Tray stacking mechanism and stacking method thereof

A technology of bowl tray and stacking tray, applied in the field of bowl tray stacking mechanism, can solve the problems of high labor intensity, complex structure, and simple structure of seedling raising, and achieve the effects of reducing manual operations, improving seedling raising efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

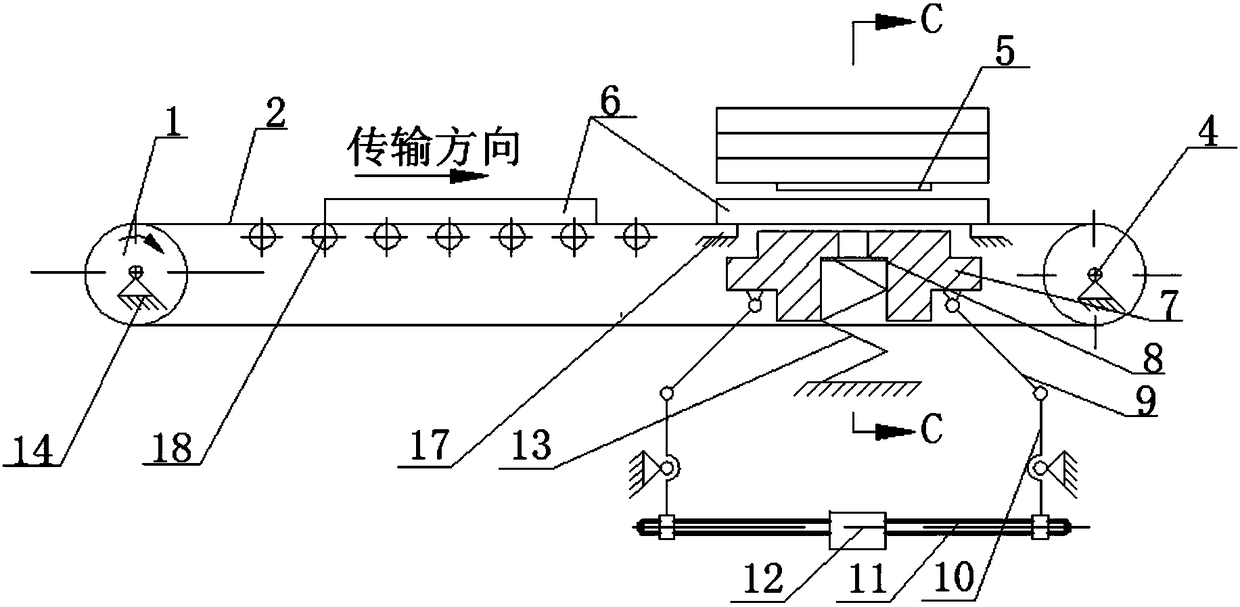

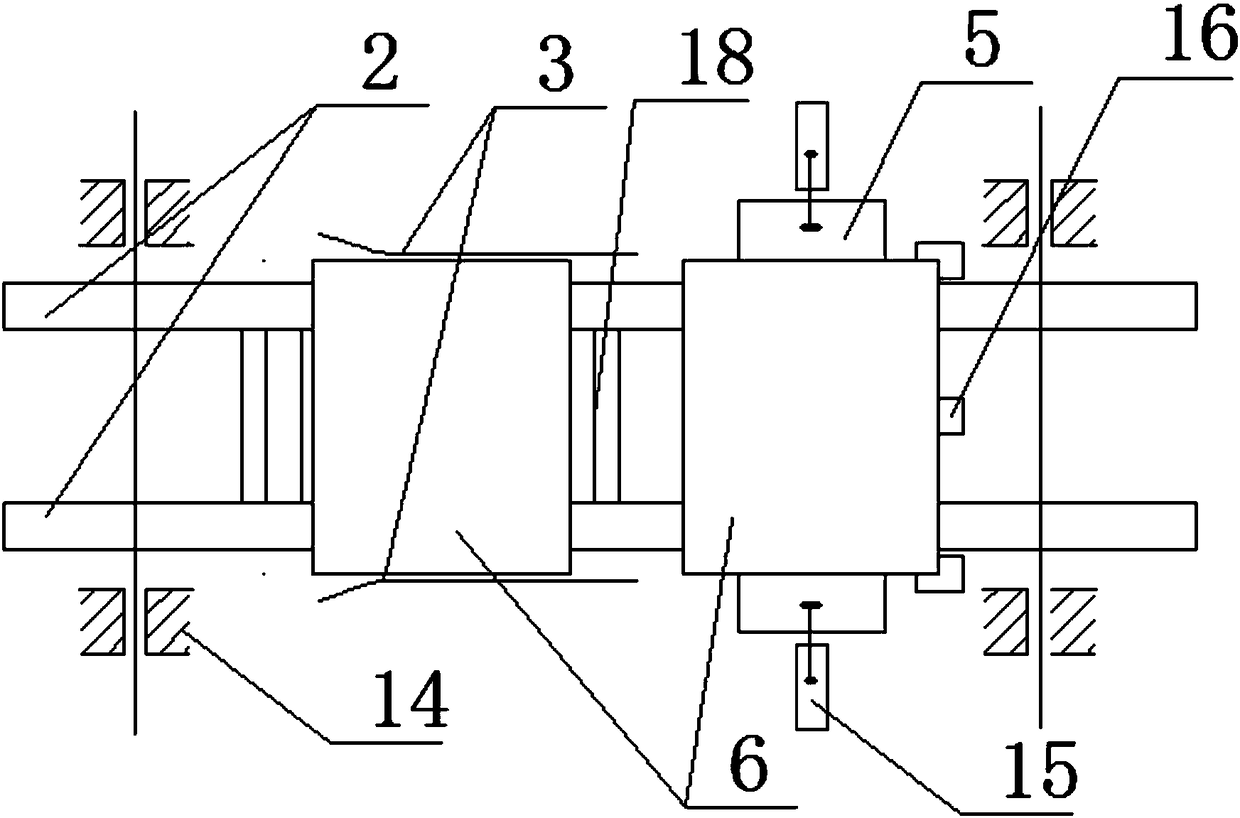

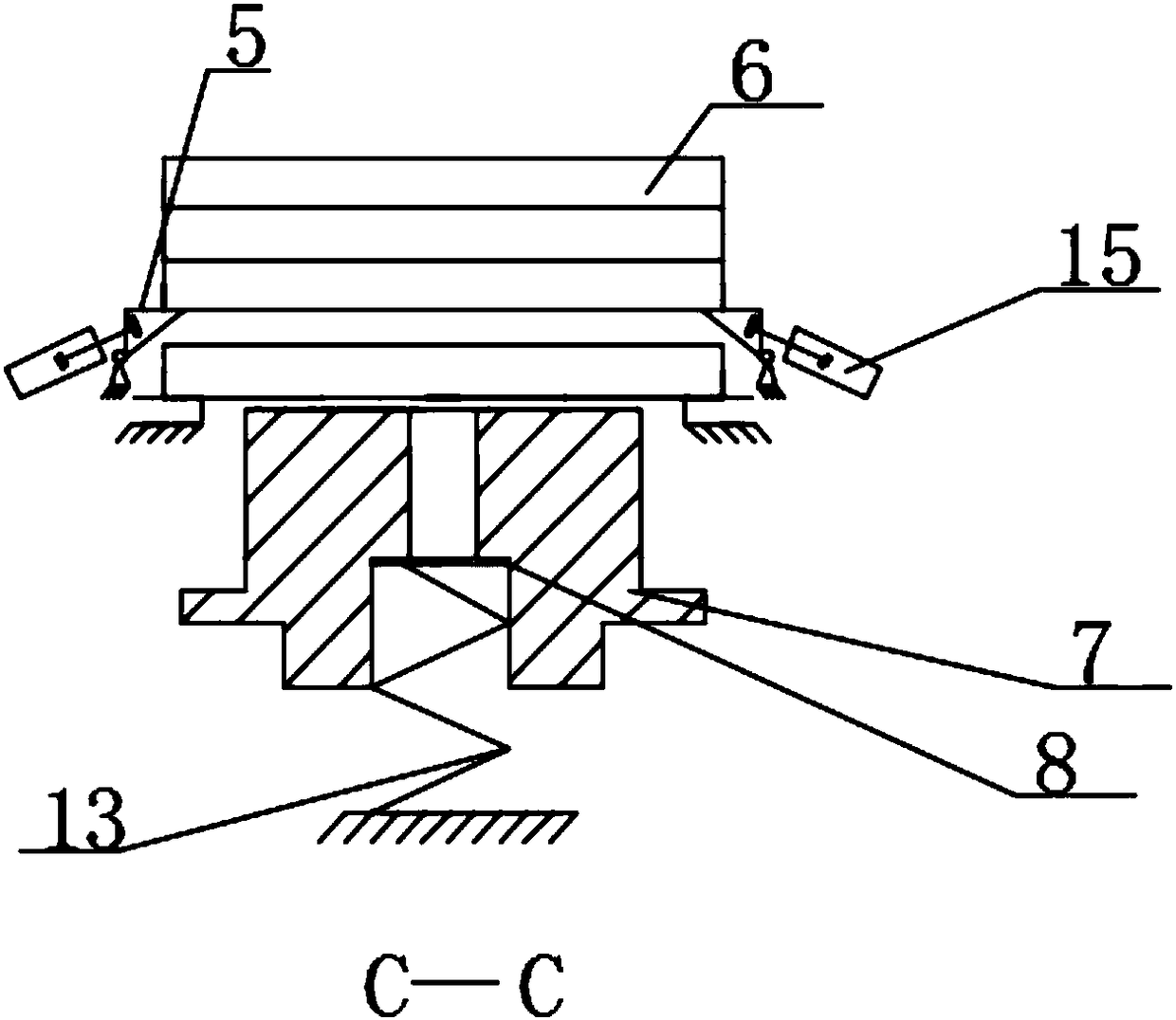

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] Such as figure 1 , 2 As shown in and 3, the pan stacking mechanism mainly realizes the stacking movement of the pan on the assembly line, including a conveyor belt mechanism, a bracket assembly, a boss 7, a gasket 8, an upper top link 9, a side swing link 10, a wire Rod 11, biaxial output motor 12, spring 13, frame 14, cylinder 15, position sensor 16 and rectangular frame 17. The conveyor belt mechanism includes a driving wheel 1, a conveyor belt 2, a guide positioning plate 3, a supporting roller 18 and a driven wheel 4; The two conveyor belts 2 are connected; the plurality of support rollers 18 arranged at intervals are fixed on the frame 14 and arranged in the conveyor belt 2 to support the weight of the alms bowl 6; the opposite sides of the two conveyor belts 2 are provided with guides Positioning plate 3, guide The positioning plate 3 guides and limits the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com