Visual imaging device for automatic detection machine

An imaging device and detection machine technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the detection machine is difficult to apply, difficult to accurately locate, and poor in versatility, so as to improve detection accuracy, reduce scrap rate, stoppage short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

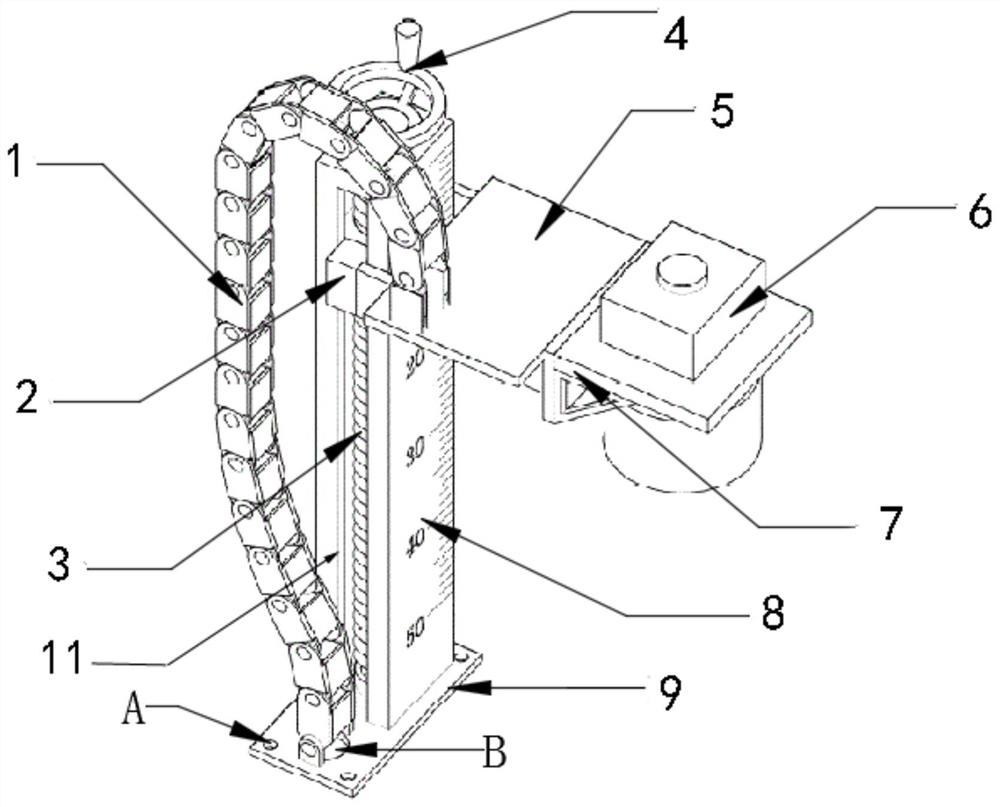

[0028] A visual imaging device used on an automatic inspection machine, the device is fixedly installed on the machine table of the automatic inspection machine, and includes a lifting part, a follow-up camera part and a tank chain 1 .

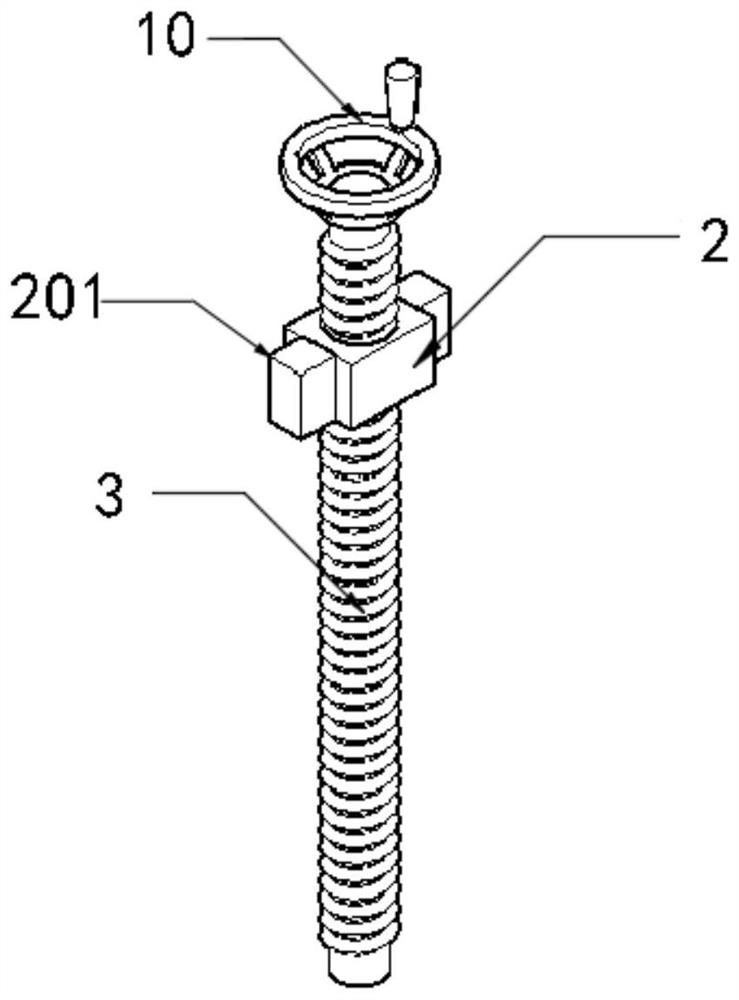

[0029] The lifting parts include a base 9, a shell 8, a screw 3, a lifting collar 2, a hand wheel 10 and a handle 4. The base 9 is provided with a fixing hole A and a wire hole B, and the base 9 is fixedly connected to the machine by using screws and the fixing hole A. , the shell 8 is marked with a vertical scale, and the shell 8 is fixedly connected to the base 9. In this embodiment, the shell 8 is provided with two guide grooves 11 in the vertical direction, the screw rod 3 is arranged in the shell 8, and the hand wheel 10 is fixedly connected to the top of the screw rod 3, the handle 4 is set on the hand wheel 10, the lifting collar 2 is sleeved on the screw rod 3, the inner thread of the lifting collar 2 matches the outer thread of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com