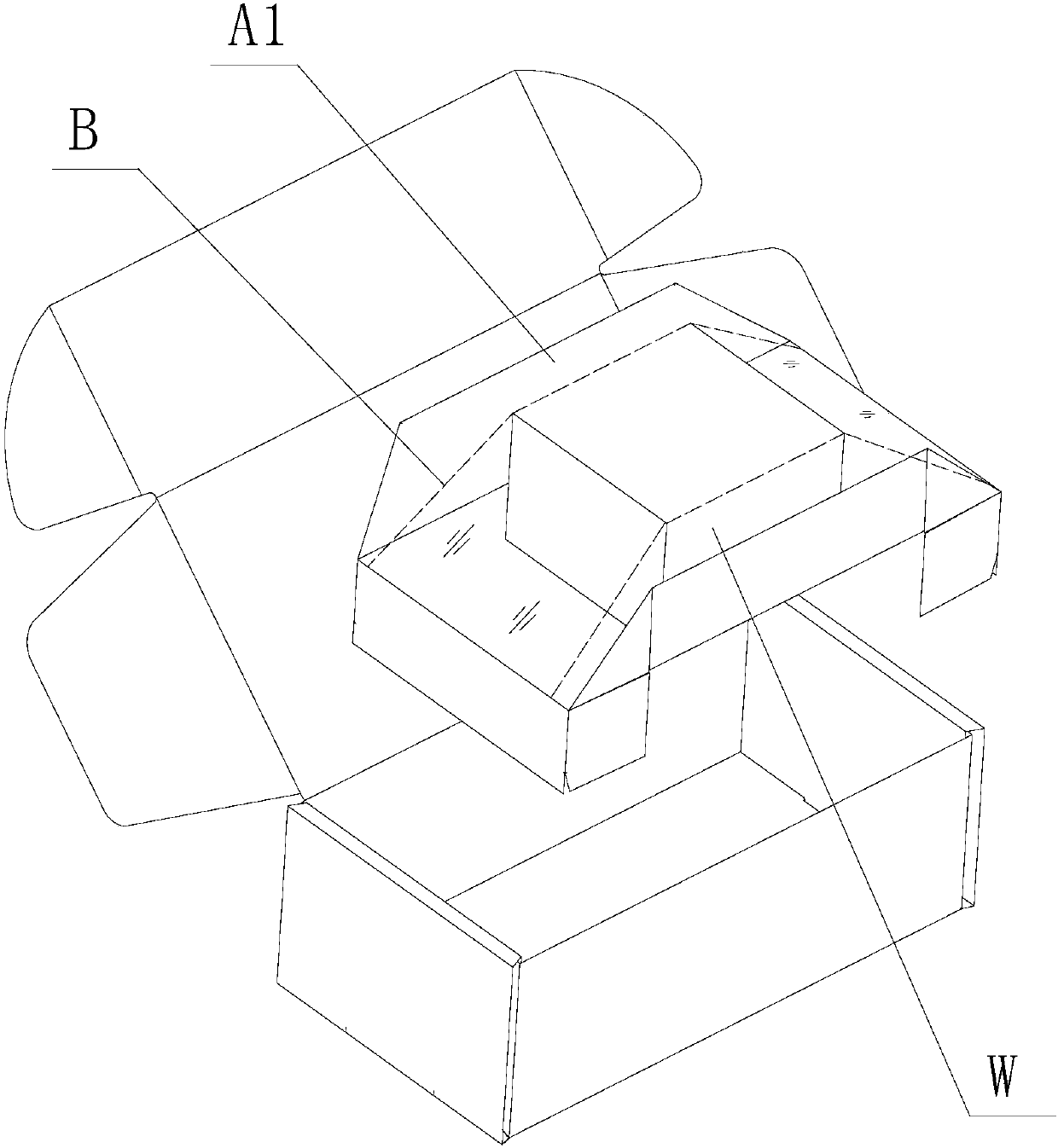

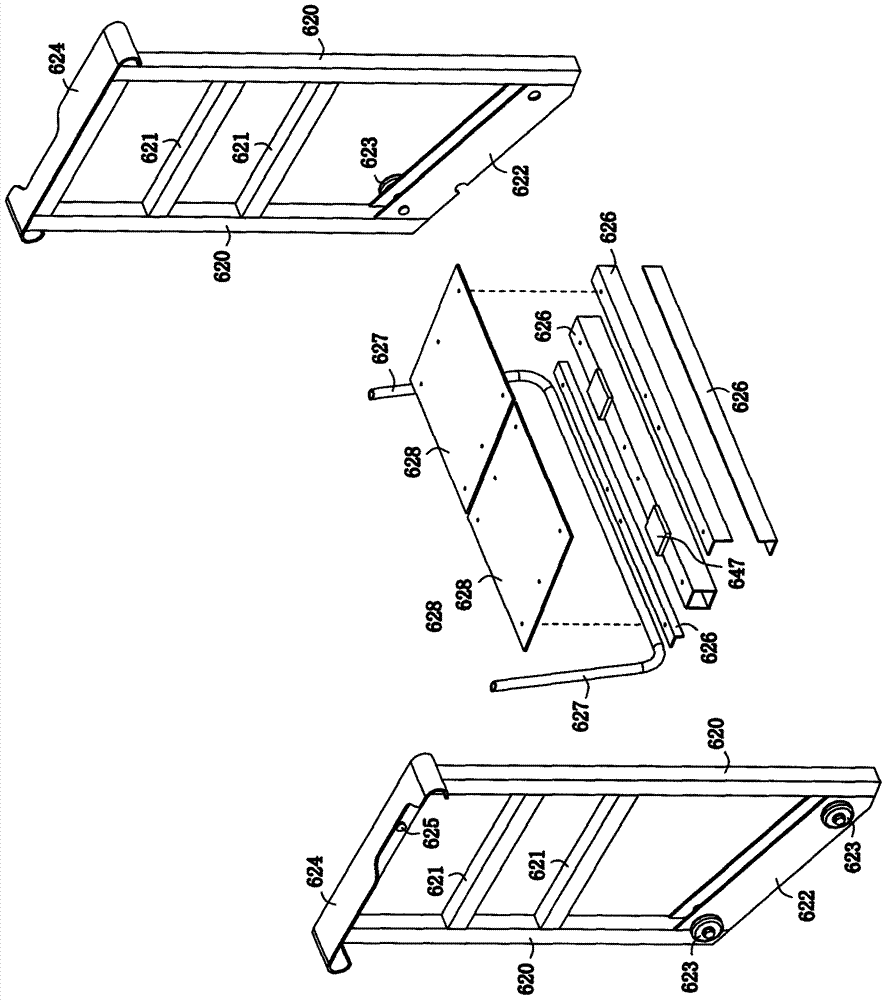

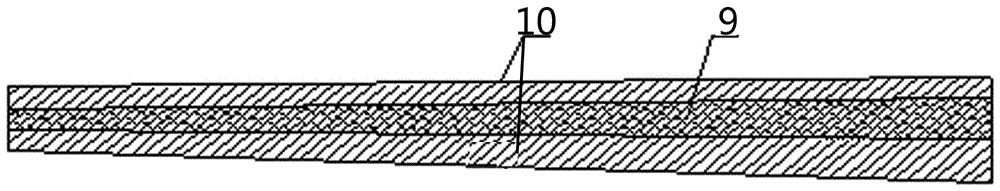

Suspended fastening packaging device and manufacturing method

PendingCN107934204ASimple structureEasy to fixContainers to prevent mechanical damageRigid containersPaperboardThin membrane

The invention discloses a suspended fastening packaging device and a manufacturing method. The suspended fastening packaging device comprises a papery suspended support body (A1) and films (B), wherein the papery suspended support body (A1) is a papery structural member, and the papery suspended support body (A1) comprises a papery supporting plane located in the middle, two side surfaces and foursupporting surfaces. The manufacturing method of the suspended fastening packaging device comprises the following steps that 1, a paperboard (A) is manufactured into the papery suspended support body(A1) according to preset folding concave marks, a corresponding folding mode and sequence; 2, the films (B) are fastened on the two sides of the papery suspended support body (A1), so that the suspended fastening packaging device is formed; and 3, an object W is fixed in the space between the lower surfaces of the films (B) and the top surface of the papery suspended support body (A1). The suspended fastening packaging device and the manufacturing method have the advantages of being scientific, reasonable, stable and reliable in supporting structure, convenient and fast to manufacture, and energy-saving and environment-friendly.

