Patents

Literature

33results about How to "Improve sand cleaning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

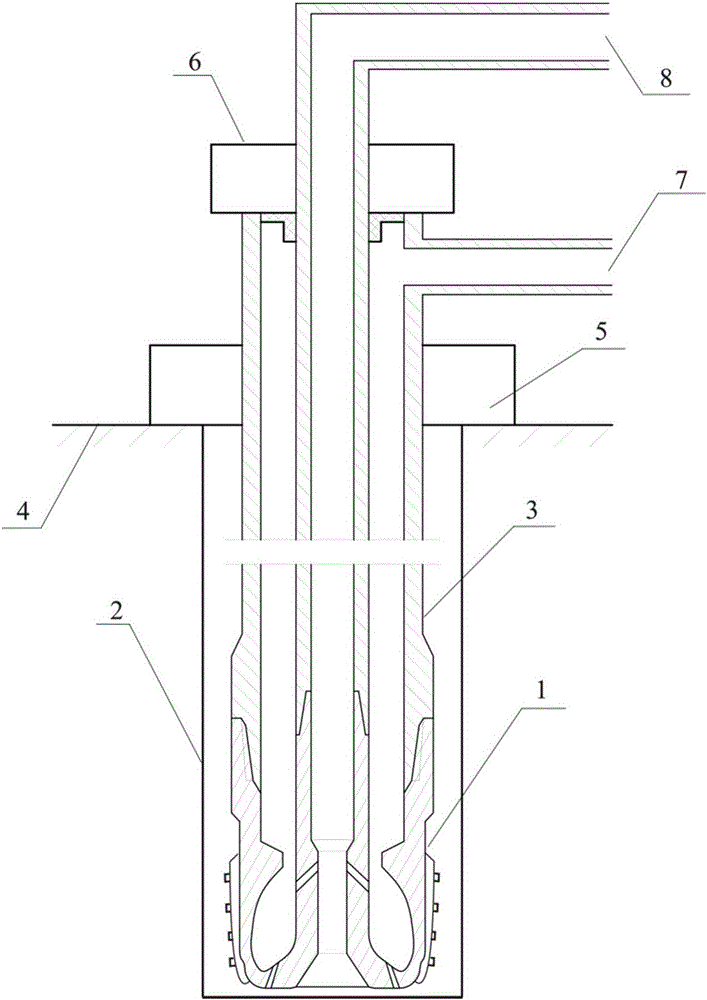

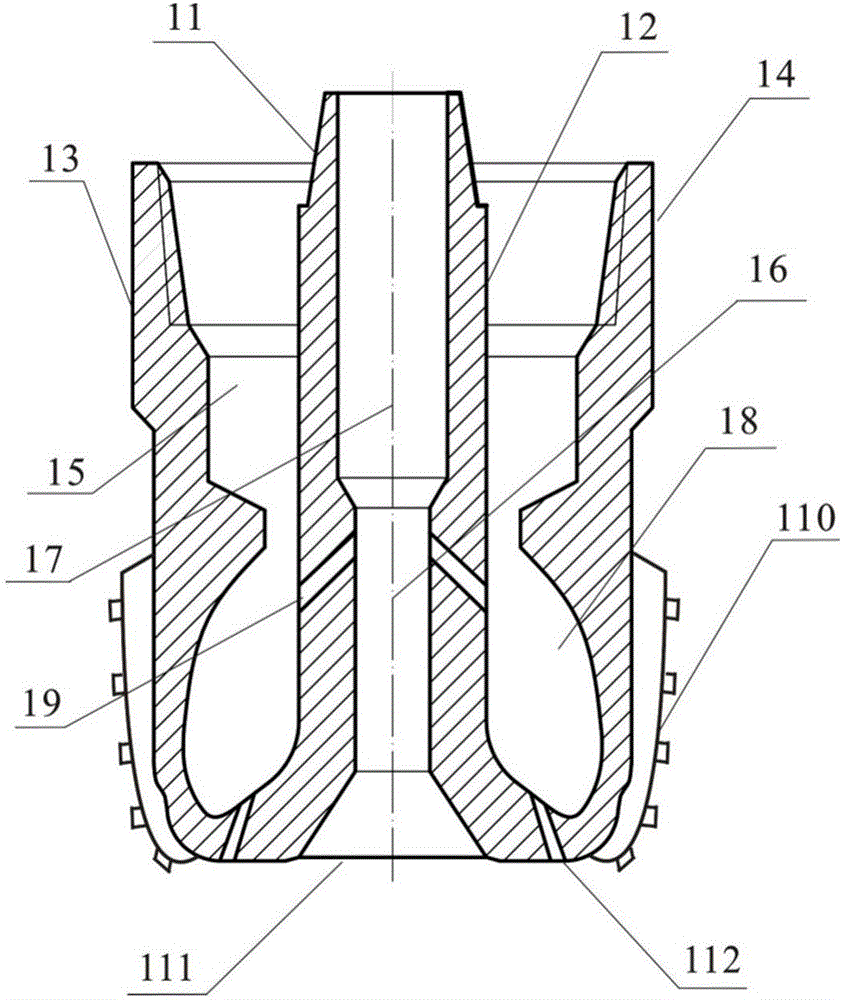

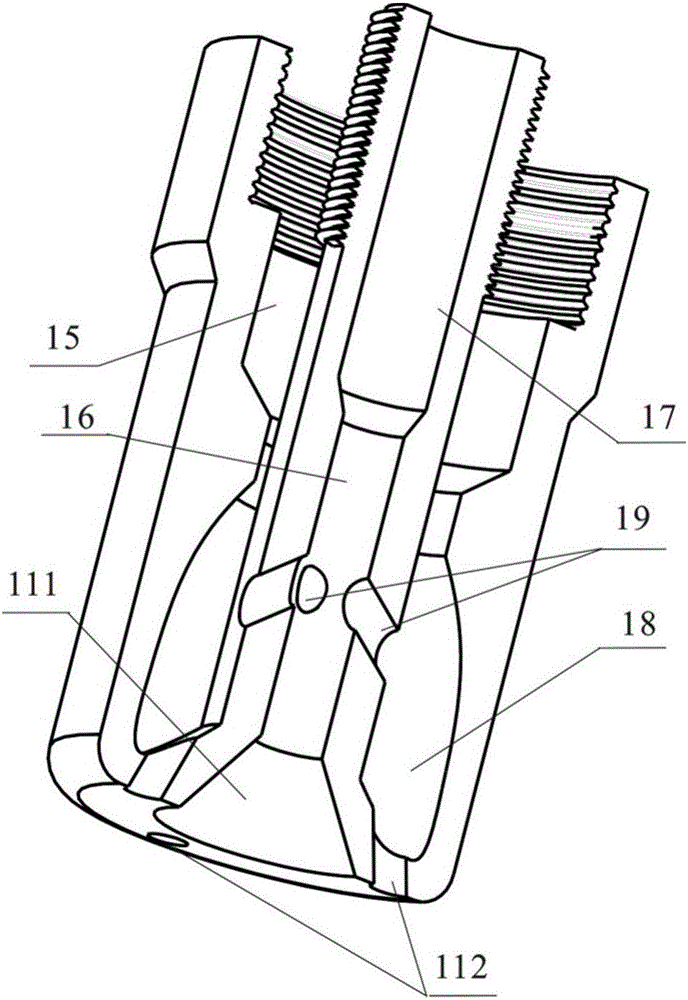

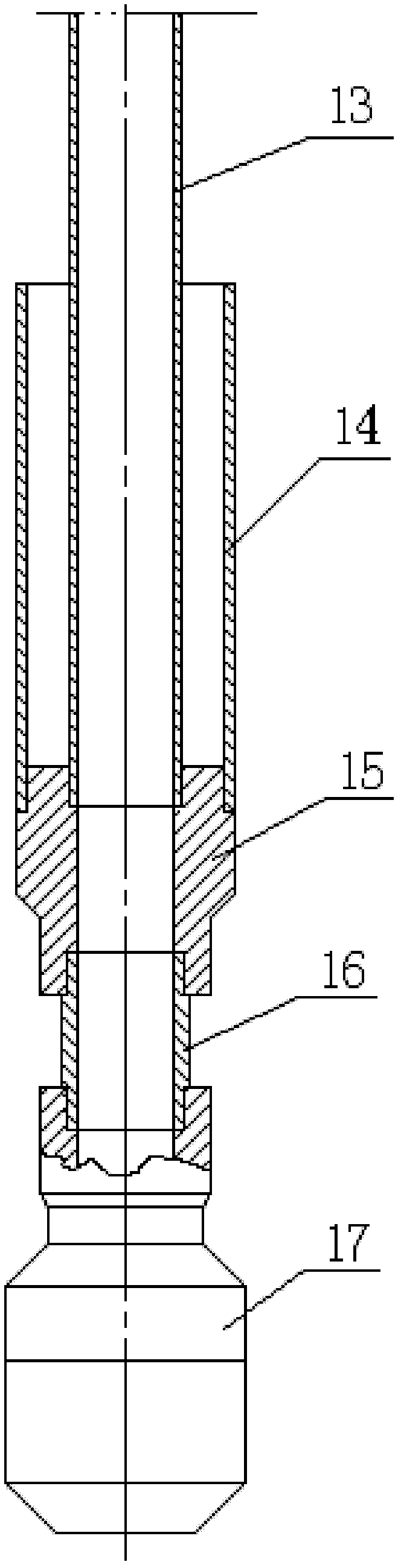

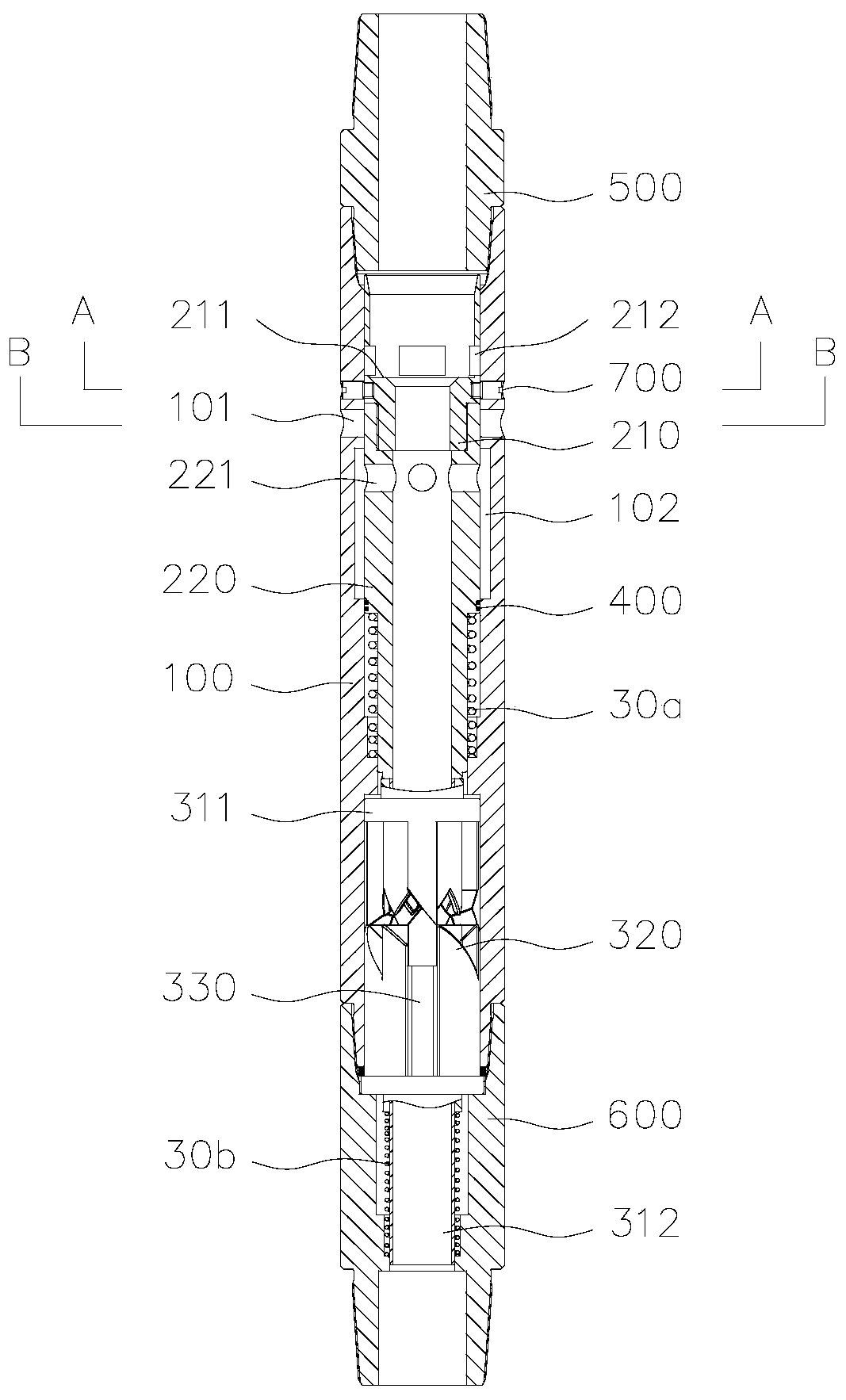

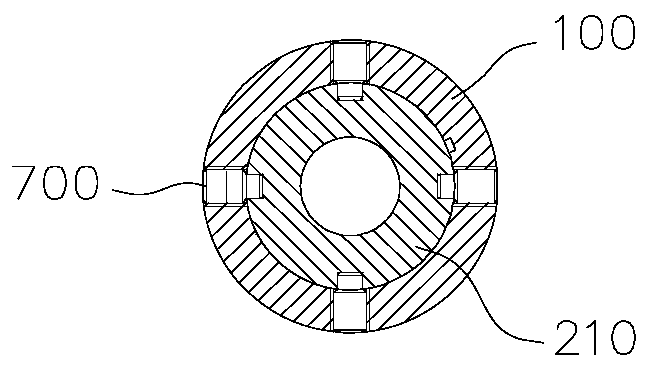

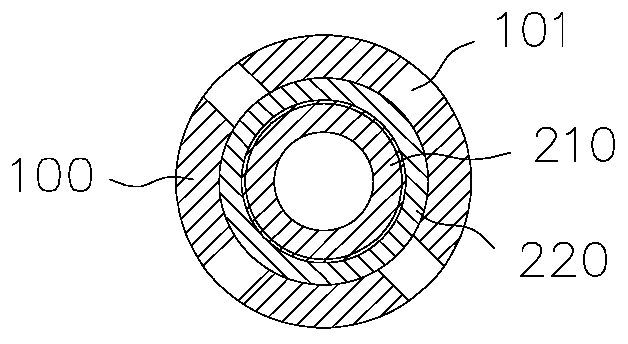

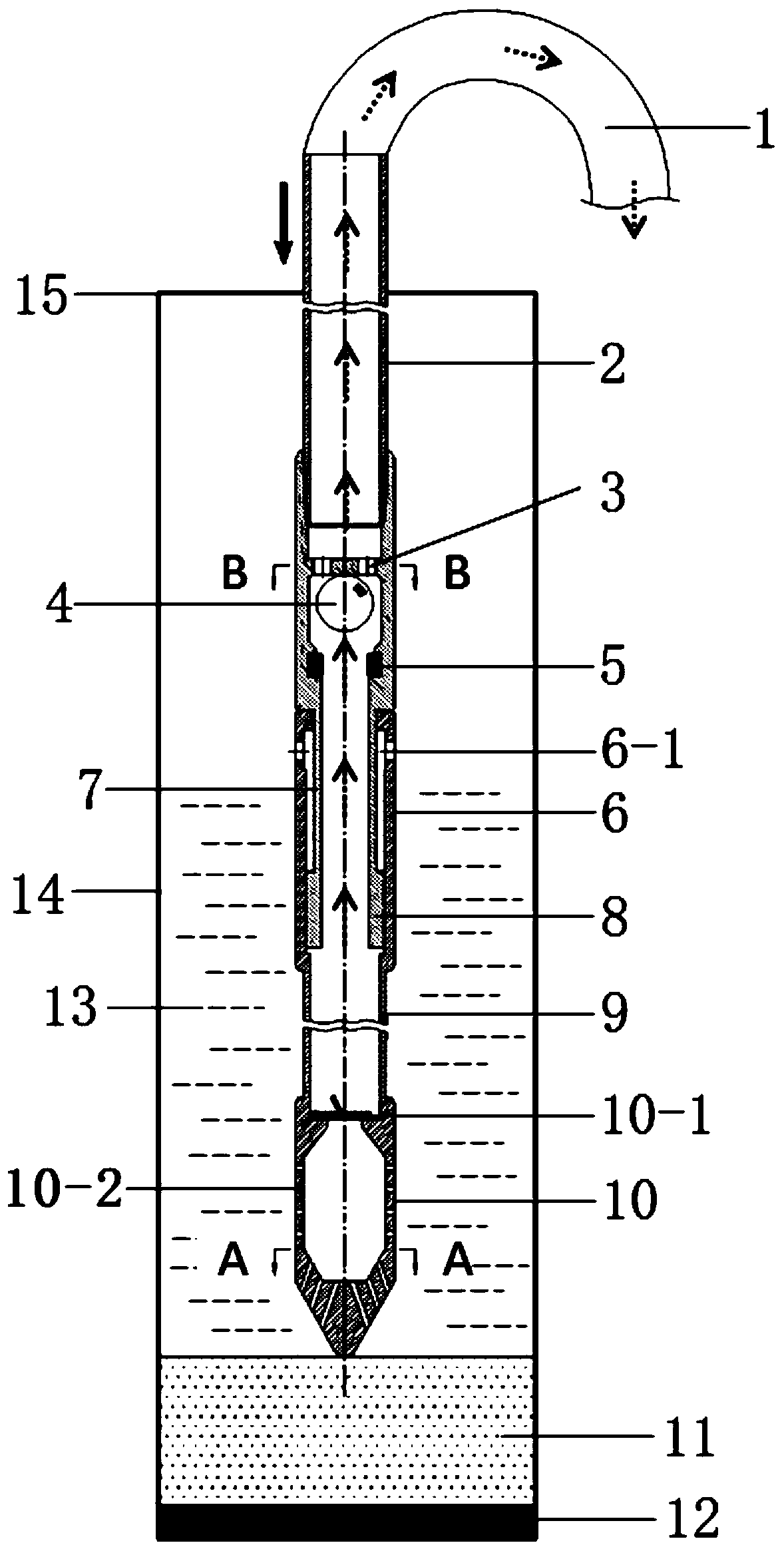

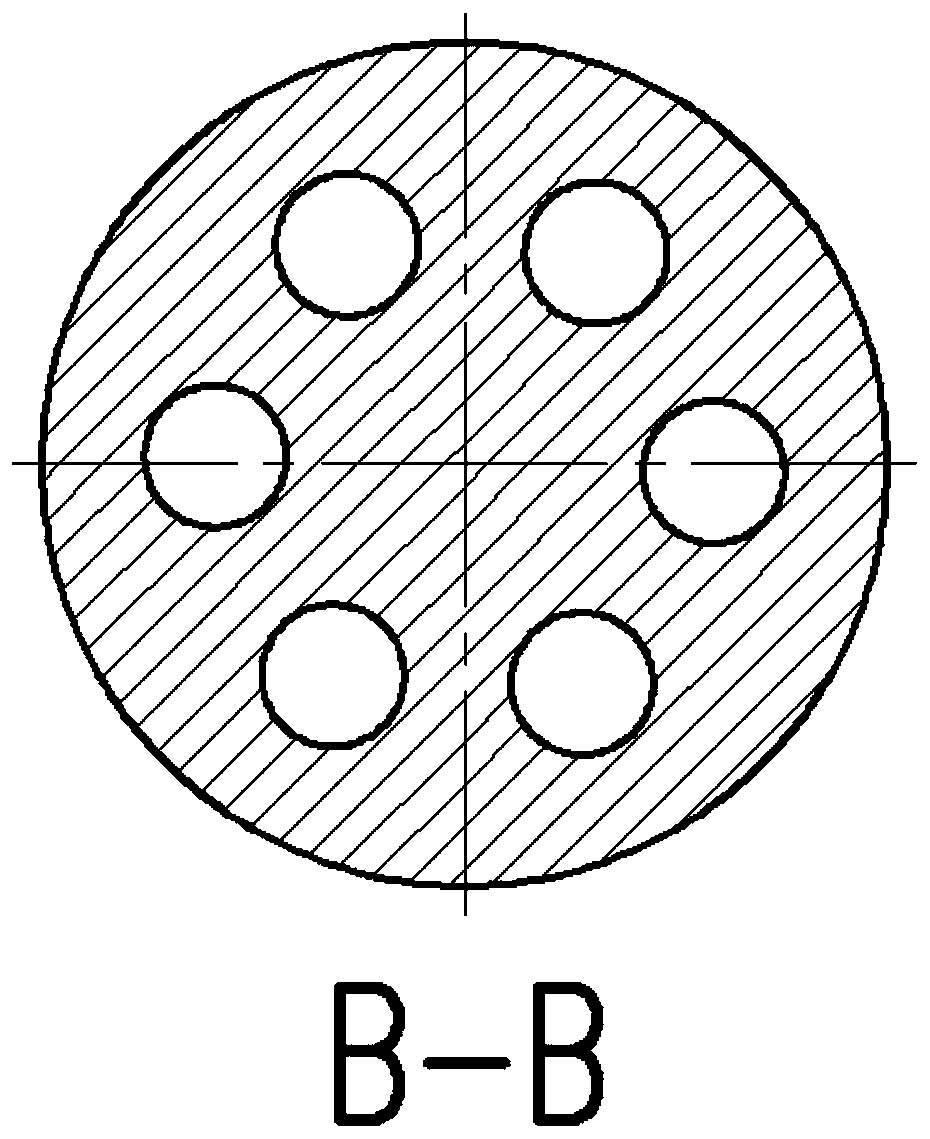

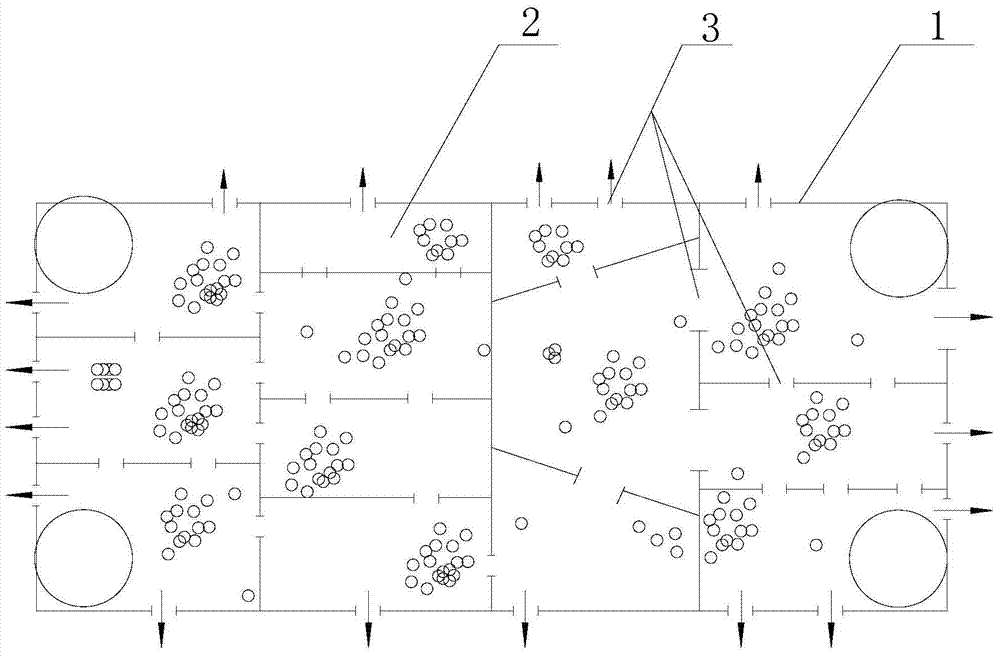

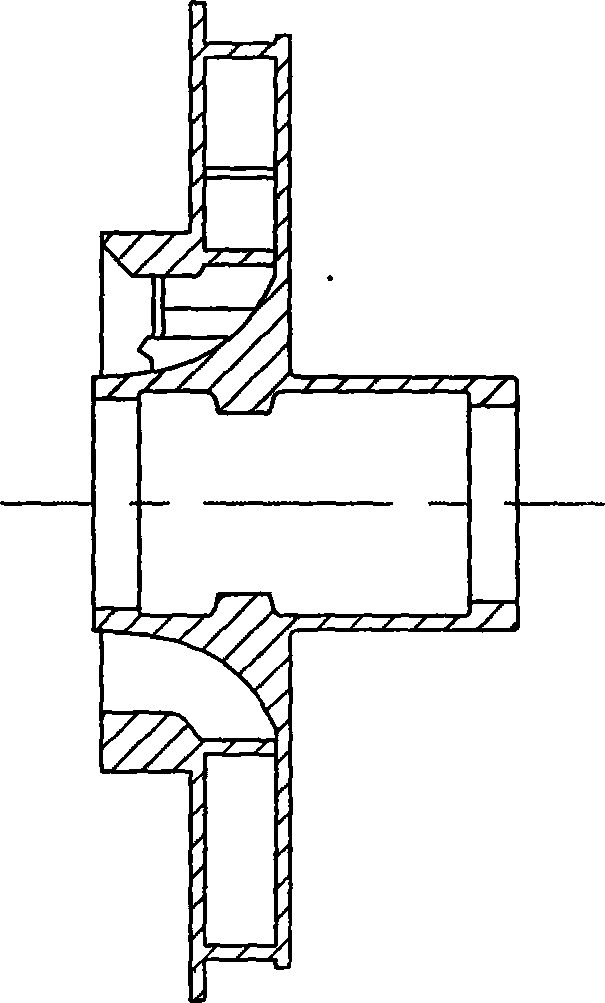

Drilling type continuous sand blasting device

InactiveCN106437570AGood for carrying sandImprove sand cleaning efficiencyDrill bitsDrilling rodsSand blastingSpray nozzle

The invention provides a drilling type continuous sand blasting device, comprising a sand blasting drill bit, a dual-wall drilling pillar, a rotational sealing well head, a rotational driving device, a sand blasting fluid manifold, and a sand carrying fluid manifold; the sand blasting drill bit includes a drill bit body and an inner drill bit body; the rotational driving device drives the dual-wall drilling pillar to rotate so as to drive the sand blasting drill bit to rotate and cut the hardware sand pillar at the bottom; a high-pressure shocking cavity with a multi-curve cavity is formed between the inner wall of the lower end of the drill bit body and the outer wall of the internal drill bit; a part of sand flushing fluid in the high pressure shocking cavity can provide suction negative pressure through a high pressure jet flow generated from a backward jet flow nozzle; thus on the one hand, normal circulation sand carrying of a low pressure well can be guaranteed; on the other hand, the settled sand at the bottom is isolated from the well bottom, so as to benefit sand carrying; the other part of sand blasting fluid is sprayed from the drill bit nozzle, asymmetry jet flow is formed, thus it is good for making the strewing sand at the well bottom enter the sand carrying suction cavity and improving the sand carrying efficiency. The device can guarantee the safety of oil gas well while effectively complete the cleaning work of the hard sand pillar of the low-pressure oil well.

