Side ditch sand cleaning device

A technology for clearing sand and side ditches, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve the problems of clogged drains, poor drainage of drains, and high labor costs. Achieve the effect of fast cleaning speed, convenient modification and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

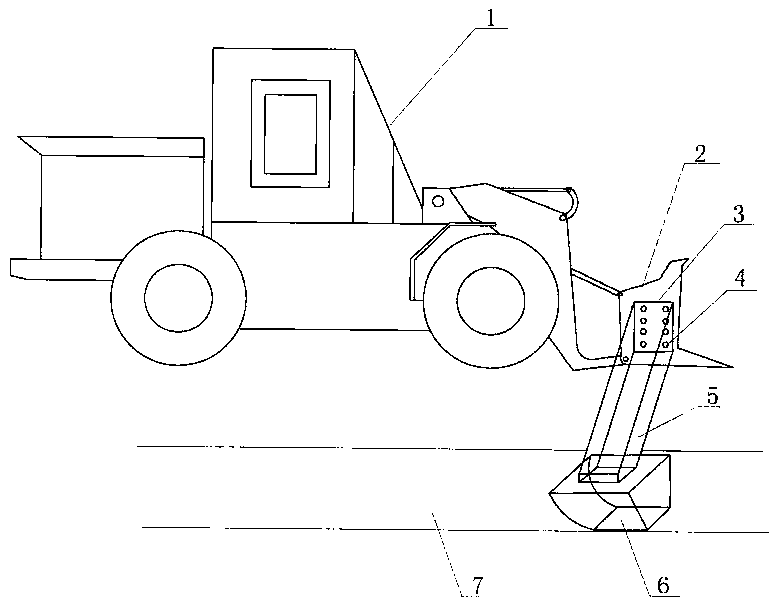

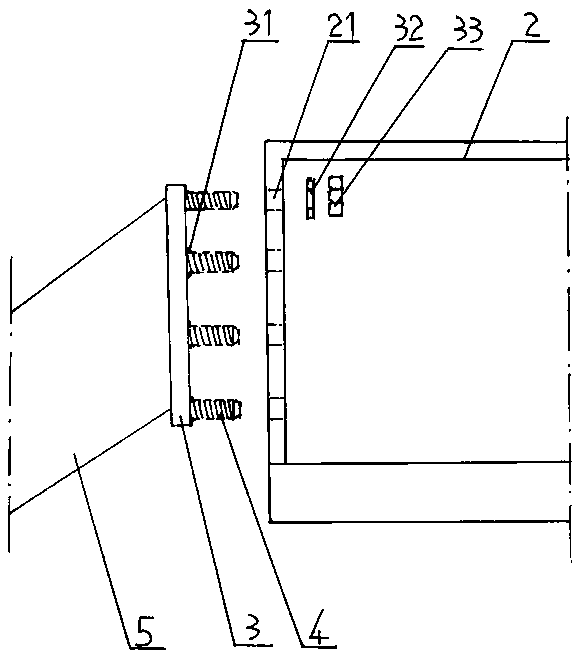

[0024] Embodiment 1: as Figure 1 to Figure 3 As shown, the side ditch sand cleaning device is as follows: the lower part of the right side of the bucket is provided with several screw holes 21 corresponding to several bolts on the fixed flange 3 . The middle part of the right side of the fixed flange and one end of the connecting arm 5 are fixed as one by welding. The included angle between the connecting arm and the right side wall of the bucket is 55-65 degrees. The optimal angle between the connecting arm and the right side wall of the bucket is the position of the bucket when the loading locomotive puts away the bucket and is in a driving state, so that the other end of the connecting arm is tilted toward the right drainage ditch 7 to the upper part of the right drainage ditch.

[0025] The screw hole on the right side wall of the corresponding bucket on the left side of the fixed flange is provided with several bolts 4 by welding, and the other end of the connecting arm...

Embodiment 2

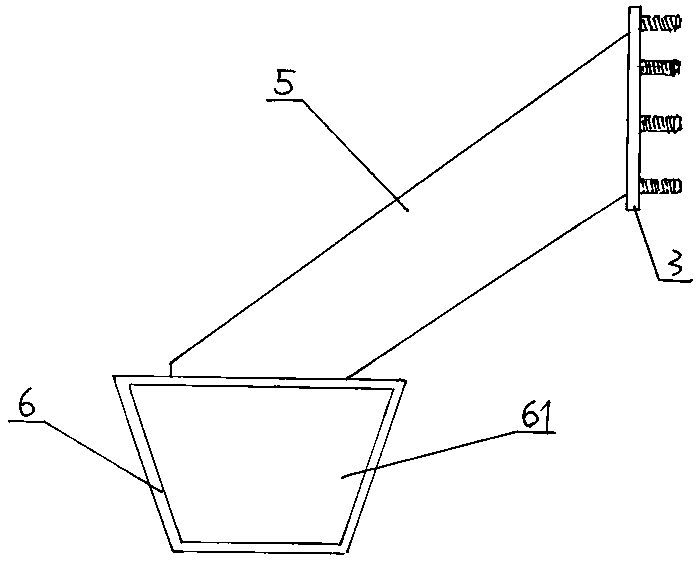

[0028] Embodiment 2: as Figure 4 and Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the aeolian sand in the bucket does not need to be transported away by a truck, but is directly thrown to the outside of the right side of the drainage ditch. That is to say, the side ditch sand cleaning device is as follows: the lower part of the right side of the bucket is provided with several screw holes corresponding to several bolts on the fixed flange, and the middle part of the right side of the fixed flange is fixedly connected to one end of the connecting arm. There are several bolts on the left side of the fixed flange corresponding to the screw holes on the right wall of the bucket. The end of the connecting arm is fixedly connected to the upper end of the bucket, and the connecting arm is fixed on the right side wall of the bucket by screwing the bolts on the fixing flange through several screw holes and washers in the corresponding part and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com