Owner:XIAMEN AMESON NEW MATERIAL INC

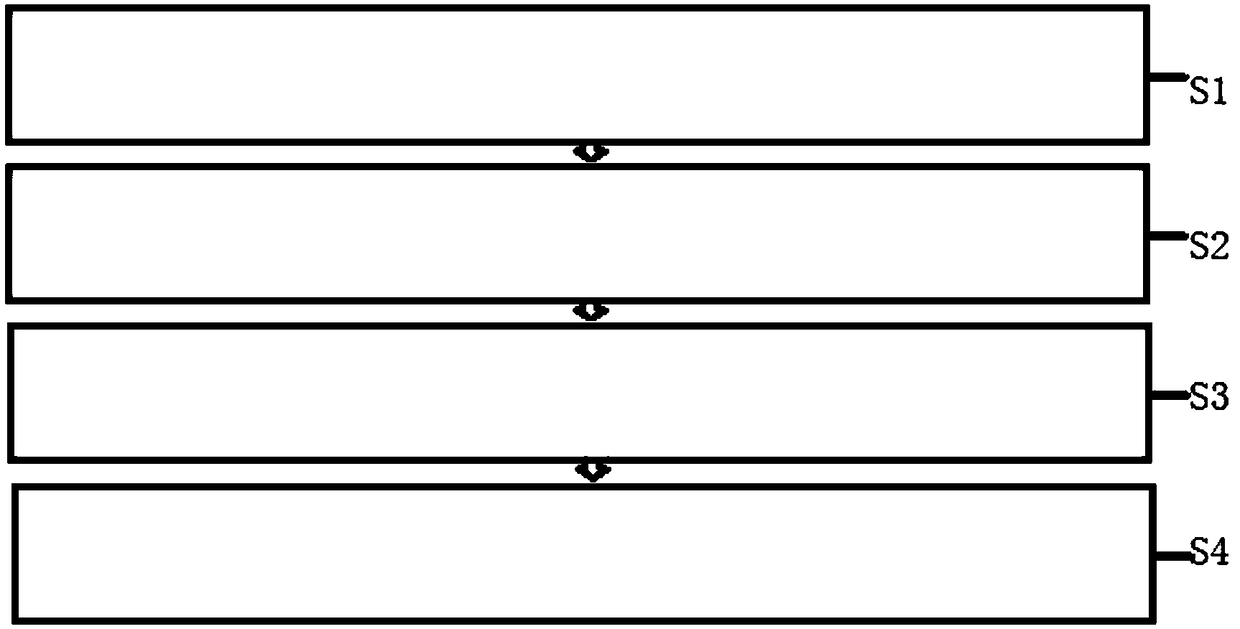

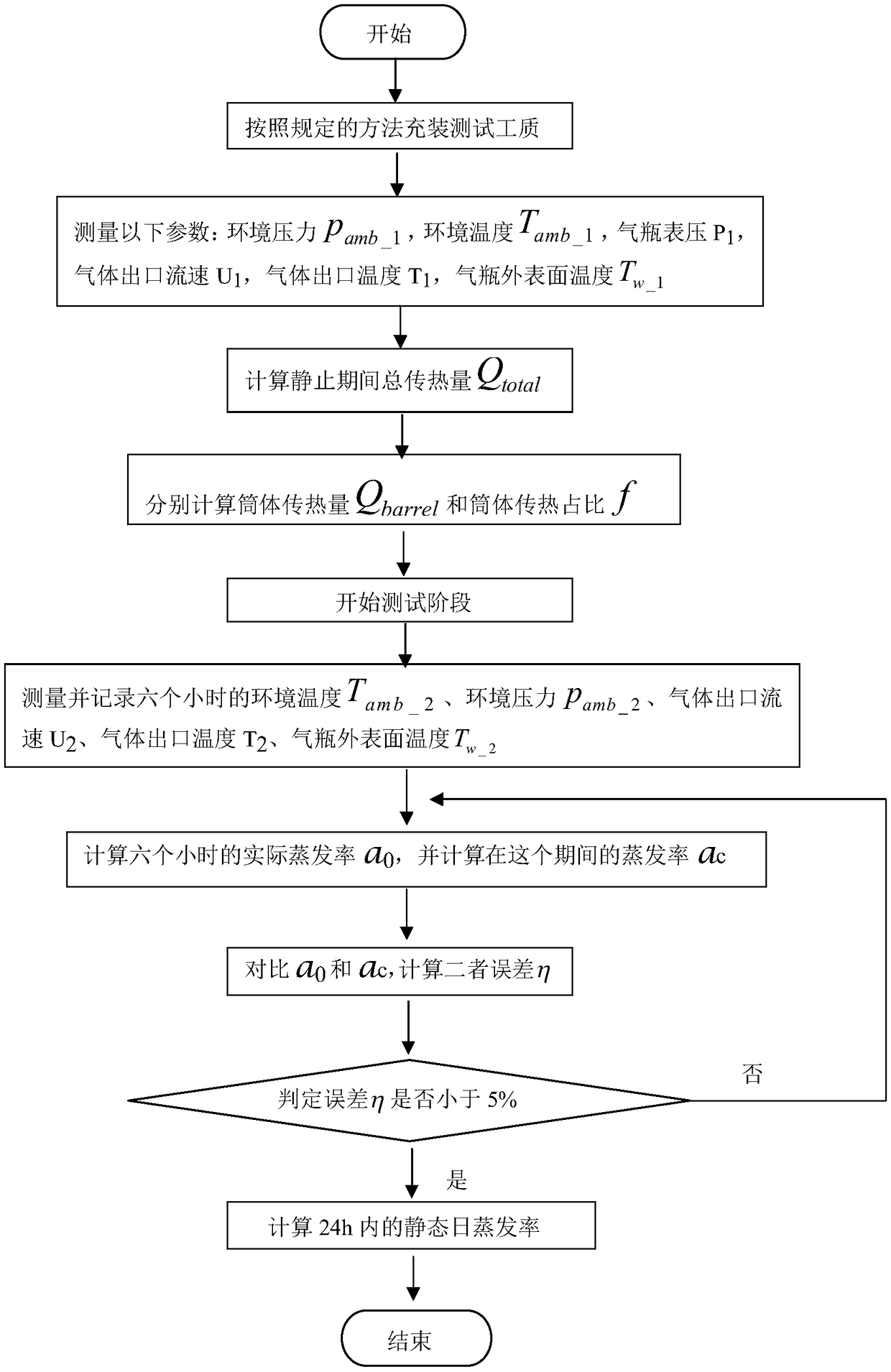

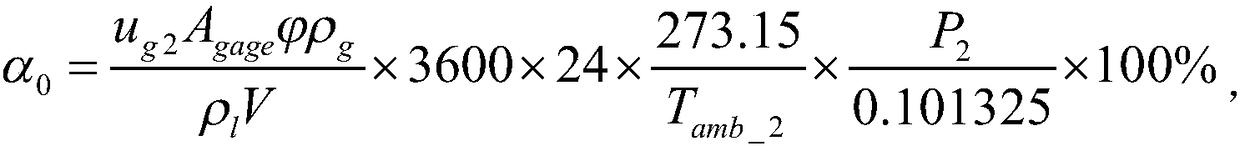

Method for detecting evaporation rate of low-temperature insulation gas cylinder

ActiveCN109458558AShortenImprove accuracyContainer filling methodsFluid handling accessoriesGas cylinderEngineering

The invention discloses a method for detecting the evaporation rate of a low-temperature insulation gas cylinder. The method comprises the following steps that after the low-temperature heat insulation gas cylinder is filled, the deflation valve is kept to be opened, other valves are closed, the low-temperature heat insulation gas cylinder is placed in the first stage, the total leakage heat Qtotal of the low-temperature heat insulation gas cylinder at the first stage and a cylinder body leakage heat Qbarrel are obtained and the ratio f of the cylinder body leakage heat in the total leakage heat is calculated and is equal to Qtotal / Qbarrel, the low-temperature heat insulation gas cylinder enters the second stage of the test, the actual evaporation rate alpha0 is calculated(the equation ofalpha0 is described in the specification), and the calculation evaporation rate alpha c of the low-temperature heat-insulation hot gas cylinder in the second stage is obtained(the equation of alpha cis described in the specification). Comparing and calculating the relative error Eta between the evaporation rate alpha c and the actual evaporation rate alpha 0(the equation of Eta is described in the specification), if the error value is within 5%, and the calculation evaporation rate alpha c is considered to be reliable.