Owner:SOUTHWEST PETROLEUM UNIV

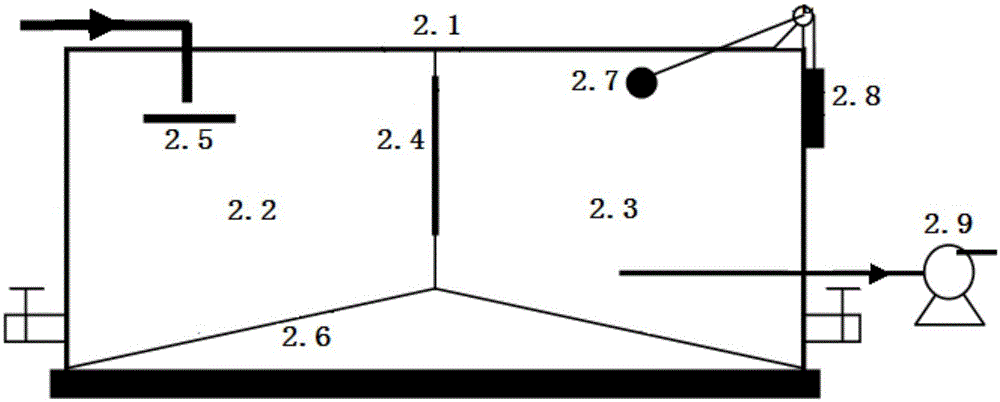

Shell-making method of investment casting of flow guiding body

InactiveCN101406934AShorten drying timeReduce wasteFoundry mouldsFoundry coresSurface layerInvestment casting

The invention provides a method for producing a shell of a guiding piece through investment casting, which comprises the following steps: (1) producing a mould shell through sizing the guiding piece with three layers of slurries including sizing a surface layer once and sizing a transition layer twice, plugging up a flow passage at the water inlet end by using paste Morley slurry after the shell is dried, spraying zircon sands of which the particle size is between 100 and 120 meshes from the water outlet end by a sand spraying machine, wherein the paste Morley slurry is prepared through evenly mixing the Morley powder of which the particle size is 200 meshes and silicasol according to the mass proportion of 80 to 20 and then prepared the mixture into paste; (2) placing the mould shell sprayed with fine sands on vibratory equipment to compact the zircon sands sprayed from the water outlet end through vibrating; and (3) conventionally stuccoing the mould shell treated in the step (2). The mould shell produced by the method after casting has the advantages of no shell leakage and no drill steel; the mould shell can be separated through vibrating the shell by a shell vibrating machine when the sands are removed so that the sand removal efficiency is greatly increased by about 80 percent; and the drying time when the shell is produced is reduced by 55 percent so that the energy waste is reduced and the production cost is reduced.

Owner:山东燕山精密机械有限公司

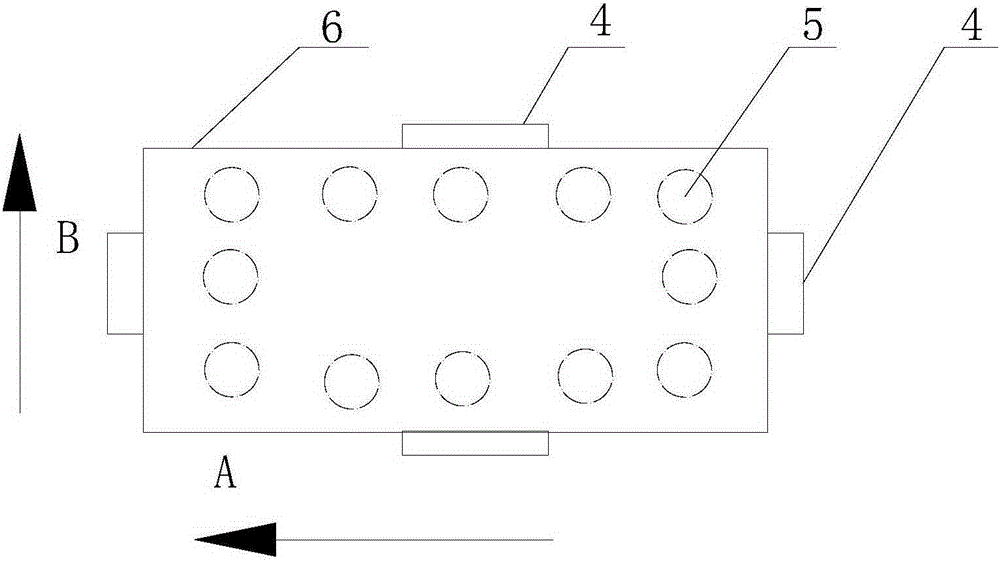

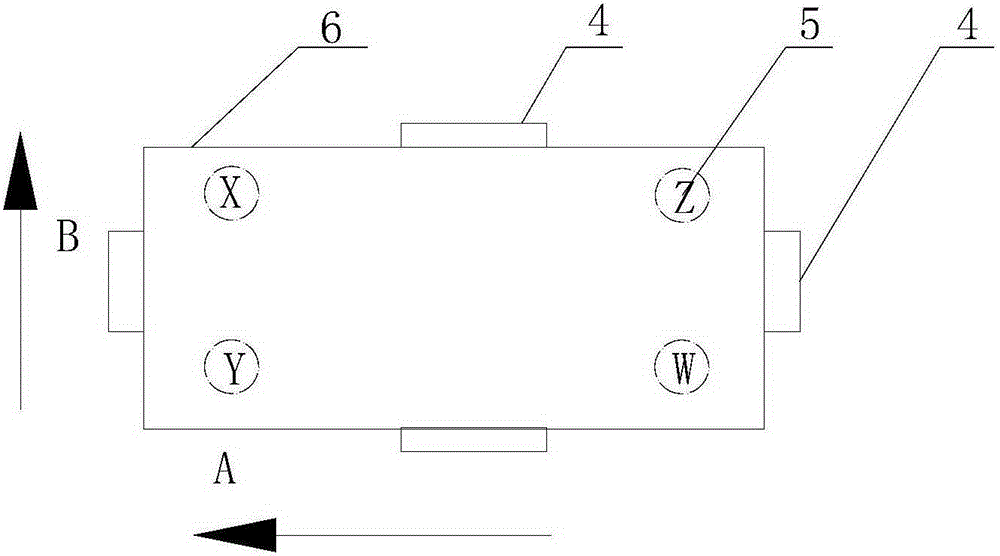

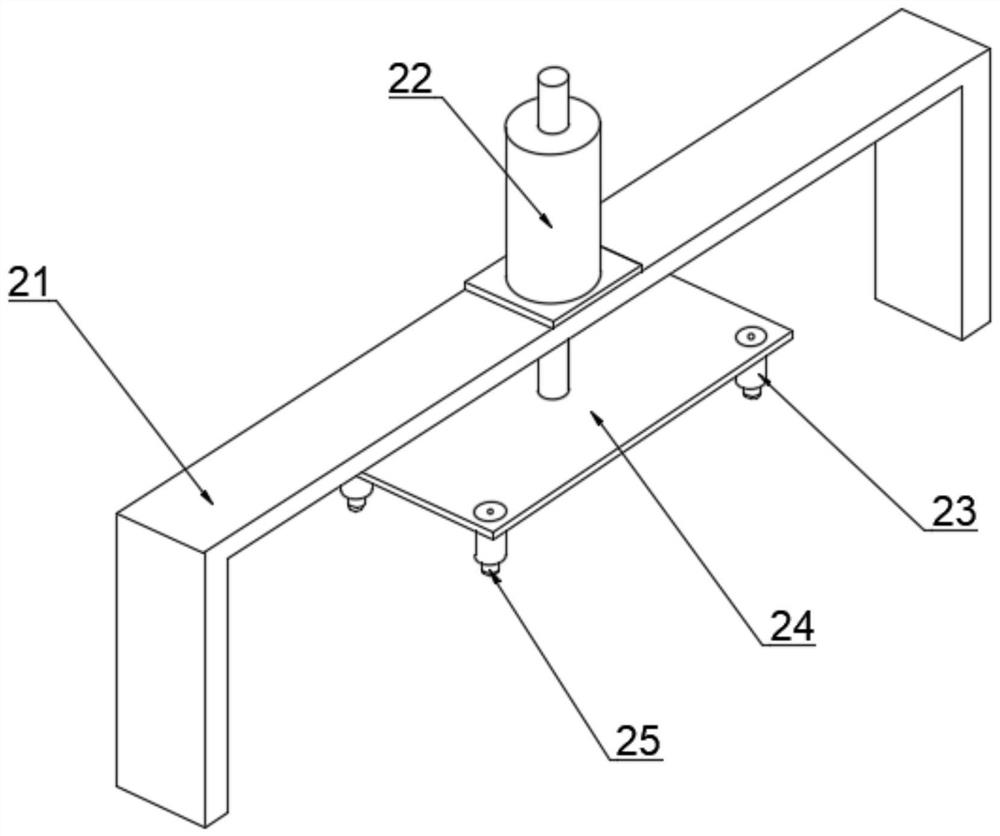

Rapid dual-way material paving full-color 3D printing machine

PendingCN109176824AShort pauseShorten the timeAdditive manufacturing apparatusCeramic shaping apparatus3d printerFull color

The invention discloses a rapid dual-way material paving full-color 3D printing machine. The rapid dual-way material paving full-color 3D printing machine comprises a shell, a control platform and a material paving mechanism; printing assemblies are arranged on the two sides of the material paving mechanism, and adopt photocuring full-color inkjet print heads, UV photocuring lamp tubes are arranged on the two sides of the bottoms of the photocuring full-color inkjet print heads, material boxes are arranged on the two ends of the shell, quantitative discharging devices are arranged at the lowerends of the material boxes, a forming cylinder body is arranged in the shell, the forming cylinder body can slide along guide rails on the two sides of the bottom in the shell, a forming cylinder upper rend powder bed is arranged on the top of the forming cylinder body, a discharging opening is formed in one end of the shell, and a sand removal device is arranged on the outer side of the discharging opening. Dual-way material paving of a material paving mechanism is achieved, in the back and forth process of the material paving mechanism, the dwell time is short, the work efficiency is greatly improved, sand removal and material taking are integrated, the automation degree is high, manpower and time are greatly saved, the sand removal efficiency is improved, the raw material use rate is high, and cost is greatly saved.

