Energy-saving stirrer for building

A technology for mixers and construction, which is applied in cement mixing devices, liquid ingredient supply devices, clay preparation devices, etc. It can solve the problems of low mixing efficiency, waste of energy, and difficult cleaning of cement on the inner wall of the mixer, and achieve high mixing efficiency and convenient use , the effect of ensuring the quality of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

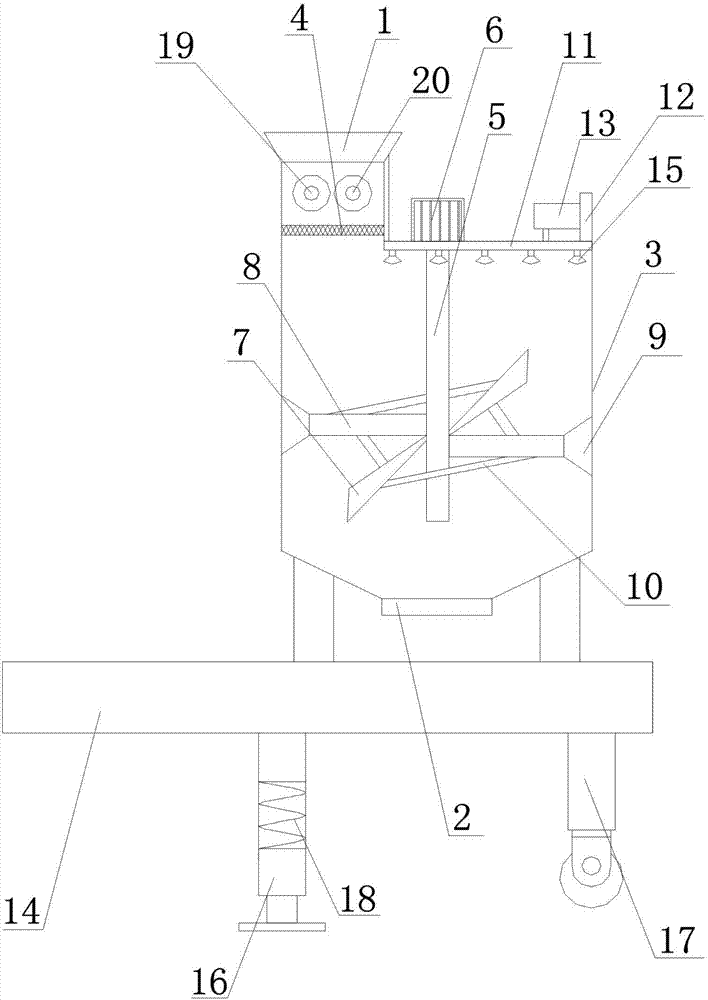

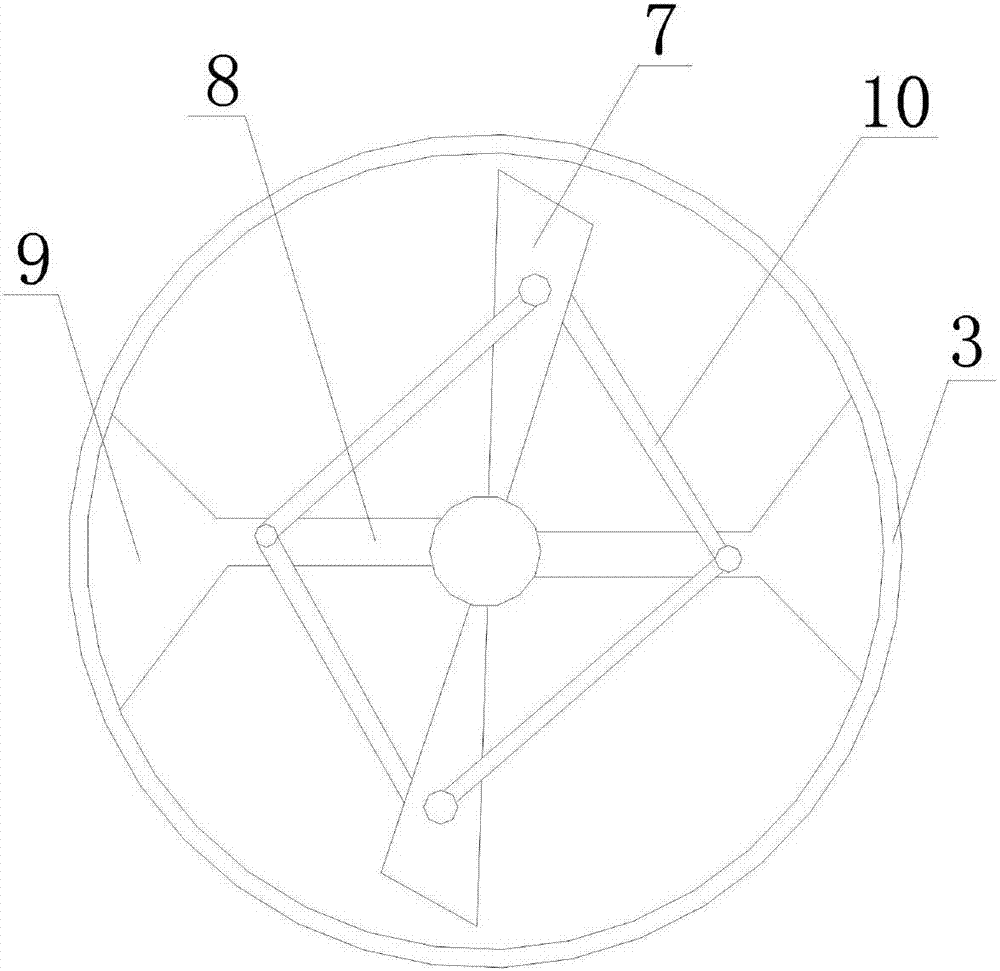

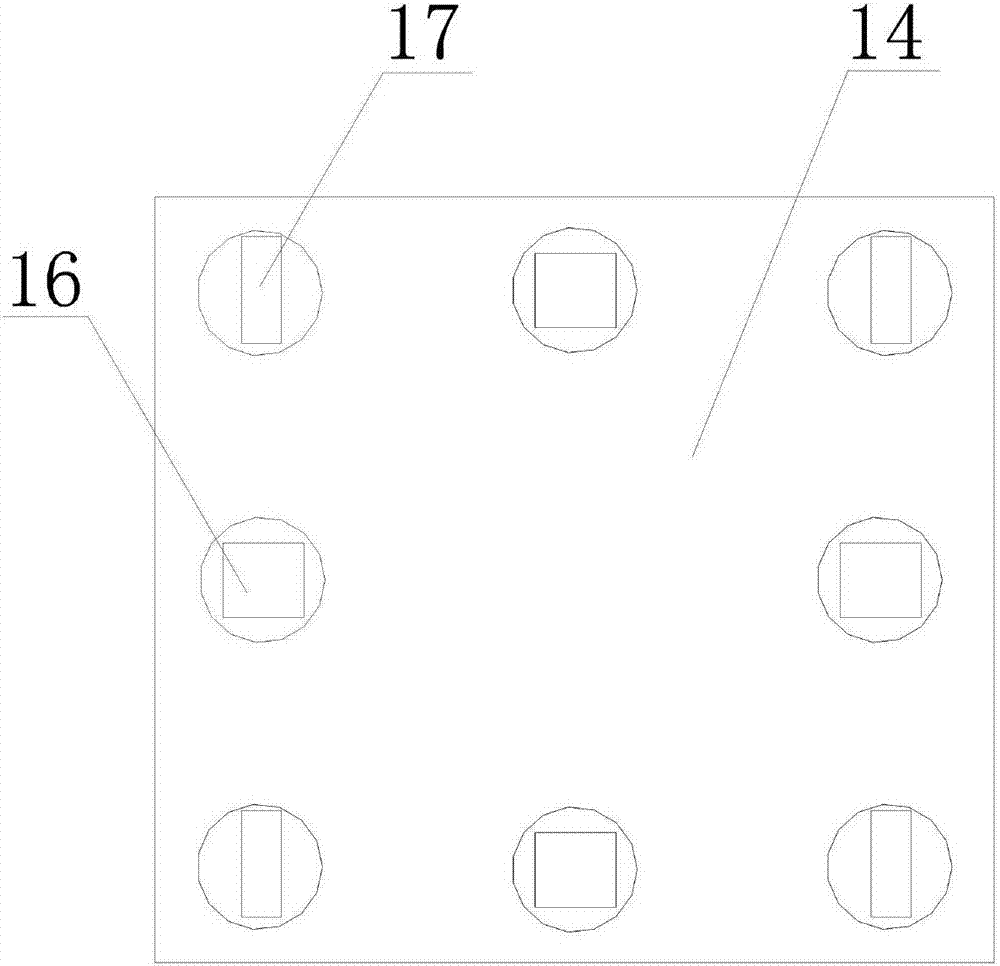

[0022] like Figure 1-3 As shown, an energy-saving building mixer provided by the present invention has simple structure, scientific and reasonable design, and is easy to use. It can automatically remove the cement on the inner wall of the mixer while stirring. Long service life, cost saving, easy to move, stable and stable, and the quality of cement discharged from the discharge port is good. The present invention comprises a cylindrical mixer main body 3 with a feed inlet 1 on one side of the top and a discharge funnel mouth 2 in the center of the bottom, and a crushing device provided at the lower part of the feed inlet 1 for crushing the materials entering the mixer main body 3, The pulverizing device includes a first pulverizing roller 19 and a second pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com