A large-displacement continuous downhole sand cleaning and plugging removal pipe string and sand cleaning and plugging removal technology

A large-displacement, sand-clearing technology, which is applied in the direction of drilling pipe, casing, and flushing wellbore, can solve the problems of incomplete sand fishing, sand fishing failure, and prolonged well occupation time, so as to improve the success rate of sand fishing, Improvement of suction capacity and improvement of sand cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

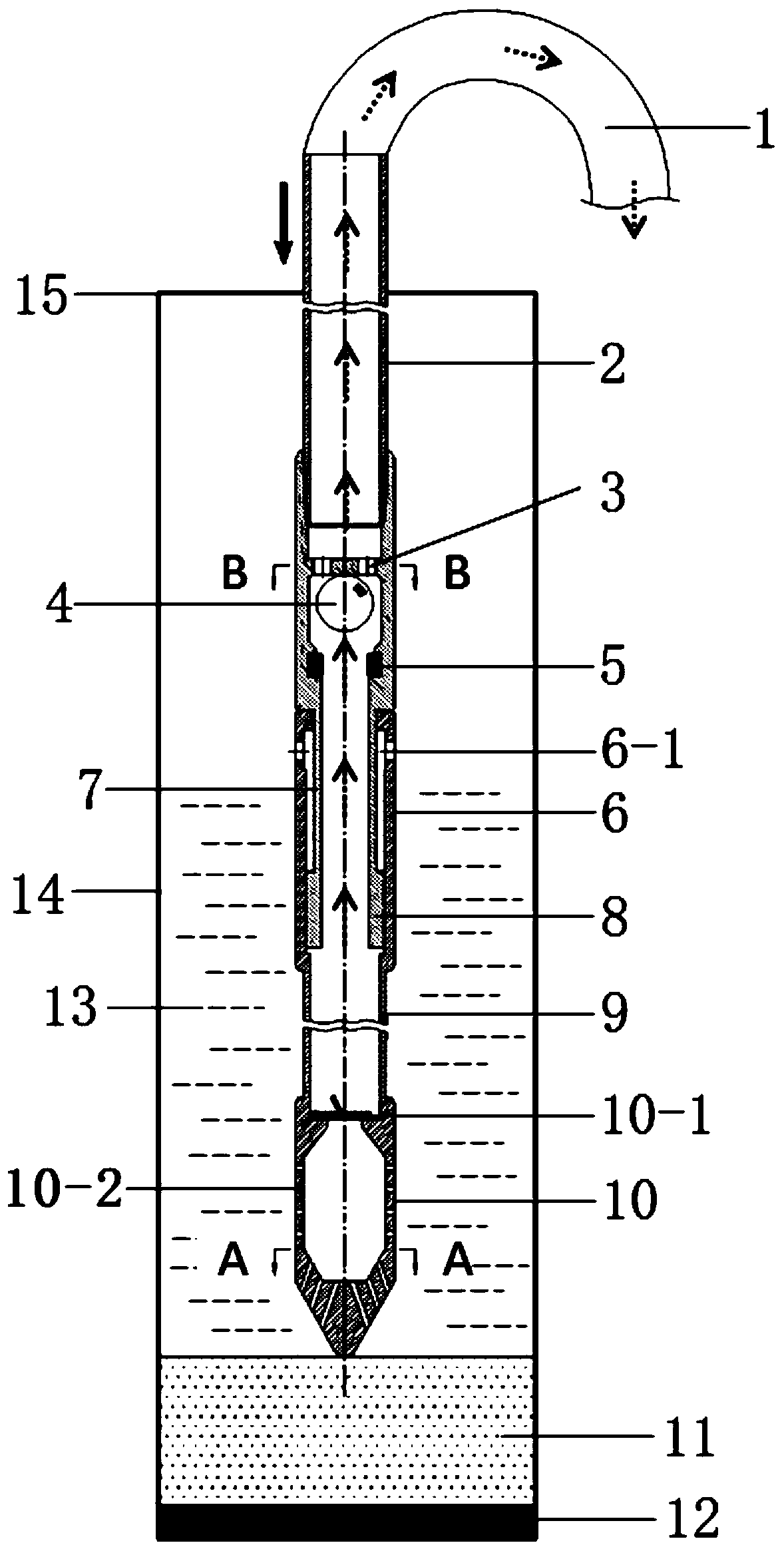

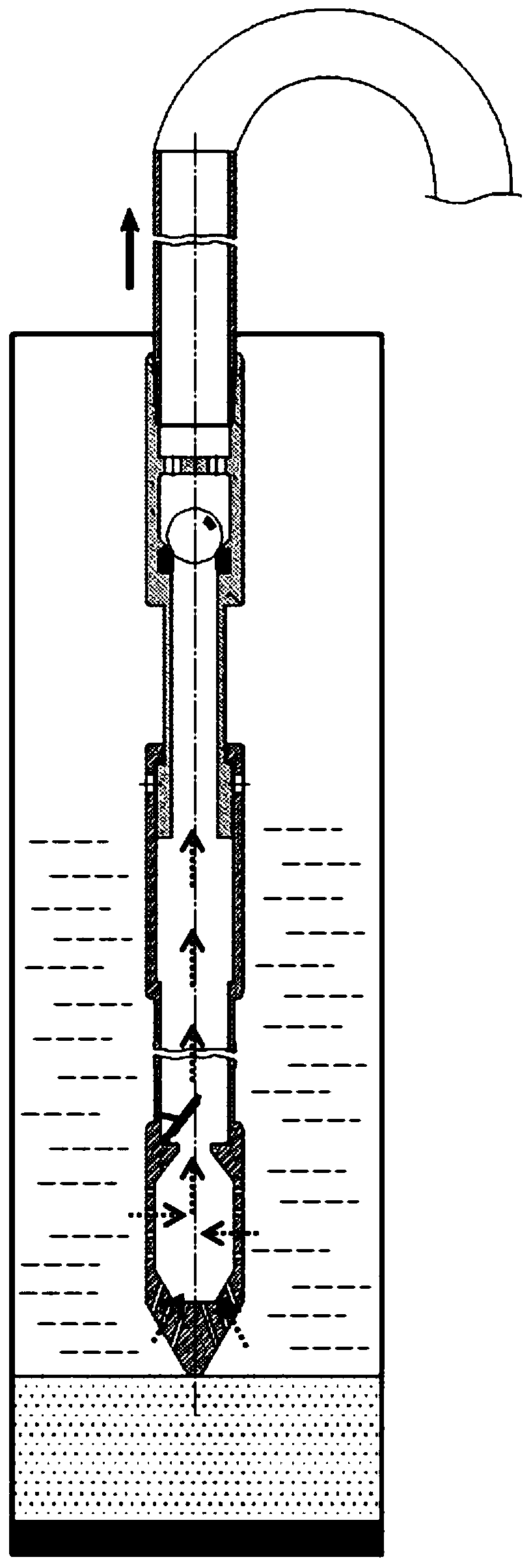

[0034] The present invention will be further described below in conjunction with accompanying drawing.

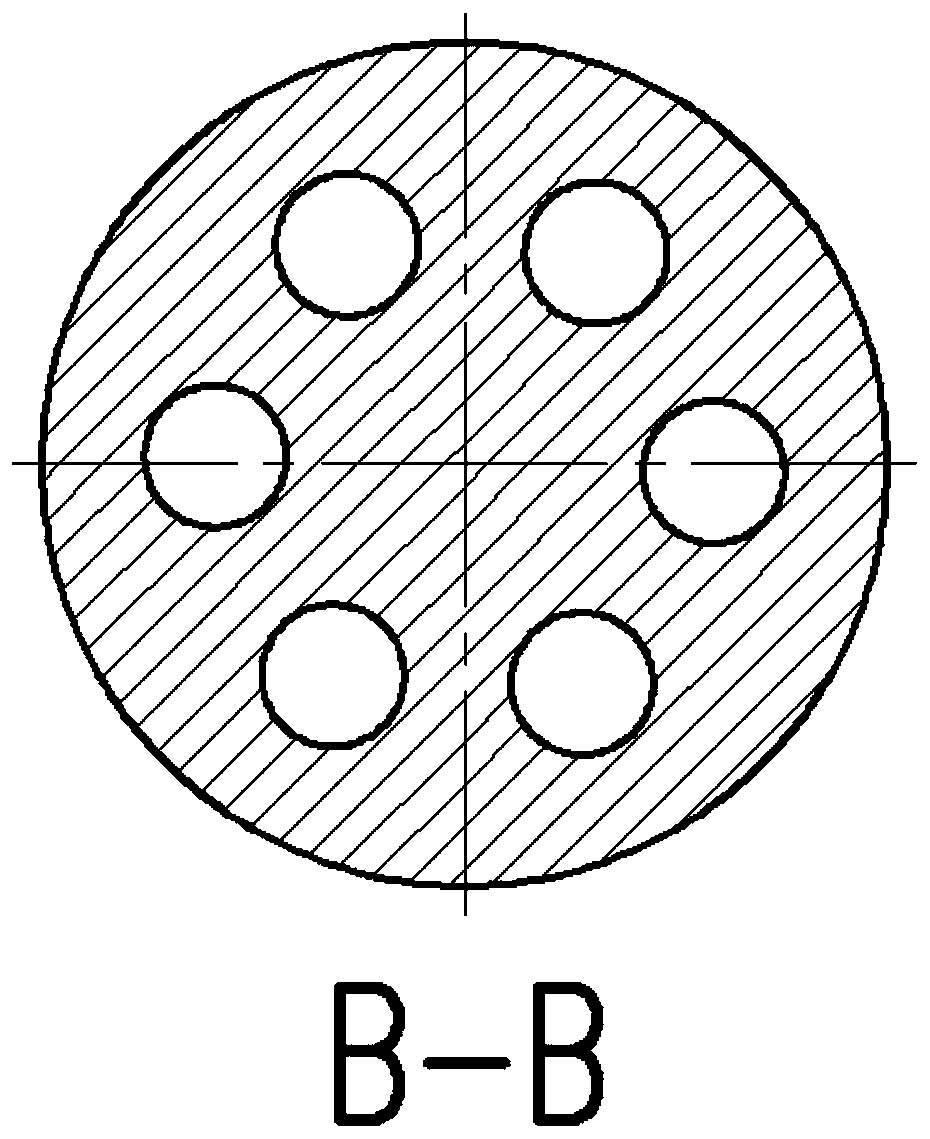

[0035] like Figure 1-4 As shown, this embodiment provides a large displacement continuous downhole sand cleaning and plugging removal string, including a pump barrel 6, a hollow plunger 8 and a plunger connecting rod 7 are installed in the pump barrel 6, and the plunger 8 can slide up and down relative to the pump cylinder 6, and the gap between the two is smaller than the diameter of sand particles. The root of the top thread. The upper end of the plunger connecting rod 7 is connected with a floating valve, the upper end of the floating valve is sealed and connected with the oil pipe 2 on the pump, and the lower end of the pump barrel 6 is connected with the sand pounder 10 .

[0036]The traveling valve includes a valve body, the two ends of the valve body are respectively connected with the plunger connecting rod 7 and the oil pipe 2 on the pump, the valve body is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com