Owner:甘肃顺域新材料科技有限公司 +2

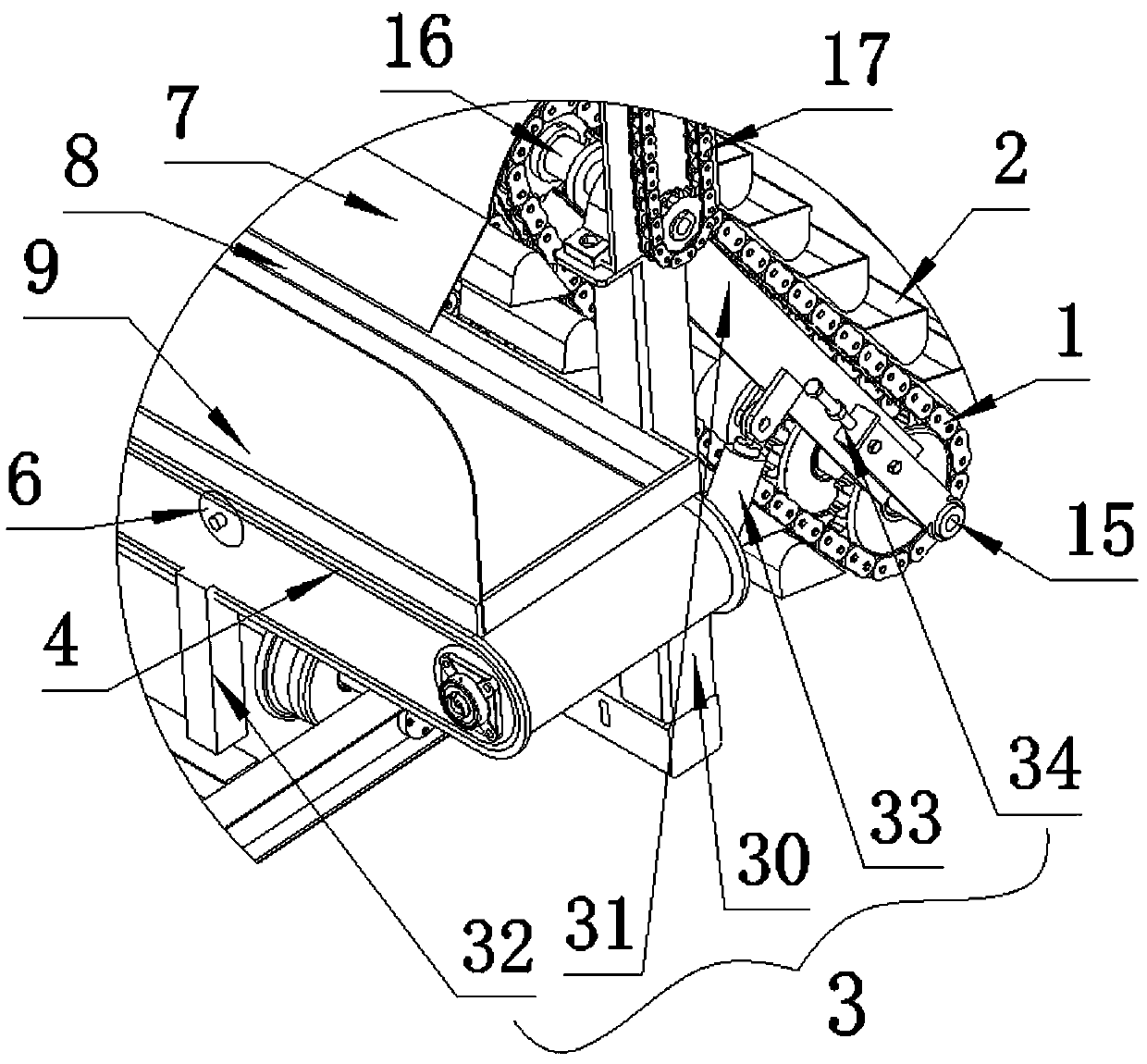

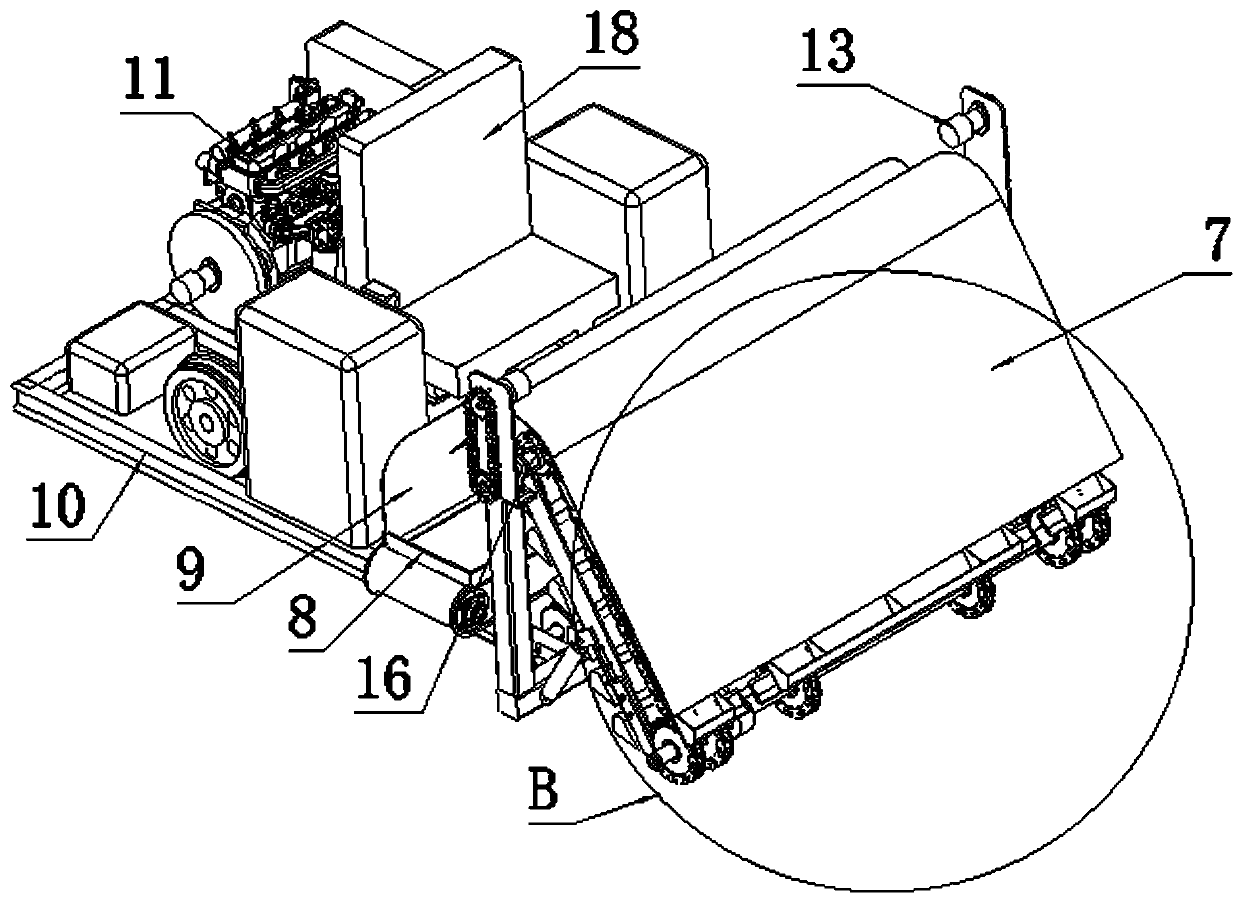

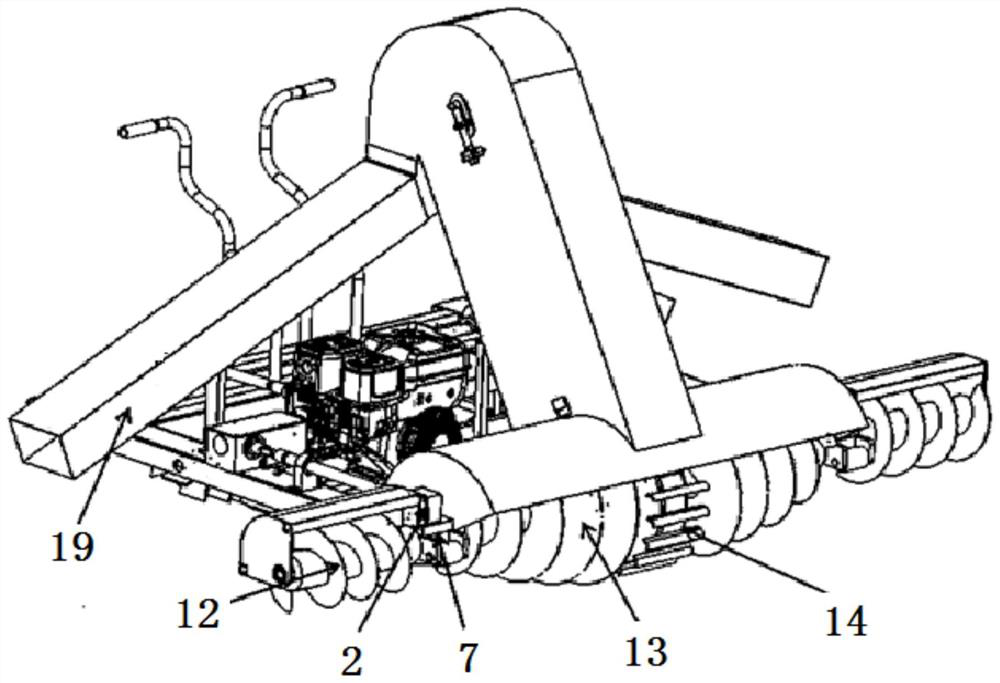

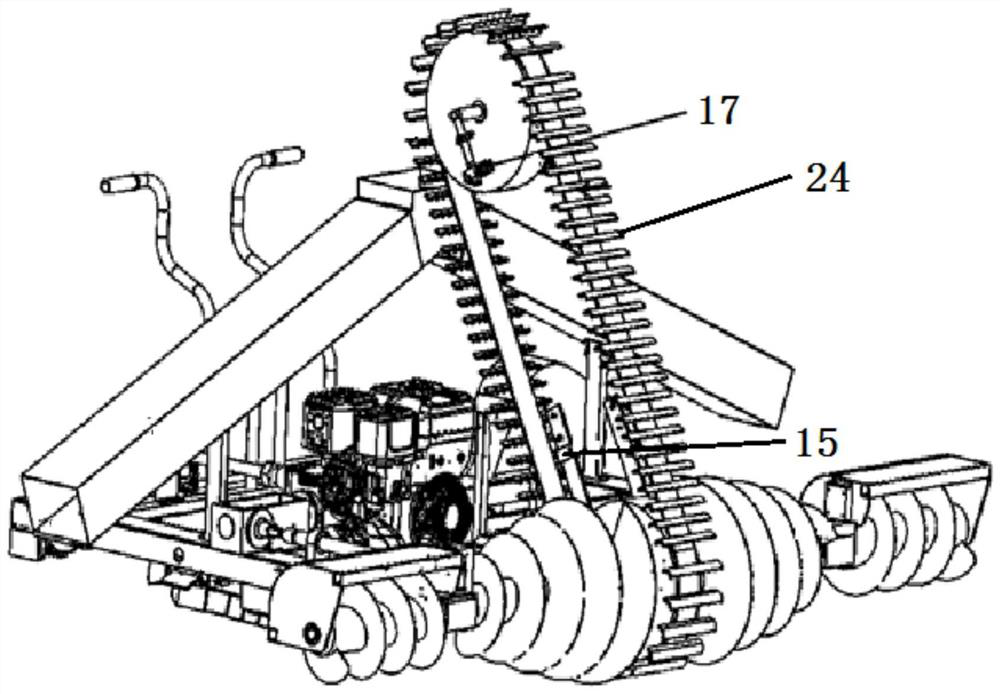

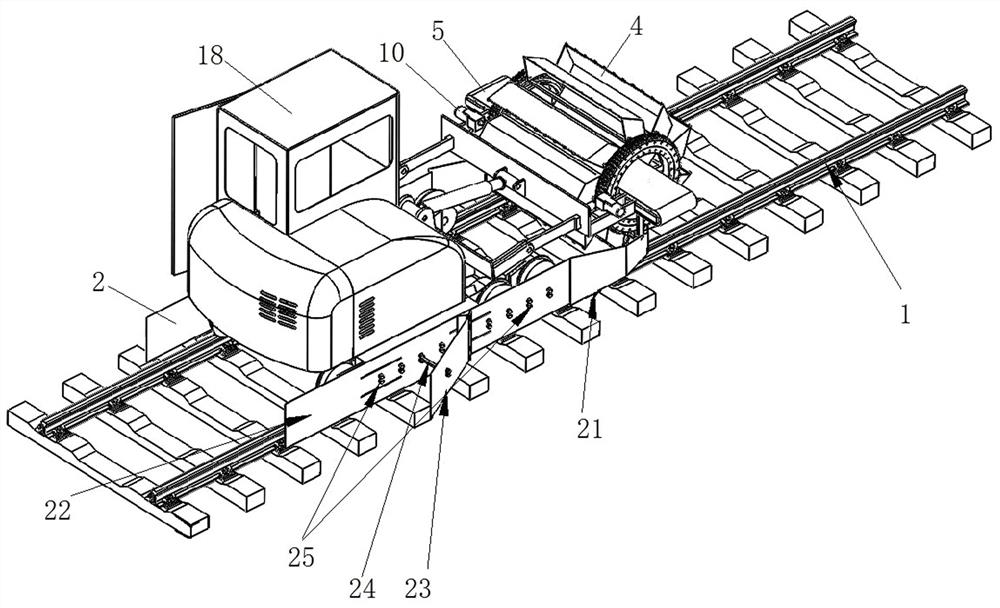

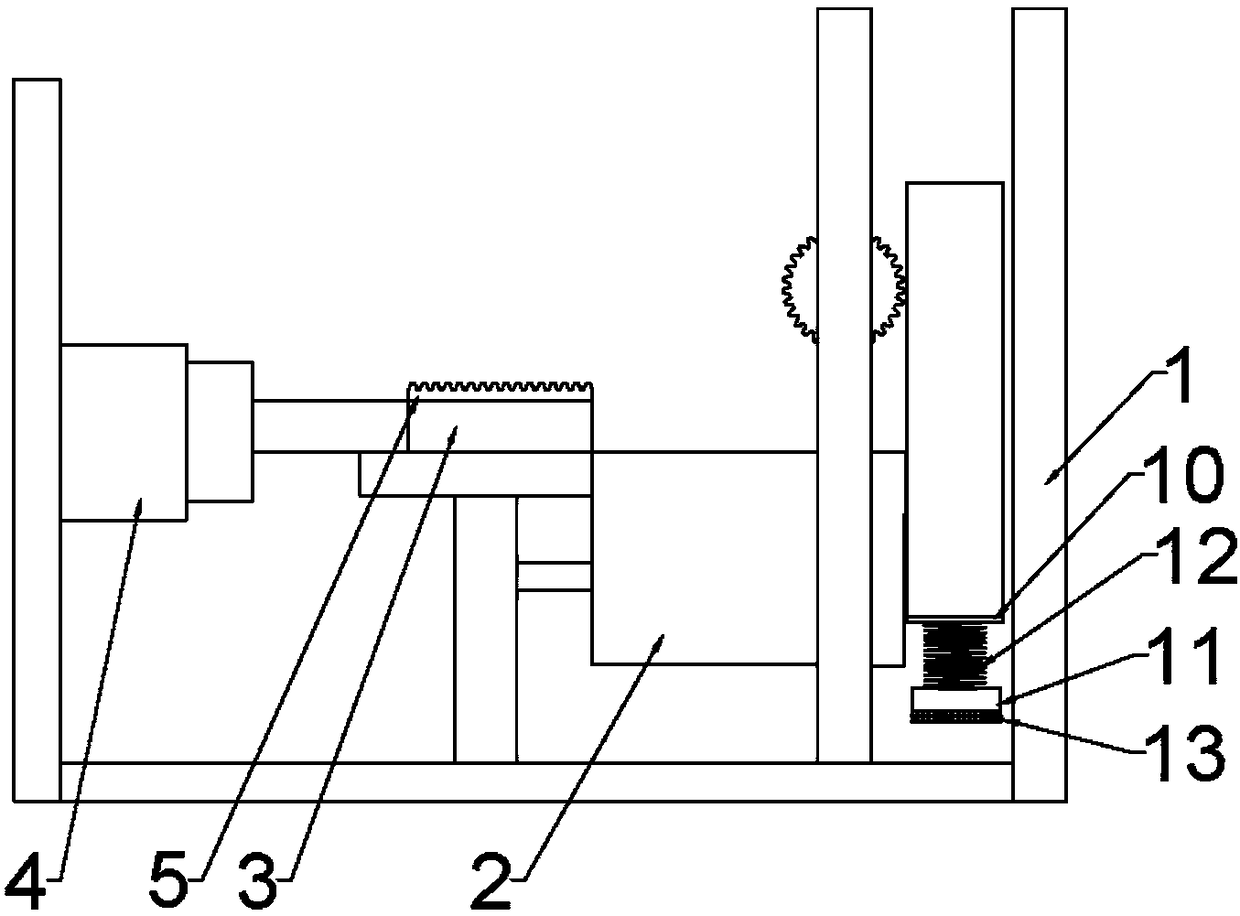

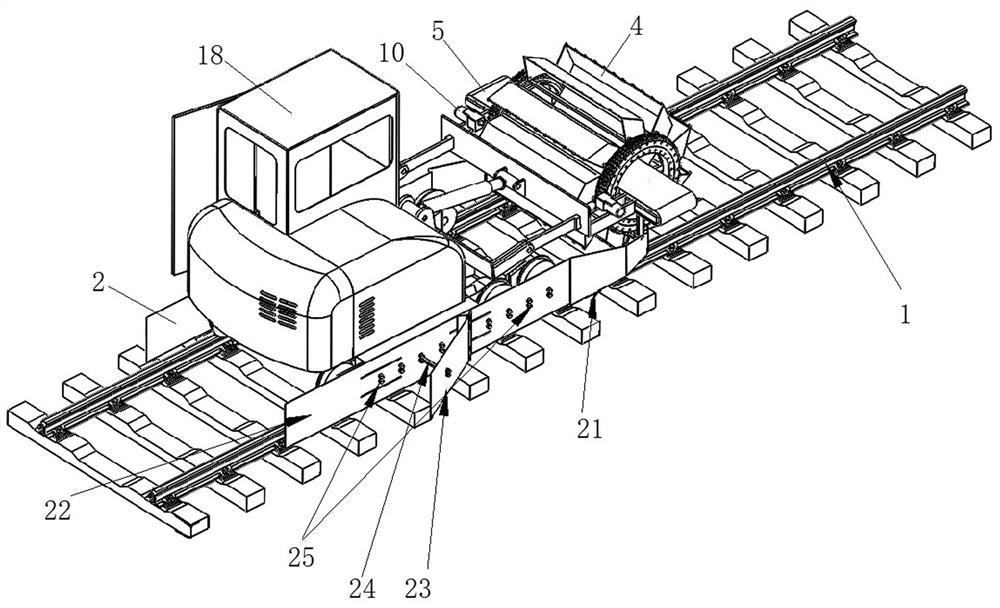

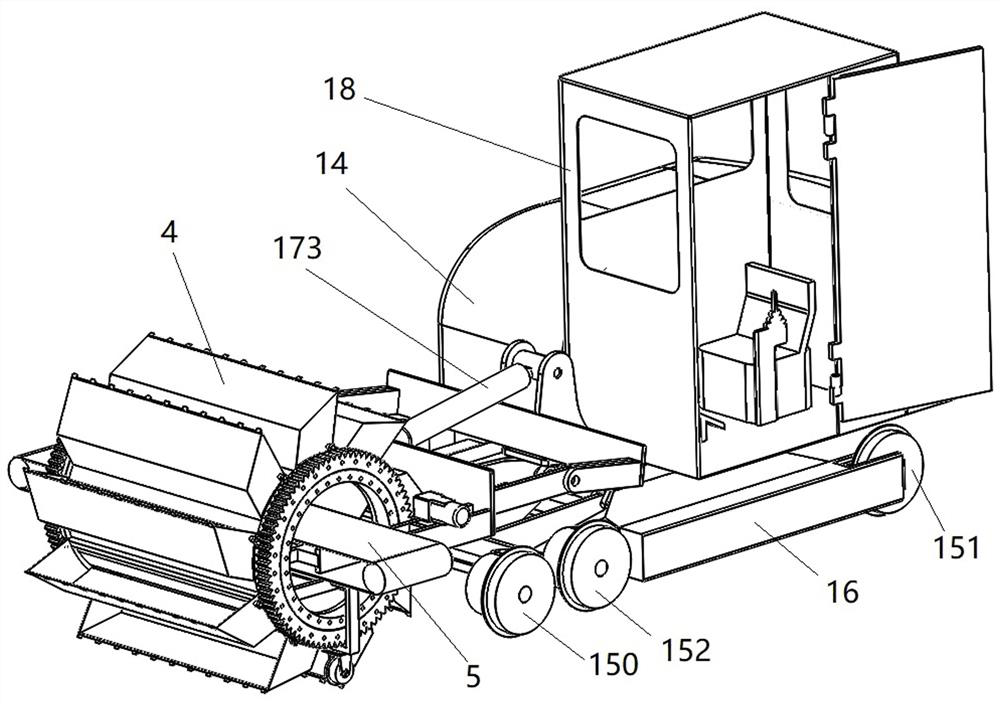

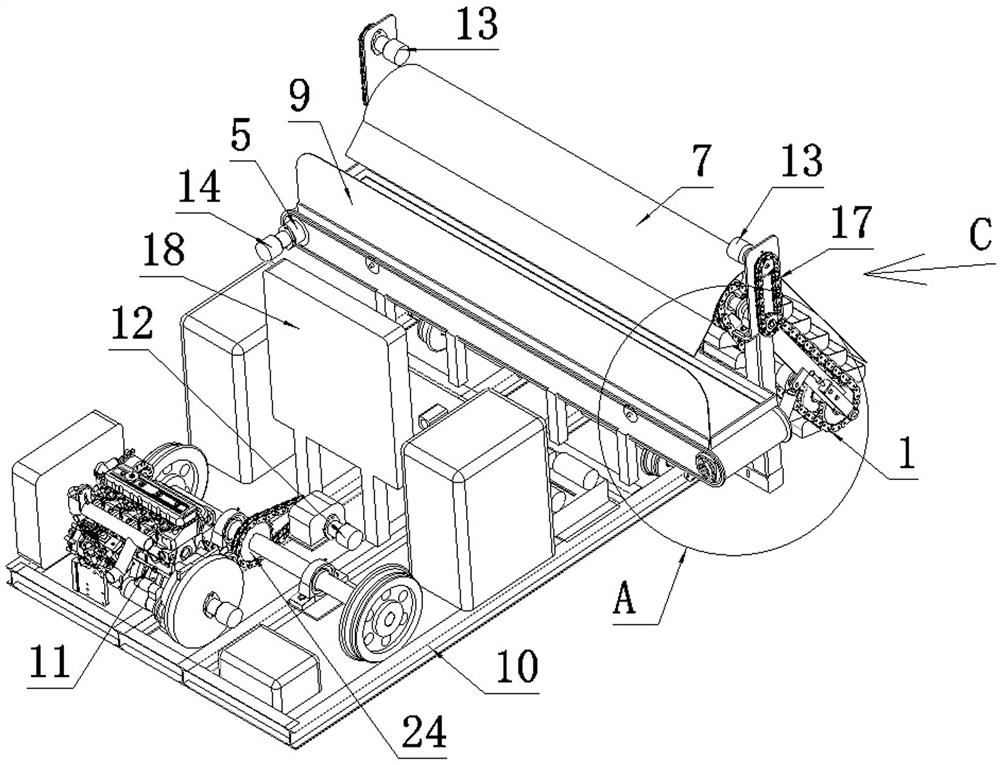

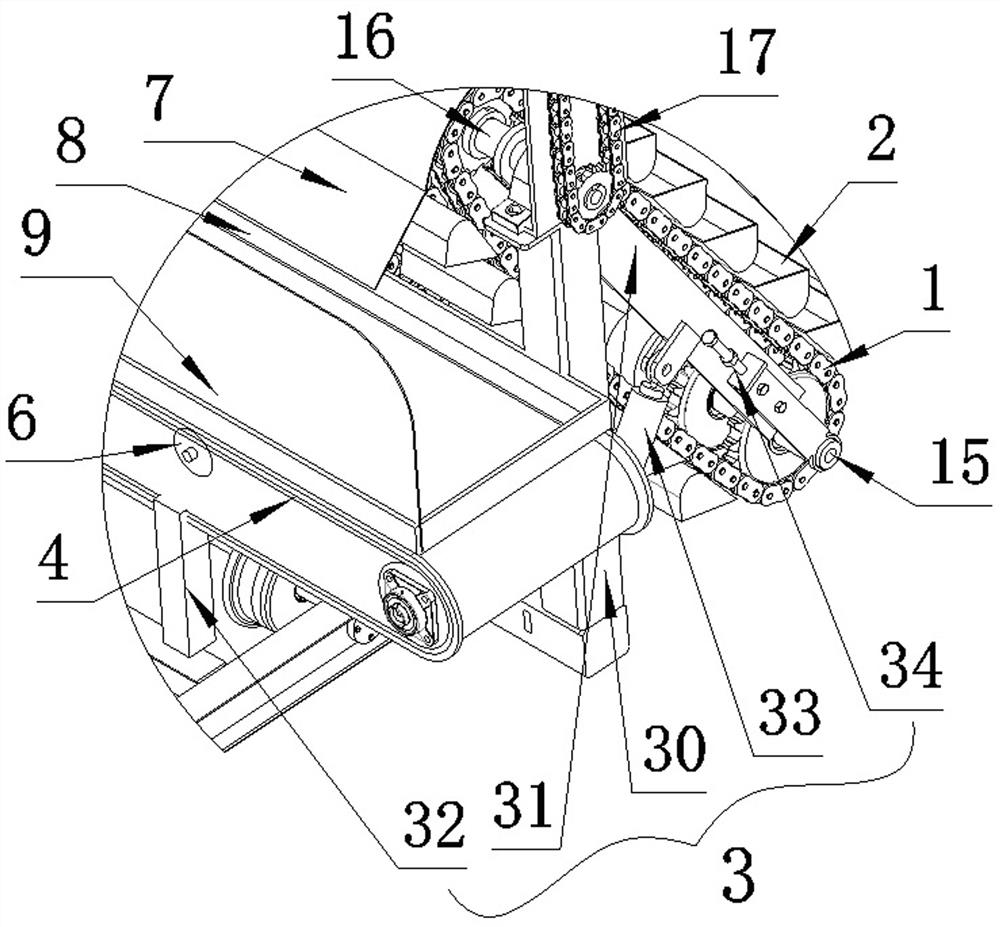

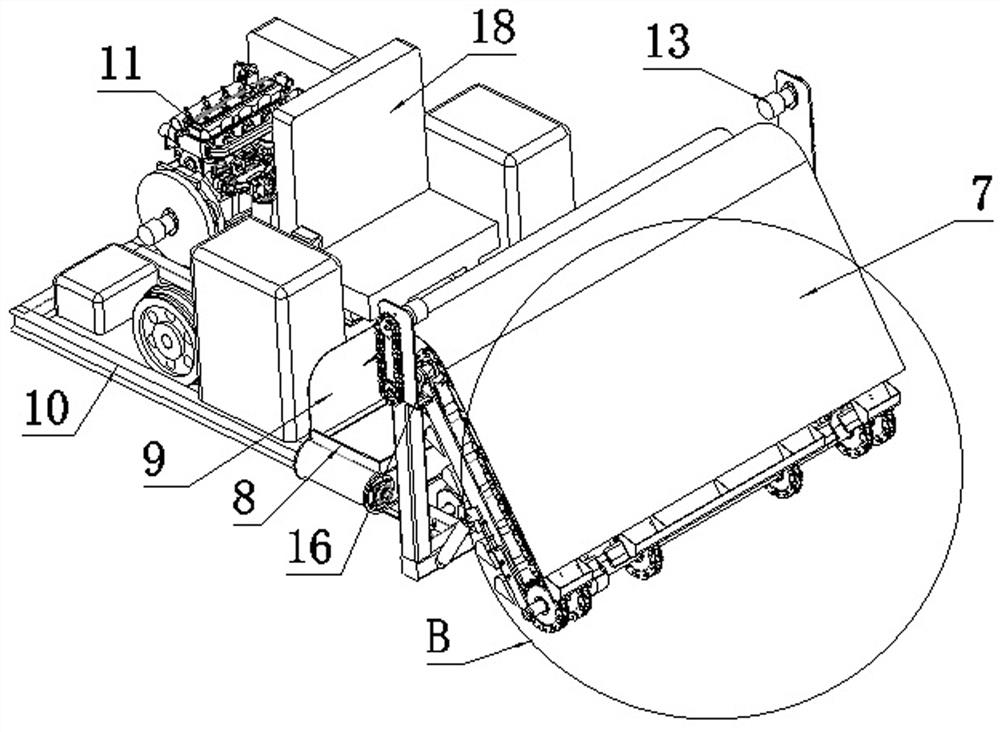

A hopper sand collecting type railway track sand-removing vehicle

The invention discloses a hopper sand collecting type railway track sand-removing vehicle, belonging to the technical field of railway track maintenance equipment, which comprises a power device, a traveling device and a sand removing device arranged on a chassis. The traveling device comprises two or more groups of traveling wheels matched with the track. The sand removing device comprises a sandcollecting mechanism for removing the accumulated sand inside and outside the track, and a sand removing mechanism for discharging the sand cleaned by the sand collecting mechanism to the outside ofthe train frame, wherein the sand collecting mechanism is arranged at the front end of the chassis; The traveling device, sand collecting mechanism and sand flushing mechanism are all driven by the power device. Driving the traveling device to walk along the track by the power device, removing the sand deposit inside and outside the track by the sand collecting mechanism and transporting the sandto the sand discharging mechanism during the traveling process, and discharging the sand to the outside of the track by the sand discharging mechanism, so as to ensure the traffic safety and avoid theoccurrence of the railway stoppage accident caused by the sand deposit on both sides of the track; At that same time, the a hopper sand collecting type railway track sand-removing vehicle has high automation degree, can greatly reduce the labor intensity of the staff, and can improve the sand cleaning work efficiency.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

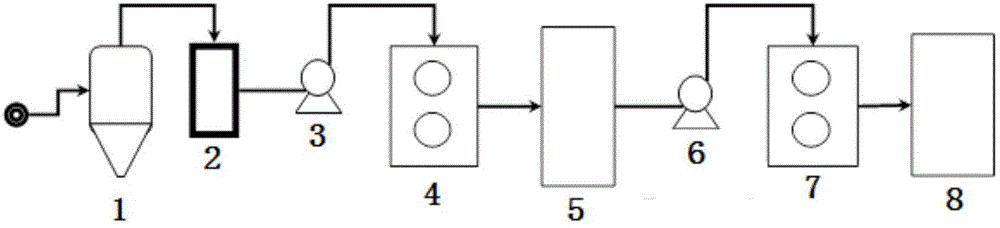

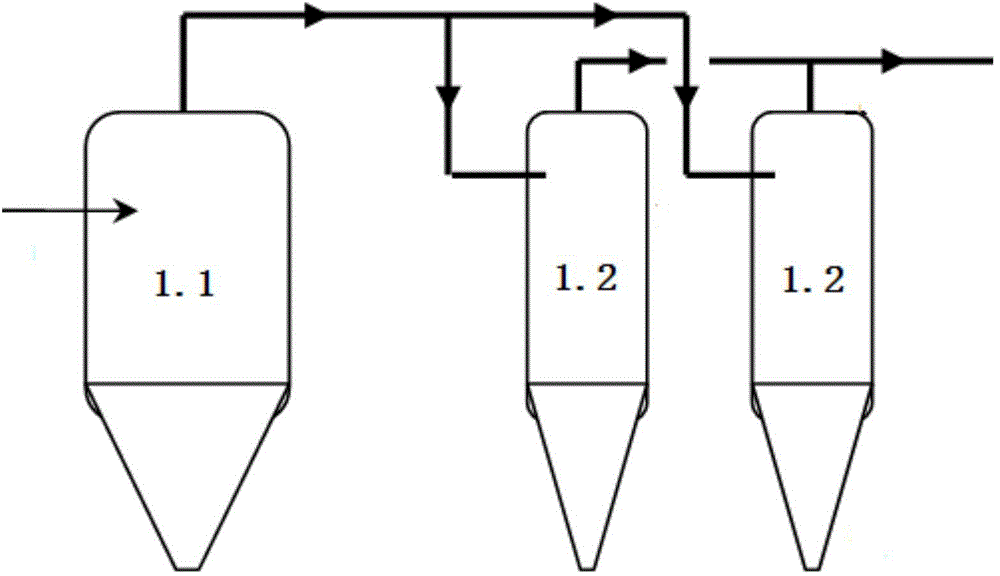

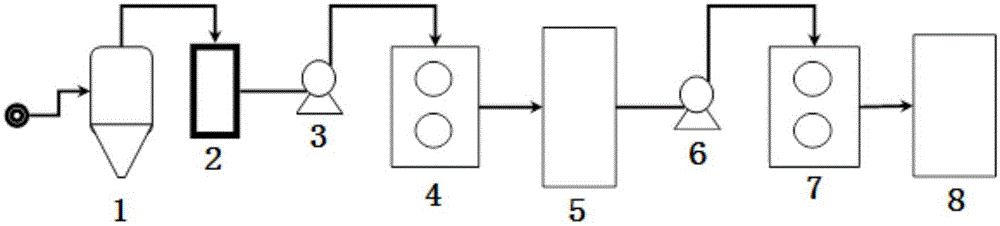

Desanding technology of oilfield flown back fracturing fluid

The invention discloses a desanding technology of an oilfield flown back fracturing fluid. The technology is designed to realize the closed continuous desanding, multilevel control and non-grounding desanding of the flown back fracturing fluid. A waste liquid is processed by a cyclone desanding device, the processed waste liquid enters a pressure relief degassing device for gas-liquid separation and filtering sedimentation, the obtained waste liquid is directly pumped into a filter-order filtering device through a first-order water pump, the filtered waste liquid is settled in a sewage pot, the settled filter waste is directly pumped into a second-order filtering device through a second-order water pump and is processed, and the finally obtained product is introduced into a purified water tank. The desanding technology has the advantages of reliable design, simple operation, no need of over-current, and substantial continuous desanding performance, and an apparatus for realizing the technology has the advantages of strong impact resistance, closed processing process, large processing capacity, and high desanding efficiency.