Owner:广东省特种设备检测研究院东莞检测院 +1

Efficient paint spraying device for bamboo and wood product production and process

InactiveCN110369194AImprove painting efficiencyShorten the timeSpraying apparatusEngineeringMachining

The invention discloses an efficient paint spraying device for bamboo and wood product production, and relates to the technical field of machining of bamboo and wood products. A bottom plate and top boxes are included; the two top boxes are arranged; the front sides and the back sides of the bottoms of the top boxes are each fixedly connected with a supporting plate, and the bottoms of the supporting plates are fixedly connected with the top of the bottom plate; the back sides of the inner walls of the two top boxes are each fixedly connected with a first motor; one end of an output shaft of each first motor is fixedly connected a first threaded rod, and the end, away from the corresponding first motor, of each first threaded rod is rotationally connected with the front side of the inner wall of the corresponding top box; and a first slider is in threaded connection with the surface of each first threaded rod. According to the efficient paint spraying device for bamboo and wood productproduction and the process, machines replace manual work, the overall paint spraying efficiency can be improved, lots of time and vigor are saved, adaption to large-batch producing and machining is achieved, paint without being sprayed onto the bamboo and wood products is recycled and reutilized, resources are reasonably utilized, and the purpose of saving energy and protecting the environment isachieved.

Owner:ANHUI SHUCHENG HUAZHU IND

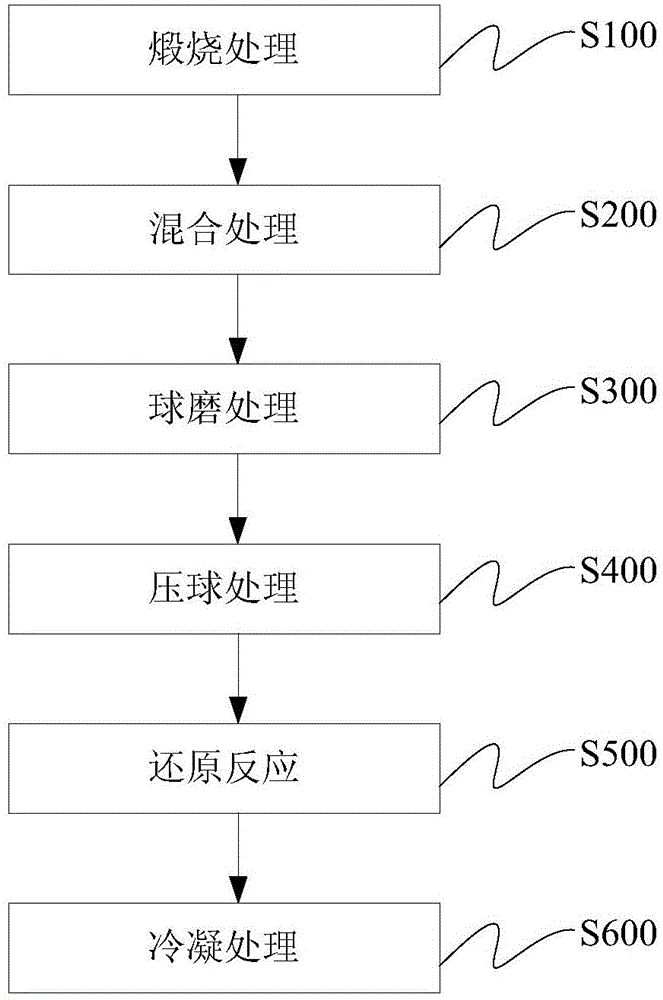

Method for preparing magnesium

The invention discloses a method for preparing magnesium. The method comprises the following steps: calcining dolomite in a rotary kiln to obtain calcined dolomite and tail gas; mixing the calcined dolomite with ferrosilicon and fluorite to obtain a mixture; performing ball-milling on the mixture to obtain a granular mixture; briquetting the granular mixture to obtain pelletized materials; arranging the pelletized materials into a feeding region in a rotary hearth furnace, gradually heating the pelletized materials in the feeding region in a preheating region and a heating region, and performing reduction reaction on the pelletized materials in a high-temperature region to obtain magnesium steam, flue gas and furnace slag; condensing the magnesium steam to obtain magnesium. The method disclosed by the embodiment of the invention is simple in process and low in energy consumption; the reduction reaction is carried out by adopting the rotary hearth furnace, so that magnesium can be continuously produced, the yield is increased, and efficient production of magnesium can be carried out.

