Rotating spray sand cleaning method

A technology of rotary jetting and sand cleaning, applied in jetting device, earthwork drilling, spraying device with movable outlet, etc., can solve the problems of low construction success rate, operation efficiency, low formation pressure, etc., and achieve reliable performance and success rate. High and sand cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

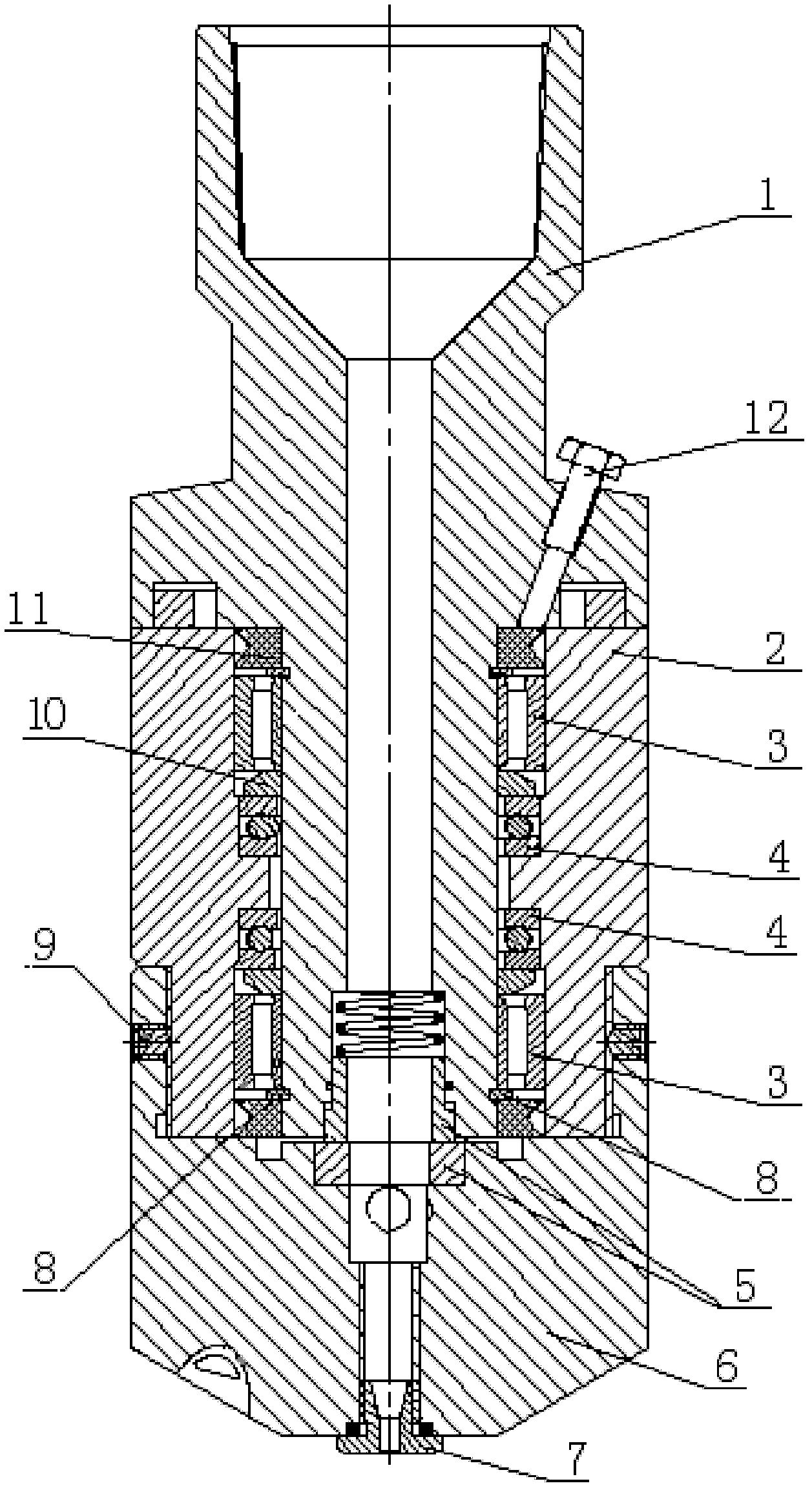

[0018] Embodiment 1: method for cleaning sand by rotary jetting, comprising the following steps:

[0019] A. Connect the wellbore sand cleaning string and lower it into the well, and use the wellbore sand cleaning string to detect the depth of the sand surface.

[0020] B. Uplift the wellbore sand cleaning pipe string to 1.5m;

[0021] C. Connect the pump from the top of the wellbore sand cleaning pipe and pump in the liquid, increase the pressure of the pumped liquid to 10MPa, and the displacement reaches 550L / min. The hydraulic rotary jet nozzle at the lower end of the wellbore sand cleaning pipe rotates and sprays high-pressure fluid. Bottom grit;

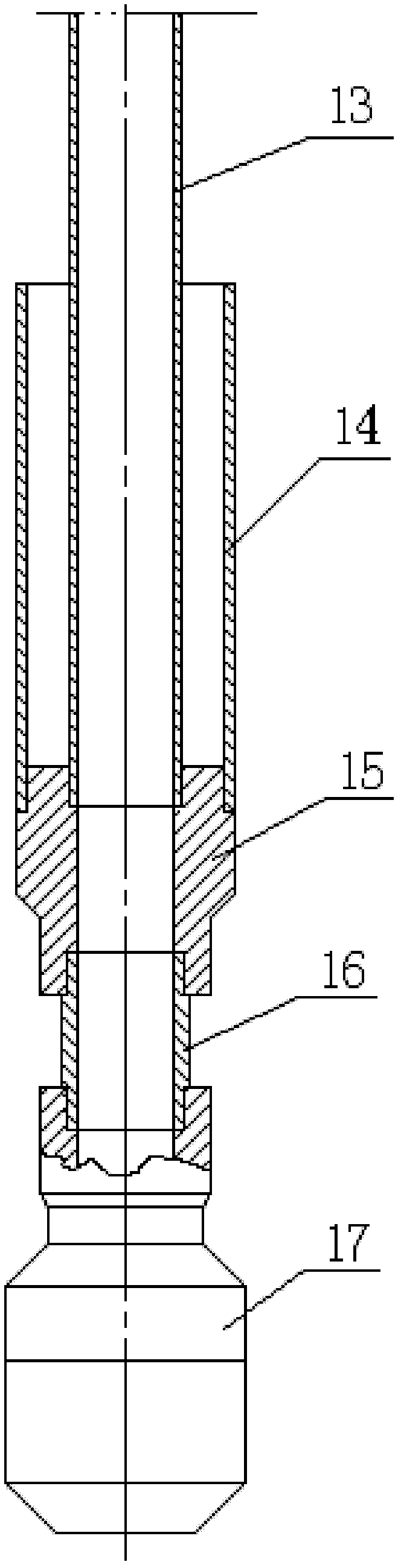

[0022] D. The washed sand flows upward together with the fluid in the oil casing annulus. When the sand-carrying fluid flows through the slotted casing 14 and reaches the oil casing annular space above the slotted casing 14, the flow velocity slows down and the sand settles downward. And sink into the annular space formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com