Owner:PETROCHINA CO LTD

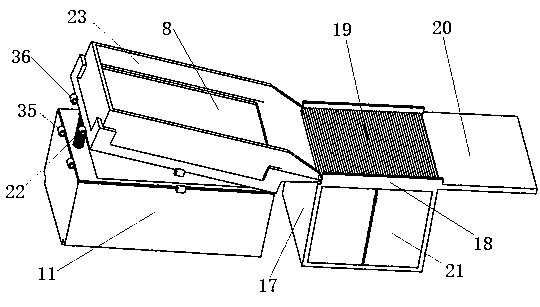

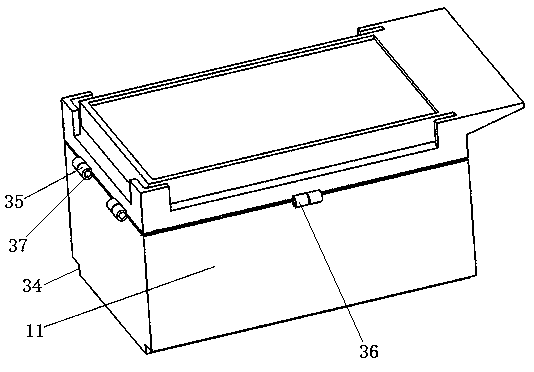

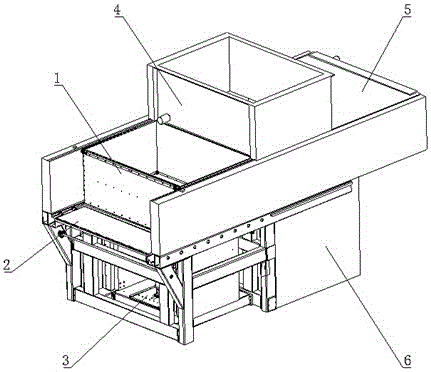

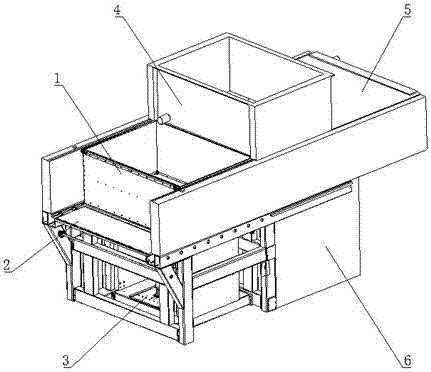

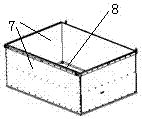

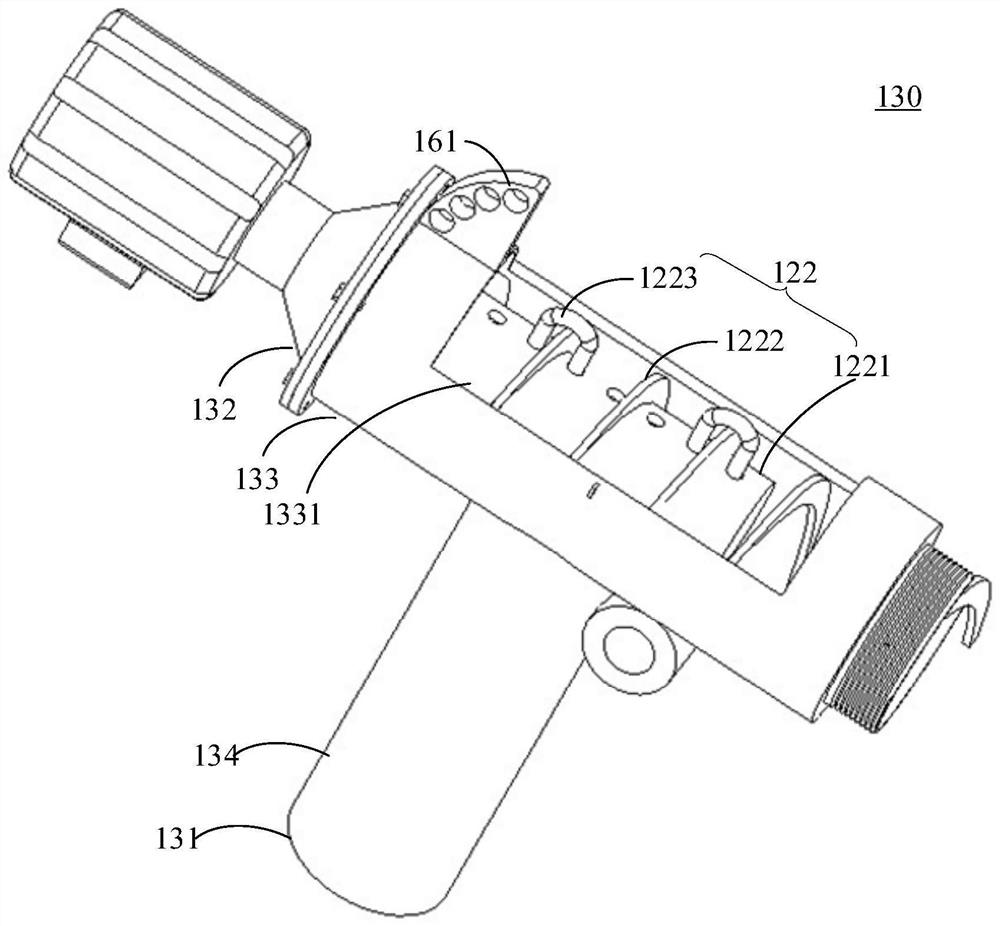

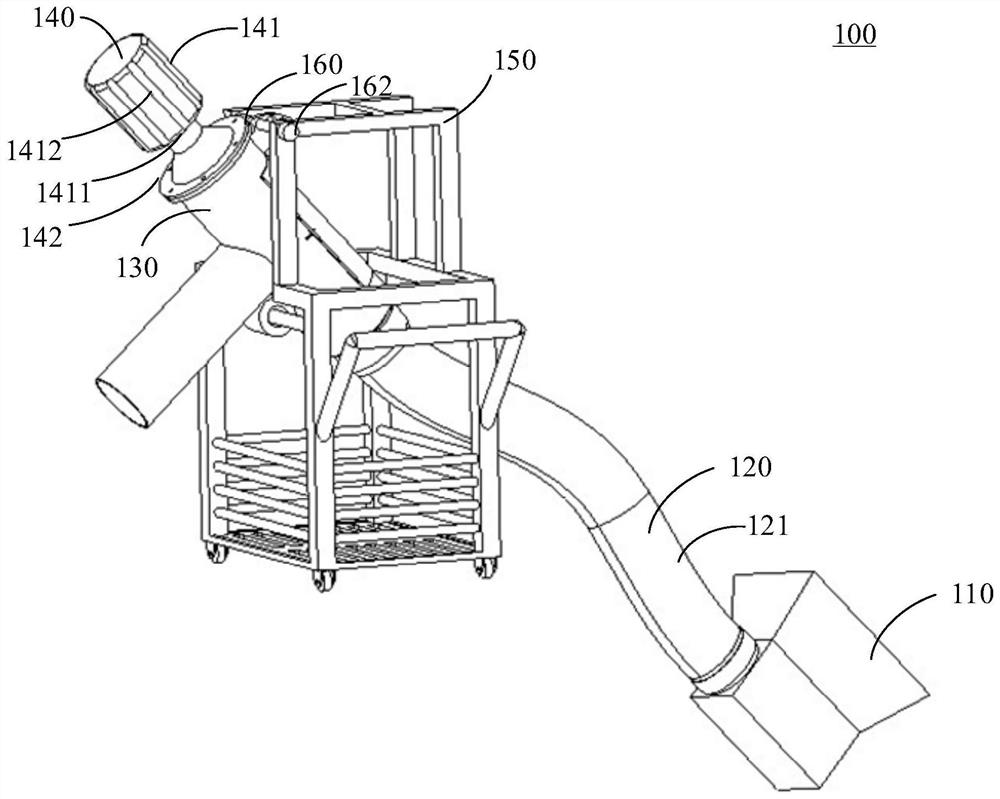

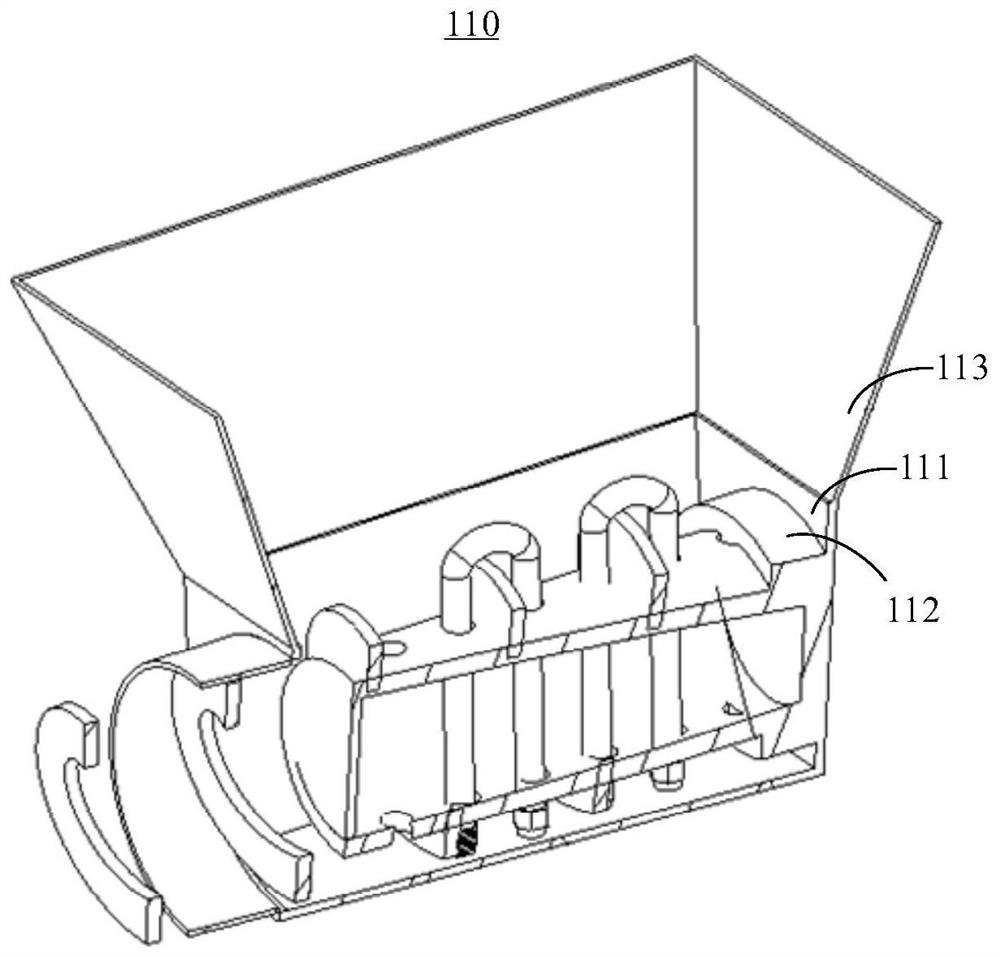

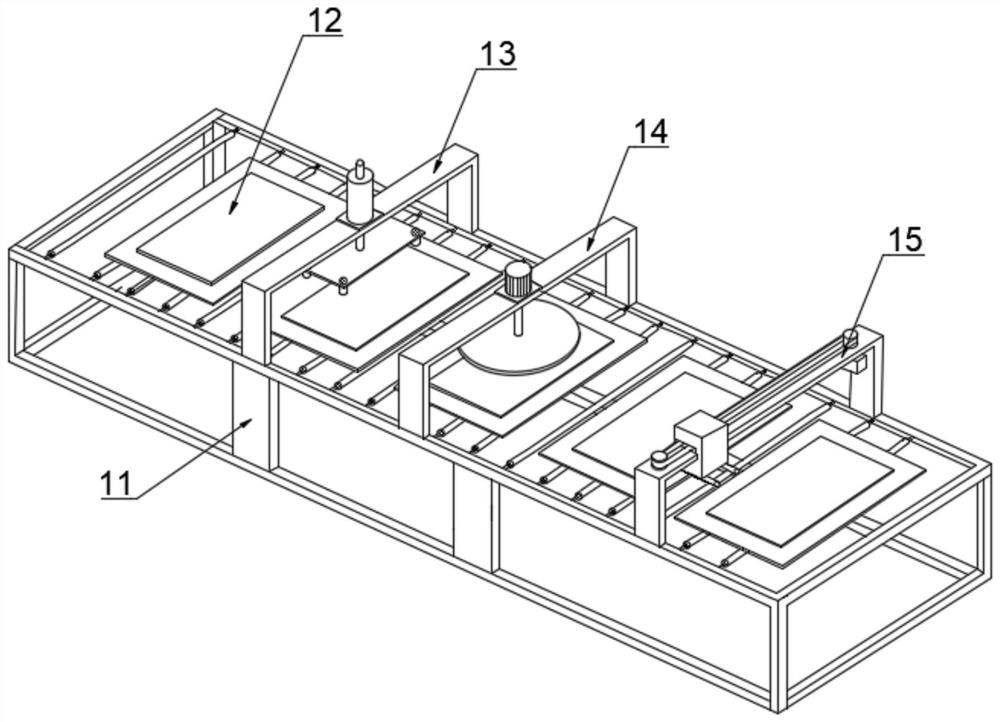

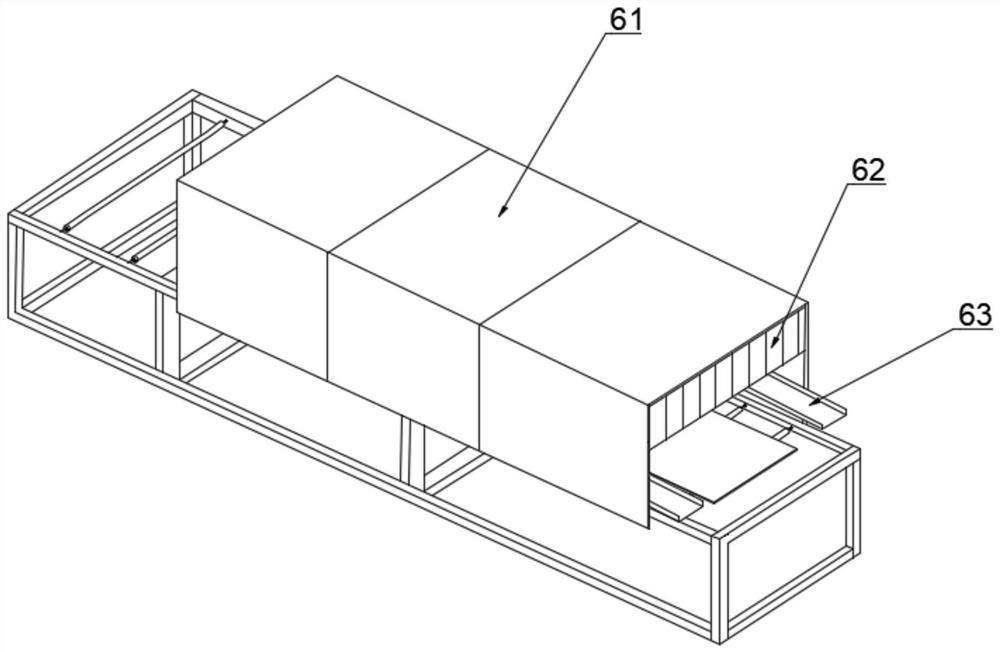

3D printing sand removal apparatus

ActiveCN106041002AFully automatedRealize intelligenceAdditive manufacturing apparatusMoulding machine componentsEngineeringAutomation

The invention relates to the field of sand mold 3D printing sand removal, in particular to a 3D printing sand removal apparatus. The 3D printing sand removal apparatus comprises a working platform, a jacking device, a sand box, a work box, a sand separation plate and a sand receiving tank, wherein the working platform comprises a control device which controls the sand box, the work box and the sand separation plate to carry out positioning movement, a roller bed conveying device and a grid plate, the jacking device comprises a lifting plate, a base, side plates c and a jacking machine located on the base, the jacking device is located below the working platform, the sand box is located on the roller bed conveying device of the working platform, the work box is located above the sand box, the sand separation plate is arranged above the sand box and below the work box, and the sand receiving tank is located below the working platform. With the 3D printing sand removal apparatus, the problem that the efficiency of traditional waste sand processing is low is solved, the efficiency of sand removal is improved, and the automation and the intelligence of the whole process of 3D printing are achieved.