Owner:SHENWU TECH GRP CO LTD

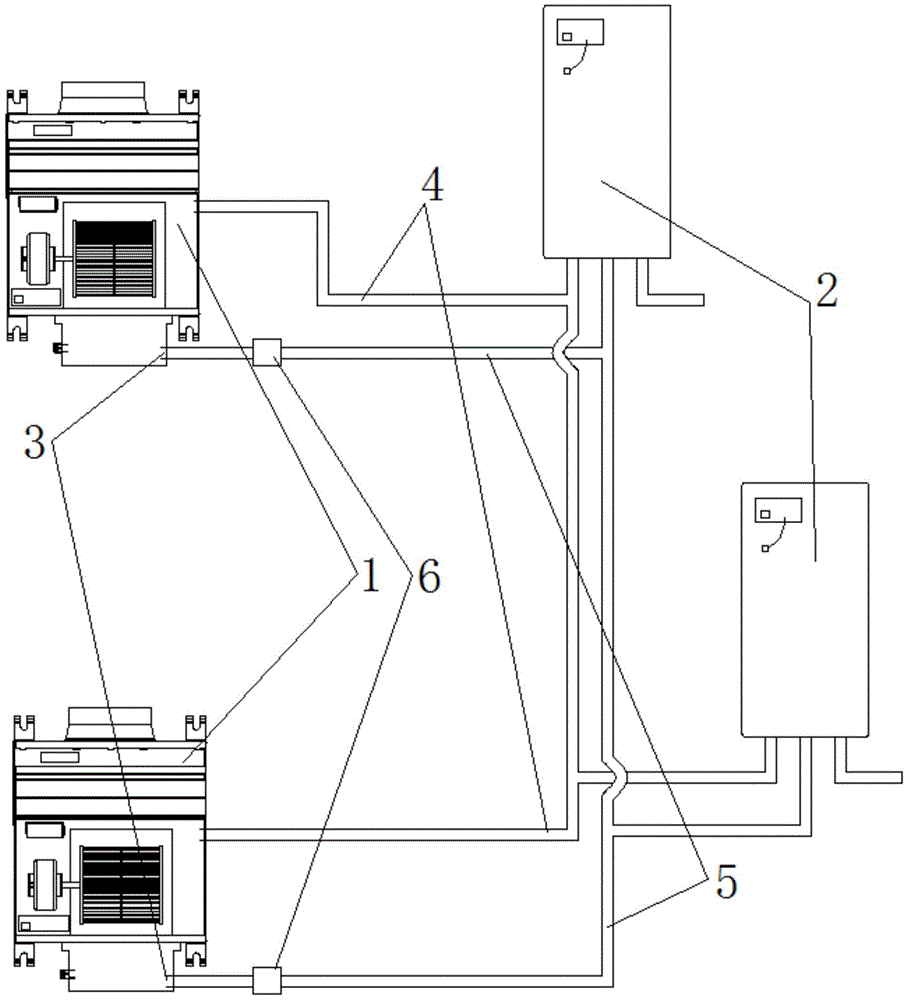

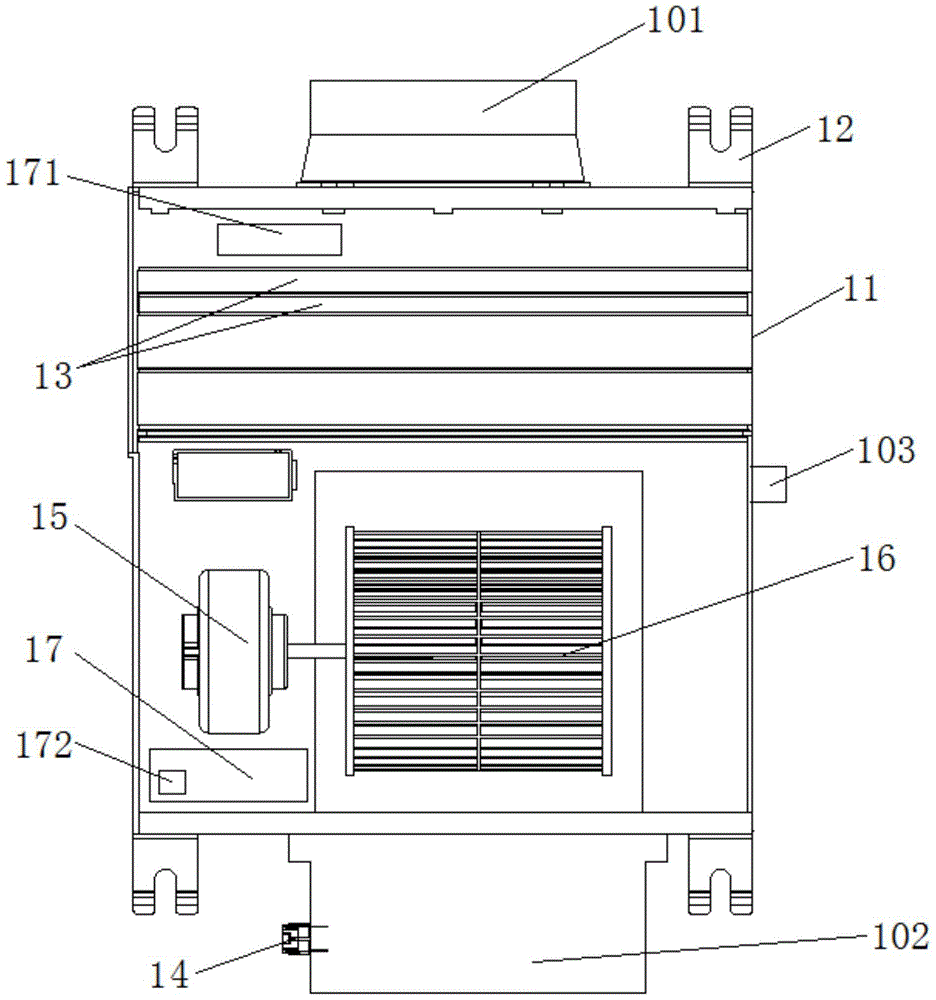

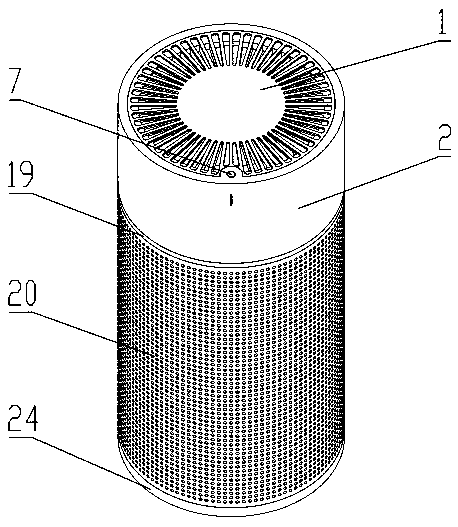

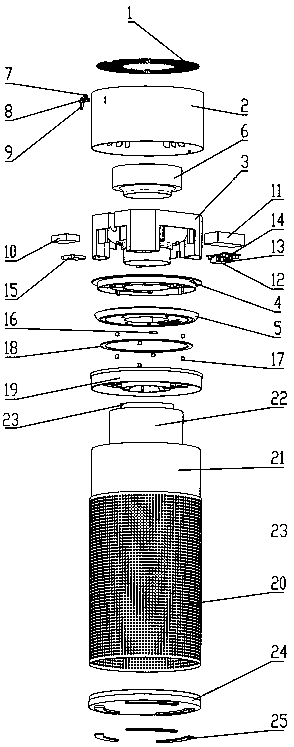

Indoor air quality optimizing system

InactiveCN105042731AIncrease oxygen contentSave resourcesMechanical apparatusSpace heating and ventilation safety systemsOxygenatorsOxygen supply

The invention relates to an indoor air quality optimizing system. The indoor air quality optimizing system comprises one or more air purification devices used for filtering and purifying air and generating anions or plasma and one or more oxygenators. The indoor air quality optimizing system further comprises a first oxygen port used for conveying oxygen separated by the oxygenators to the indoor part. Each air purification device comprises a shell, an installing plate, a combined filtering module used for purifying and filtering air, an ion generator, a motor and blades. The oxygenators are provided with sensors used for detecting the pressure of oxygen in oxygen supply pipelines. The oxygenators are further provided with first control plates. The sensors are electrically connected with the first control plates. The air purification devices are provided with second control plates. One air purification device can be connected with and control one or more oxygenators. One oxygenator is connected with one or more air purification devices. The problems of fast oxygen consumption and the slow occasion oxygen supply are solved; meanwhile, the indoor air quality optimizing system can be installed in multiple rooms at the same time; and intelligent starting or stopping of the oxygenators is achieved during using, and the resource utilization rate is high.

Owner:深圳维安云联技术有限公司

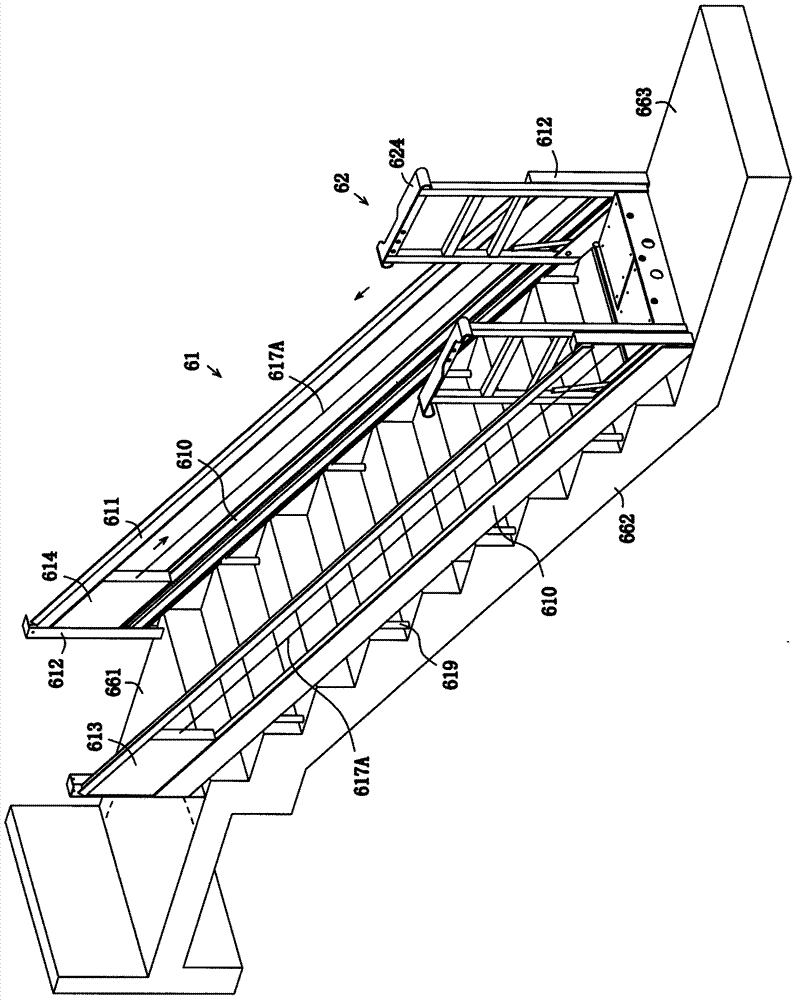

Corridor double escalator with balancing units

ActiveCN107352356AChange appearanceDoes not affect ventilation and lightingElevatorsBuilding liftsEngineeringElectromagnetic brake

