T-shaped diaper for adults and manufacturing process thereof

A technology for manufacturing crafts and diapers, applied in medical science, bandages, etc., can solve the problems that the structure of T-shaped diapers cannot meet the needs of consumers, and achieve the effects of novel process design, beautiful appearance, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

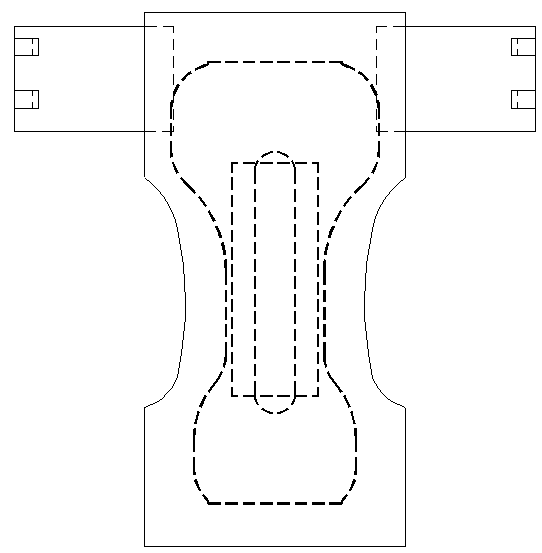

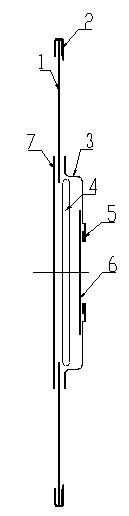

[0011] Embodiment 1: with reference to attached Figure 1-2 . An adult T-shaped diaper, which includes a diaper, the trouser body 3 of the diaper is unfolded into a T shape, and the waistbands 1 on both sides are symmetrically bonded to the protective non-woven fabric 3 and the bottom film of the trouser body of the T-shaped diaper. 7, two groups of left and right stickers 2 are respectively bonded on the belts 1 on both sides.

[0012] The middle of the protective non-woven fabric 3 is a notch, and the notch and the core 4 below the middle non-woven fabric 6 and the middle non-woven fabric 5 are made into a polymer groove absorber, and the bottom of the core 4 is Bottom film7.

[0013] There are elastic side crotch walls standing upright on both sides of the polymer groove absorber, and elastic bands are arranged inside the elastic side crotch walls.

Embodiment 2

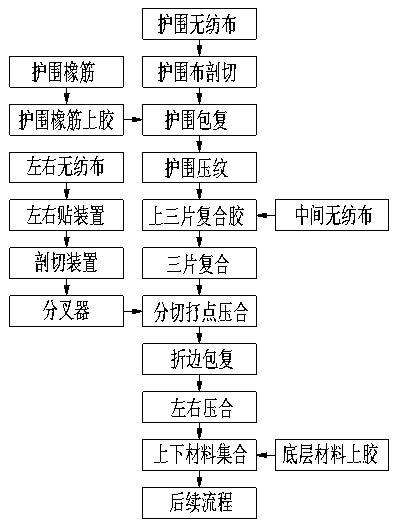

[0014] Embodiment 2: with reference to attached image 3 . On the basis of Example 1, a large-size side waistband manufacturing process for adult T-shaped diapers,

[0015] ⑴Unfold the non-woven side belt 1 of appropriate width through the action of the traction device and the unwinding device. This process must be assisted by the swing rod and the correction device to ensure that the material has proper tension and prevent the material from deviation;

[0016] (2) Glue the ready-made left and right stickers 2 to both sides of the side belt 1 through heat-sealing glue through the left and right stickers device;

[0017] (3) Use a cutting device to cut the side belt 1 into two from the middle;

[0018] ⑷Since the position of the material after cutting is not in the position specified by the product, it is moved to the corresponding position through the material fork at this time;

[0019] ⑸: After the bifurcation is completed, first use the cutting device to cut the non-wove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com