Owner:NINGXIA KOCEL MOLD

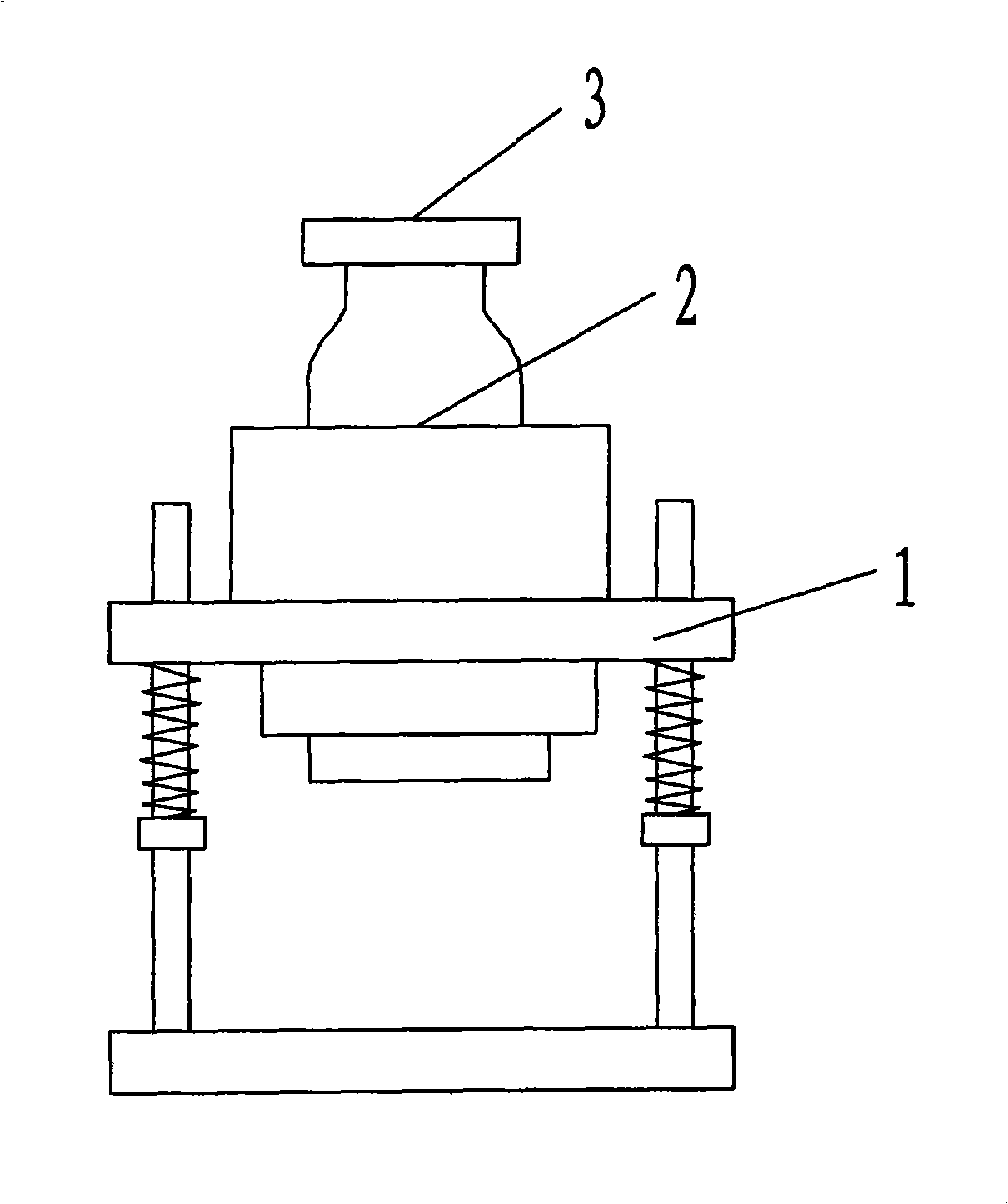

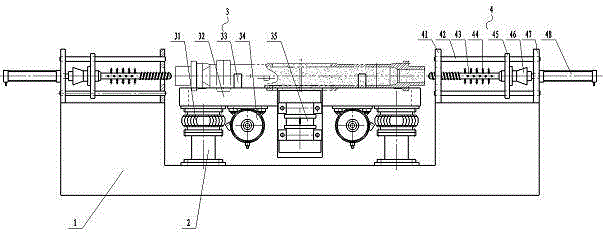

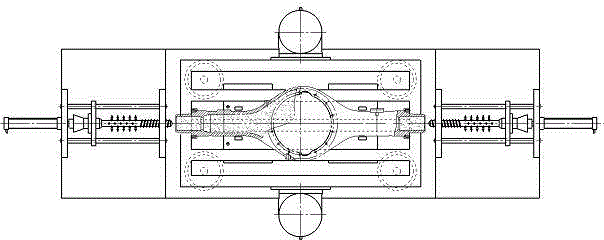

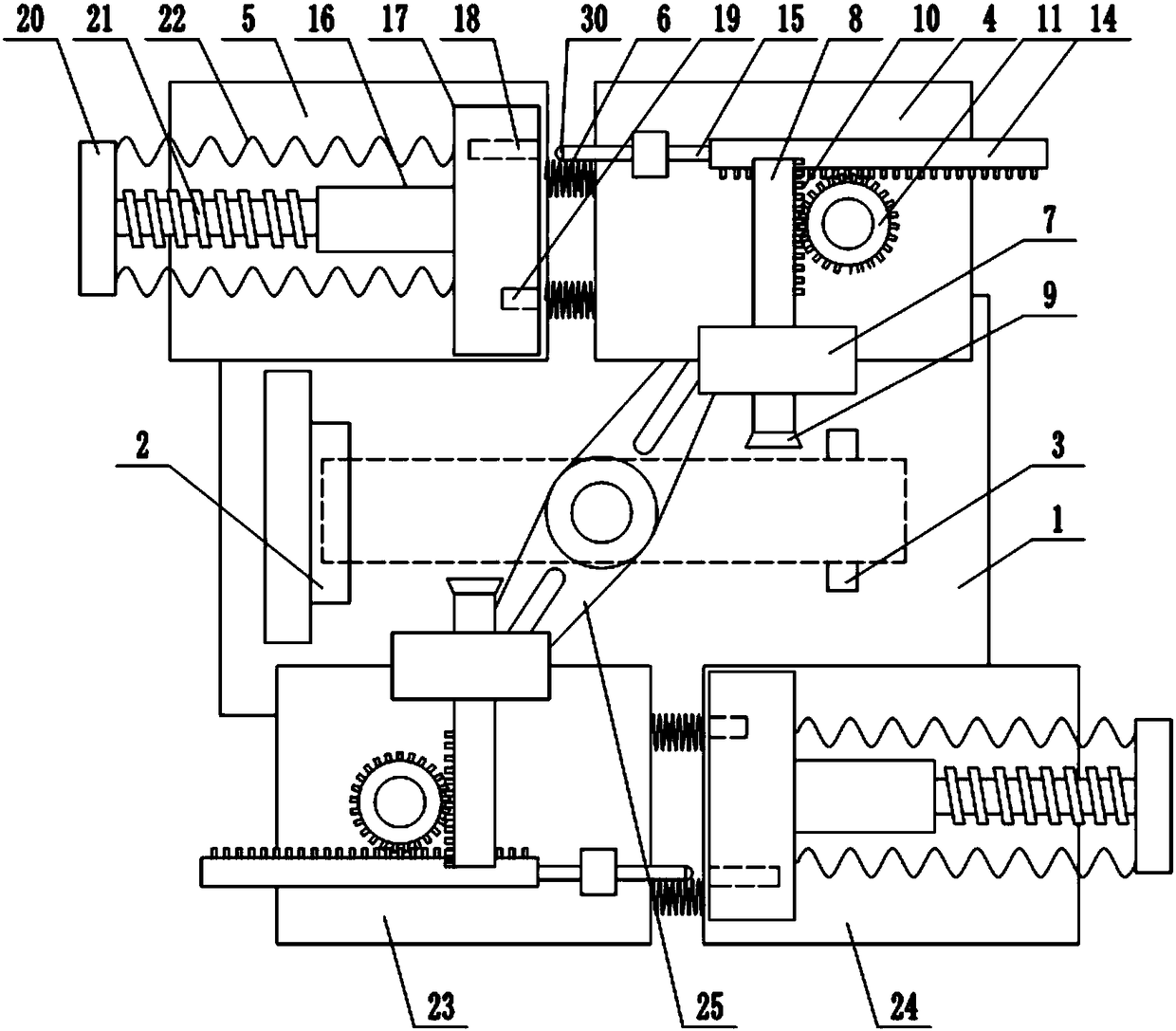

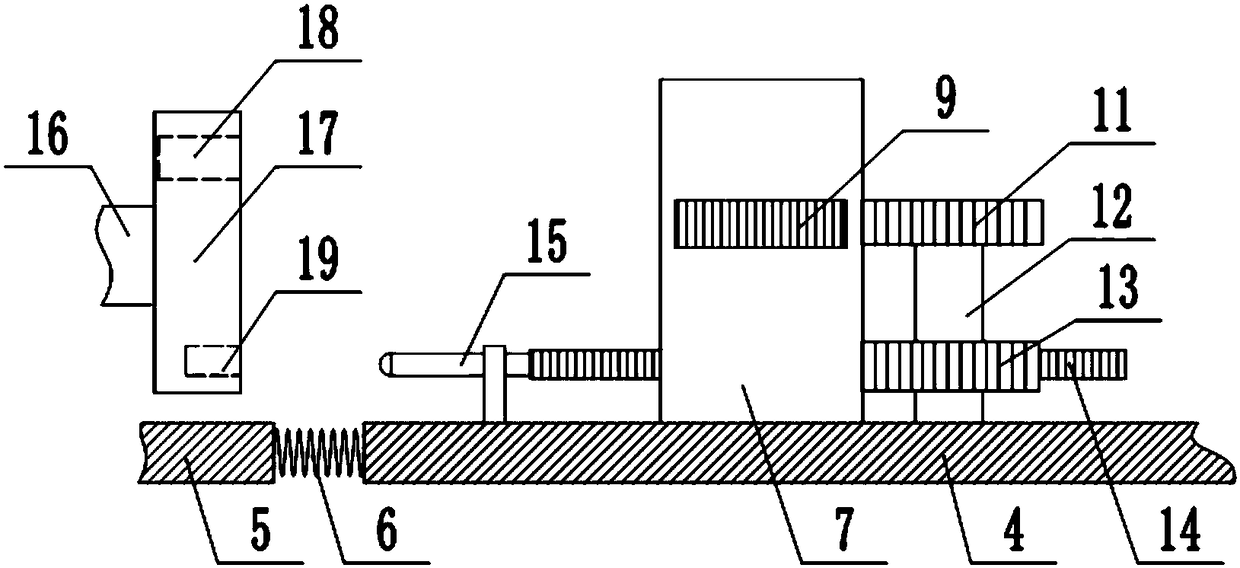

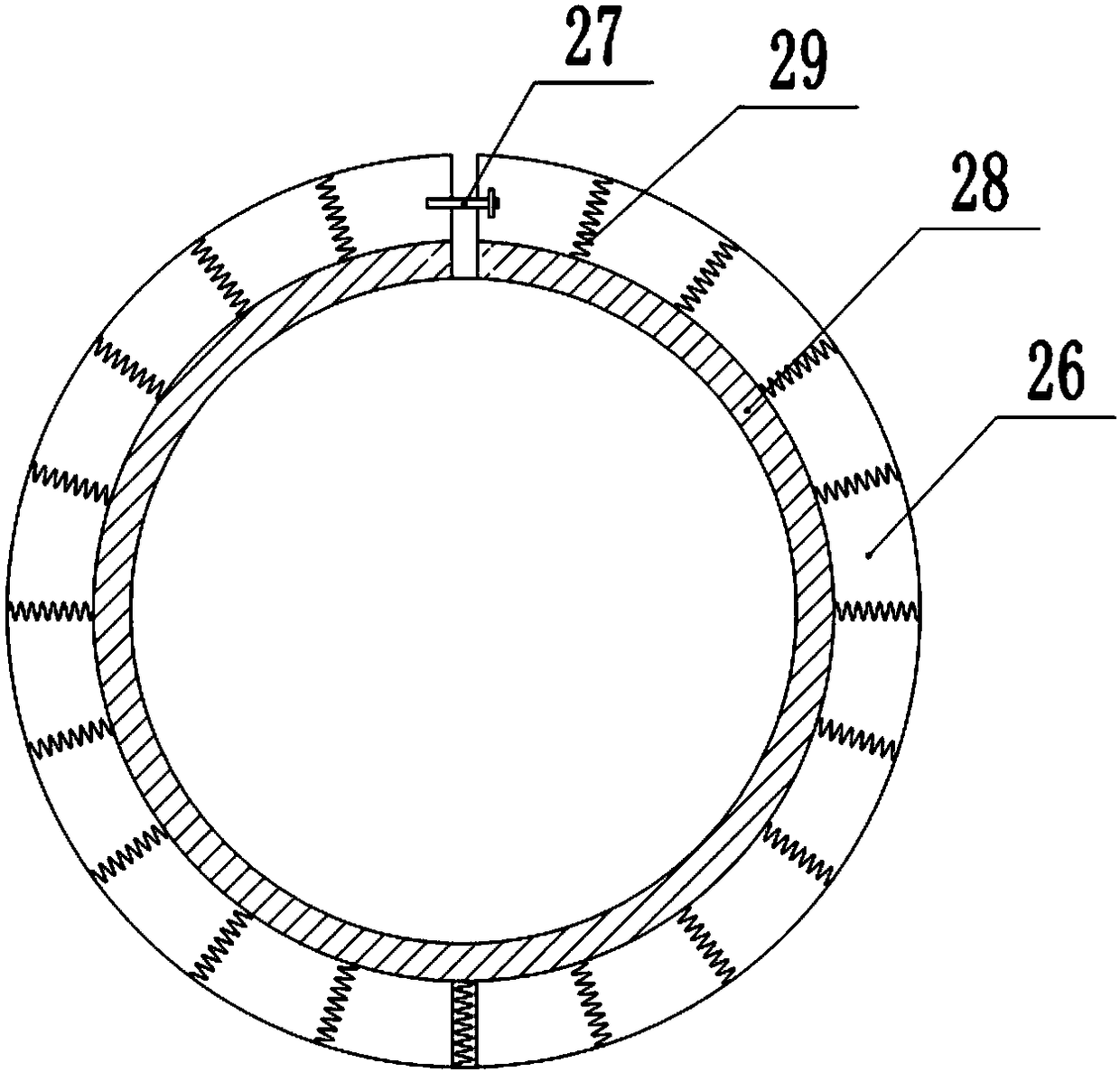

Sand cleaning machine for axle case casting

The invention discloses a sand cleaning machine for an axle case casting. The sand cleaning machine for the axle case casting comprises a machine seat, vibrating mechanisms and cleaning mechanisms, wherein the vibrating mechanism comprises air springs which are mounted on upright posts of the machine seat; a vibrating table is mounted on each air spring; a vibrating motor is mounted on each vibrating table; each cleaning mechanism comprises supporting plates, wherein the supporting plates consist of an inner supporting plate and an outer supporting plate; a guide rail is arranged between each inner supporting plate and the corresponding outer supporting plate; a sliding plate is mounted on each guide rail; an air hammer is mounted on each sliding plate; an air cylinder is mounted on each rear supporting plate; a punching head is mounted on each air hammer; the front end of the punching head faces the corresponding inner supporting plate; the piston rod of each air cylinder is connected with the rear end of the corresponding air hammer. According to the sand cleaning machine for the axle case casting, the sand in the inner cavity of an axle case is drilled to be loosened through the air hammers, and simultaneously, the axle case casting is vibrated through the vibrating tables, so that the sand on the outer surface and in the inner cavity is vibrated to fall. The sand cleaning machine for the axle case casting is simple in structure and high in sand cleaning efficiency; the labor intensity of a worker is greatly reduced; the production efficiency is improved; the production cost is reduced.

Owner:龙岩市八仙岩茶业有限公司

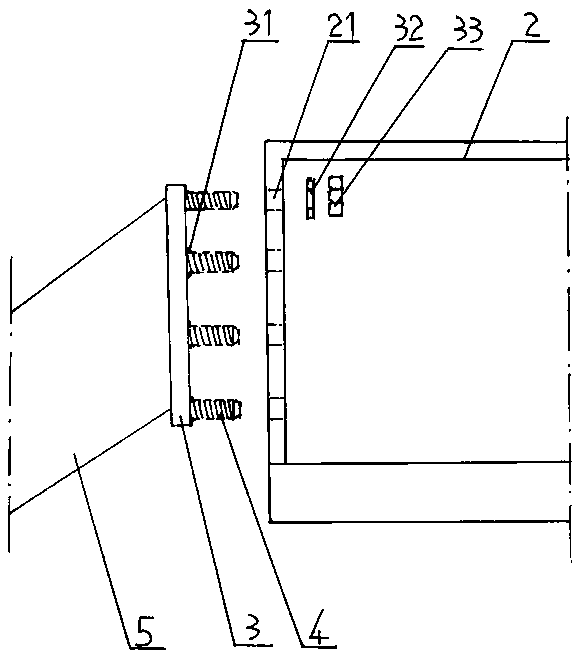

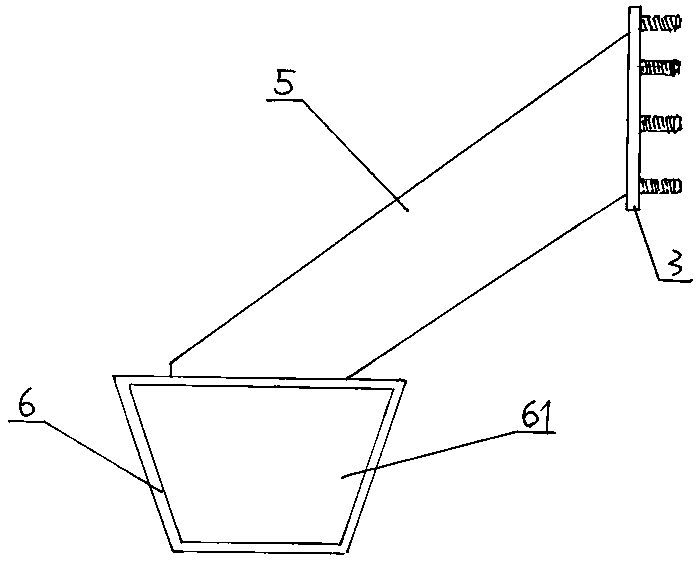

Vehicle coupler inner-cavity steel shot cleaner for railway vehicles

InactiveCN102390040AEasy sand cleaningImprove sand cleaning efficiencyAbrasive machine appurtenancesAbrasive blasting machinesDrive shaftTurning frames

Owner:CRRC YANGTZE CO LTD

Binder for chemical hardened sand mold casting

InactiveCN106734862AModerate viscosityImprove sand cleaning efficiencyFoundry mouldsFoundry coresPolyethylene glycolGlycerol

The invention discloses a binder for chemical hardened sand mold casting, and relates to the technical field of sand mold casting. The binder is composed of, by weight, 30-40 parts of activated clay, 10-15 parts of modified sepiolite powder, 10-15 parts of cera alba, 10-15 parts of paroline, 8-13 parts of sulfated castor oil, 7-11 parts of polyethylene glycol, 5-10 parts of sodium carboxymethyl starch, 5-10 parts of glycerol polyoxyethylene ether, 4-8 parts of terpene resin, 3-5 parts of furfuryl alcohol, 3-5 parts of tributyl citrate, 2-3 parts of nanometer aluminum oxide and 1-2 parts of ferric trichloride. The binder is proper in viscosity, is capable of being fully mixed with chemical hardened sand, and fully improves the sand forming performance and quality of a casting. The sand cleaning efficiency of the casting is high, and a sand adhesion phenomenon is avoided. In addition, poisonous organic gas is not generated during pouring of the casting, and the safety and environmentally friendliness are high.

Owner:CHIZHOU GONGHE MACHINE

Casting cleaning equipment

The invention relates to the field of casting machining, and discloses casting cleaning equipment. The casting cleaning equipment comprises a base; the base is provided with a clamping piece and a support block; a first console and a second console are arranged on one side of the base; a tension spring is connected between the first console and the second console; the first console is fixedly connected with a first support base; a first sand removing rod is slidingly connected into the first support base, and is connected with a first brush head; a driving tooth is arranged on the first sand removing rod, and is engaged with a first gear; the first gear is coaxially and fixedly connected with a first rotating shaft; the first rotating shaft is coaxially and fixedly connected with a secondgear; the second gear is engaged with a first rack; the first rack is fixedly connected with a first butting rod; the second console is fixedly connected with a first sleeve; the first sleeve is connected with a first driving disc; a first groove and a second groove are arranged on the first driving disc; the first groove is deeper than the second groove; the base is fixedly connected with a firstlead screw; and the first lead screw is in threaded connection into the first driving disc. The device is thorough in sand removal.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

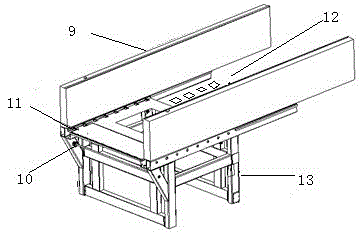

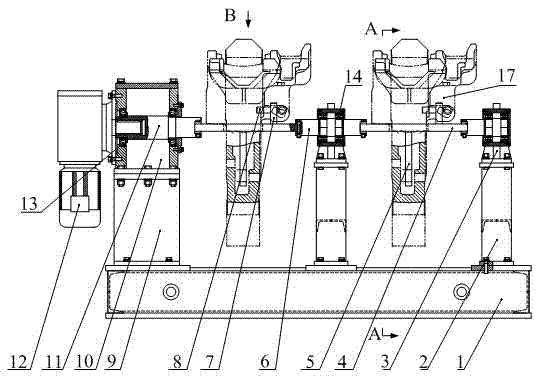

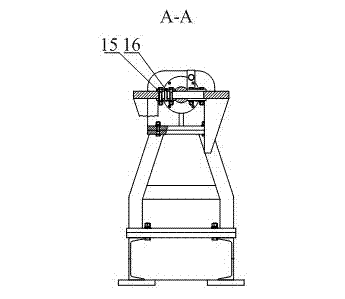

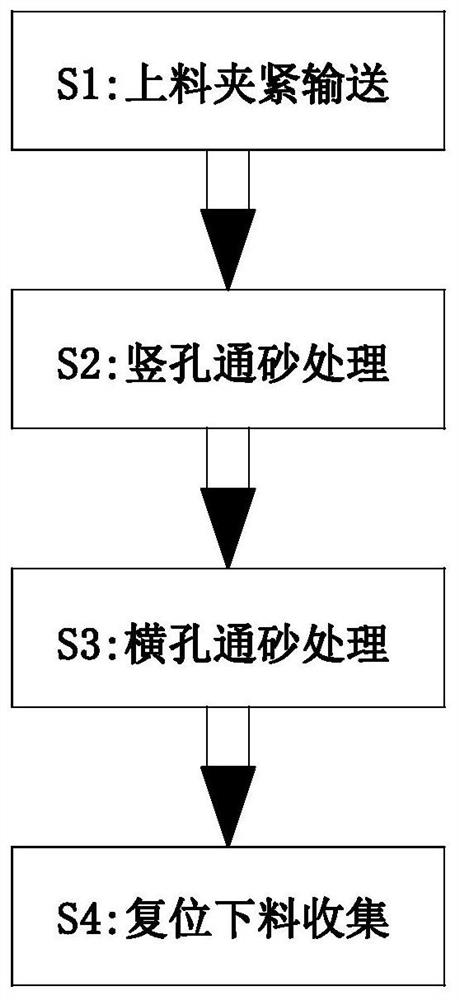

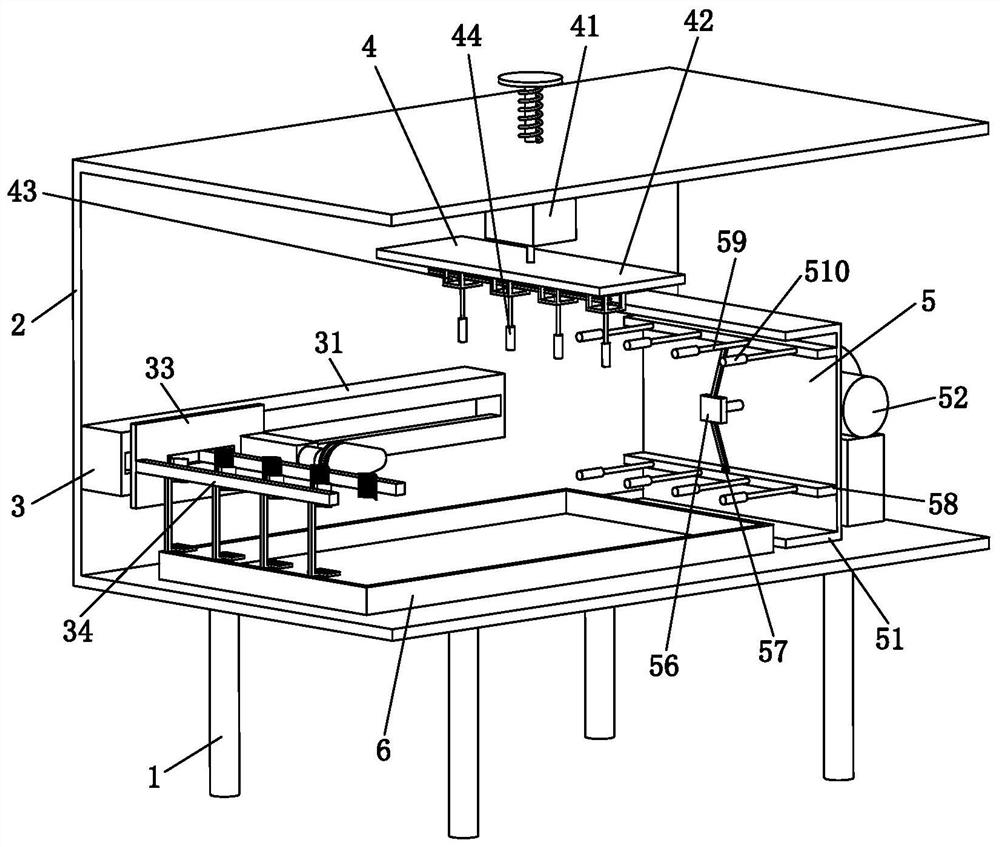

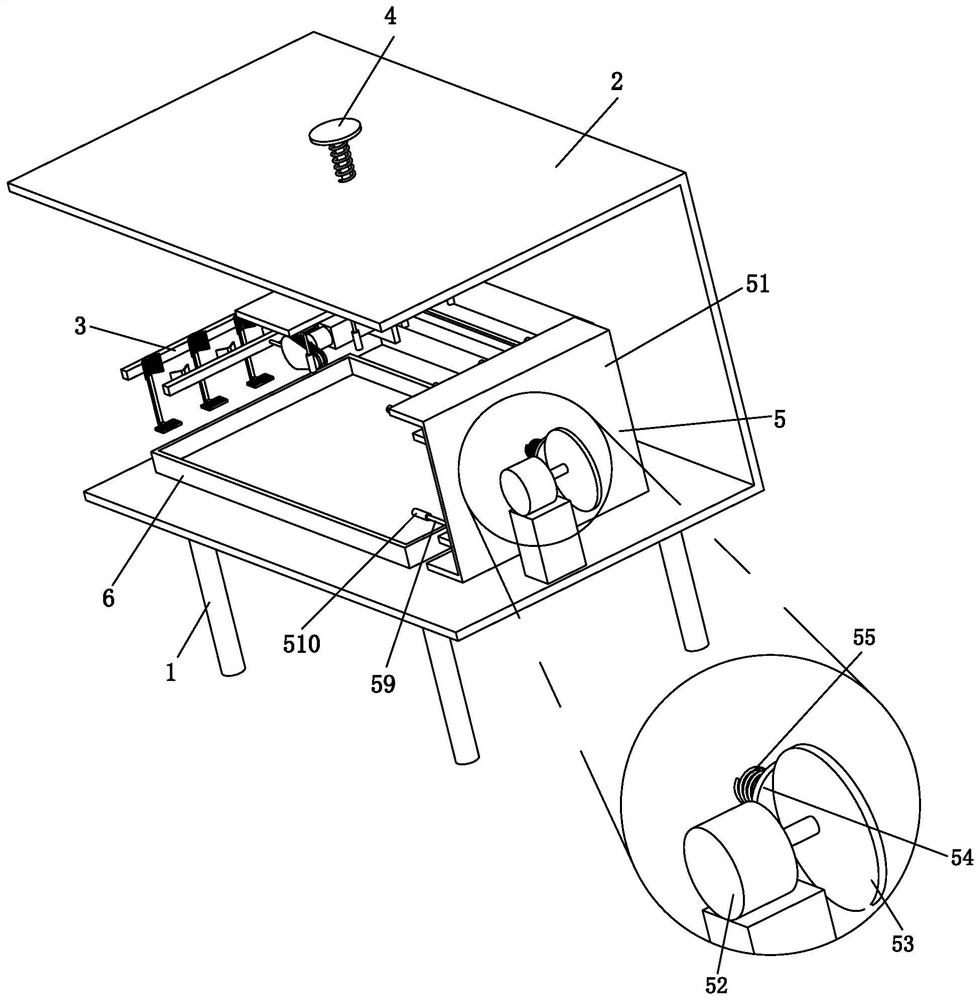

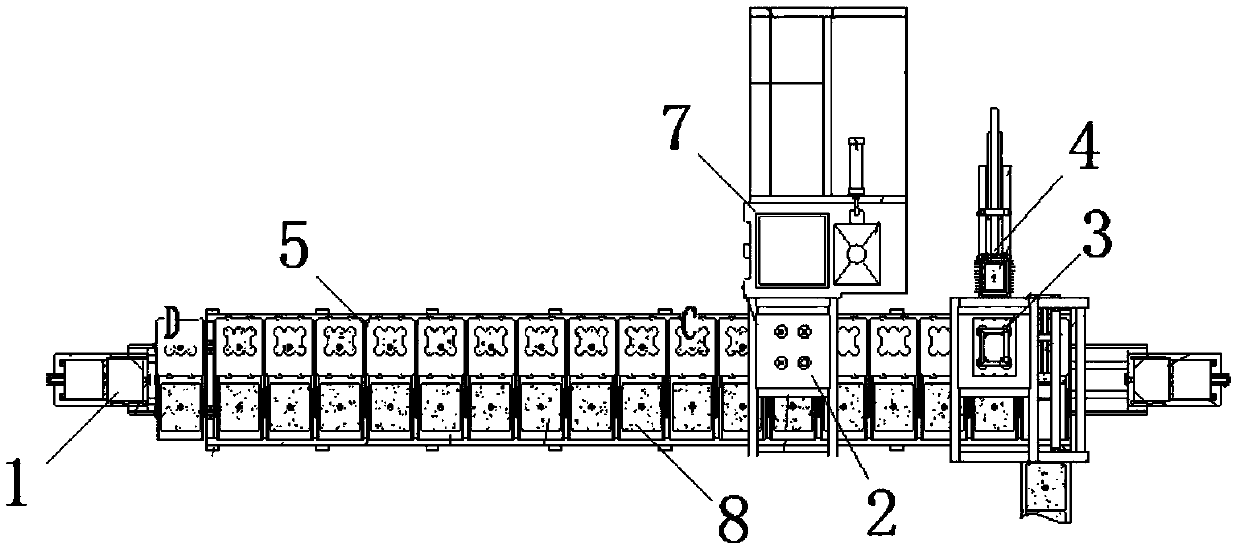

Steel structure engineering grouting sleeve manufacturing and machining technology

InactiveCN113351534ASave loading timeReduce labor costsRevolution surface grinding machinesGrinding drivesMachining processIndustrial engineering

The invention relates to a steel structure engineering grouting sleeve manufacturing and machining technology. Supporting legs, a first [-shaped plate, a clamping conveying device, a first sand cleaning device, a second sand cleaning device and a shakeout collecting frame are included. The steel structure engineering grouting sleeve manufacturing and machining technology can solve the following problems possibly encountered in the sand cleaning process of an existing grouting sleeve that a, sand cleaning treatment is carried out on the inner wall of a grouting sleeve manually by using a sand cleaning tool, the required labor cost is relatively high, the labor intensity is relatively high, and the sand cleaning efficiency is relatively low; and b, the phenomenon of incomplete sand removal is prone to occurring due to manual sand removal, the sand removal effect is poor, the production quality of the grouting sleeve is reduced, and the use effect of the grouting sleeve is influenced.