The invention discloses a corridor double escalator with balancing units, and relates to an elevating device. The escalator is arranged in a corridor, and is advantaged in that the escalator does not affect ventilation and natural lighting, operates safely and reliably, can keep the corridor unobstructed, and is simple and convenient to use, low in cost and short in construction period and the like. The corridor double escalator comprises guide frames, main frames, the balancing units, a driving unit and safety protection units, the guide frames are symmetrically and fixedly arranged on walls at two sides of the corridor and are parallel to the slope of stairs, the main frames are movably arranged on the guide frames and move on the guide frames through the driving unit, the balancing units are arranged on the guide frames and are connected with the main frames through wire ropes and rope guide wheels, and the safety protection units are arranged on the main frames or the guide frames, and are connected with a controller and an electromagnetic brake. The corridor double escalator with the balancing units can be used as an escalator and also can be used as a staircase. By employing the corridor double escalator with the balancing units, conflict of residents on high and low floors can be alleviated, the elevator mounting problem which puzzles us for many years is solved, and the corridor double escalator can be widely applied to duplex apartments, small villas and urban and rural low-rise buildings.

Owner:张向阳

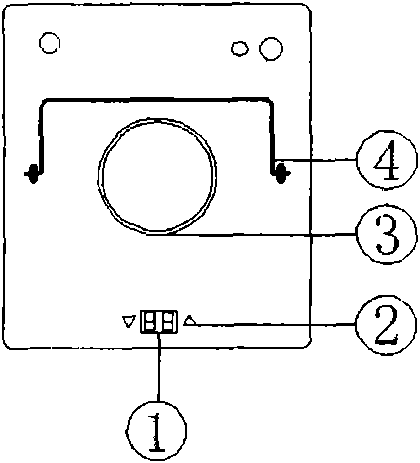

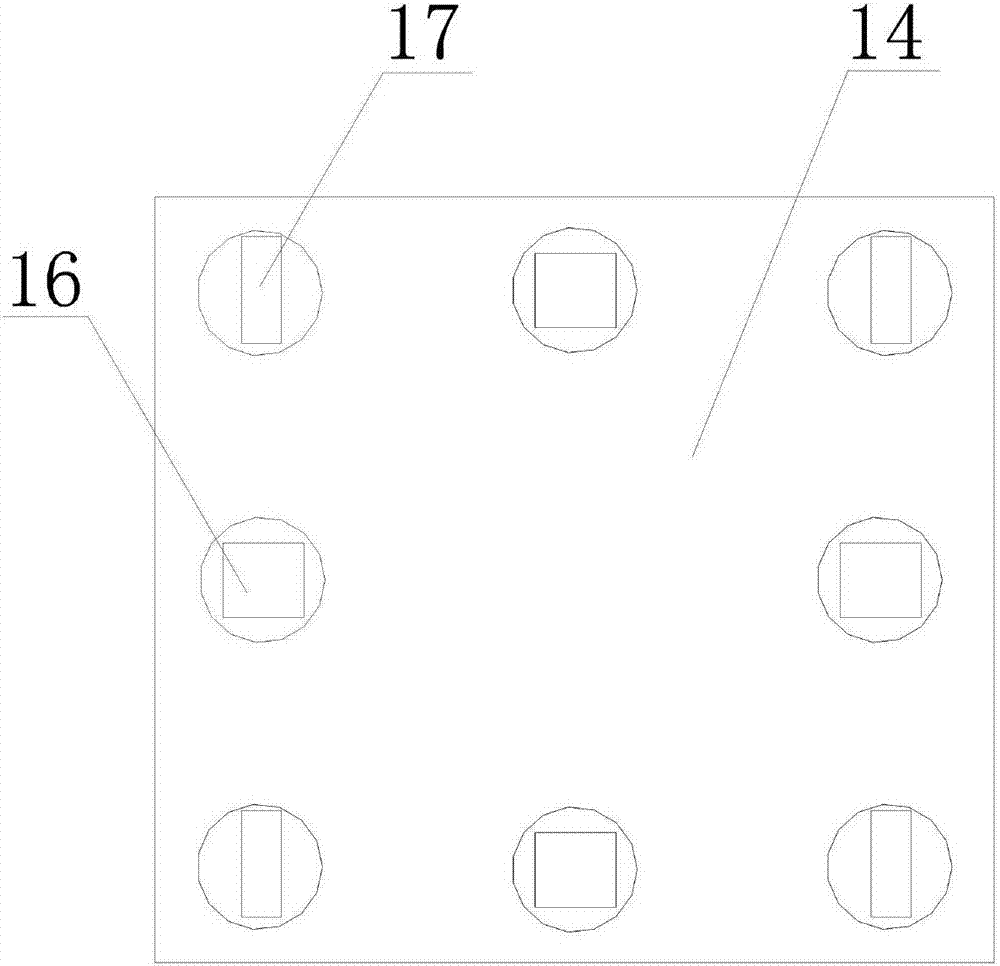

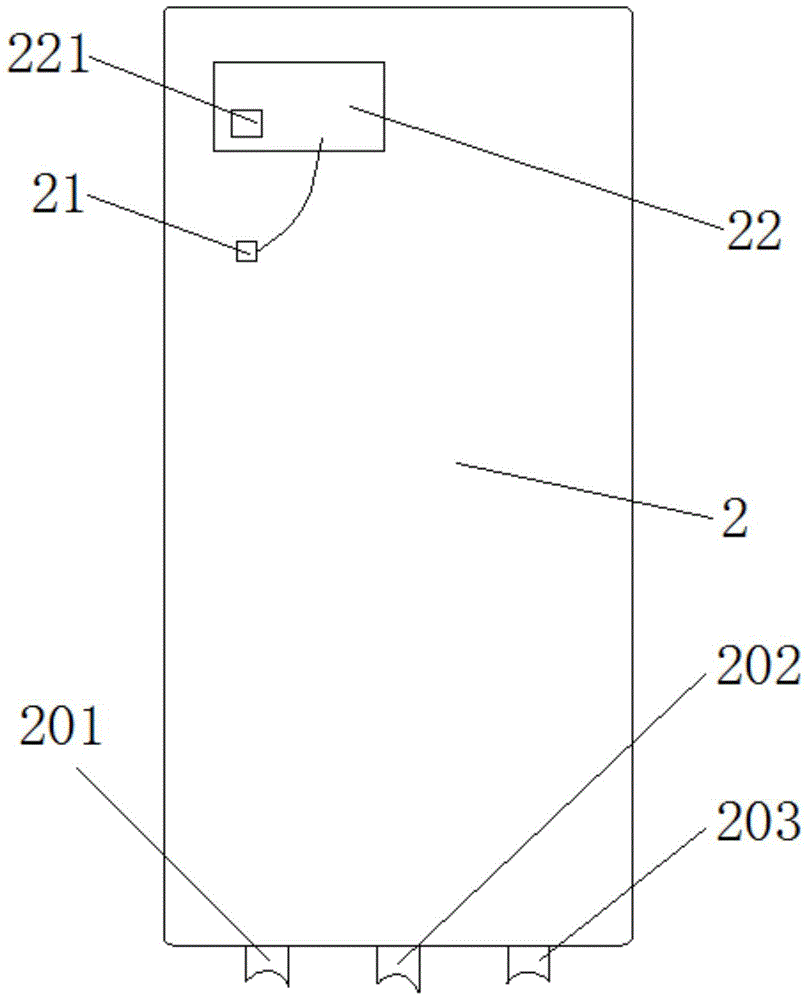

Split type air purification device

InactiveCN108800360AEasy to replaceSimple structural designMechanical apparatusLighting and heating apparatusPaperboardLaser detection

