Sand cleaning machine for axle case casting

A sand cleaning machine and casting technology, applied in the field of casting sand cleaning equipment, can solve the problems of low sand cleaning efficiency, poor sand cleaning effect, high labor intensity of workers, etc., achieve high sand cleaning efficiency, simple structure, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

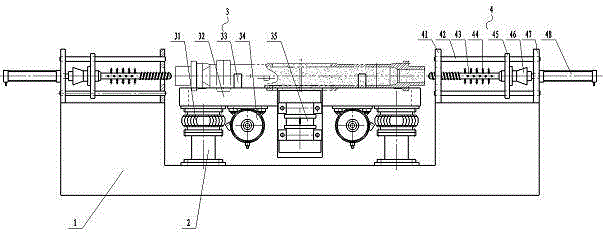

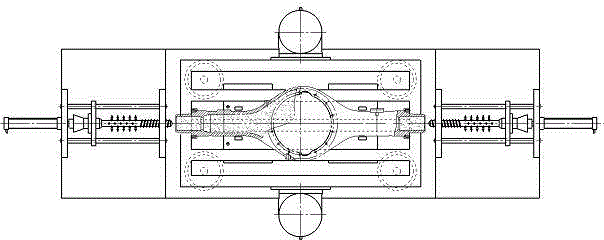

[0018] Such as figure 1 or figure 2 As shown, the present invention includes a machine base 1, four columns 2 are installed in the middle of the base 1, and a vibration mechanism 3 is installed on the column 2, and the vibration mechanism 3 includes an air spring 31 that will be installed on the column 2. , a vibrating table 32 is installed on the air spring 31, two vibrating motors 34 are installed below the vibrating table 32, a vibrating motor 35 is respectively installed on the front and rear sides of the vibrating table 32, and the vibrating table 32 The limit block 33 is installed on the top, the middle part of the vibrating table 32 is hollowed out, and the sand can fall from the hollowed out part; the cleaning mechanism 4 is installed on both sides of the base 1, and the cleaning mechanism 4 includes a support plate. The support plate is an inner support plate 41 and an outer support plate 47 fixed on the machine base, four guide rails 42 are arranged between the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com