Vehicle coupler inner-cavity steel shot cleaner for railway vehicles

A technology for railway vehicles and cleaning machines, applied in the field of cleaning machines, can solve the problems of incomplete sand cleaning, time-consuming, labor-intensive, etc., and achieve the effects of facilitating sand cleaning operations, avoiding occupation of traffic, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

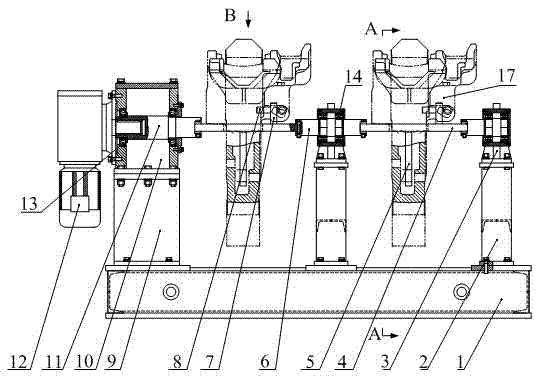

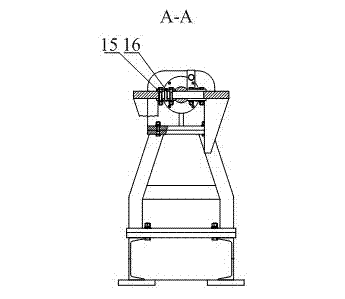

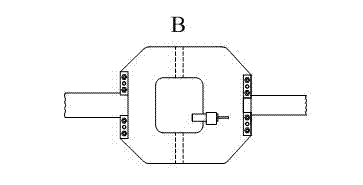

[0020] Such as Figures 1 to 3 As shown, the coupler inner cavity steel sand cleaning machine for railway vehicles includes a frame 1, a main transmission box seat 9 and two auxiliary transmission box seats 2 installed thereon. The main transmission box 10 is installed on the main transmission box seat 9 by connecting bolts. A pair of rolling bearings 13 in the main transmission box are arranged in the box for installing the main transmission shaft 11. The input end of the main transmission shaft 11 is connected with the reduction motor 12. This axle has the output end of notch and coupler turning frame 4 to be fixed by four clamping plates 15, and every clamping plate 15 is installed on the coupler turning frame 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com