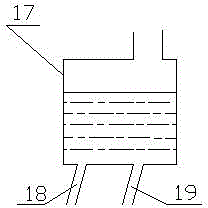

The invention relates to a split type air purification device which is formed by a control host and a purification filter element. The split type air purification device is characterized in that the control host comprises an air outlet (1), an outer shell (2), an air flue structure part (3), an air guide fixing part (4), an air inlet cover plate (5), a draught fan (6), a key cap (7), a key plate (8), a light guide column (9), a main control panel (10), a power panel (11), a PM2.5 laser detection sensor (12), a TVOC sensor (13), a sensor fixing support (14), a WIFI communication module (15), amagnetically controlled switch (16), magnets (17) and a sealing rubber ring (18); and the purification filter element comprises an upper filter element end cover (19), an outer filter element paperboard cover (20), HEPA filter paper (21), an activated carbon filter net (22), a metal liner net (23), a lower filter element end cover (24) and a bottom rubber pad (25). The split type air purificationdevice is simple and reasonable in structure, consumables are easily replaced, the area of the filter element is large, the effect is obvious, meanwhile a novel degradable material is adopted for thepurification filter element, the cost can be reduced, and the purposes of energy conservation and environmental can be realized.

Owner:QINGDAO DAOYIKONGYOU TECH

Bauxite sintering furnace dust-removing purification device

InactiveCN101612519AEmission reductionNo dischargeUsing liquid separation agentIncreasing energy efficiencyCoesiteHigh pressure

The invention discloses a bauxite sintering furnace dust-removing purification device. Smoke dust generated in the bauxite sintering process is intensively delivered into a spraying temperature-reducing dust remover to reduce temperature and remove dust so as to complete primary temperature-reducing and dust-removing process; the smoke dust processed with temperature reduction and dust removal is led into a lime water smoke dust filtering tank by a high-pressure blower to be atomized and purified by lime water so as to complete the second-time purification processing of the smoke dust; the smoke dust processed with secondary purification is led into an atomizing and purifying neutralization reaction tank, and a right amount of purification processing media are added into atomized water inside a main spraying system of the atomizing and purifying neutralization reaction tank to subject to neutralization reaction with harmful gases contained in the smoke dust so as to complete the third-time dust-removing and purification processing of the smoke dust, thereby the invention realizes the discharge of burnt gas reaching the standard, reduces the discharge amount of carbon dioxide and has no harmful gas discharged into air so as to achieve the purpose of energy saving and environmental protection.

Owner:史献争

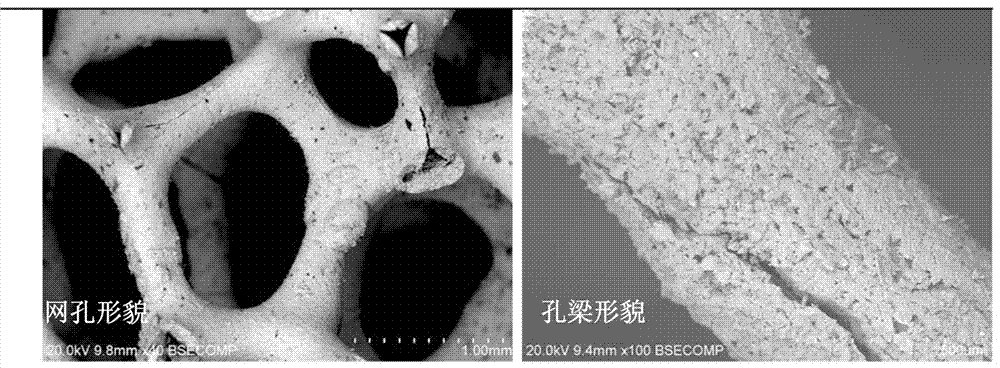

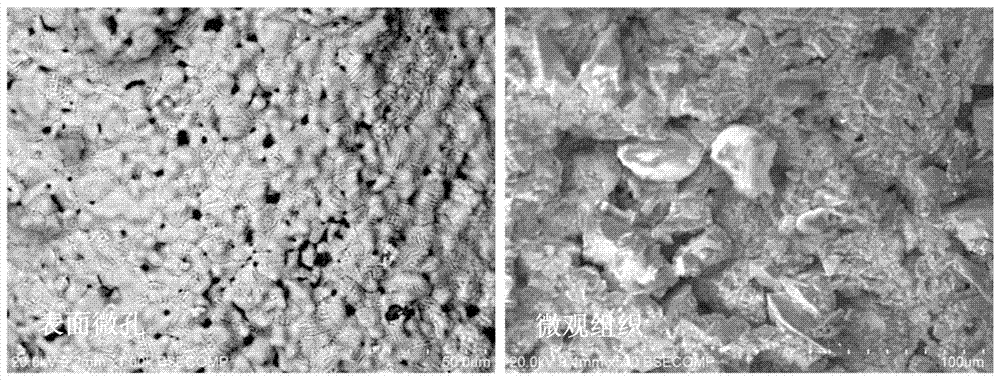

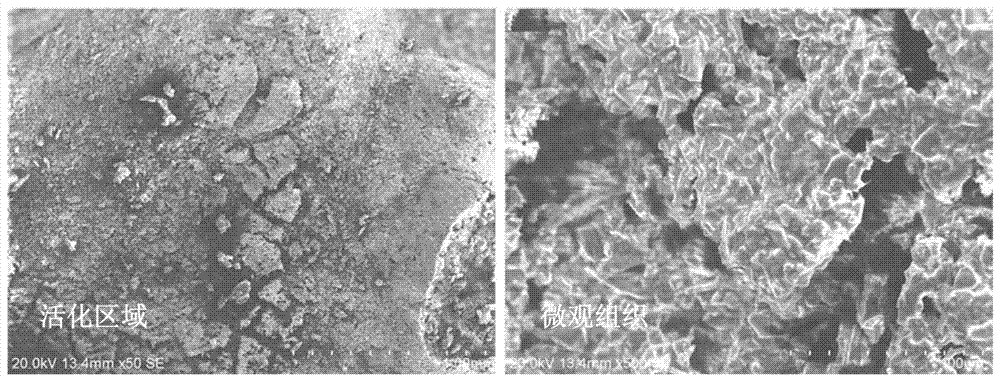

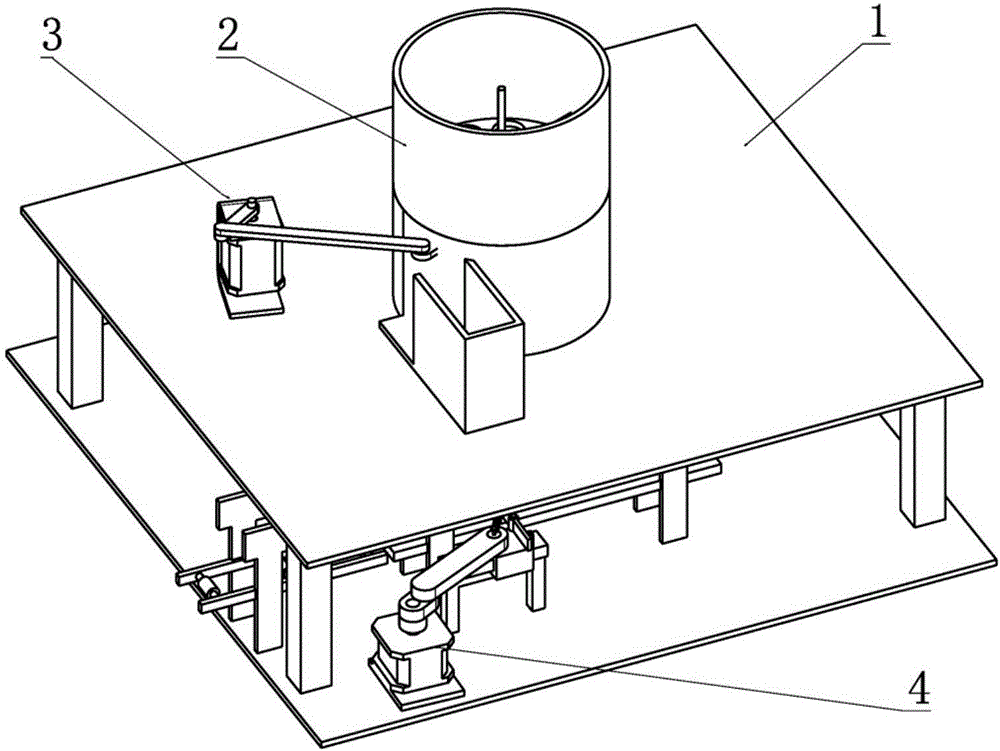

Nanometer mercury material with lasting adsorption performance

ActiveCN107159088AGuaranteed coverageGuaranteed adsorption effectGas treatmentOther chemical processesSulfate radicalsLow-temperature thermal desorption