Owner:毛国运

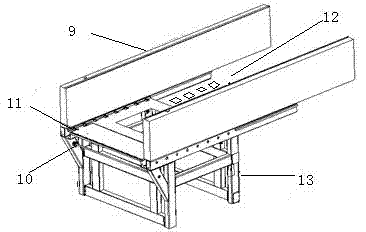

Sand cleaning mechanism for sand mold sleeve box

PendingCN108672664AReasonable structural designImprove sand cleaning efficiencyMoulding toolsMoulding flasksEngineeringManufacturing line

The invention discloses a sand cleaning mechanism for a sand mold sleeve box. The mechanism comprises a sand cleaning rack, a reciprocating arm, a cleaning brush for cleaning the inner wall of the sleeve box removed from a sand mold, and a reciprocating driving structure for driving the reciprocating arm to move, wherein the reciprocating arm and the reciprocating driving structure are arranged onthe sand cleaning rack; and the cleaning brush is arranged on the reciprocating arm through a cleaning brush lifting structure. The sand cleaning mechanism for the sand mold sleeve box is reasonablein structure design; the work of cleaning the sand of the inner wall of the sleeve box can be automatically performed in a production line after the sleeve box is removed from the sand mold, thus thesand cleaning efficiency is greatly improved, and the cost is decreased.

Owner:ANHUI XINNING EQUIP

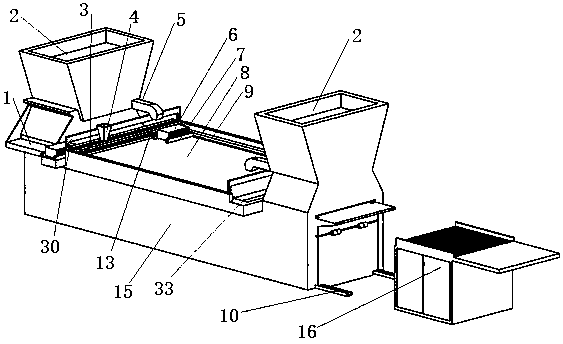

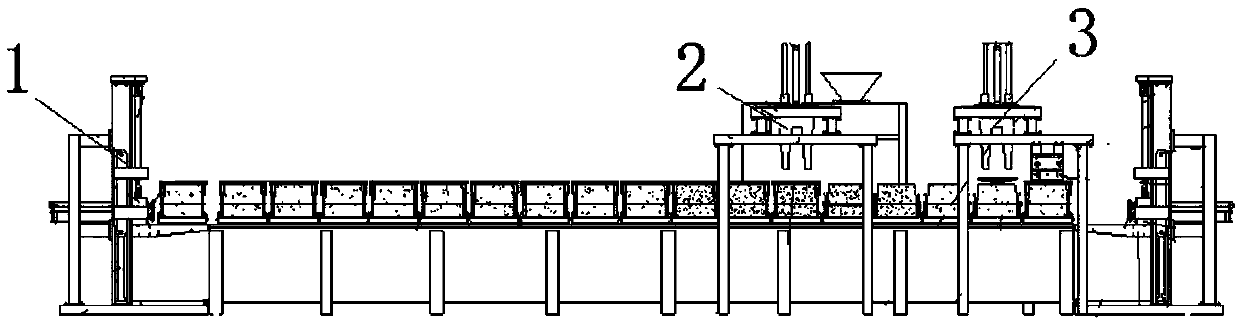

Efficient line sand cleaning machine

PendingCN114182678AQuick clean upImprove sand cleaning efficiencyRailway cleaningTrackwayProcess engineering

The invention discloses an efficient line sand cleaning machine which is used for a rail and comprises a bottom frame, a sand collecting device, a conveying device, a walking device and a power device, the sand collecting device is used for collecting sand on sleepers of the rail, and the sand collecting device is installed on the bottom frame; the conveying device is used for conveying the concentrated sand to the outer side of the rail, the conveying device is connected with the sand collecting devices, and the sand collecting devices are located on the two sides of the conveying device; the power device is connected with the sand collecting device and the conveying device to provide power; the walking device is used for walking along a track of a rail and installed on the bottom frame. According to the sand cleaning machine, sand collecting and sand discharging can be conducted at the same time in the process that the sand cleaning machine walks along the rail, and therefore the sand cleaning efficiency is improved.

Owner:CHONGQING DINGYU ELECTROMECHANICAL +1

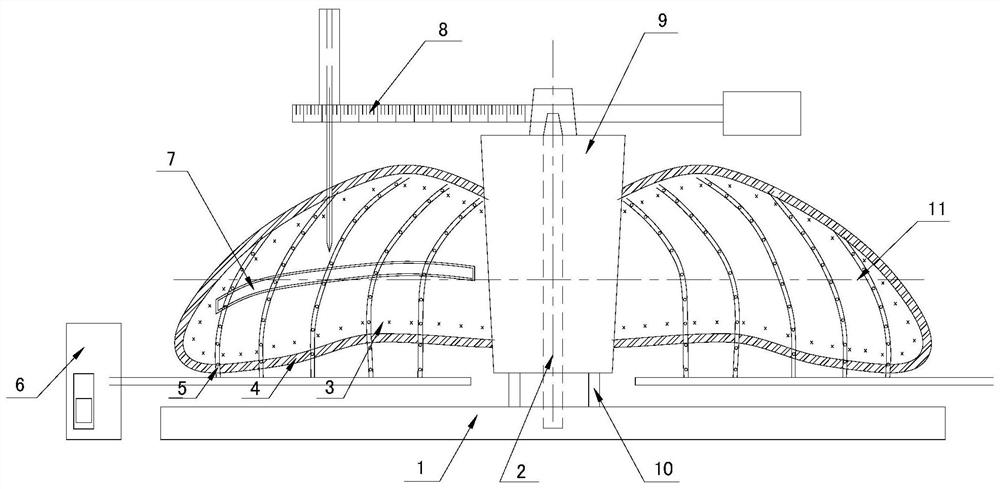

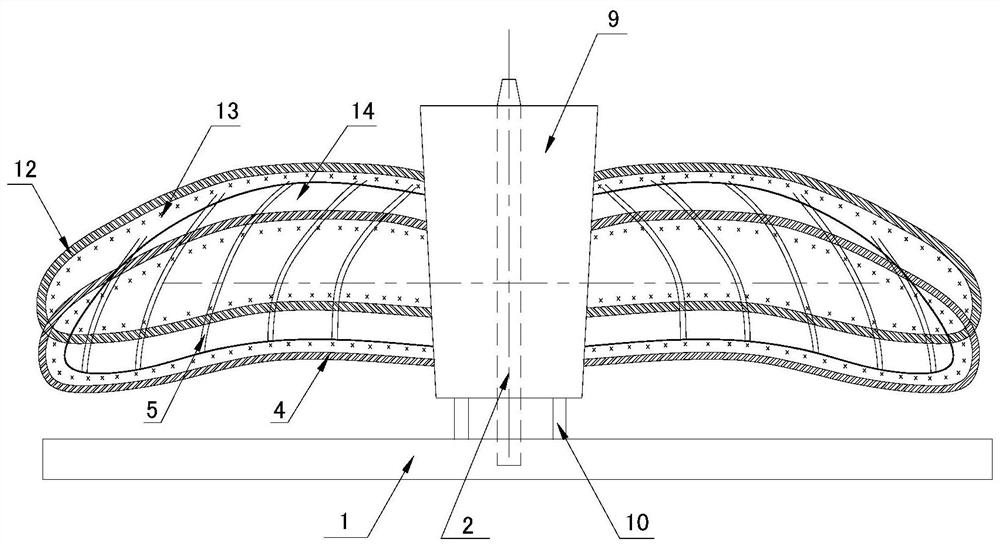

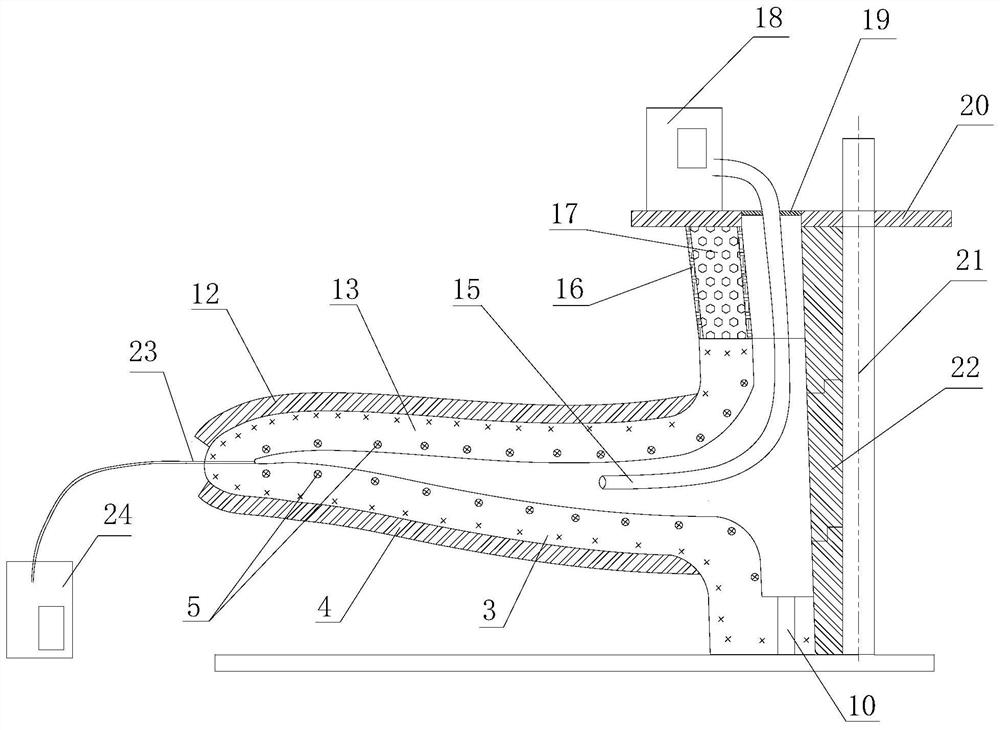

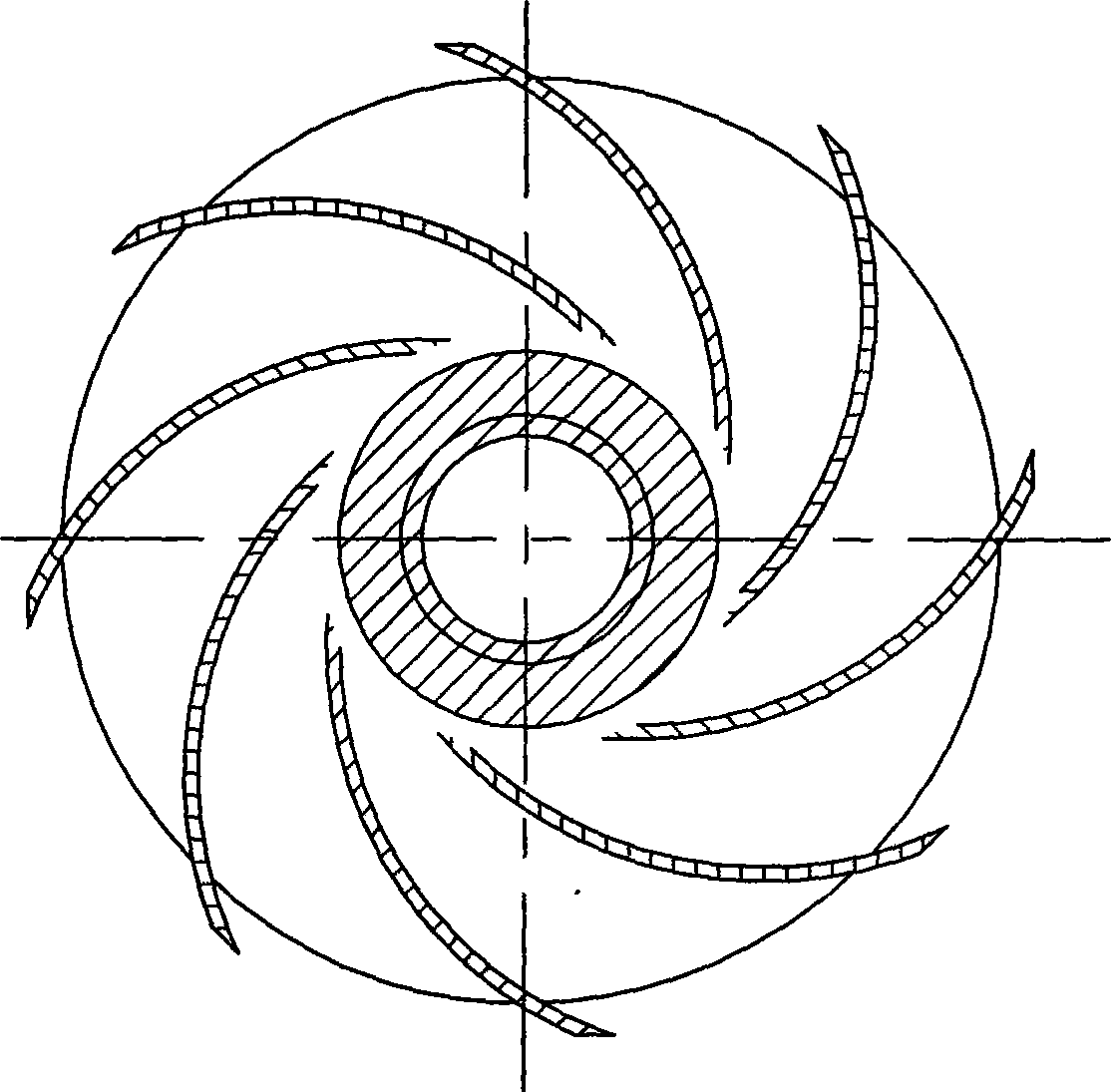

Molding material, molding structure and molding process for marine propeller manufacturing

ActiveCN112828239AGood liquidityShort hardening timeFoundry mouldsFoundry coresPropellerSodium silicate

The invention discloses a modeling material, a modeling structure and a modeling process for marine propeller manufacturing, and relates to the technical field of propeller manufacturing, in particular to a modeling structure and process for manufacturing by adopting a recyclable modeling material. The molding material for marine propeller manufacturing comprises ester-hardened modified sodium silicate-bonded sand and CO2-hardened modified sodium silicate-bonded sand. According to a preparation method of the ester-hardened modified sodium silicate-bonded sand, 15% of fresh sand, 85% of reclaimed sand, 1.5-2.5% of modified sodium silicate and ester accounting for 15-20% of the modified sodium silicate are mixed according to the ratio. According to a preparation method of the CO2-hardened modified sodium silicate-bonded sand, 30% of fresh sand, 70% of reclaimed sand, 2-3% of modified sodium silicate and a hardening accelerator accounting for 20-30% of the modified sodium silicate are mixed according to the ratio.

