Hull sand cleaning system and hull sand cleaning method

A hull and sand cleaning technology, which is applied in the field of hull sand cleaning and hull sand cleaning systems, can solve the problems of time-consuming, laborious, low efficiency, and affecting the process of shipbuilding, etc., and achieve the effect of high sand cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

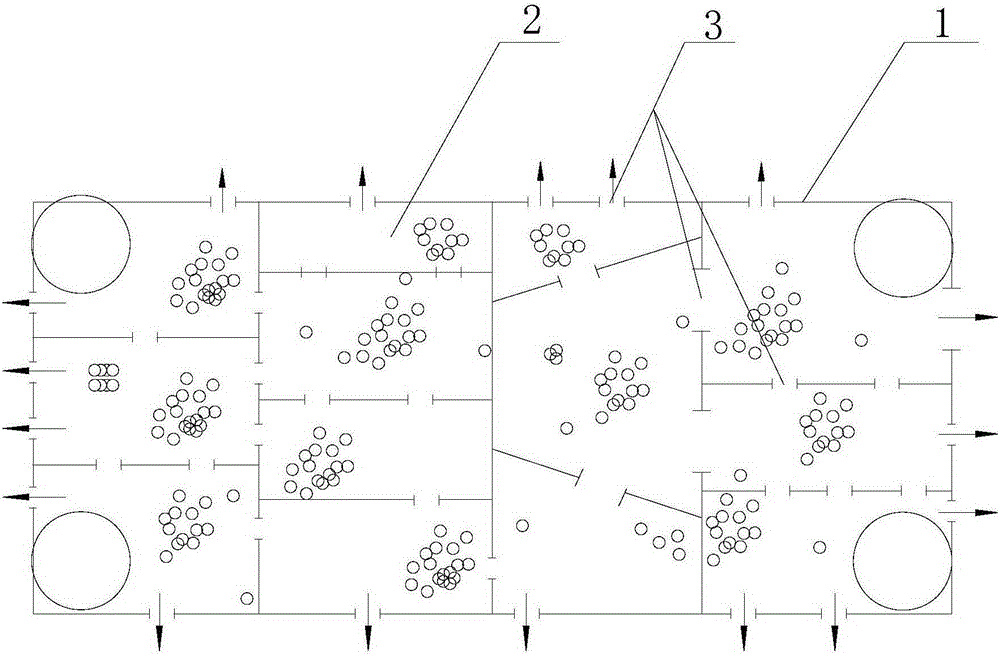

[0032] This embodiment provides a hull sand cleaning system, such as figure 1 As shown, there are multiple sand retention areas 2 surrounded by various plates on the hull 1 . After the hull 1 has been subjected to the sandblasting process, the medium used in the sandblasting process, sandblasting sand or shot (herein, this medium is simply referred to as sand) will remain in the sand retention area 2 . Since the mass and volume of the hull 1 are relatively large, it is relatively difficult to remove sand from the hull 1 .

[0033] In order to make the sand cleaning work more time-saving and labor-saving under the premise of ensuring the quality of sand cleaning, the following technical solutions are adopted:

[0034] Flow holes 3 are arranged on the hull 1 and the plate body surrounding the sand retention area 2, such as figure 1 As shown, the flow holes 3 communicate with the adjacent sand retention areas 2 and the outer sand retention areas 2 communicate with the outer sid...