The invention relates to the field of environment purification and protection, in particular to a nanometer mercury material with lasting adsorption performance. Firstly, a composite aluminum oxide ceramic material is prepared by an organic foam dipping process to serve as a carrier; secondly, an activator is loaded on the surface of the carrier and in a micro pore of the carrier by an immersion method, wherein the coverage area of the activator is 85 percent or more, oxidization of chloride ions, sulfate radicals and nitrate ions in the activator to mercury is used to fix elemental mercury, silver and mercury are formed into amalgam to react and solubilize the elemental mercury, and the huge surface of porous ceramic is used to absorb valence state mercury; and finally, the mercury is reclaimed through a low-temperature thermal desorption method, and circular utilization of the carrier is realized. The material has performances of large surface area, strong permeability, high compression strength, impact resistance, high temperature resistance, environmental friendliness, high chemical stability and the like, the carrier can be circularly used, mercury recovery is simple and feasible, and secondary pollution is not caused. Furthermore, a material preparation process is simple and low in cost. The nanometer mercury material has very good application potential and good social and economic benefits.

Owner:XUZHOU ZHENFENG NEW TYPE WALL MATERIAL CO LTD

Rotor sliding block-type coin sorting counting packaging machine

The invention discloses a rotor sliding block-type coin sorting counting packaging machine, which comprises a rack, a coin sorting device, a coin counting device and a coin finishing device, wherein the coin sorting device is arranged in the middle part of the rack; the coin counting device is arranged on the rack and is connected with the coin sorting device; the coin finishing device comprises a coin finishing support and a sliding block pushing mechanism, the sliding block pushing mechanism is arranged on the rack and is connected with the coin finishing support, the coin finishing support is connected with the coin sorting device via a coin gathering device, and the whole coin finishing device is arranged inside the rack. The sliding block-type coin cylinder pushing mechanism is adopted to be matched with a coin gathering cylinder supporting platform, thereby improving the accuracy and the efficiency of the coin finishing device; and coin packaging box and coin integrated transfer can be realized among a bus company, a supermarket and a bank with a large use amount, thereby saving the use of the packaging paper and realizing the energy-saving and environmental protection purposes.

