Desanding technology of oilfield flown back fracturing fluid

An oil field fracturing and flowback fluid technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problem of poor wellhead flowback pressure and impact resistance, equipment that cannot be directly connected to the oil well flowback port, and on-site Due to problems such as large application limitations, it achieves the effects of strong impact resistance, remarkable continuous sand removal performance and reliable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

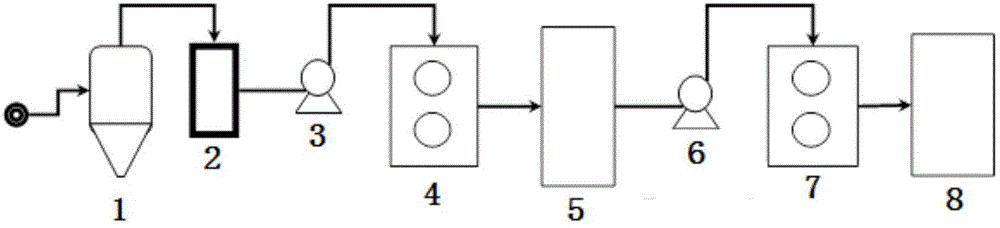

[0012] refer to Figures 1 to 3 Embodiments of the present invention are further described:

[0013] The specific implementation steps of this desanding process are as follows:

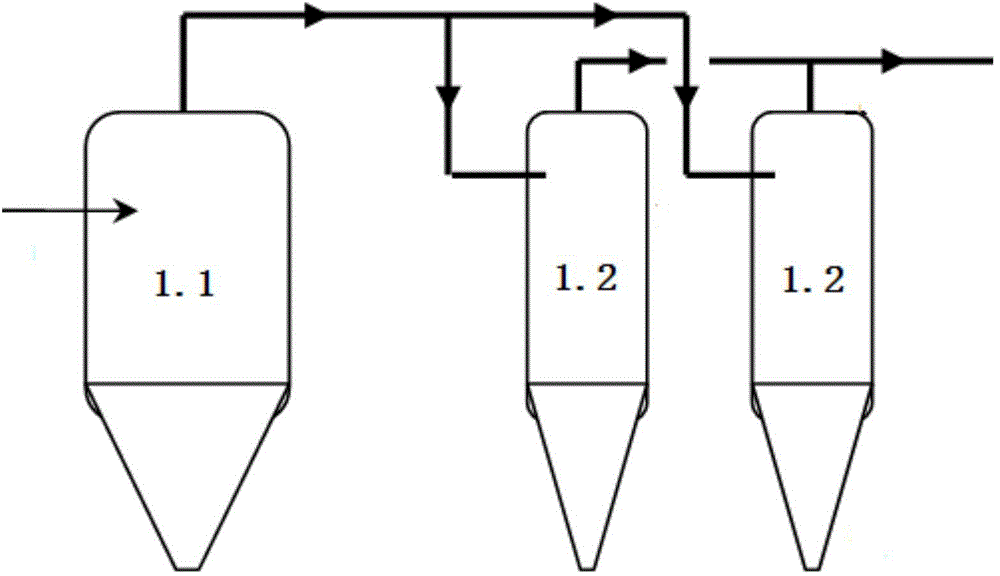

[0014] 1) Connect the cyclone desanding device 1 to the wellhead, so that the cyclone desandering device 1 operates with the pressure of the fracturing flowback fluid in the wellbore of the oil well;

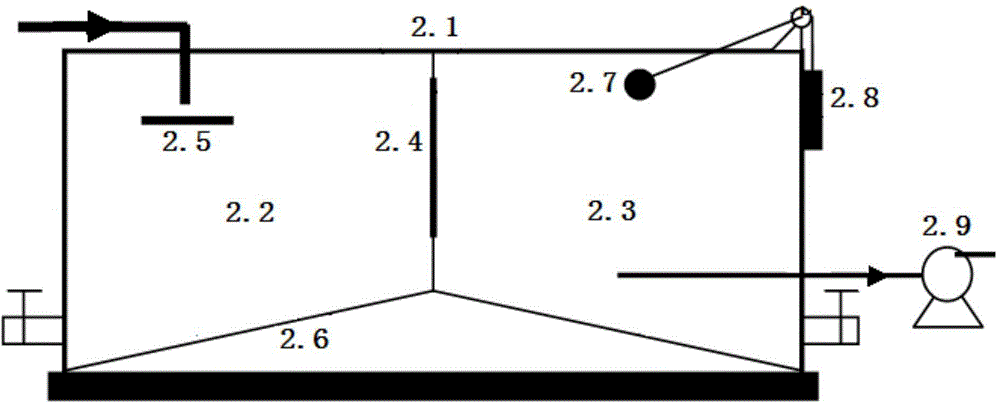

[0015] 2) Connect the outlet water from the cyclone sand removal device 1 to the pressure relief and degassing device 2 for gas-liquid separation and filtration and sedimentation; then, the primary water transfer pump 3 is directly pressed into the primary filter device 4 and the sewage tank 5, and left to stand Precipitate for 30-40min;

[0016] 3) After precipitation, the water is directly pressed into the secondary filter device 7 by the secondary transfer pump 6, and the content of sand particles and mechanical impurities in the treated water is below 0.2%;

[0017] 4) Import the treated water in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com