Slideway sealing device for sintering pallet

A sealing device and trolley technology, which are applied in the furnace type, furnace, lighting and heating equipment, etc., can solve the problems of air pollution, accelerated wear of the upper slide and slideway, economic loss, etc., and achieve a good sealing effect. , The effect of reducing production costs and saving lubricating oil costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

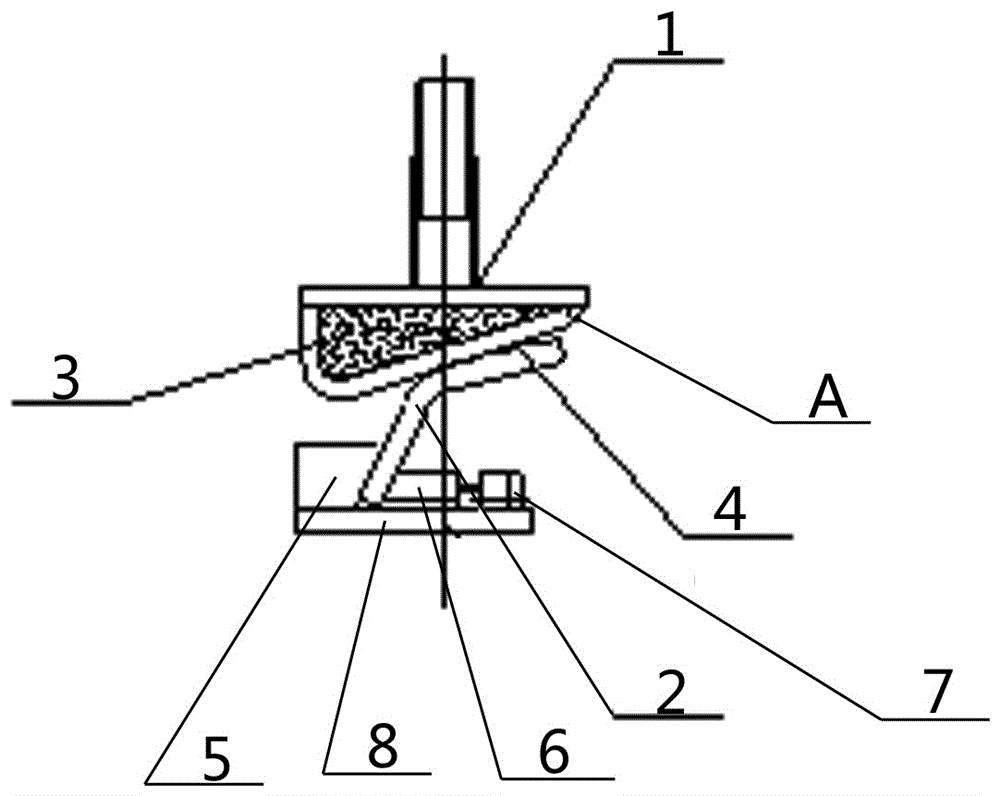

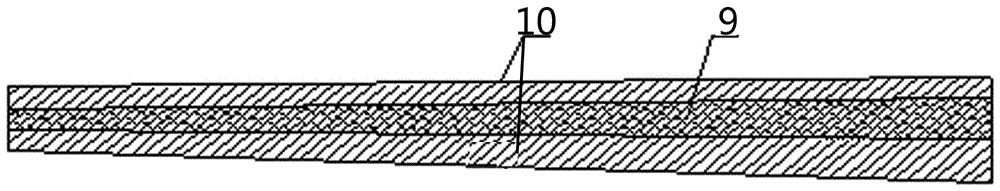

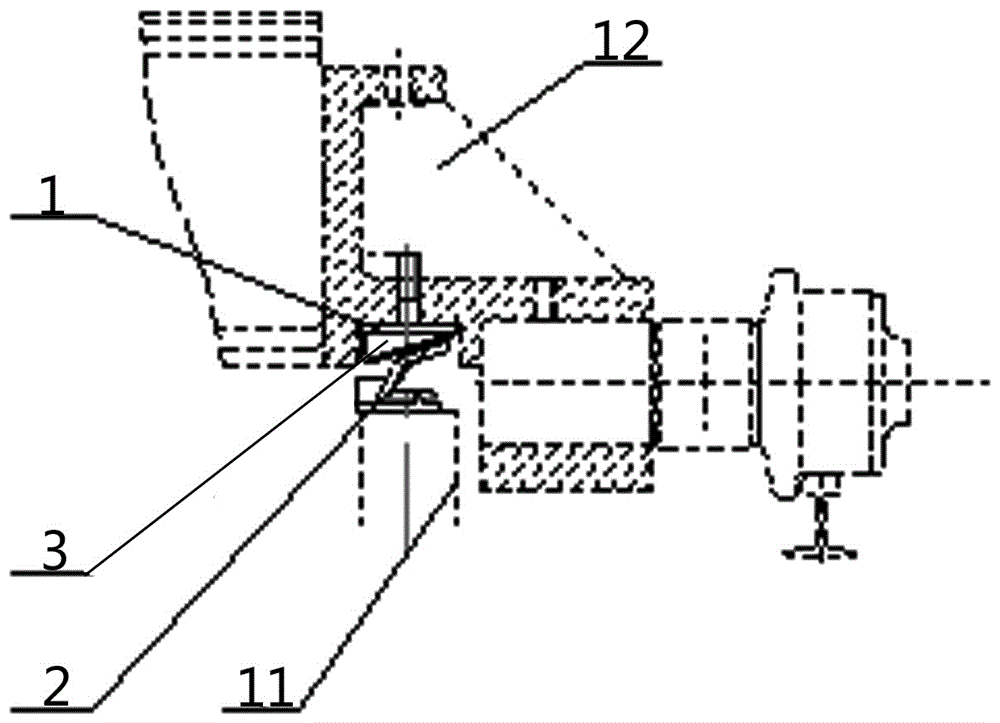

[0019] See figure 1 , figure 2 The slideway sealing device of a sintering machine trolley shown includes an upper slideway 1 installed in the grooves on both sides of the trolley. sliding seal structure. In the present invention, the upper slideway 1 is a special-shaped cavity body, a rigid sealing surface A formed by the special-shaped cavity body, and the rigid sealing surface A of the special-shaped cavity body is distributed with lubrication through holes ( not shown in the figure), and the solid or liquid lubricating medium filled in the special-shaped cavity of the upper slide 1. The solid lubricating medium used in this embodiment is graphite powder 3, which leaks out through the lubricating through holes distributed on the upper slideway 1 to play a lubricating role. The glideway 2 in this embodiment has a flexible sealing plate 4 that is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com