Owner:NANNING UNIV

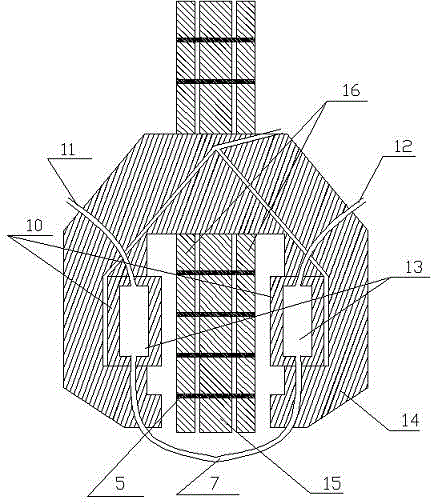

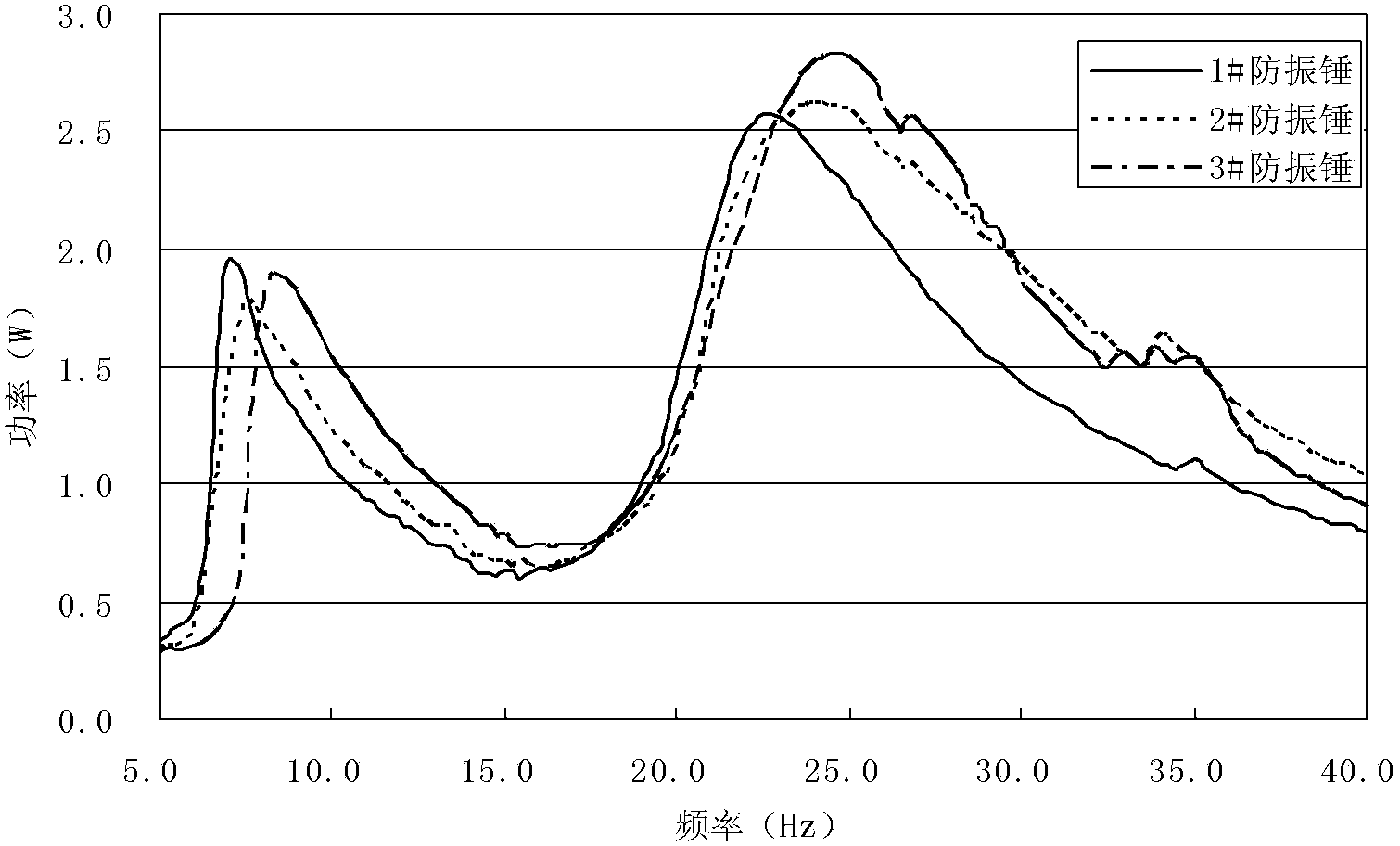

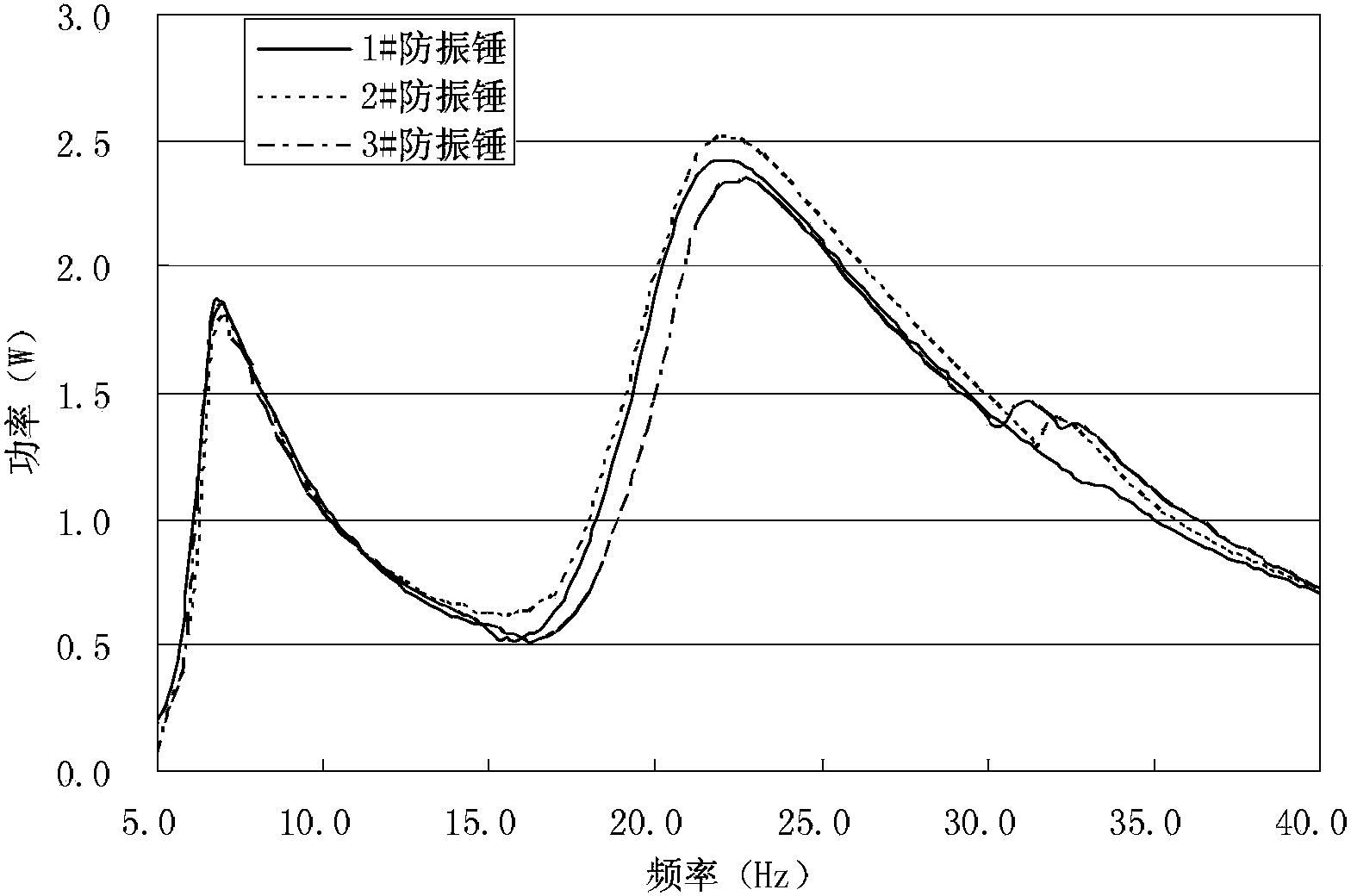

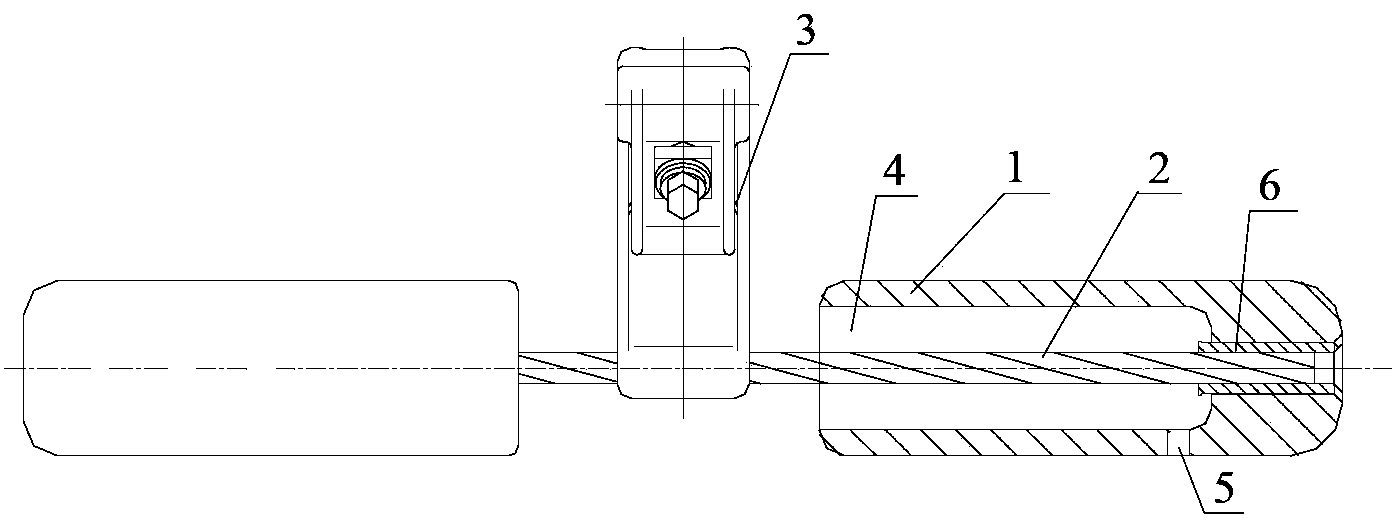

Bell jar type damper used in high altitude areas

InactiveCN103633607AGood anti-halo effectAnti-halo performance guaranteeDevices for damping mechanical oscillationsControl theoryBell jar

The invention provides a bell jar type damper used in high altitude areas. By applying the bell jar type damper, the corona audible noise and the corona loss of a 330kV high altitude area electric transmission line can be effectively reduced, and the damper has the advantage of good damping performance. The damper comprises a damper head, a steel strand and a wire clamp. The damper head has a cylinder structure, one end of the damper head is provided with a lightening hole having a diameter of phi 3 in the inside, the other end of the damper head is provided with an installation having a length of L2 in the inside, and the damper head is provided with a drain hole having a outer diameter of phi 4 at the circular ring of the outer side of the lightening hole, wherein the drain hole runs through the circular ring in the axial direction. According to the bell jar type damper of the invention, through simulating calculation, the surface maximum field strength is reduced to 22kV / cm which is reduced by 19% compared with the surface maximum field strength of a conventional bell jar type damper; the corona onset voltage of the damper is 390kV in the 4000 meter altitude height simulation condition which is much higher than the 330kV rated operating voltage, so the occurrence of corona can be effectively restrained, and the damper has the advantage of good damping performance.

Owner:CHINA ELECTRIC POWER RES INST +1

Slideway sealing device for sintering pallet

ActiveCN105737605ASave on lubricating oil costsReduce manufacturing costFurnace componentsFurnace typesEngineeringPallet

The invention discloses a slideway sealing device for a sintering pallet. The slideway sealing device comprises upper slideways mounted in grooves on two sides of the sintering pallet, and a sealing structure is formed after the upper slideways contact with lower slideways mounted on a slideway support beam. Each upper slideway is a special-shaped cavity which forms a rigid sealing face, lubricating through holes are distributed in the rigid sealing face, and solid or liquid lubricating medium fills the special-shaped cavity. Each lower slideway is provided with a flexible sealing plate which contacts with the sealing face of the corresponding special-shaped cavity. The slideway sealing device has the advantages that by the newly designed sealing structure, sealing and self-lubricating are achieved, and abrasion and air leakage are avoided; the problems that traditional lubricating oil is easily drawn into an air box and cannot achieve a lubricating effect, air leakage between the upper and lower slideways is caused, and the abrasion of the upper and lower slideways are accelerated are solved.

Owner:秦皇岛隆正科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com