Owner:DALIAN MARINE PROPELLER CO LTD

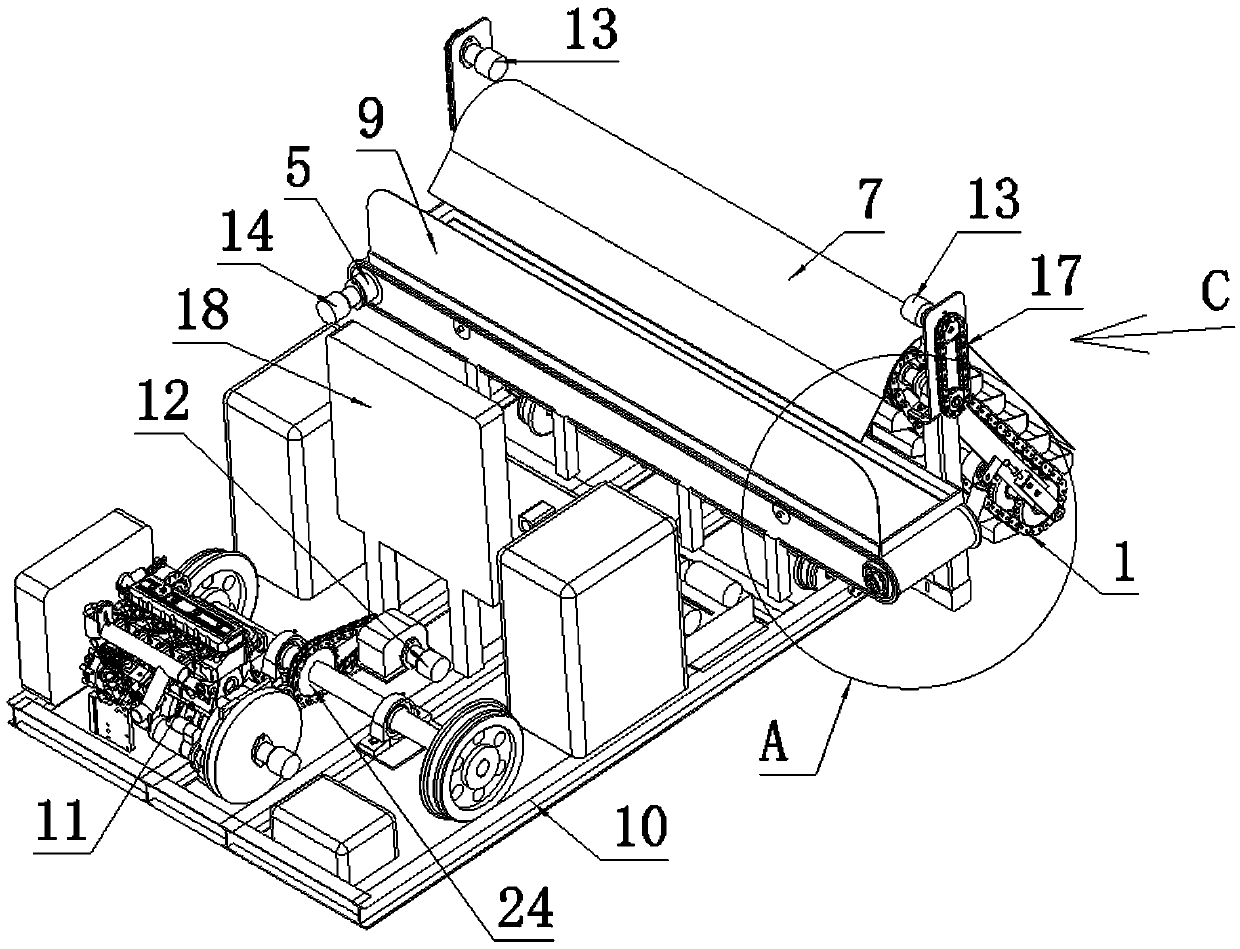

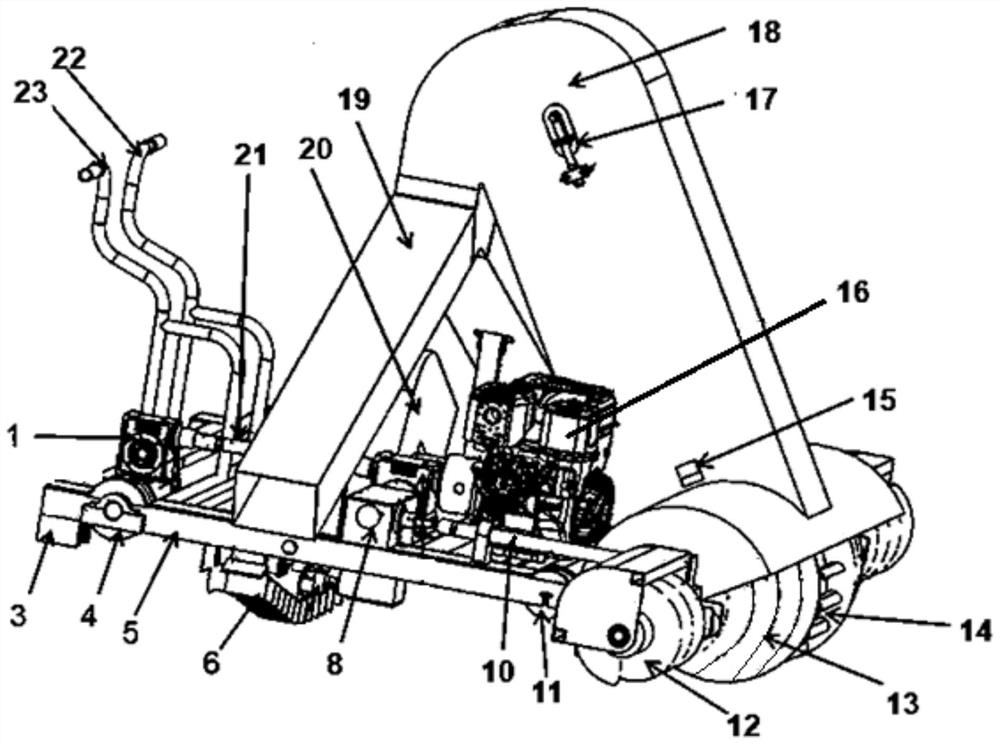

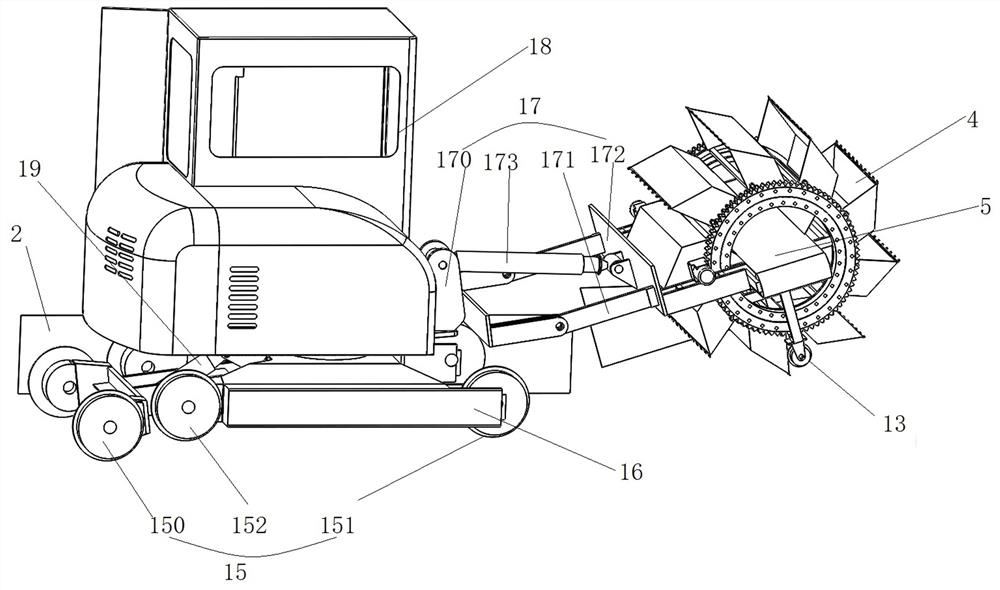

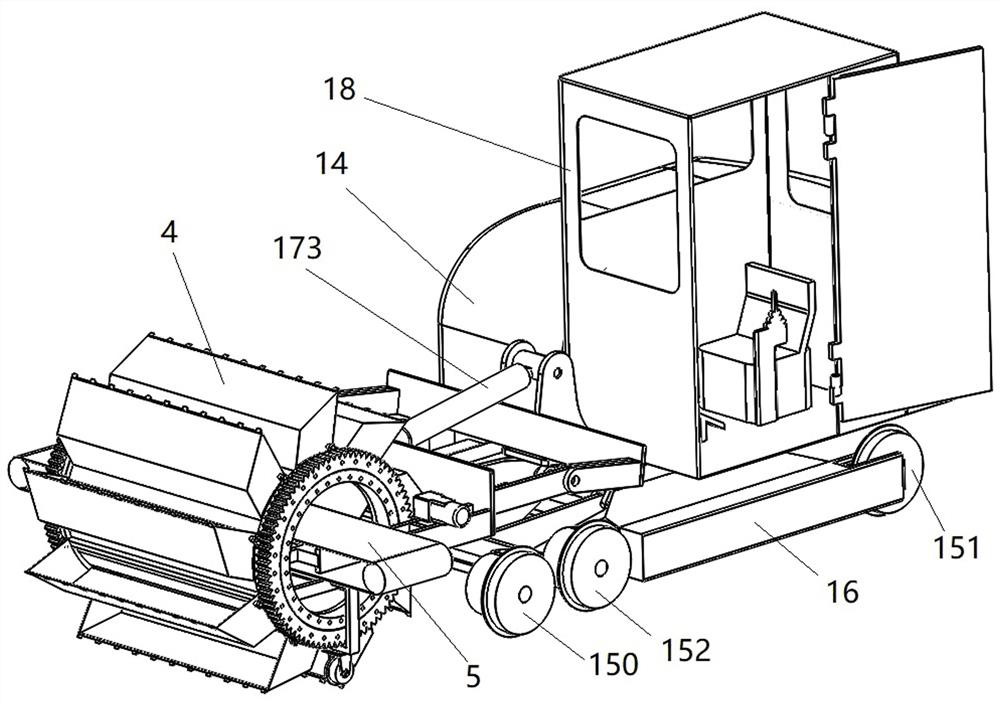

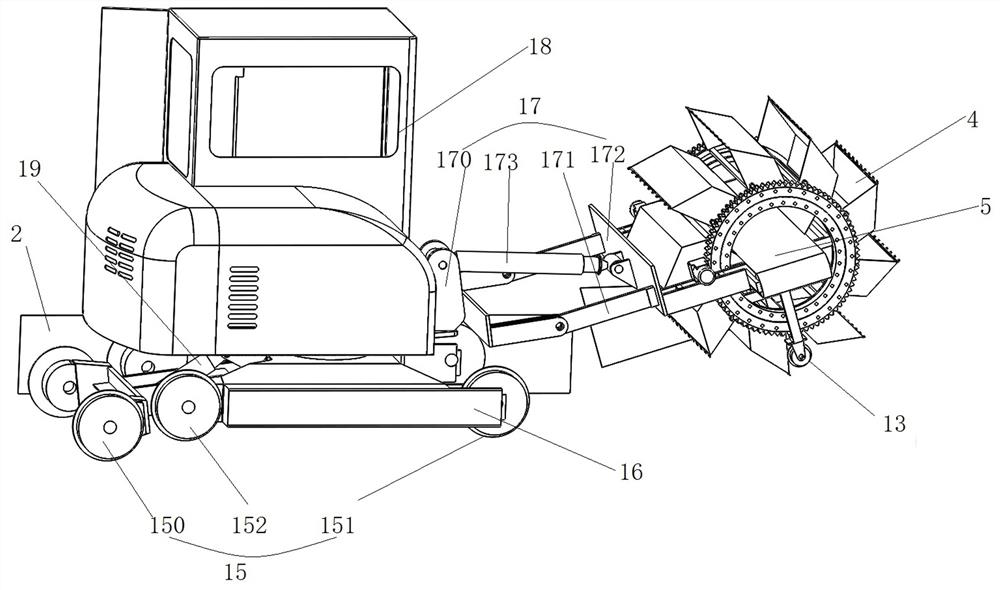

Bucket Wheel Sand Removal Device for Maintenance of Train Tracks

The invention discloses a bucket wheel type desanding device for maintaining train tracks, which belongs to the technical field of railway track maintenance equipment, and includes a sand collection and desilting device for cleaning the sand accumulated inside the track and a sand pusher for cleaning the sand accumulated outside the track The sand collection and discharge device can be connected with the walking equipment that walks along the track. The sand collection and discharge device is set between the two tracks. The sand collection and discharge device is equipped with a guide wheel that can run along the track. Two adjacent The sand pushing plate provided on the outer side of the track is arranged on the outer side of the guide wheel. The invention walks along the track driven by the walking equipment, and the guide wheel guides the sand collection and discharge device; the sand accumulation on the inside of the track is cleaned by the sand collection and discharge device, and the sand on the outside of the track is pushed to the two sides by the sand pusher. The side push ensures the safety of driving and avoids the occurrence of railway outage accidents caused by sand accumulation on both sides of the track; at the same time, the invention has a high degree of mechanization, which greatly reduces the labor intensity of the staff and improves the efficiency of sand cleaning.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Vibration casting sand cleaning machine

The invention provides a vibration type casting sand cleaning machine and relates to the field of casting equipment. The vibration type casting sand cleaning machine comprises a rack and a casting platform, wherein a push plate is arranged at one side of the casting platform; the upper end face of the push plate is connected with a first rack; a storage rack is arranged at the other side of the casting platform; the storage rack comprises a first vertical plate and a second vertical plate; a groove is connected between the first vertical plate and the second vertical plate; the first vertical plate is in sliding connection with a first bracket; the second vertical plate is in sliding connection with a second bracket; pins are arranged between the first vertical plate and the first bracket, and between the second vertical plate and the second bracket; the pins are fixedly connected with a connecting rod parallel to the first bracket, and a wedge block is arranged above the connecting rod; a second rack is connected with one side, close to the casting platform, of the first bracket; a third rack is connected with one side, close to the casting platform, of the second bracket; the second rack is engaged with a first gear; the third rack is engaged with a second gear; the first gear and the second gear are coaxially connected with a third gear and a ratchet wheel; and the ratchet wheel is engaged with a pawl. Compared with the prior art, the vibration type casting sand cleaning machine has relatively high casting sand cleaning efficiency.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

Rotating spray sand cleaning method

ActiveCN102287152BSimple structureImprove performanceMovable spraying apparatusFlushingAdhesiveWellbore

The invention discloses rotating spray sand cleaning method, which is used for cleaning sand at the bottom of a well. The method comprises the following steps of: A, connecting a shaft sand cleaning pipe column, inserting into the well, and detecting the depth of a sand surface by using the shaft sand cleaning pipe column; B, lifting the shaft sand cleaning pipe column by 1-3 meters; C, connecting a pump to the top of the shaft sand cleaning pipe column and pumping liquid for impacting settled sand at the bottom of the well; D, making the impacted sand flow upwards in an oil thimble along with fluid, settle downwards and settle into a slotted casing; and E, putting the shaft sand cleaning pipe column down, continuously washing sand to a designed construction well depth position, and pulling the shaft sand cleaning pipe column out of the well to finish rotating spray sand cleaning operation. Due to the adoption of the method, settled sand, metal smashed blocks, stained metal blocks and corrosion inhibitor adhesives at the bottom of the well can be cleaned, a production layer is exposed, and high sand cleaning efficiency is achieved.

Owner:PETROCHINA CO LTD

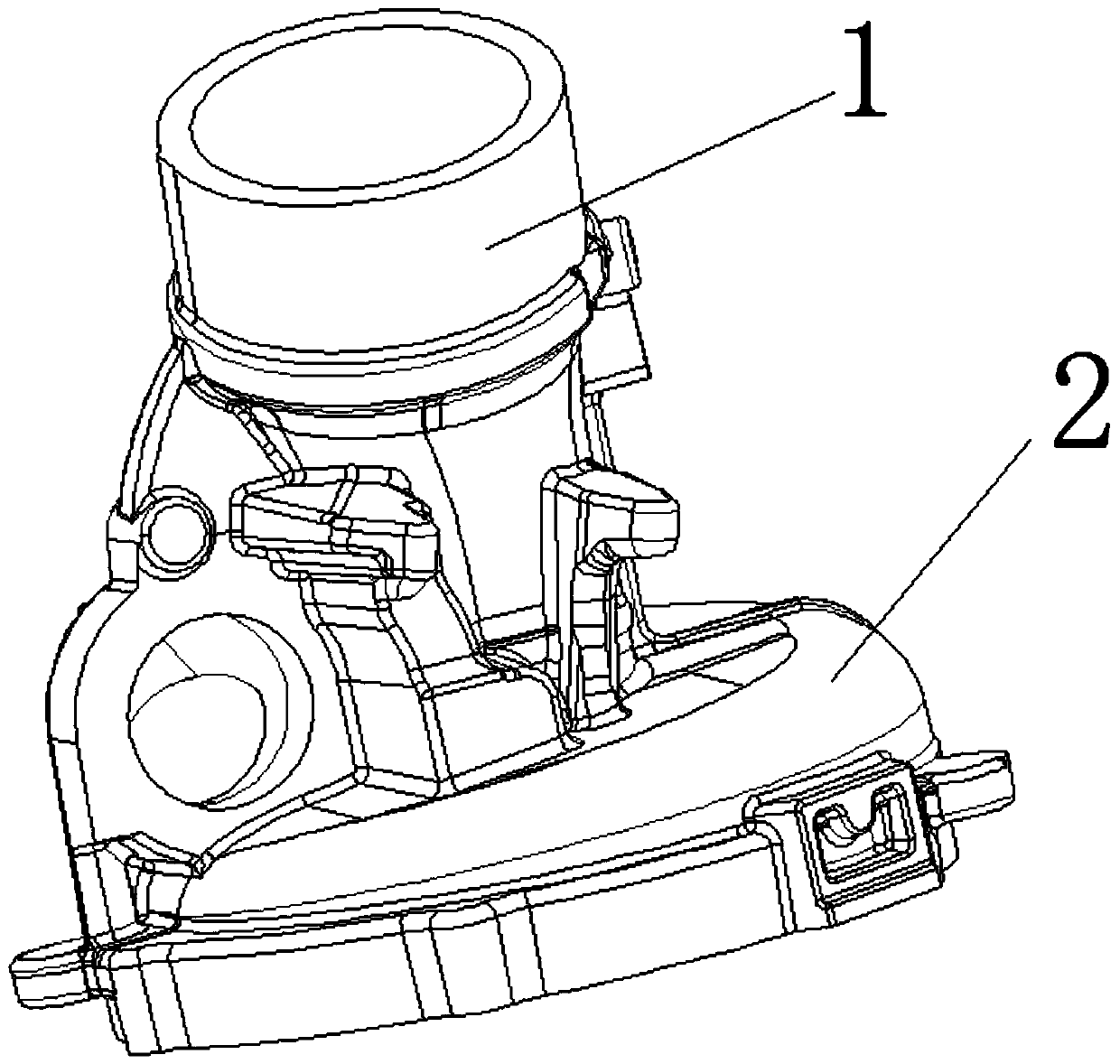

Mold core sand removal method for low-pressure cast turbocharger shell

A mold core sand removal method for a low-pressure cast turbocharger shell comprises the steps that the redundant part of the end of an aluminum alloy turbocharger shell casting with a sand core is cut off by cutting machining equipment; the end of the turbocharger shell casting with molding sand is downward, and the molding sand loosened when the end is cut just now is poured out; the turbocharger shell casting with the molding sand is arranged to be subjected to T6 heat treatment, and most molding sand of the turbocharger shell casting obtained through T6 heat treatment and with the loosenedmolding sand is removed manually with a sand drawing tool; and the turbocharger shell casting which is not cleaned up is transferred to a mold sandblasting machine workshop, a sandblasting head of amold sandblasting machine is aligned with the residual molding sand part of an inner cavity of the turbocharger shell casting, and sandblasting treatment is conducted. The sand is removed in the modecombining T6 heat treatment and the mold sandblasting machine, sand removal efficiency can be fast improved, the inner wall of the casting is not damaged while sand removal quality is ensured, and sand removal efficiency is improved greatly.

Owner:江苏新安驰铝业有限公司

Sand removal technology for oilfield fracturing flowback fluid

Owner:PETROCHINA CO LTD

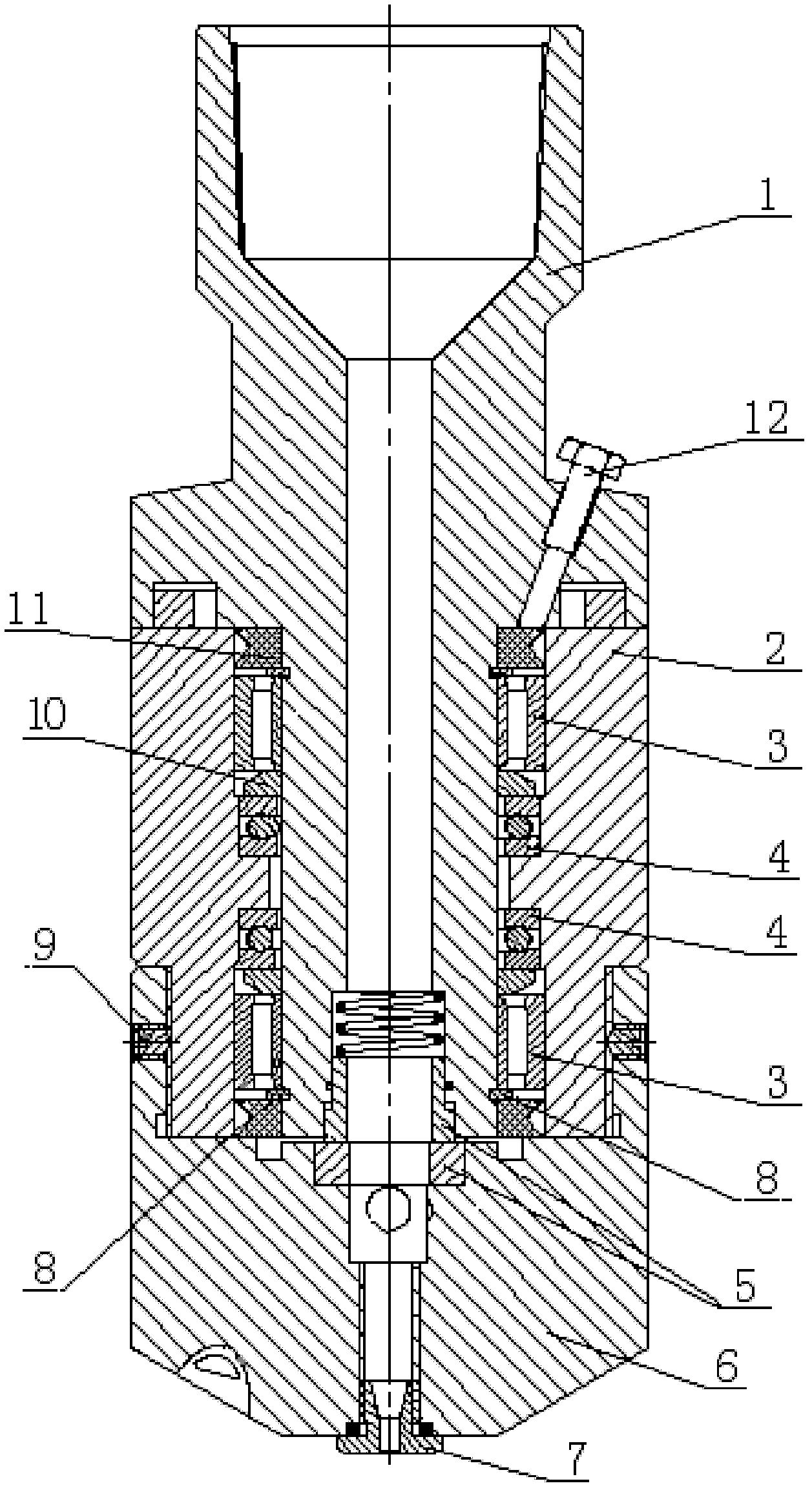

Repeatable bypass valve

ActiveCN106337669BImprove stabilityAccurateWell/borehole valve arrangementsSealing/packingVALVE PORTBypass operation

The invention relates to a bypass valve capable of repeating switch, including a valve body and a valve core capable of sliding in the valve body. The valve body is formed through a valve core to form an axial through main flow passage, where the valve body is provided with a bypass passage and an inner ring groove in the axial direction of the valve body. The bypass passage is formed when the bypass passage is communicated with the main flow passage through the connection passage, and the through flow passage is formed when the inner ring groove is communicated with the main flow passage through the connection passage. The valve body is also provided with a reset mechanism which is connected to the valve body and that positions the valve body at the time of opening the bypass flow passage and through the flow passage. The bypass valve can greatly improve the stability of the bypass operation and the straight-through operation, and realize the cycle switching between the multi-pass operation and the straight-through operation. It also has the advantages of fast plugging and high sand removal efficiency, and can greatly improve the drilling efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

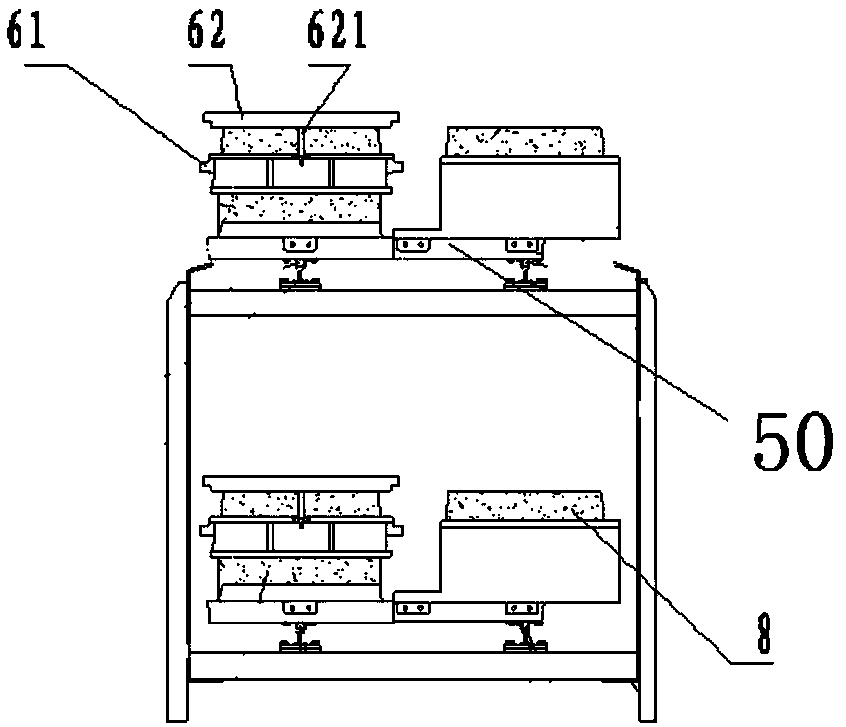

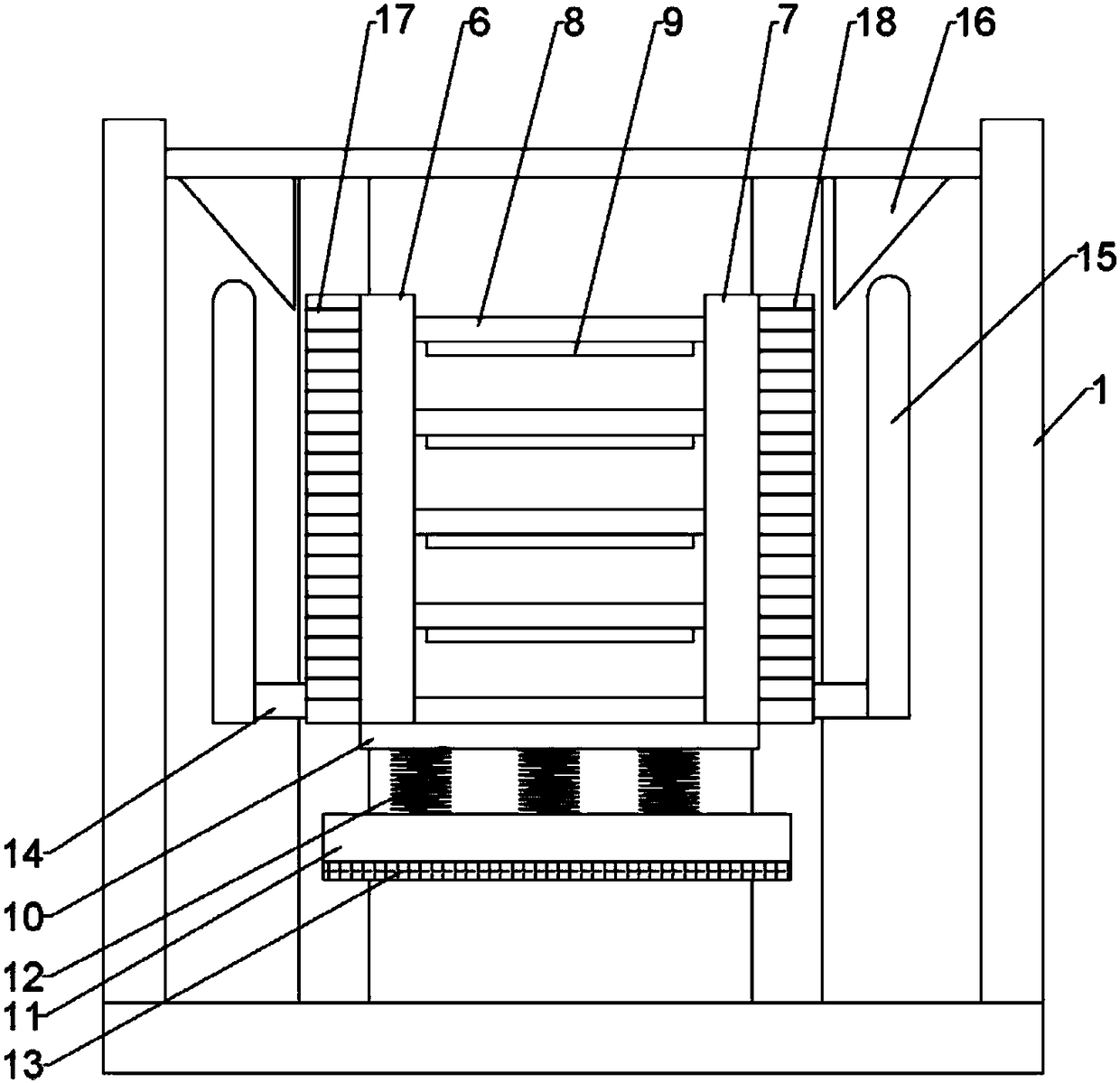

A 3D printing sand cleaning equipment

ActiveCN106041002BFully automatedRealize intelligenceAdditive manufacturing apparatusMoulding machine componentsEngineeringAutomation

The invention relates to the field of sand mold 3D printing sand removal, in particular to a 3D printing sand removal apparatus. The 3D printing sand removal apparatus comprises a working platform, a jacking device, a sand box, a work box, a sand separation plate and a sand receiving tank, wherein the working platform comprises a control device which controls the sand box, the work box and the sand separation plate to carry out positioning movement, a roller bed conveying device and a grid plate, the jacking device comprises a lifting plate, a base, side plates c and a jacking machine located on the base, the jacking device is located below the working platform, the sand box is located on the roller bed conveying device of the working platform, the work box is located above the sand box, the sand separation plate is arranged above the sand box and below the work box, and the sand receiving tank is located below the working platform. With the 3D printing sand removal apparatus, the problem that the efficiency of traditional waste sand processing is low is solved, the efficiency of sand removal is improved, and the automation and the intelligence of the whole process of 3D printing are achieved.

