Rapid dual-way material paving full-color 3D printing machine

A 3D printer, full-color technology, used in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of narrow location, time-consuming and laborious removal and cleaning, low efficiency, etc., to achieve short pause time and save time. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

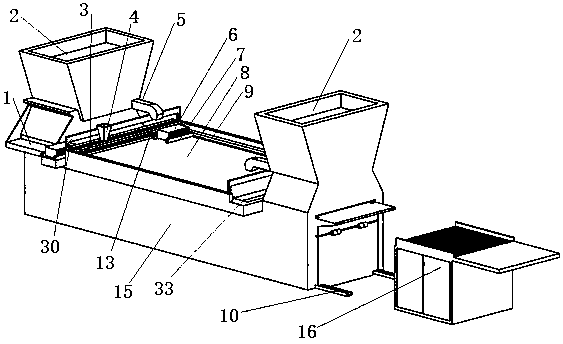

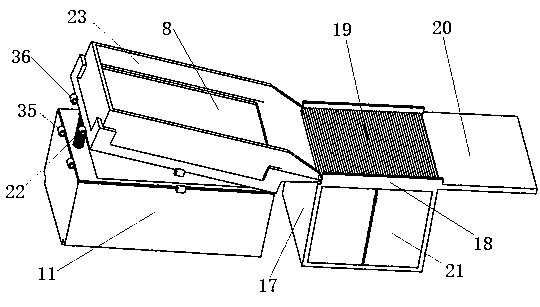

[0031] Such as Figure 1-4, 7-9, a fast two-way material-laying full-color 3D printer, including a housing 15 and a control platform 1 arranged on the housing 15, the top of the housing 15 is provided with a material-laying mechanism 3, the material-laying mechanism 3 Comprising a material spreading trough 28, a screw rod 29 is provided in the material spreading trough 28, and one end of the screw rod 29 is connected with a motor, a synchronous beam 30 is arranged above the material spreading trough 28 and the two ends of the synchronous beam 30 are fixed on the material spreading trough 28, The synchronous beam 30 is provided with a hopper 4, the hopper 4 can move along the synchronous beam 30, and the bottom of the laying tank 28 is provided with a vibrating screen 31, and the mesh number of the vibrating screen 31 is slightly larger than that of the raw material, which is convenient for feeding and vibrating. The sieve 31 can ensure extremely high printing accuracy. The bot...

Embodiment 2

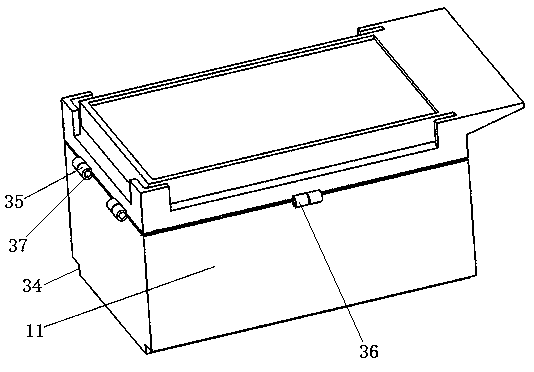

[0034] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the sand cleaning device 16 includes a sand storage box 25 and a transparent cover 26 hinged on the top of the sand storage box 25, and the inner wall of the sand storage box 25 is provided with a control platform 1 The connected mechanical arm 27 is provided with a vacuum cleaner and a slender brush. During sand cleaning, the control platform 1 controls the molding cylinder 11 to slide along the guide rail 10 so that the molding cylinder 11 and the finished product are located in the space formed by the sand storage box 25 and the transparent cover 26, and the control platform 1 controls the mechanical arm 27 to move according to the specified trajectory The fine sand on the surface of the finished product is sucked off by the vacuum cleaner on the mechanical arm 27. After cleaning, the transparent cover 26 is opened to take out the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com