Embodiment 2

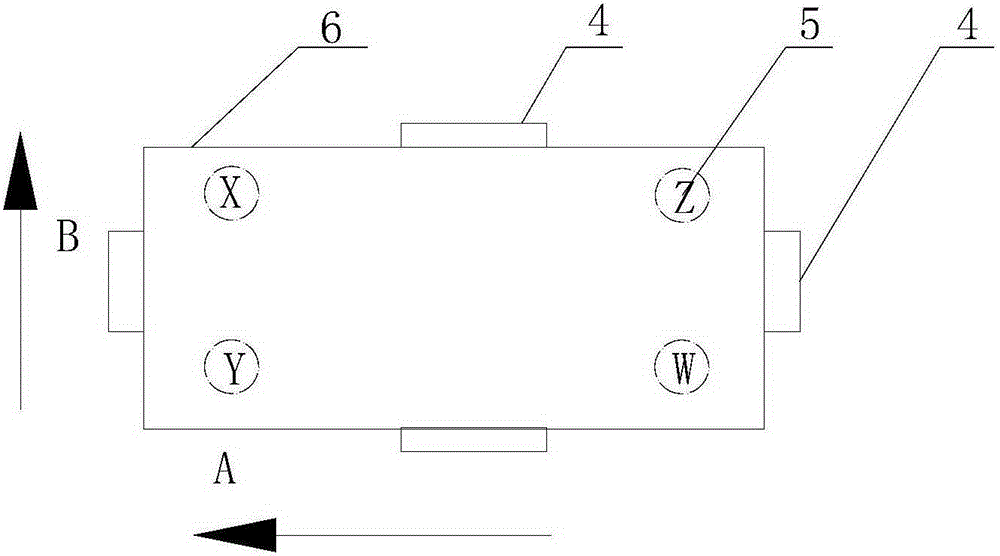

[0045] This embodiment provides a ship hull sand cleaning system, which is similar to the ship hull sand cleaning system in the preferred embodiment, the difference is that: the sand cleaning platform includes three hydraulic cylinders, and the three hydraulic cylinders can be arranged arbitrarily. The sand cleaning platform can drive the hull to tilt at any angle, for example, the hull tilts along a diagonal direction. There are two diagonals of the hull, so when tilting along the diagonals, there are four ways of tilting the hull. At this time, the vibrating device can be set corner.

[0046]On the basis of the above structure, the setting direction of this embodiment is any angle of the hull. Preferably, the set direction is the diagonal direction of the hull.

Embodiment 3

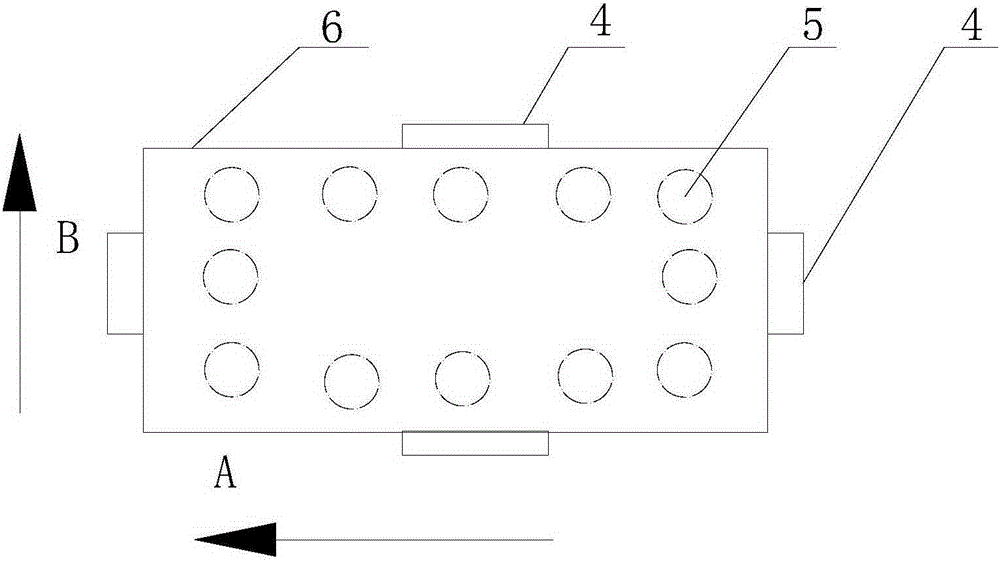

[0048] This embodiment provides a ship hull sand cleaning system, which is similar to the ship hull sand cleaning system in preferred embodiment 1, except that the specific structure of the sand cleaning platform is different.

[0049] The sand cleaning platform of this embodiment includes a support plate and a movable lifting crane, the support plate is used to fix and support the hull, and the lifting crane can raise a certain part of the hull to set an angle to realize the inclination of the hull. In order to better define the trajectory of the movable elevating crane, the movable elevating crane can be slidably arranged on slide rails, and the slide rails include horizontal slide rails and longitudinal slide rails.

[0050] The movable lifting crane is electrically connected with the control device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com