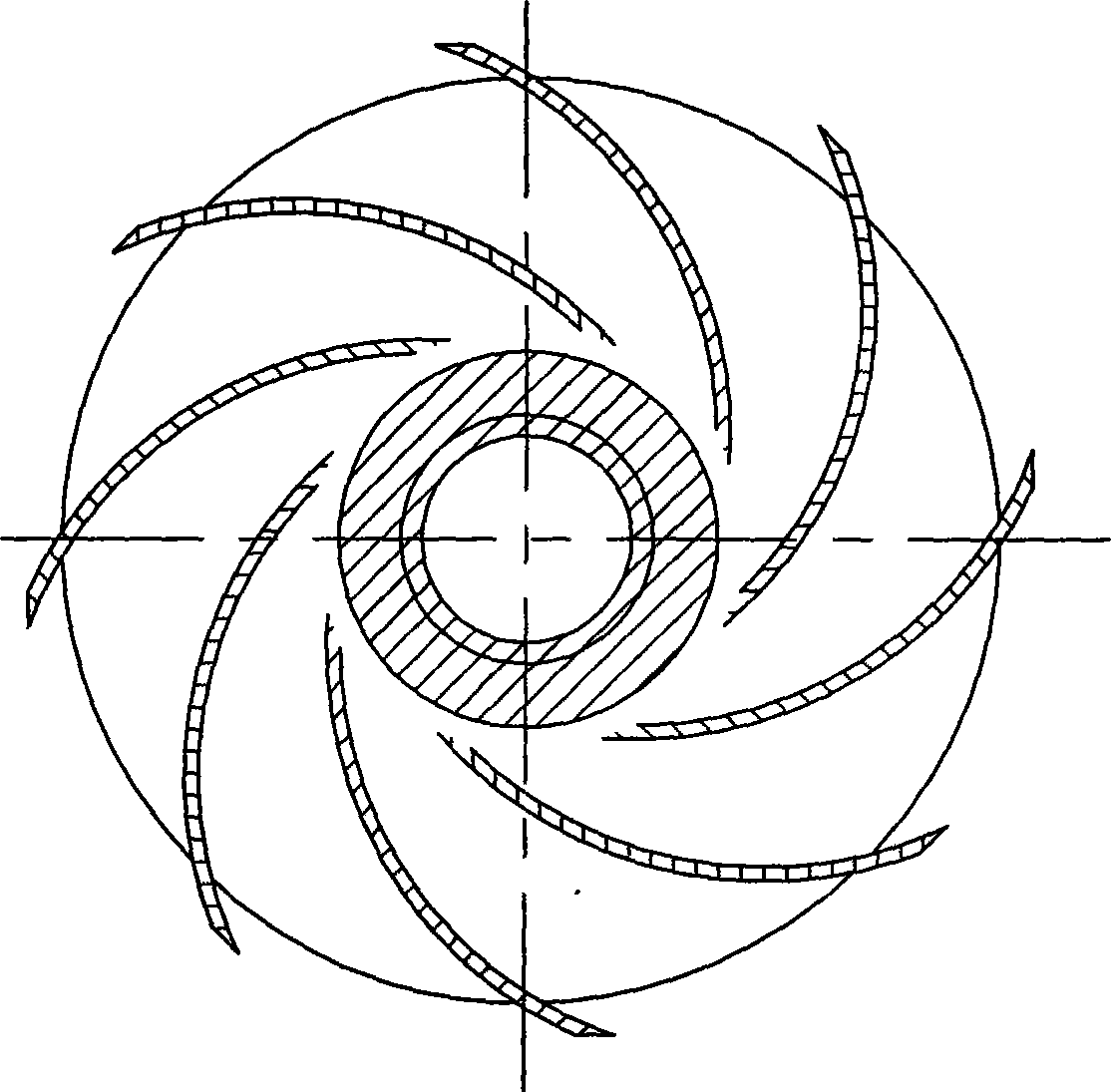

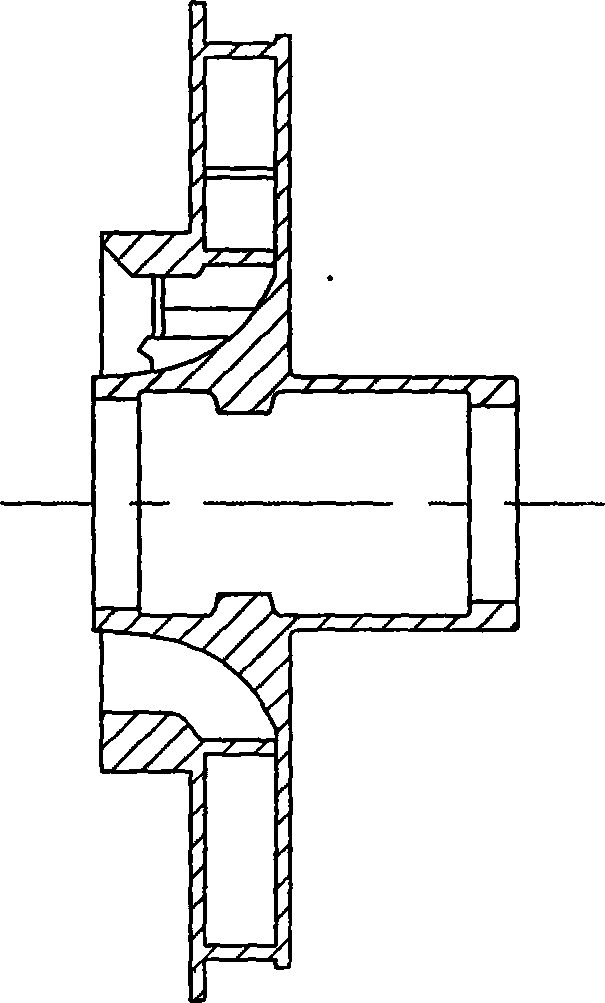

Process for manufacturing shell of impeller of electrical pump

A manufacturing process and impeller technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of long production cycle, high rejection rate, narrow flow channels, etc., and achieves improved labor efficiency, The effect of short production cycle and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Prepare a casing of an electric pump impeller with a channel height of 7.5mm, the steps are as follows:

[0028] 1) Shell making: use zircon powder slurry and mullite powder slurry to sizing, sanding and drying the impeller wax model layer by layer;

[0029] The zircon powder slurry is obtained in the following way: 100kg S830 silica sol, 450g wetting agent, 220g defoamer, 380kg 300 mesh zircon powder are added in the empty slurry tank successively; when adding 300 mesh zircon powder , While adding, use manual auxiliary stirring to prevent the 300-mesh zircon powder from accumulating and agglomerating during the addition process. After the 300-mesh zircon powder is added, measure the flow rate after 2 hours and add 1.2Kg of zircon powder for 32 seconds. , After fully stirring for 26 hours by the rotation of the slurry bucket, measure its flow rate again to be 35 seconds.

[0030] The mullite slurry is obtained by adding 90kg S1420 silica sol and 140KG200 pur...

Embodiment 2

[0037] Embodiment 2: an electric pump impeller with a channel height of 6 mm, the steps are the same as in Embodiment 1, wherein the processes involved in step 1) are shown in Table 2:

[0038] Table 2

[0039] level

[0040]

[0041] The test proves that all 75 impellers poured into the shells manufactured in Examples 1 and 2 are qualified, and the shells in the runners are very easy to remove during the sand cleaning process of the shells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com