Owner:NINGXIA KOCEL MOLD

Bucket wheel track desanding vehicle

Owner:SHIJIAZHUANG TIEDAO UNIV +1

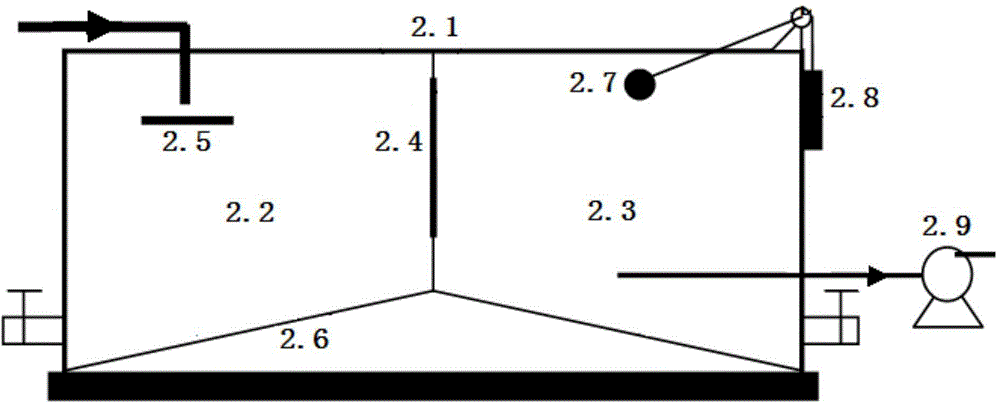

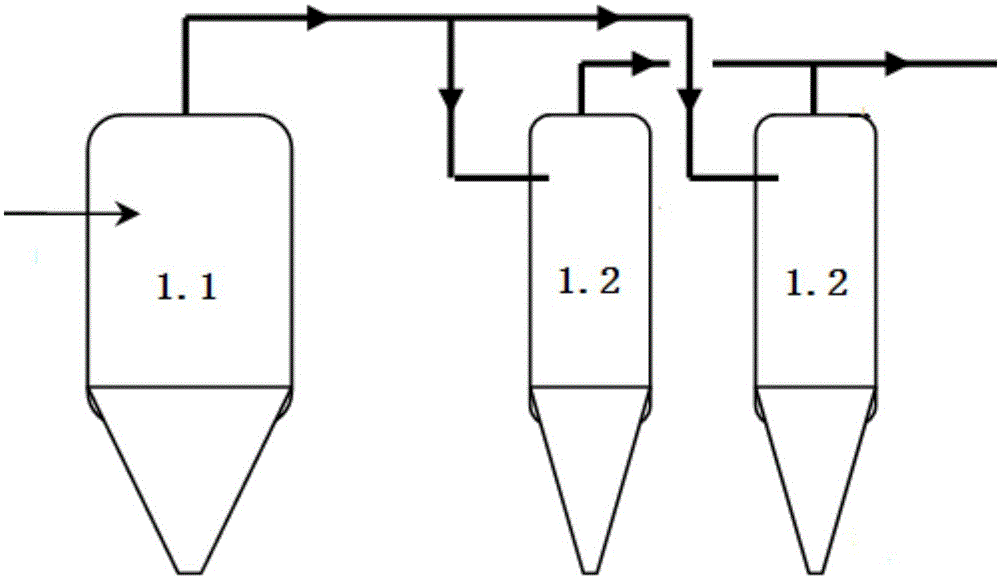

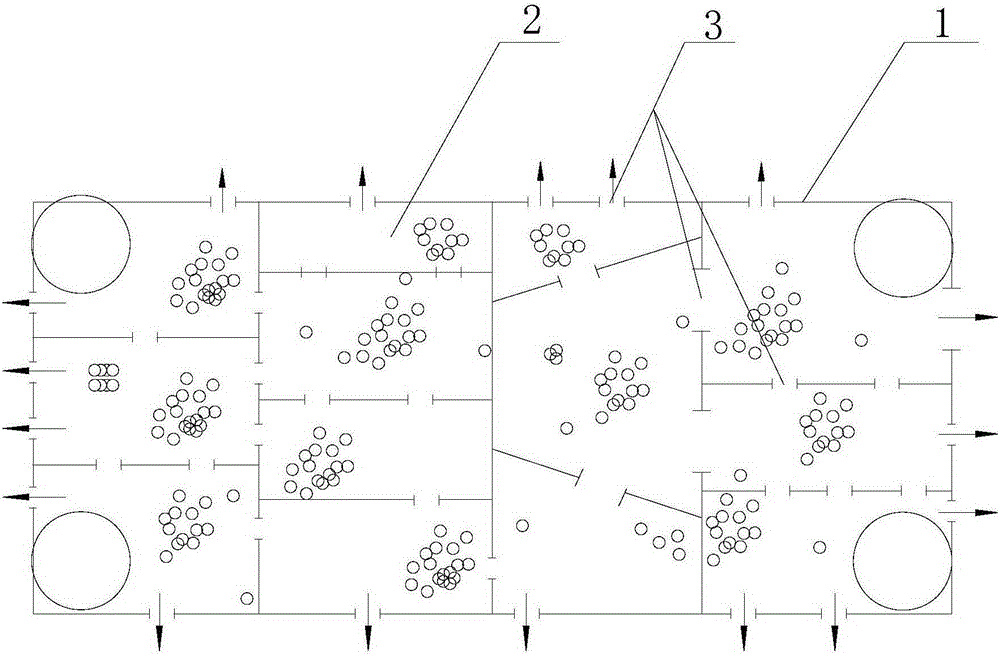

Hull sand cleaning system and hull sand cleaning method

The invention provides a hull sand cleaning system and a hull sand cleaning method, and belongs to the field of hull sand cleaning of ships. The problem that for an existing device and method, the sand cleaning efficiency is low is solved. A hull of the sand cleaning system is provided with multiple sand detention areas which are formed by various boards in an enclosed mode, and each sand detention area is communicated to the outer side of the hull directly or indirectly by being communicated with other sand detention areas; the hull sand cleaning system further comprises a sand cleaning platform, and the hull can be arranged on the sand cleaning platform which makes the hull edge incline in one or more set directions and by one or more set angles. The hull sand cleaning method based on the hull sand cleaning system comprises the steps that the hull is inclined through the sand cleaning system, and the sand is discharged out of the outer side of the hull. According to the hull sand cleaning system and the hull sand cleaning method, a hull inclining mode is adopted, sand in all the sand detention areas in the hull gradually flows to the sand detention areas at the edges of the hull and flows out of the hull finally, and the sand cleaning efficiency is high.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Sand pumping machine

PendingCN112623651ASave human effortImprove sand cleaning efficiencyPackagingConveyor partsProcess engineeringMechanical engineering

The invention relates to a sand pumping machine. The sand pumping machine is used for groove sand removal operation, and comprises a feeding device, a material conveying device, a discharging device, a driving device, a rack and a limiting piece. The discharging device is rotatably connected to the rack around an axis, one end of the material conveying device is connected with the feeding device, the other end of the material conveying device is connected with the discharging device, the material conveying device is used for outputting sand input by the feeding device to the discharging device and discharging the sand, compared with a traditional time-consuming and labor-consuming manual sand removing mode, manpower is saved, and the sand removing efficiency is improved. In addition, due to the arrangement of the limiting piece, the sand pumping machine can be suitable for sand removal operation of grooves with different depths.

Owner:SHENZHEN POWER SUPPLY BUREAU

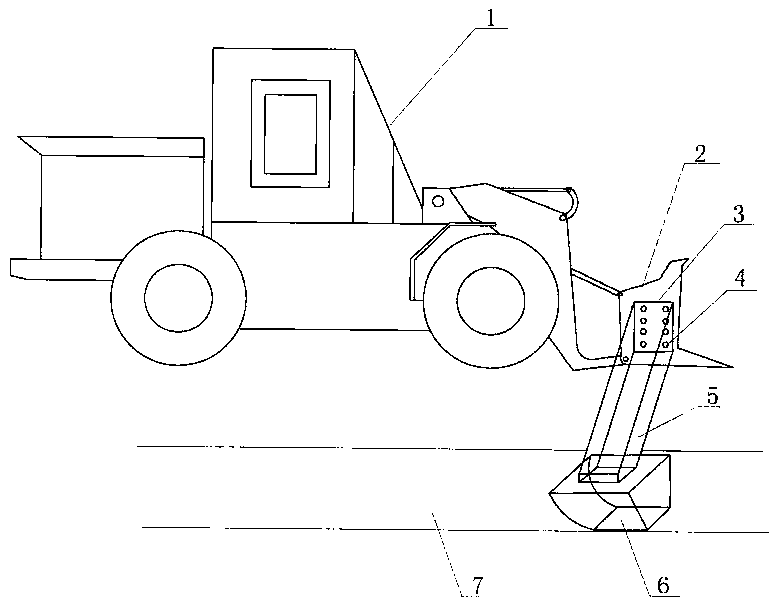

Side ditch sand cleaning device

The invention belongs to a side ditch sand cleaning device. The side ditch sand cleaning device includes a loading locomotive, a fixed flange is arranged on the side wall of a loading locomotive bucket facing the side ditch direction, the middle part of the fixed flange is fixedly connected to one end of a connecting arm, the other end of the connecting arm is inclined to the edge ditch directionto the upper part of a side ditch, and an excavator bucket capable of moving in the side ditch is fixedly arranged at the other end of the connecting arm. Or a driving gear on a motor shaft at the back of the excavator bucket drives a driven sprocket through a chain to rotate roller shafts on a left side throwing belt support and roller wheels on the roller shafts quickly, then each roller wheel and throwing belts are driven to rotate clockwise quickly, wind-accumulated sand entering the excavator bucket falls into the upper end faces of the fast-rotating throwing belts from a discharge port,and the throwing belts with convex racks throw the wind-accumulated sand on the throwing belts to the outer end of the right side of a highway drainage ditch. The side ditch sand cleaning device enables the loading locomotive to have the function of cleaning the wind-accumulated sand in the highway drainage ditch by mechanization, and has the advantages of simple structure, shortening time and saving effort, less manpower, convenient refit, quick cleaning speed, low cost, high universality and high efficiency.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

A kind of sand cleaning method of casting mould

ActiveCN113441442BAvoid damageImprove sand cleaning efficiencyCasting apparatusCleaning using toolsUltrasonic vibrationSteel ball

The invention discloses a sand cleaning method for a casting mold, which belongs to the technical field of wear-resistant steel ball production and solves the technical problems in the prior art that the sand cleaning of the wear-resistant steel ball casting mold is difficult and easily causes abrasive damage. In the invention, the molding sand on the surface of the mold is ultrasonically dispersed, and then the stubbornly attached molding sand is brushed up with a wire brush, and finally the stripped molding sand is blown out and collected. The invention discloses a sand cleaning equipment suitable for the sand cleaning method. The equipment includes Roller conveyor, the mold loading device is conveyed on the roller conveyor, a sand brushing device is installed above the middle of the roller conveyor, an ultrasonic sand loosening device is installed on one side of the sand brushing device, and an ultrasonic sand loosening device is installed on the other side of the sand brushing device. Sand blowing device, which decomposes the sand cleaning process and realizes automatic flow operation, which improves the sand cleaning efficiency on the premise of ensuring the quality of sand cleaning.

Owner:安徽省凤形新材料科技有限公司

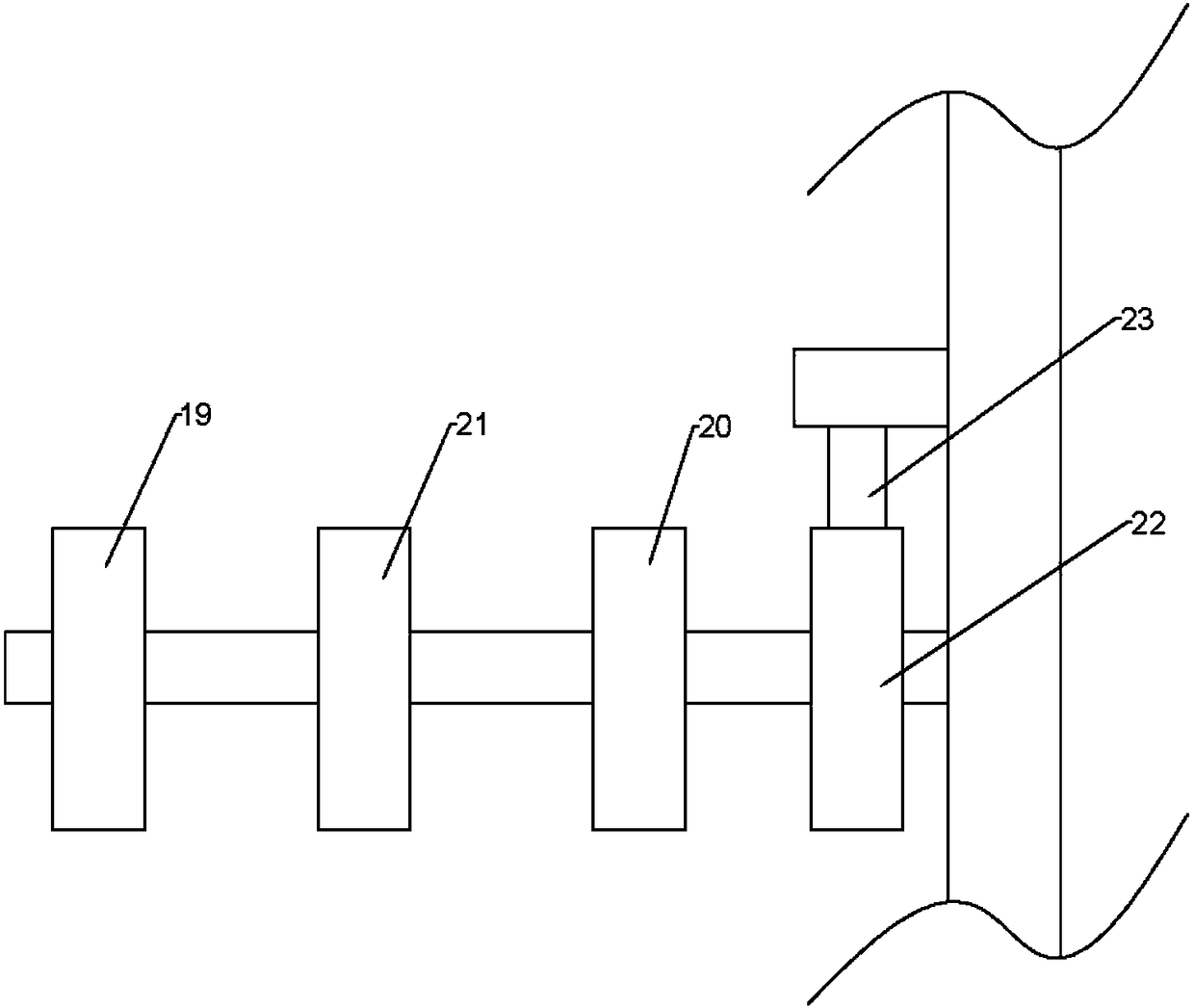

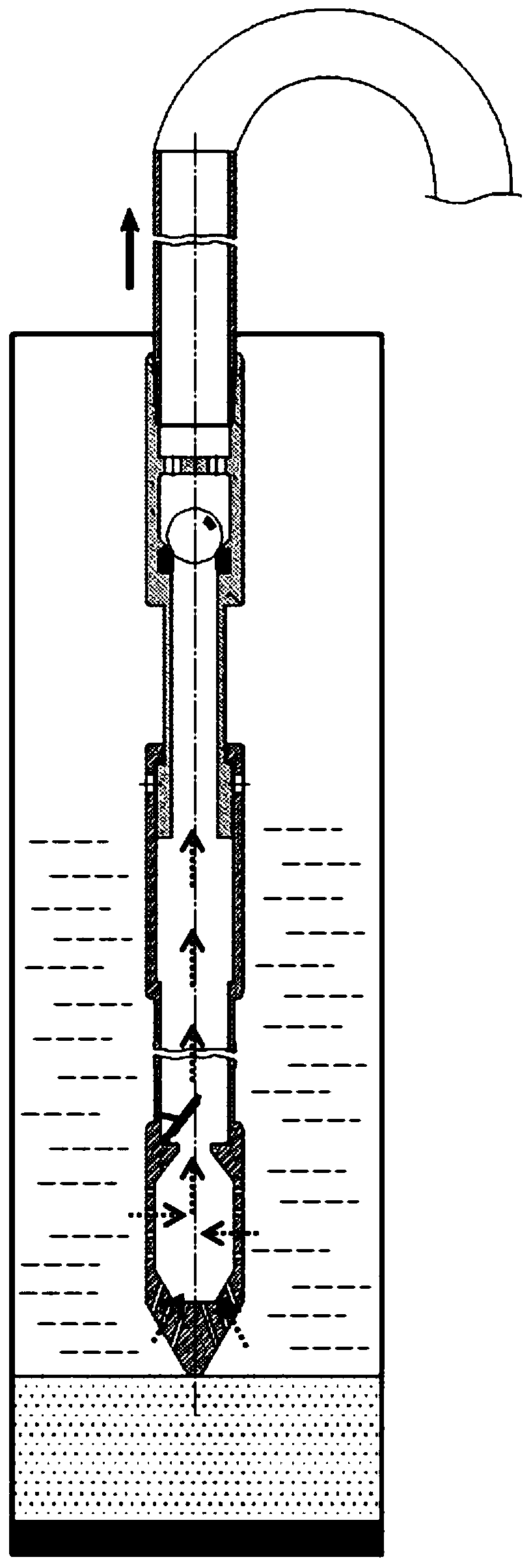

A large-displacement continuous downhole sand cleaning and plugging removal pipe string and sand cleaning and plugging removal technology

ActiveCN106150409BImprove sand cleaning efficiencyRealize the function of continuous pumping and sand cleaningDrill bitsDrilling rodsEngineeringContinuous operation

The invention discloses a large-displacement continuous downhole sand and plug removing tubular column and a sand and plug removing process thereof. The tubular column comprises a pump cylinder, wherein a hollow plunger and a plunger connecting rod are arranged in the pump cylinder, the plunger can slide up and down relative to the pump cylinder, a traveling valve is connected to the upper end of the plunger connecting rod, the upper end of the traveling valve is connected with an on-pump oil tube in a sealing mode, the lower end of the pump cylinder is connected with a sand smasher, and a bottom valve is arranged in the upper end of the sand smasher. In the sand removing process, clear water of a certain volume is injected into the on-pump oil tube from a wellhead, and a valve ball of the traveling valve is connected with a valve port in a sealing and matching mode; the on-pump oil tube is lifted up and dropped down continuously to drive the plunger to move up and down ceaselessly, and sand carrying well liquid is discharged back to the wellhead through the on-pump oil tube after being pumped into the pump cylinder. According to the tubular column, the upper portion of the traveling valve is closed, sand accumulating in a shaft can be thoroughly removed simply through continuous operation of the technological tubular column next time, and the sand removing efficiency is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ship hull sand cleaning system and ship hull sand cleaning method

The invention provides a hull sand cleaning system and a hull sand cleaning method, and belongs to the field of hull sand cleaning of ships. The problem that for an existing device and method, the sand cleaning efficiency is low is solved. A hull of the sand cleaning system is provided with multiple sand detention areas which are formed by various boards in an enclosed mode, and each sand detention area is communicated to the outer side of the hull directly or indirectly by being communicated with other sand detention areas; the hull sand cleaning system further comprises a sand cleaning platform, and the hull can be arranged on the sand cleaning platform which makes the hull edge incline in one or more set directions and by one or more set angles. The hull sand cleaning method based on the hull sand cleaning system comprises the steps that the hull is inclined through the sand cleaning system, and the sand is discharged out of the outer side of the hull. According to the hull sand cleaning system and the hull sand cleaning method, a hull inclining mode is adopted, sand in all the sand detention areas in the hull gradually flows to the sand detention areas at the edges of the hull and flows out of the hull finally, and the sand cleaning efficiency is high.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

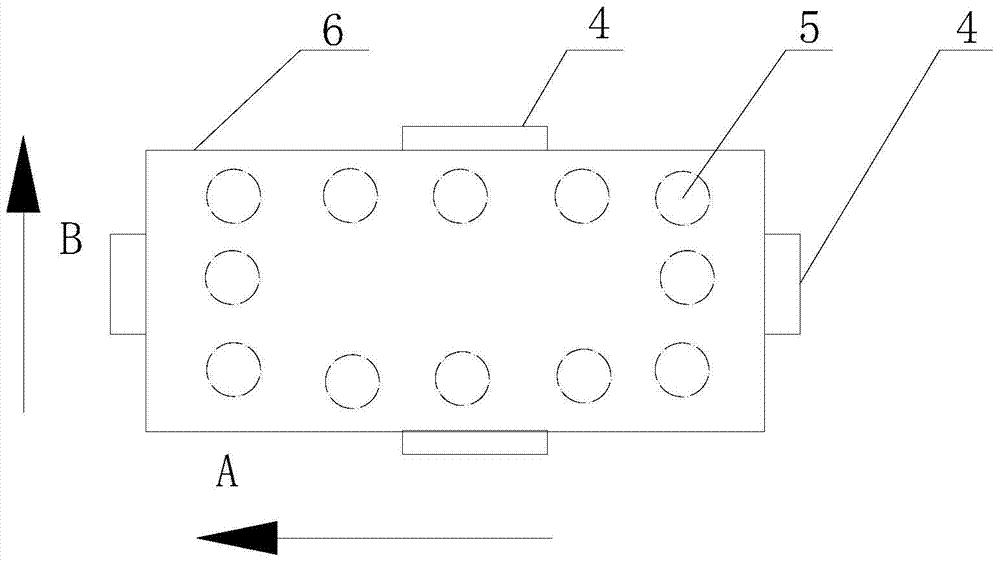

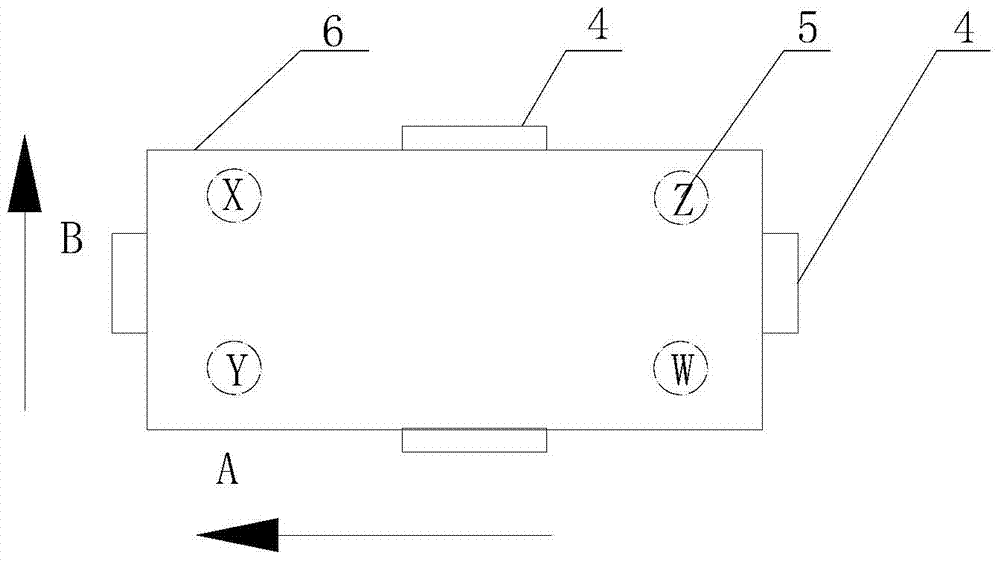

Process for manufacturing shell of impeller of electrical pump

The invention discloses a process for manufacturing a shell of an impeller of an electrical pump, which comprises: 1) a step of shell manufacturing, in which a wax mold of the impeller is subjected to sizing, stuccoing and drying layer by layer by zircon powder slurry and mullite sand slurry; 2) a step of dewaxing under conditions of a pressure of between 0.6 and 0.75 MP and a temperature of between 150 and 170 DEC C for 6 to 10 minutes; and 3) a step of roasting, in which the roasting temperature is 1,000 to 1,100 DEG C, and the temperature is kept for at least 30 minutes when the resulting product of the dewaxing reaches the temperature. The shell of the impeller of the electrical pump manufactured by the invention has the advantages that: the rate of leaking shell is low; and at the same time, a flow passage is filled with dry and scattered mullite sand, so the shell in the flow passage is easy to clean after a casting is poured, labor efficiency is greatly improved, and consequently the rate finished casting and the sand cleaning efficiency are improved. The preparation process of the invention has the advantages of high rate of finished product, short production period, easy sand cleaning and the like.

Owner:山东燕山精密机械有限公司

Hopper sand collection type railway track sand removal vehicle

The invention discloses a hopper sand-collecting type railway track desanding vehicle, which belongs to the technical field of railway track maintenance equipment and includes a power device, a running device and a sand cleaning device arranged on the bottom frame. The walking wheel; the sand cleaning device includes a sand collection mechanism for removing sand accumulated on the inside and outside of the track and a sand discharge mechanism for discharging the sand cleaned by the sand collection mechanism to the outside of the train frame. The sand collection mechanism is located at the front end of the chassis ; Walking device, sand collection mechanism and sand discharge mechanism are all driven by the power unit. Drive the walking device to walk along the track through the power device. During the walking process, the sand collecting mechanism is used to remove the sand accumulated inside and outside the track and the sand is transported to the sand discharge mechanism. The sand is discharged to the outside of the track through the sand discharge mechanism to ensure driving safety and avoid track The accumulation of sand on both sides leads to the occurrence of railway outage accidents; at the same time, the invention has a high degree of automation, which greatly reduces the labor intensity of the staff and improves the efficiency of sand removal.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com